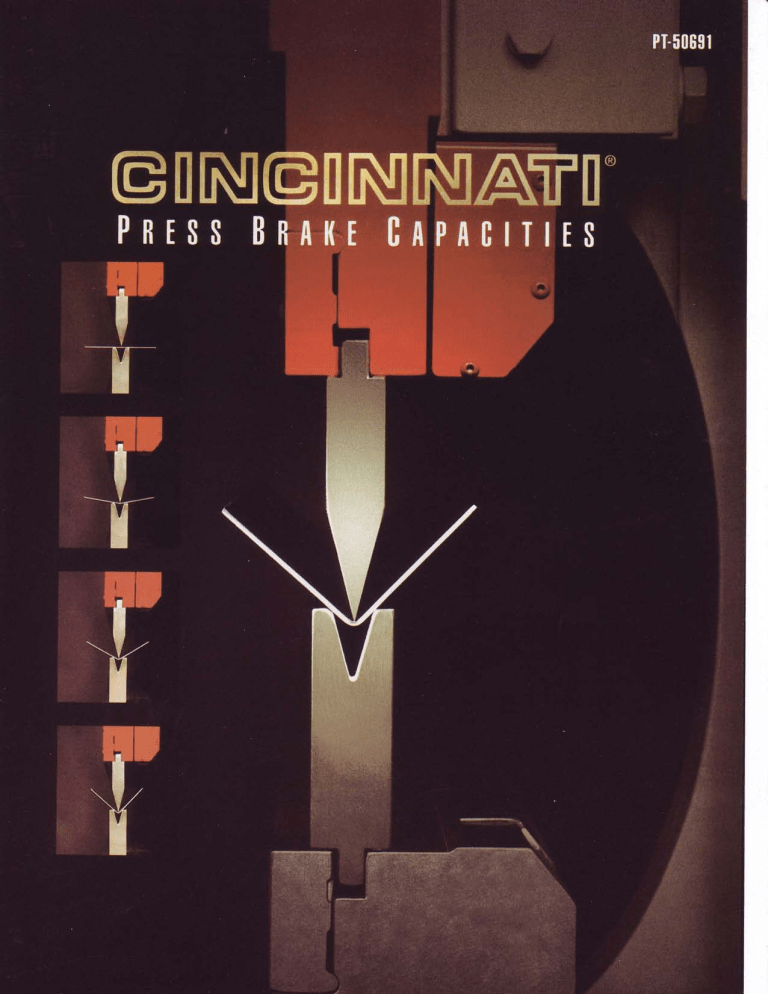

Learn more about Press Brake Capacities.

advertisement

practices

andproper

safety

Good

is

operator

brake

trainingofeachpress

ona

Bending

operator,

Comprehensive

pages

Brake

.............

Press

CINCINNATI

3-7 mandatory.

provide

manuals

maintenance

andsafety

Forming

CINCINNATI

procedures

and

0nproper

instruction

page8

Publications

methods

andshould

bewiththe

safety

.........page9

CapacifJ

Press

BrakeBending

press

signs

Waming

brake

atalltimes,

MildSteelAirBend

safety

ofoperator

andachecklist

pages

10-13 guidelines

.........................

Chart

Capacifl

atstrategic

should

beplaced

pagal4L7 locations

Facton

Chart......,.....

Bending

onthepress

brake.

forproper

responsible

Usen

are

Reference

Chart.....pages

Cross

18-1!

Steel

useofpoinr

installation

andcontinued

Brake'*pa4esZUZI

Punching

ona Press

safeguarding

andother

of-operation

guards.

assure

Thishelps

machine

withOSHA

safety

andcompliance

operator

requirements.

press

brake

Each

newCINCINNATI

ANSI

atagshowing

thatit meets

displap

Acopyof

requirements.

811.3

construction

care

whichcovers

theproper

thisstandard,

isincluded

tohelp

anduseofpress

brakes,

programs.

Refer

to

usenwiththeirsafety

Brake

Manuals,

Press

theSafety

ANSI

Bulletin

PI50686,

Safeguarding

orconsult

81l.j Safety

Standards

forfurther

Incorporated

Cincinnati

information.

............

Safety

page2

............

