XV-Series Standard Vertical Machining Centers St Ve

advertisement

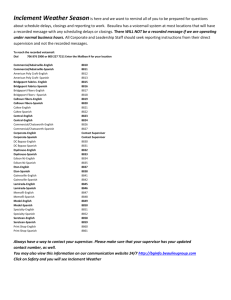

MILLING XV-Series St Standard Ve Vertical Machining Centers TURNING MILLING GRINDING WORKHOLDING www.bpt.com ROTARY Bridgeport® XV-Series Standard Vertical Machining Centers Sharpen your competitive advantage with Bridgeport’s affordable XV-Series VMCs Value and performance XV 1000 • Travels X-axis - 1020mm (40”) Y-axis - 610mm (24”) Z-axis - 559mm (22”) • Worktable Length - 1100mm (43.3”) Width - 500mm (19.68”) • Rapid rates (x/y/z)—30m/min (1,181ipm) • Spindle horsepower*—15kW (20hp) • Spindle speeds—8,000 rpm; 40 taper • Control - Fanuc i Series XV We know how important it is to get a quality machining center at a great price! That’s why we’re pleased to introduce the all-new Bridgeport XV-Series vertical machining centers. These VMCs are an outstanding machine value when it comes to features and price! The robust and thermally stable machine structure provides excellent damping and vibration characteristics. This ensures high precision and unmatched longevity, while providing excellent surface finishes with consistent accuracy and long tool life. Our XV machines feature linear guide construction and pre-tensioned and stretched ball screws. We incorporate rigorous controls and procedures to ensure precise alignments and increased levels of accuracy and stability. * 1 Minute rating XV 710 • Travels X-axis - 711mm (28”) Y-axis - 457mm (18”) Z-axis - 457mm (18”) • Worktable Length - 760mm (29.9”) Width - 420mm (16.5”) • Rapid rates (x/y/z)—30m/min (1,181ipm) • Spindle horsepower*—15kW (20hp) • Spindle speeds—8,000 rpm; 40 taper • Control - Fanuc i Series XV * 1 Minute rating 2 Built the Bridgeport Way for long lasting performance These XV-Series machines offer superior features, performance and value at a very competitive price. They are designed for OEMs and the shop owner looking for an affordable machining solution rich with features…built with the same quality and integrity as Bridgeport machines in use at thousands of installations worldwide. Standard features include: • Heavy-duty cast iron construction • State-of-the-art Fanuc i Series XV control • Complete machine documentation • Full 1-year warranty Metered volumetric lubrication system ensures proper lubrication to all components. Optional features include: • A1 APC look-ahead control • Data server • Linear glass scales • 10,000-rpm Spindle • 12,000-rpm Spindle with cooler • Rigid tapping • Coolant system • Oil skimmer • Swing-arm ATC • 4th Axis • Tool touch probe • Chip conveyor • Worklight Large high-quality linear guideways on X- Y- and Z-axes provide greater p positioning accuracy and su superior surface finishes, o offering very low friction a high stiffness for better and m machine longevity. Best-in-class spindle design incorporates 4 angular contact bearings for superior rigidity, thermal stability and overall spindle p life. Best overall working cube (axes travels) in its class—unique 600mm (24”) Y-axis travel on XV 1000. High class double-nut preloaded ballscrews—fixed and pre-tensioned to provide superior machine accuracy and repeatability. All geometric alignments conform to ISO 230-2 Machine Tool Standards. Strict laser and ballbar tests are performed on every machine and conform to ISO 230-2 standards. 3 www.bpt.com Machine base and all majorr castings are made with high-quality Meehanite FC30 cast iron for superior rigidity, durability and thermal stability. Bridgeport® XV-Series Standard Vertical Machining Centers All the control you’ll ever need right at your fingertips As you might expect with advanced technology from Bridgeport, the XV machines are powered by the latest generation control systems from Fanuc. The Fanuc i Series XV control offers over 200 standard features that are designed to increase your productivity and offer long term reliability over the life of your investment. • Fourteen-year MTBF (Mean Time Between Failures) • Advanced digital control technology • Latest Fanuc drive technology • Onboard PCMCIA card slot—ideal for large programs and program storage • Extended help functions and alarm/operation history • Compatibility with other Fanuc control products • Easy transition for operators and programmers with Fanuc experience Superior features for affordable machining capabilities 