98W series - De-Sta-Co

advertisement

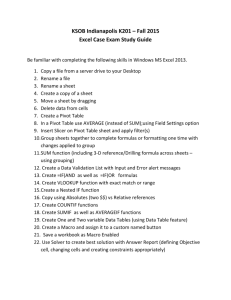

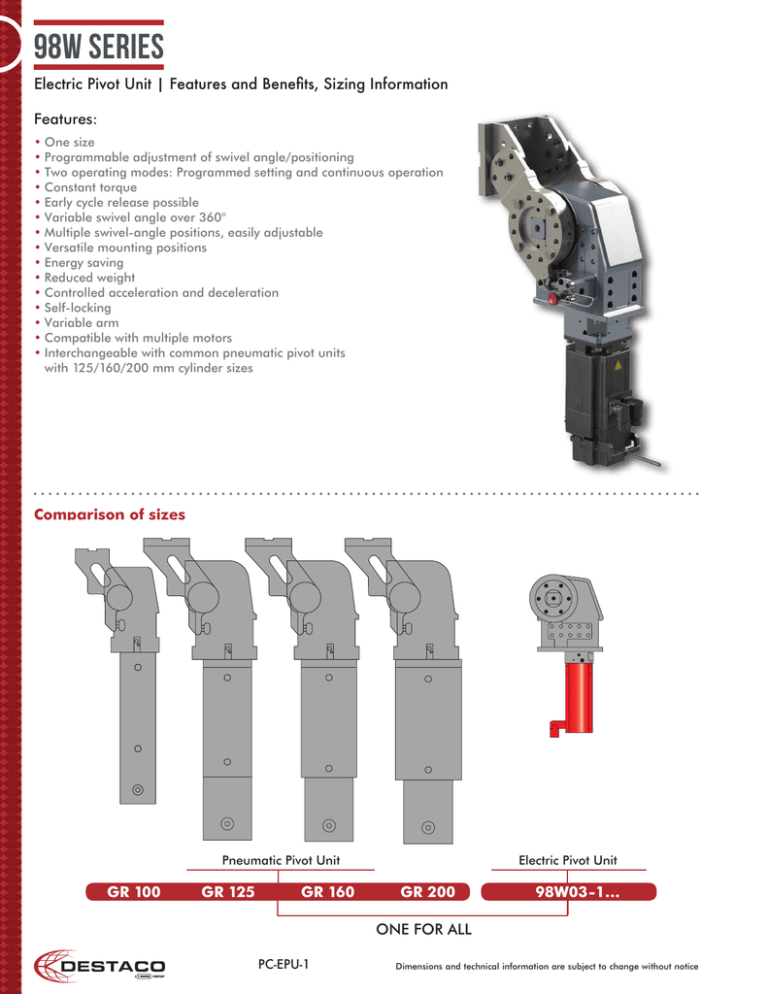

98W series Electric Pivot Unit | Features and Beneits, Sizing Information Features: • One size • Programmable adjustment of swivel angle/positioning • Two operating modes: Programmed setting and continuous operation • Constant torque • Early cycle release possible • Variable swivel angle over 360° • Multiple swivel-angle positions, easily adjustable • Versatile mounting positions • Energy saving • Reduced weight • Controlled acceleration and deceleration • Self-locking • Variable arm • Compatible with multiple motors • Interchangeable with common pneumatic pivot units with 125/160/200 mm cylinder sizes Comparison of sizes Pneumatic Pivot Unit GR 100 GR 125 GR 160 Electric Pivot Unit GR 200 98W03-1… ONE FOR ALL Dimensions and technical information are subject to change without notice Electric Pivot Unit 2-Jaw Parallel Grippers | Variable Arm High application flexibility: The variable arm of the Electric Picot Unit can be adjusted in three different positions, whereby the Pneumatic Pivot Unit utilizes different arm types for multiple positions. Dimensions and technical information are subject to change without notice 98W Series Electric Pivot Unit | Technical Speciications The Pneumatic Pivot Unit operates with a toggle-action mechanism period. The Electric Pivot Unit implements a worm gear to rotate. 98W _ _ _ 600 1800 1600 1400 1200 1000 800 600 400 200 0 Force at 1000mm (N) Force at 1000mm (N) This results in different force diagrams 500 400 300 200 100 0 0 15 30 45 60 75 90 105 120 Force depending on opening angle 0 15 30 45 60 75 90 105 120 Continuous force independent of opening angle Dimensions and technical information are subject to change without notice 98W Series Electric Pivot Unit | Technical Speciications, How to Order Technical information: Input supply voltage for external controller Control signal of external programmable controller Feedback signal to external programmable controller Operating modes • Rotation from 135° to 0° • Holding • Rotation from 0° to 135° • Holding Torque Static holding torque Motor torque to be limited Duty cycle E-Stop Acceleration Slow down Weight Repeatability with hard stop Repeatability without hard stop 400 VAC 4 sec/135° 3 sec 4 sec/135° 3 sec 500 Nm 2000 Nm Max. 6Nm 70% 0.4 sec @ 500 N = ca. 10° 2 sec 2 sec 46 kg ± 0.01mm @ 500mm ± 0.05mm @ 500mm Order Number Example: 98W03-2 10 A A 0 B 0 = without hard stop C 98W03-2 = 500Nm 10 = SEW-Motor 400V-Brake Dimensions and technical information are subject to change without notice -00-0 00-0 = Internal, consecutive number 400V L1/L2/L3 N PE Programmable logic controller Power supply CPU 86-1600 NSI „Root Switch“ 1 central network access per unit Production network – 100MBit 24V=(SG) US1 (System) US2 (Load) 24 VDC Power supply 24VDC Power supply Switch production network Transformer station – 400V AC / 100 to 630A max. 98W Series Electric Pivot Unit | Wiring Diagram Dimensions and technical information are subject to change without notice 98W Series Electric Pivot Unit | Application Example Holding fixture with BodyBuilder profiles and power clamps 82M attached to an Electric Pivot Unit Dimensions and technical information are subject to change without notice