WITH

BRAKECOMPLIES

ANSI811,3SAFETY

FORCONSTRUCTION

STANDARDS

springback

to aIlaina90'bend.

sufficient

Inmostcases,

theangle

cutonthedies

Metalformed

byanupperandlower

willbebetween

30"to85i Forair

dieasshown

in Figure

1onlyhasthree

radius

thenose

oftheupper

die

pointsofcontact.

lf.metal

ispushed

into bending,

Press

Btoke

Roling

should

beequaltoorslightly

lessthanone

alowerdiesufficient

toformaspecific

press

AllCINCINNATI

areruted

brakes

fractions.

metalthicknes

usingsimple

angle,

whentheforceisreleased,

the

pressure,

foramaximum

bending

or

withair

angle

willopen

upduetospringback. Note: Ifpartsaretobeformed

Tonnage

canthenbeconverted

tonnage.

bmddiasona,pressbrahewith

springback

formild$eelis2' to

Normal

intobending

capacities

through

an

contputsr

controltodetermine

4". If thematnflalis

hard,hasahigher

understanding

ofbasic

factors

affecting

ramrwasalpositions,

thedies

tensile

$rength,

or alugerthannomal

theformability

ofmetal.Bending

factors,

mustbecuttoan anglethatuill

inside

radius,

ttrespringbackwill

begeater.

ofthumb",

forpress

0r"rules

brake

compensate

for allposible

forming

arebased

onusing

mildsteel

(Figure

AhBending

II

materialsp4ngback,

(60,000

psimaximum

tensile

strength).

Airbending

metalintoastrai$tline

Anexplanation

factonwillhelp

ofthese

BottonBending

angleisthemostcommon

formofpress

youunderstand

theperformance

ofyour

Bottom

bending

material

withdiescut

brake

work.Atop,orupper

die,pushes

press

brake

andthemildsteel

airbend

thefinished

angle(e.g.

themetalintoalower

veedie.Themetal toapproximately

in thisbooklet,

capacify

charlspresented

880,

890or90) willincrease

theforming

onlytouches

thepointofcontact

ofthe

tonnage.

Thereason

for"true"bottoming

ofthe

VeeDieOpening

ondInsideRodius upperdienoseandthetwoedges

andcoining

ist0"set"thematerialin

lowervee

die(Figure

1),Thematrriil,

Ihe recommended

veedieopening

for

ordertoovercome

springback

andobtain

does

notcontact

anyotherpartofthe

mildsteel

uptoI/2" (,500";

thickiseight

better

angularaqclrasl(see

Figures

3 and

tooling

during

theforming

cycle.

timesthemetalthickness.

Forthicker

isoften

selectedwhen

Most"airbend"

toolsaremanufacfured4), Bottoming

thanl/2"mild$eel,it maybenecessary

boxes

orpanels,

Minimizing

the

sothattheupperandlowerdieshavethe forming

toincrease

theveedieopening

uptoten

keeps

thefinalbends

from

same

angle.Thisisdonetominimize

set- overbending

timesthematnnalthickness

tominimize

previously

hittingthe

formed

flanges

and

uptime.In ordertoobtainatrue90"air

cracking

ofthematerial.

Todetermine

causing

distortion,

Potentially

smaller

bend,

thetooling

mustbecuttoallow

forasimple

theveeopening

!0'bend,

inside

radiimayaisobeachieved

usingttre

multiplythemetalthickness

byeight.

comngprocess.

Theanswer

isthenrounded

tothenext

There

arethree

U P P E RD I E

higher1/8"figure,Forexample:

14ga,

different

types

of

(.075")

x 8 = .600".Thisisrounded

toa

forming

whichare

NOSERADIUS

5/8"veeopening.

classified

as

Theinside

radius

ofabend

in mild

"bottom"

bending:

isabout

steel

5/32'(J56')x theveedie

bottomingwith

opening

regardles

ofthegauge

ofmetal

spring

back,true

Thisfigurewasdetermined

beingformed.

bottoming

and

formed

bymeasuring

samples

bentover

VEEDIEOPENING

coining.

various

dieopenings.

Toillu$rate:

If a

LOWER(ORVEE)DIE

L/8"(.I25")sheetand

a1/4"(.250")

plateareformed

oyer

a2"veedie,each

willhave

ttresame

inside

radius

of

Figure

l-AirBending

(.312"7.

approximately

5/T6'

Springbock

withSpringbock

Bottoming

(tigure

2l

angle.

partmayspringbackto thedesired

is

ofthismethod

Theangularconsistency

(tigute

4l

Coining

airbendtonnage.

than

metal,in orderto obtainasharper

insideradius,

the

onemetalthickness

term"coining"is applied.

Whentheupperdieismadewithless

onuniformmaterialthicknes. thanonemetalthickness

dependent

radius,

thenose

isnot

withspringback

Bottoming

aresimilar

Normally,angtiartolerances

intothemetal

ofthediewill embed

"true"bottoming.