20-Tool ATC (Automatic Tool Changer) BT or CT40 spindle features powerful 15 kW (20-hp), 8,000-rpm spindle drive (optional swing-arm ATC shown) Large pre-tensioned and stretched double-nut ball screws 4 Optional Rotary Solutions manufactured by Hardinge in the U.S.A. Increase your productivity by adding affordable automation to your machining center for rapid positioning of single or multiple part setups. Hardinge offers standard gear-driven, gearless direct-drive and 2-axis rotary systems and trunnion products as well as a complete line of flexible workholding products that can be shared between your lathe and mill! The gear-driven systems can be used as a manual system with a servo control, or it can be integrated into the machine, operating in a fully interpolated fashion with the other axes of the machine. The machining center must be configured for immediate or future 4th-axis operation. All-Digital Servo Control Hardinge's state-of-the-art servo control features a multi-line display and will store up to 50 programs. Infrared sensor capability allows you to upload/download programs from a pocket PC. A servo control is not required when 4th-axis integration is chosen. 5C2, 16C and 3J gear-driven Indexing / Rotary Table Systems 2 Hardinge's 5C rotary system is based on a long history of Hardinge 5C spindle and manual indexer designs. The dual-bearing spindle accommodates heavy axial and radial loads with the ability to run a triple or quad unit with tailstocks. 16C and 3J systems will handle larger part positioning and can be configured in single, dual and triple units depending on the machine table size. The motor can be ordered on the left or the right side according to operational needs. Refer to brochure 2372 for a complete rotary product offering with dimensions and specifications. Trunnion Products Hardinge Trunnion Systems allow for multiple part fixturing to increase output. Imagine the possibilities. Low-profile clamping, window box fixturing for 4-sided machining, toggle & saddle clamping and collet blocks are just some of the possible customer clamping arrangements. Adjustable, two-sided plates or four-sided cube models are available. A bearing pillow block assures rigid, accurate positioning and will accommodate heavy loads. Hardinge has expanded their line of collet blocks for horizontal or vertical setups on towers, trunnions or machine tables. Choose from 1C to 35J sizes. Hardinge’s collet-ready spindle nose design allows quick change between collets, expanding collets, step chucks, chucks and face plates. Common spindle tooling can be shared between the Hardinge Rotary System(s) and a lathe. The gripping is in the spindle, closest to the spindle bearings, unlike surface-mounted adapters used on traditional rotary tables. Multiple workholding options provide alternate gripping solutions for increased precision and capability. 5 www.bpt.com The Most Flexible Quick-Change Workholding Concept on the Market… The Hardinge Group … Bridgeport milling machines, Hardinge turning centers, Hauser, Kellenberger , Tripet and Tschudin grinding machines, and Workholding and industrial products ™ ® ® ® The Hardinge Group produces more than just the XV-Series machines shown in this brochure…we build a full range of valuepacked and high-precision turning centers; vertical and horizontal machining centers; high-speed and 5-axis milling machines; creep-feed, jig, universal cylindrical and ID/ OD grinding machines; and workholding systems and equipment. Hardinge machine tool technology is not only the most comprehensive on the market, it's also creating new benchmarks as a solutions provider for quality, productivity and reliability. Hardinge standard, performance and high-performance turning centers We can help you turn your business around! From our competitively-priced standard SV-Series machines to our performance GS-Series and ELITE®Series range of quickchangeover bar and chucking machines right through to our high-performance QUEST® GT gang tool, RS- and SR-Series multi-tasking machines, we can provide you with the optimum turning solution. Whether you are an OEM or sub-contract precision engineering company—regardless of the sectors you serve (aerospace, automotive, medical, autosport, mold, tool and die or general engineering)—the Hardinge product portfolio will interest