When

considered

to airbending.

condition.

an apparent

overbend

causing

intorecommended

metalispushed

In ordertopushtheupperdieintothe

tooling,it will formaninsideradiusthat

(Figute

3)

TrueBottoming

toobtainthedesired

metalfarenough

to the5/32x veedieopening

isequivalent

Vhentheupperdieismadewitha

insideradiusandbendangle,therequired

isthenbuiitupatthe

rule.Pressure

(tothe

metal

thickness

radius

of

one

will beatleastfivetimestheair

tonnage

theformed

causing

bottomofthestroke

sufficient

tonnage

fraction),

closest

simple

If thedesired

insideradius

bendtonnage.

metalto"kink"in theinsiderudiusarca.

of

the

up

at

the

bottom

must

be

built

the

or less,

isone-half

themetalthickness

metalto

Thiscauses

thelegsoftheformed

to "set"themetalandeliminate formingloadcouldapproachten

stroke

times

will

tonnage

springback.Therequired

ontheairbendchart.

thetonnage

shown

rangefromthreetofivetimesthenormal Whenthetopdieembeds,

ordisplaces

during

forming

operation

Figure

2-lvubending

of

enough

to touchthecorners

overbend

(Figure

2). Theforce

theupperdie

willbeaboutI I/2to 2l/2times

buildup

forairbending.

thetonnage

required

isreleased,

the

Whentheformingpressure

tigure

3-Bottoming

4-hining

Figure

(rotking

S-t*'

can

Whenforming pIate,"ctac\rJng"

canoftenbe

beerratic.Smallflanges

makingthesame

bendin

formed

whereas

will cause

failure.

thecenter

ofthesheet

will alsobefoundwhen

Differences

across

thegrainversus

bending

bending

isoften

withthegrain.Cracking

thenoseradius

minimized

byincreasing

oftheupperdie.

ECCENTRIC

DIES ALIGN -----+"1

WITHBED & RAM

I

CENTERLINE

ADJUSTMENT

SCREW

Figure

6-DieAlignment

ADJUSTMENT

MINIMUM

D I ES P A C E

DOVETAIL

SLOT

DOVETAIL

SLOT

CROSSHOLDDOWNSLOT

CROSSHOLDDOWNSLOT

Hydraulk

Press

Brokes

llechani

cslPrusBrokrls

consistency.

If thediesarenotclosely

aligned

tothetoolingcenterline,

inaccuracies

canoccur.Asa result,it is

important

toevaiuate

theavailable

toolingwithrespect

tothetypeofpress

brake

beingusedin ordertoobtainthebest

possible

formingangles.

Vee

dieswitha

orless

mayrequirc

a*.005"

5/8"veeopening

alignment

toobtaingoodconsistency.

Figure

S-DieSpace

Bend

Allowonce

(Figure

DieSpote

5)

(tigure6)

DieAlignment

In orderto determine

theproper

blank

sizepriortoforminga part0napress

Nways

totaltheheightofthepress

brake In ordertoobtaingoodaccuraqr

in

brake,a bendallowance

foreachbend

diesandtheheightofthefillerblock(die press

brakeforming,thetoolingmustbe

mustbedetermined.

Thisinformation

holder)

tomakesurethetooling

aligned

willfit

sothatthenoseoftheupper

dieis

throughmany

intotheavailable

diespace.

Forcomplete ascentral

to thelowerveedieasposible. hasbeenmadeavailable

engineering

textbools

buttheinformation

information

0n "dieheightselection

Withmo$press

brakes,

manybends

could

,

provided

isnotconsistent.

If questions

request

currentiiterature

fromCincinnati bemadewithanalignment

accvany

ol

ariseconcerning

a blankdevelopment

for

+I/54" aroundthecenterline

Incorporated,

of thevee

yourpart,CINCINNATI

hasavailable

a

opening.

bendallowance

chartwhichmaybe

Press

brakes

featuring

computerized

helpful.Contact

yourCINCINNMI

controls

thatallowtheoperator

to input

representative

to obtainmoreinformation.

a specific

bendangledepend

onmathematicalmodels

toobtaingood

Acturocy

lensile

or YieldSlrengths Angulor

Actuol

to improve

the

press

andoptions

brakes

ofmanyparts.

andconsistency

acc:;racy

^cc'rraqislimitedby:

Bending

witha tensile

aresupplied

Manysteels

yourlocalCINCINNATI

sales

andrepeatability Consult

1.Press

brakecondition

asa

identified

andyieldstrength

officefor assistance,

"minimumvalue"

ability

withthe"maximum" 2.0perator

oftooling

Incorporated

unspecified.