you. Bridgeport standard, performance and high-performance milling machines and machining centers Our comprehensive line of Bridgeport milling machines have been designed to meet any manufacturing challenge you might be facing today or in the future. Our market-leading XR-Series of vertical machining centers continue to grow in popularity—and we have similar expectations with our new competitively-priced XV and GX VMCs as well. For heavy-duty, high metal removal we offer our HMC range of Horizontal Machining Centers and for increased manufacturing flexibility and improved productivity there’s our 5-axis (5AX) model that is well worthy of consideration. If you are making your first step up to CNC machining, you will find that our entry-level GX 480 and GX 480 DT machines provide the ideal solution. For high-speed machining applications, our HSC machining centers are second to none. Our advanced manufacturing technologies in combination with our range of aftersales and support services (maintenance and service contracts; operator training; technical and applications support) have been designed to help you improve your performance and maintain your competitive advantage. If you would like to know more about our manufacturing solutions, call us at 800.843.8801 or 607.734.2281 and request our Product Guide #1365. You can also e-mail us at info@hardinge.com or visit our web site at www.hardinge.com. 6 Kellenberger, Hauser, Tripet and Tschudin grinding machines The Hardinge grinding companies include Hauser, Kellenberger, Tripet, Tschudin and, most recently, Bridgeport. Collectively we have all the technology, experience and know-how you need to transform your manufacturing operations. From highperformance cylindrical and jig grinding machines through to multi-functional ID/OD and universal machines—not to mention Bridgeport’s state-of-the-art Flexible Grinding Centers (FGC 2). It doesn’t get more comprehensive than this. Hardinge workholding and industrial products Because we design and manufacture market-leading, technically-excellent machine tools it’s no surprise that we know more than a thing or two about workholding solutions. From our extensive portfolio of CNC toolholders, collets and chucks—right through to our 5C Indexing systems—our workholding and fixturing technology will improve your performance when and where it matters most. Hardinge rotary products Specifications Axis Travel Table (X axis) Saddle (Y axis) Head (Z axis) Positioning Auto Mode (X and Y axes) Auto Mode (Z axis) Feedrate Range (X and Y axes) Feedrate Range (Z axis) Minimum Increment Ball Screw Dia. and Pitch (X,Y, Z) Spindle Speed Motor HP Rating (1 min) Torque - 8,000 rpm (15 min) Retention Force Spindle Taper Tool Holder Distance from Table Surface to Spindle Gauge Plane Spindle Options Speed Motor HP Rating (1 min) Torque - 10,000 rpm (15 min) Speed Motor HP Rating (1 min) Torque - 12,000 rpm (15 min) Worktable Working surface Table Load Number of T-Slots T-Slot Size T-Slot Center Dimension Control—Fanuc Automatic Tool Changer (Carousel) Type of Tool Shank Magazine Capacity Tool Select by Shortest Path and Random Select Max.Tool Diameter (adjacent pockets) Max.Tool Length Max.Tool Weight Random Change Time (tool to tool) Opt. Swing-Arm ATC Type of Tool Shank Magazine Capacity Tool Select by Shortest Path and Random Select Max.Tool Diameter (adjacent pockets) Max.Tool Length Max.Tool Weight Random Change Time (tool to tool) Coolant Swarf Removal Coolant Tank Capacity Wash Down Wash Gun Accuracy—ISO 230-2 Positioning Repeatability Linear Scales Option Positioning Repeatability Machine Size Machine Dimensions (WxDxH) Nozzle Coolant Wash Down XV 1000 711mm (28”) 457mm (18”) 457mm (18”) 1020mm (40.16”) 610mm (24”) 559mm (22”) 30 m/min (1,181 ipm) 30 m/min (1,181 ipm) .0025-5.9 m/min (0.1-236 ipm) .0025-5.9 m/min (0.1-236 ipm) 0.001mm (0.00004”) 32 x 10mm (1.26” x .393”) 30 m/min (1,181 ipm) 30 m/min (1,181 ipm) .0025-5.9 m/min (0.1-236 ipm) .0025-5.9 m/min (0.1-236 ipm) 0.001mm (0.00004”) 40 x 10mm (1.57” x .393”) 8,000 rpm 15kW (20hp) 60Nm (44ft-lb) 10,008 N (2,250 lbf) No. 40 CT40 or BT40 128 min – 585mm max (5.04” min – 23.03” max) 8,000 rpm 15kW (20hp) 60Nm (44ft-lb) 10,008 N (2,250 lbf) No. 40 CT40 or BT40 125 min – 684mm max (4.92” min – 26.93” max) 10,000 rpm 15kW (20hp) 48Nm (35ft-lb) 12,000 rpm 15kW (20hp) 