Cincinnati

3.Condition

Off(enterLooding

(pages

"BendingFactors"

14to17)allow 4.Qualityofmaterial

(Figure

7)

are

fourconsiderations

psiin steels

ksumingthese

using

anincrease

of 15,000

ChartGeepages

TheAirBendCapacity

reviewed,

normaltolerances

should carefully

minimumfigures.Thisallowance

symmetrical

10-13)isforcenterline,

workfor over90%of thesteelsavailable. wouldbe+1 1/2'whenformingupto 10'

formingor

special

steel.If plate loads.Occasionally

orthinnersheet

is of 10gauge

ofthematerial

In cases

wherebreakage

punching

donothavetheirload

setups

tothe

addonedegree

orwhenthepress

brakewill not isbeingformed,

occurring

onthebedandrumcenterlines.

centered

will cut

operations

Bottoming

has

tolerance.

makea bendevenafterthetonnage

caremustbe

circumstances,

Underthese

in half,butwill

theairbendtolerance

tofallwithinthepress

beencalculated

themaximum

takennottoexceed

andcould

theformingtonnage

increase

thematerial

should

be

brakecapacily,

(fronfto-back)loal,capacity

of.

eccentric

ofthedies.

necessitate

someshimming

and

tested

to identifytheacfialtensile

whentheload

thepress

brake.Similarly,

yieldstrengths.

Onehalfoftheangttlarvarialion

atthemachine

centerline

isdueto normalmateial isnotlocated

above

described

offull rated

onlyaportion

Steels

torming

HighTensile

foundin commercial (left-to-right)

variations

thickness

is

isavailable.

Eachhousing

capacity

psior

Hightensile

$eels(70,000

to

$eel,Theotherhalfcanbeattributed

limitedtoone-half

ofthemaximum

higher)donotreactlikemild$eel.The

in themetal,edge

hardandsoft

spots

Incorporated

Cincinnati

formto theradiusof the

materialmay

deflections rating.Contact

holesandnotches,

conditions,

forsnecific

information.

thenoseradiusof

upperdie.In thiscase,

in themachine

or toolingandmachine

tothesteel

thedieshouldconform

A

manufacturer's

recommendations.

to

largerveeopening

mayberequired

hx available

INNATI

repeatability.

CINC

tonnages

andang,tlar

obtainacceptable

"Bending

Factors"

charton

arrtJraly.

See

pages

14to 17fortypicalrecommendations.

steelsusuallyreact

Note: Stainless

similar to mild steel,

Bending

FoctorDeterminotion

"Bending

Factofs"

areobtained

by

relating

theactualtensile

andyield

to those

strengths

of thesteelbeingformed

hasbeen

ofmildsteel.Consideration

givenin Cincinnati

Incorporated's

"Bending

Facton"chartto allowfor

increasing

theinsideradiusoftheplateif

cracking.

required

toeliminate

LEFT-TO.RIGHT

OFFCENTERLOADING

MACHINE

CENTERLINE

FRONT-TO-BACK

OFFCENTERLOADING

BED& RAM

L- Load

(forming

or punching)

D-Distance

between

machinecenterline

and loadcenterline

Figwe

7-hff Gnter

Loading

Goging

In ordertoobtaingoodconsistency

thegaging

duringthefonningoperation,

priort0parts

mustbeevaluated

sequence

p

Figu

rel-lonnoge

Build-U

(Figure

Build-Up

Ionnoge

8)

(Figure

Shimming

9l

Whenmakinga90"airbend,theload

reaching

increases

veryrapidly,

85%of

themetalisbent20'

maximumwhen

(10'perside).Maximum

is

tonnage

reached

whenthemetalisbenta totalof

40".Theloaddropsoffa fewpercent

Tocompensate

forbedandnm

deflection,

aswellasuneven

wearonthe

press

ofthe

brakeandtooling,shimming

toolingmayberequired

toobtaina

uniformbend.Allshimming

shouldbe

donewitha goodquality$eel(notbrass)

papercanbe

cases,

shimstock.In some

used.Keep

freefromdirtor

all surfaces

niclasinceformingarcuracy

canbe

affected

bypoorworkhabits.

whenthemetalisbentto90'.

60"

9i--tbo.t^^.

005"

. Theavulabihty

beingformed

ofCNC

gaging,

manually

setfrontandback

gagingor

gages

mounted

tothelowerdie

to determine

the

all mu$ bereviewed

bestmethod.

Note: RemembEr

tbalgaging

detuminestbepositionof the

bend.,engularaccuracyis

detwminedby tbemethod

offorming,

Morking

purpose

General

veediessometimes

cause

marksonpolished

stainless,

aluminumorpainted

stock.Marking

can

by:

beminimized

1. Increasing

thecornerradiusatthetop

oftheveedieopening,

2. Polishing

theentireveedieopening,

thecorners

of thelarger

I. Hardening

lead-in

radii.

In somecases,

tapeordiecoverings

canbeused.Plastic

coating

onstainless

results

in the

$eelmaygiveinconsistent

your

reduction

ofdiemarls.Contact

CINCINNATI

representative

for additional

information.

thelowwdie

Note: Sectionali,zing

oftenraulh in objectionable

marking.

UNDERFILLERBLOCK

t

."il:

"l l'i .. ,lr.

:

",.",,:

'

. , , t 1. , t t , t

"

tl

Figwe

9-lypkalShinming

hnfigur

ation

7

ond

DieHeight

Selecfion

GenerolTerms

. Mechanical

Press

Brakes

. Hydraulic

Press

Brakes

andtechnical

Thefollowingbrochures

and

A glossary

ofdefinitions

provide

helpfulinformation

datasheets

diesand

usedwhenselecting

terminology

for safe

techniques

onthemo$effective

press

discussing

brakeapplications.

press

andefficient

brakeoperation.

Press

Broke

Sofeguordingfor0wners

ond

Suggestions

IheirEmployees

Press

Broke

Setup

Hydroulk

Only"

Procedure

"AirBending

leads

the

Thisstep-by+tep

checklist

setup

through

theproper

operator

reading

forallpress

brake

Required

procedure

forairbending.

recommended

illu$rates

usen,

thisbooklet

mettrods

for Bosic

devices

andproper

safeguading

Rules

on

Punching

It alsolistsothersupplien Press

safeoperation.

Brokes

ofsafety

devices,

tofollow

forsafe

Fundamental

steps

Operolion,

Sofety

ond

lUlonuols

ltlloinlenonce

punching.

andefficient

Ptessute

Chofi

Bending/Punching

andveedieopenings

0ptimaltonnages

forbendingandpunching20gauge

throughoneinchmildsteel.

FillerBlockSpetifitotions

Stondord

dimensional

dataonstandafi

Complete

fillerblocla.

nanowflattopandunivenal

Melol

Allowon(es

fol Sheet

Bend

AirBends

allowance

Thischartshows

90"bend

for2igaugethrou$

based

5/8"mildsteel,

die

onrecommended

veediewidth,upper

radius.

radius

andtheoretical

bend

MoiorConditions

Cousing

Excessive

Bow

Adetailed

explanation

ofthevarious

lmproving

Port0uolityond

parts.

whichcause

streses

bowin formed

. 4 Series

Mechanical Producfivity:

through

50Series

Press

HowAdvonced

(onHelp

PresBrakes

Broke

lechnology

Minimizing

DieMorksonOuolity

. CBPress

Brake

techniques

and Bends

AnoveMew

ofbending

. CBII Press

Brake

. FomMasterPresBrake

. FormMaster

Press

Brake

II CNC

. AUT0SHAPE@

CNC

Forming

Center

e AUTOFORM@

Forming

Center

CNC

guides

Complete

totheinstallation,

adjustment

and

setup,

operation,

press

maintenance

ofeachCINC

INNATI

brake

model

line.Theyinclude

bending

procedures

fundamentals,

safety

and

basic

proper

gaging

methods.

press

to

technolory

useofthelatest

brake

partquality

and

maximum

achieve

forming

efficiency.

lips

Goging

ondForming

guide

bending

Ahelpful

thatshows

partryalityand

techniques

thatimprove

production

efficienry.

increase

DieTemplote

Gooseneck

Ahandyreference

forfivegooseneck

Theclear

diesizes

andconfigurations,

templatecanbelaidover

thepartto check

for interference

duringforming.

Provides

13$epslhataidinreducing

metal.

diemarkingonsheet

publications,

Toobtain

anyofthese

press

orforbrochures

onCINCINNATI

models,

diesets

andaccessories,

brake

phone

please

Incoryorated

at

Cincinnati

orfax(5r3)367-7552.

$13)367-7100

to

sizepress

brake

theproper

3. Select

(.375")

thickA36

12'of.3/8"

airbend

yield$rength

$eelwithamaximum

length

of1/4"

Copority

ftort

L. Determine

themaximum

AirBend

psi.