40Nm (29ft-lb) 10,000 rpm 15kW (20hp) 48Nm (35ft-lb) 12,000 rpm 15kW (20hp) 40Nm (29ft-lb) 760 x 420mm (29.9 x 16.5”) 450kg (990lb) 3 18mm (.708”) 100mm (3.937”) i Series XV 1100 x 500mm (43.3 x 19.68”) 450kg (990lb) 5 18mm (.708”) 100mm (3.937”) i Series XV BT40 or CT40 taper 20 Tools BT40 or CT40 taper 20 Tools Bi-Directional 150mm (5.9”) 99mm (3.9”) 200mm (7.87”) 7kg (15.43lb) 12 sec. Bi-Directional 150mm (5.9”) 99mm (3.9”) 200mm (7.87”) 7kg (15.43lb) 12 sec. BT40 or CT40 taper 24 Tools BT40 or CT40 taper 24 Tools Bi-Directional 125mm (4.92”) 80mm (3.14”) 300mm (11.8”) 7kg (15.4lb) 4 sec. Bi-Directional 125mm (4.92”) 80mm (3.14”) 300mm (11.8”) 7kg (15.4lb) 4 sec. Chip Conveyor Option 270L (71 US gal)—Opt Opt Opt Chip Conveyor Option 380L (100 US gal)—Opt Opt Opt ±0.005mm (±0.0002”) ±0.0025mm (±0.0001”) ±0.005mm (±0.0002”) ±0.0025mm (±0.0001”) ±0.003mm (±0.0001”) ±0.0015mm (±0.00006”) ±0.003mm (±0.0001”) ±0.0015mm (±0.00006”) 2,187 x 2,178 x 1,981mm (86.10” x 85.75”x 78.00”) XV 1000 XV 710 2,993 x 2,205 x 2,276mm 2,464mm (97.01”) 4,100kg (9,020lb) (117.85” x 86.81” x 89.61”) 2,710mm (106.69”) 5,400kg (11,880lb) Balanced 3-phase 60 Hz 16 KVA 208 – 230 volt 5.98 kg/cm2 (85 psi @ 5.2 cfm) 79.5 l/min (21 gal/min) 79.5 l/min (21 gal/min) Balanced 3-phase 60 Hz 16 KVA 208 – 230 volt 5.98 kg/cm2 (85 psi @ 5.2 cfm) 79.5 l/min (21 gal/min) 79.5 l/min (21 gal/min) 1—Other voltages require external transformer 7 www.bpt.com Height (Max.) Mass of Machine Installation Specifications Electrical Supply (Input) Structure Cycles Power Voltage 1 Compressed Air (Pressure Flow) XV 710 Hardinge Companies Worldwide Canada Canadian Hardinge Machine Tools Ltd. 7111 Kennedy Road Mississauga, Ontario Canada L5S 0A4 Phone: 905.624.8252 Fax: 905.624.8494 web site: www.hardingecanada.com Over the years,The Hardinge Group™ steadily diversified both its product offerings and operations. Today, the company has grown into a globally diversified player with manufacturing operations in North America, Europe and Asia. In addition to designing and building turning centers and collets, Hardinge is a world leader in grinding solutions with the addition of the Kellenberger, Hauser,Tripet and Tschudin brands to the Hardinge family. The company also manufactures Bridgeport machining centers and other industrial products for a wide range of material cutting, turnkey automation and workholding needs. Expect more from your Hardinge products. Choose Hardinge precision and reliability for increased productivity and value! Germany Hardinge GmbH Saalestrasse 20 47800 Krefeld Germany Phone: (49) 2151 496490 Fax: (49) 2151 4964999 Holland Hardinge-Holland P.O. Box 346 4940 AH Raamsdonkveer Holland Phone: +31 (0) 1625 19565 Fax: +31 (0) 1625 19575 e-mail: info@bridgeport.nl Switzerland L. Kellenberger & Co. AG Heiligkreuzstrasse 28 Ch-9009 St. Gallen Switzerland Phone: 41 071 242 91 11 Fax: 41 071 242 92 22 e-mail: info@kellenberger.com web site: www.kellenberger.com Hardinge Group Europe Kellenberger HTT (Hauser Tripet Tschudin) Längfeldweg 107 CH-2500 Biel-Bienne 8 Switzerland Phone: ++41 (0)32 344 11 52 Fax Sales Department : +41 (0)32 341 13 93 Fax Service Department: +41 (0)32 342 25 36 e-mail: info@htt.ch web site: www.httgrinding.com Call us today, we’ve got your answer. All specifications subject to change without notice. All marks indicated by ® and ™ are trademarks of their respective owners. Brochure #1354-A • Litho in USA • ©Hardinge Inc. 2008 • 7.5M February 2008 United Kingdom Bridgeport Hardinge Machine Tools, Ltd. Whiteacres Cambridge Road Whetstone Leicester LE8 6BD England Tel: +44 (0)116 2869900 Fax: +44 (0)116 2869901 Bridgeport e-mail: sales@bpt.com Bridgeport web site: www.bpt.com Hardinge e-mail: sales@hardinge.co.uk Hardinge web site: www.hardinge.co.uk China Hardinge Machine (Shanghai) Co. Ltd. Hardinge China Limited No.1388 East Kang Qiao Road Pudong , Shanghai 201319 Tel : 0086 21 38108686 Fax: 0086 21 38108681 Taiwan Hardinge Taiwan Precision Machinery Ltd. 4 Tzu Chiang 3rd Road Nan Tou City 540 Taiwan, R.O.C. Phone: 886 49 2260536 Fax: 886 49 2252203 e-mail: cs@hardinge.com.tw United States Hardinge Inc. One Hardinge Drive Elmira, NY 14902-1507 USA General Information: 607-734-2281 Sales: 800.843.8801 Sales Fax: 607.734.8819 Workholding Fax: 607.734.3886 Service: 800.424.2440 web site: www.hardinge.com