(.250")

press

a 5Series

brake of45,ooo

mildsteel

10Chart(pages

TheAirBendCapacity

vee

thenominal

usingtherecommended StepL: Determine

capacities canairbend

13)liststhepress

brakebending

forA35fromtheBending

dieopening

(8x metal

thickness).

veedieopening

in linearfeetofmild$eelfordifferent

14)Factors

Chart(page

in the

.250"

thickness

Step1:Locatn

whenairbending

only.

metalthicknesses

8T=8x,375'=1.00".

ontheAirBend

Capacity

fint column

the

Theshaded

areaindicates

formability

facor

Step2: Detennnethe

(page

Chart

10).

foreach

veedieopening

recommended

yieldstrength

forA35(maximum

of

2.00"

recommended

Step2: Followthe

Thenominalbending

metalthickness.

psi)fromtheBending

Facton

45,000

lineovertothe

veedieopening

shaded

(1ton= 2000lbs.)is

forcein tons/foot

(page

14)-1.3.

Chart

intenecting

vertical

lineforstandard

5

listedin thethirdcolumn.Allcapacities

Step3: Determine

theequivalent

press

Series

mechanical

brake.Read

a maximum

arelistedformildsteelwith

the

ofmild$eelbymultiplying

maximum

lengthofsixfeet.A5Series length

psianda

of60,000

tensile

strength

times

theformability

mateiallength

ACislisted

ateightfeetofbending

yieldstrength

psi.

maximum

of40,000

=

x7.3 15.6'

.

provided

it isused

atlowspeed. f.antor-L2'

capacity

Nominal materialvariationallowances

press

thesmallest

Step4: Determine

of.a

2. Determine

airbending

capacity

ratings.

havebeenmadefor allcapacity

fromtheAir

brakethatcan

beused

press

when

230tonhydraulic

brake

otherthanmildsteel,

refer

Formaterials

(pages

12utdl3)

Bend

Capacity

Chart

A.

I/4' (.250")

thickCor-Ten

bending

14

Facton"chart(pages

to the"Bending

thefirstpress

byselecting

brake,

Step1: Refer

to"Steel

Cross

to 17)for theproperformabiliryfantor,

mechanical

orhydraulic,

which

(page

18)tofind

Reference

Chart"

15.6'capacity

f0r.375"

thick

exceeds

(hoil

Bending

Fodors

proper

ASTM

number.

specification

mateialover

a3.00"

veedie.A

Aplate.

ASTM

M42forCor-Ten

Select

Whenmaterialother

thanmildsteelis

(21.0')

mechanical

or500

toASTI4

A242

onBending 21Series

Step2:Refer

forming

to beformed, therequired

(17,7')

press

tonhydraulic

brake

will

Factors

14)todetermine

Chart(page

The

will probably

change.

tonnage

formthismatnnaL

for1/4"

recommended

veedieopening

I4tn17)

"Bending

Factors"

chartfuages

thetonsperfootofforce

4. Always

check

= 1.00".

plate.I2T=

t?x .250"

numben,

ofASTM

offenawideselection

required

toformmildsteel

withthe

ttreproper

Step3: Determine

noseradiiand

theirrecommended

upperdie

press

available

tooling.This

brake

formabilityfactorfor

M42fromthe

Theequivalent

length

veedieopenings,

information

canbeused

fordesigning

(page

Bending

Factors

chart.

I4)-L7.

materialwhich

canbe

of anyspecial

ttreunitpressure

g capanig toolsanddetermining

thebendin

Step4: |r:temine

brakeiscalculated

formedona givenpress

loading

onthebedandram,which

press

fora230tonhydraulic

brake

bythe

bydividingthemild$eelcapacity

mustnotexceed

15tons/in.Z

forming

.250"

mildsteel

over

when

formabilityfactor.Thisformabilityfactor

(1ton= 2000

lbs.).

veedieopening

byusingtheAir

3.00"

in thefarrighthandcolumn.

isshown

TheAir

BmdCapaciA

Chart

(page

Bend

11)-21'.7. Caution:

Capacity

Chart

dnwnotapplytonon(rossReference

(hort

Steel

themaximum

airbend

Step5: Divide

standard

strokemech

anical

(StA4)bytheformability

capacity

18&19)isprovided

Thischart(pages

prws

the

brakes.Consult

= 12.8

(StE9 2L7'/1.7

factor

feet.

manufacturen'

names

tocros-index

trade

applications.

factoryonthese

For

withtheproperASTM

specification.

names

0rclassifications

notlisted,conlant

Incomorated

forassistance.

Cincinnati

VEE

MILD

D I E TONS

(2000

STEELOPENING

T H I C K . N O M I - LB)

NOMINAL NAL

PER

I N C H E SINCHES FOOT

(20GA.)

0.036

( 1 8G A . )

0.048

.25

J.l

.312

2.3

52.3

69.4

92.6

52.3

69.4

92.6

69.8

92.5

69"8

92.5

37.2

463

54.8

74.3

94.6

49.6

61.7

49.6

66.1

oo. I

ot./

82.2

82.2

73.0

73.0

22.3

27.8

32.0

44.6

56.7

69.4

833

16.4

22.3

27.8

32.0

44.6

56.7

69.4

833

37.2

46.3

54.8

74.3

to.+

19.8

19.8

26.0

35.7

26.0

35.7

4 t.o

4 t.b

50.0

59.5

50.0

59.5

27.4 27.4 36.5

3 3 . 0 3 3 . 0 44.0

44.3 44.3 59.0

5 9 . 5 5 9 . 5 79.3

69.4 69.4

83.3 83.3

18

694

9.7

8.0

6.5

5.6

4.6

12.9

694

12.9

2.5

2.2

1.7

36

50

89.1

23.6

JI.Z

41.6

50.0

56.7

73.4

94.6

t.J

5.6

AE

3.8

2.8

2.2

1.8

t5

7.6

6.3

4.7

3.5

3.0

2.5

2.1

4.1

J.L

23

-7E

11.1

.875 9 . 0

, l , .7 , 5

125

6.3

25

5.5

.50

4.4

2.00

2.5

.875 1 1 . 9

00

9.9

125

8.5

( 1 0G A . )

.25

7.3

0.135

50

5.8

2.00

4.0

250

1 . 1 2 5 16.4

1 . 2 5 14.3

.50 11.2

0.188

2.00

7.5

2.50

5.7

AA

.00

1 . 2 5 29.5

1.50 22.7

2.00 15.4

0.250 2 . 5 0 1 1 . 4

3.00 9.0

ai

3.50

o. l

4.00

t0

39.3

52.0

69.4

83.3

94.6

39.3

52.0

69.4

83.3

3.0

.438

50

.625

( 1 4G A . )

75

0.075

.875

1.00

1.125

00r

89.5

23.6

31.2

41,6

50.0

56.7

73.4

09

5.3

4.0

1.00

( 1 1G A . )

0.120

34

1.1

.375

.438

.50

.625

.75

.875

1.50

200

89.5

90.5

1.7

|.tJ

40.3

54.3

73.4

89.1

o/.I

1A

.625

.75

875

( 1 2G A . )

1.00

0.105 1j25

40.3

54.3

73.4

o/.I

.438

.50

62s

.25

.312

.375

.438

.50

.625

1.25

5AC

nn./

too%uoo

--.7300

26%qoo,uY*,'9400t

n%tu n%t ,u%rru'uYuu2o%soo

%ro u'%ooo

90.5

.375

.75

( 1 6G A . )

0.060

5

LINEAB

FEEI

BRAKES-ANDARISTROKE

ONLY

MECHANICAL

PRESS

13AC 21

12AC

t3

12

I

9AC

15.6

1,0i0 ; 1Sto

22.3

22.3

27.1 27.1

30.5

30.5

38.4

39.0

402

53s

t.J

11.3

13.9

3.9

16.7

D./

19.8

9.8

2 2 . 7 22.7

2 7 . 9 28.4

3 1 . 9 42.4

10.5

0.5

Iz.o

2.6

14.0

4.0

71

17.1

I t.z

21.5

ZJ. I

30.8

25.3 31.8

7.6

7.6

8.7

8.7

2.A

11.0

12.3

6.4

13.8

7.3

14.0

8.6

4.2

4.2

5.5

5.5

6.0

8.0

6.5

8.6

6.8

9.1

Lt

9.5

7.4

10.0

tc.o

94.6

2 1 . 5 21.5

26.0 2 6 . 0

32.n r 32.0

37.2 37.2

45.2 45.2

50.8 5 0 . 8

65.0 65.0

48.7 7 3 . 0

58.7 88.1

flil

j

56.9

3 8 . 1 57.2 7 1 . 5

46.3 69.4

56.9 85.3

oo. I

oo. I

80.4

80.4

oJ. I

33.3

41.1

49.3

58.7

67.3

84.1

33.3

41.1

49.3

58.7

67.3

84.1

23.3

28.0

32.0

38.0

47.8

69.4

23.3

28.0

32.0

38.0

47.8

69.4

31.1

37.4

43.5

50.7

63.8

92.4

31.1

37.4

43.5

50.7

63.8

92.4

88.8

88.8

16.9

19.4

22.6

25.9

25.0

34.0

37.0

48.3

60.0

9.4

12.2

18.0

24.2

29.3

31.1

32.7

49.3

62.3

70.9

12.5

22.6 33.8 42.3

25.9 3B.B 48.5

34.0 49.6 6 1 . 9

49.3 74.0 92.4

62.3

70.9

12.5 1 8 . 8 23.5

16.3

30.6

24.A 36.0 45.0

3 1 . 0 46.6 60.9

34.7 56.0 74.6

4 0 . 5 58.4

4 5 . 9 65.6

28.6

34.7

28.6

34.7

42.:7:t' 42.7

49.6

49.6

60.3

60.3

67.7

86.7

86.7

18.8 18.8 25.0

tJ. I

30.8

27.8 27.8 37,0

3 3 . 0 33.0 44.0

37.8 37.8 50.5

47.3 47.3 o J . I

25.0

30.8

37.0

44.0

50.5

38.1

46.3

90.4

zJ. I

7 1. 7

.:i;''

3 6 . 5 48.7

44.0 58.7

59,0 ti 78.7,

75.3

67.7

90.4

99.1

50.0 63.0

83.3

61.7 7 7 . 1

74.0

88.1

7 1. 7

t/.c

t/.c

21.0

25.0

28.5

35.9

52.0

57.0

12.7

14.6

'19,0

21.0

25.0

28.5

35.9

52.0

57.0

16.9

1 4 . 6 19.4

1 9 . 0 25.0

27.8 27.8 37.0

3 1 . 0 3 1 . 0 48.3

32.7 40.9 60.0

7.1

7.1

9.4

9.2

9 . 2 12.2

13.0 1 4 . 0 1 8 . 0

5.5 t3.3

24.2

6.0 20.0 Z V . J

6.7 2 0 . 8 3 1 . 1

7.6 22.0 32.7

12.7

to.J

24.0

31.0

34.7

40.5

43.7

*Press

brake

tonnage

capacity

atmidstroke

andnearbottom

ofstroke.

tonnage

Series

SAC,

9ACand13AC

capacity

ratings

listed

areforlowspeed

operation.

46.6 58.3

56.1 70.1

65.3

76.0

77.7

cb.4

84.6

64.7

82.6

E

J I-J

40.7

60.0

81.0

47.0

61.1

90.1

?

E

E

'6

a

o

MILD

VEE

IONS

D I E ( 2 0 0 0L B )

STEEL

T H I C K . OPENING P E R

NOMINAL NOIV]INALFOOT

IN C H

E S INCHES

120GA.)

0.036

25

,312

3.1

2.3

,375

,438

1.7

.50

.625

.E

.312

375

1 8G A . )

.438

0 , 0 4 8 .50

625

.75

375

.438

1.4

1.1

0.9

5.3

4.0

3.0

2.5

2.2

1.7

LJ

5.6

4.5

( 1 6G A . ) .50

625

0.060 .75

3.8

.875

1.8

2.8

2.2

LINEAR

FEET

HYDRAULIC

PRESSRAKEONNAGE

60

to.4

22.2

30.0

36.4

46.3

56.7

9.6

12.7

17.0

20.4

23.2

30.0

35.2

9.1

11.3

13.4

18.2

23.2

t.c

28.3

34.0

.438

7.6

6.7

.50

.625

6.3

B.t

4.7

( 1 4G A . ) 75

0 . 0 7 5 875

3.5

10.9

14.6

17.0

20.4

24.3

28.3

1.00

3.0

2.5

1.00

1.125

1.25

.625

.75

2.1

1.8

9.7

.875

1 2G A . ) 1.00

0.105 1.125

6.5

5.6

4.6

| .za

4.1

1.50

3.2

2.00

.75

.875

00

11GA.)

125

0.120 25

50

2.00

875

1.00

1.125

(10GA.)

|.z?

0 . 1 3 5 1.50

0.188

8.0

Z.J

11.1

9.0

7,,5

6.3

5.5

4.4

2.9

11.9

9.9

8.5

7.3

5.8

2.00

2.50

4.A

1.125

1.25

1.50

16.4

14.3

11.2

7.5

5.7

4.4

29.5

2.00

2.50

3.00

1.25

1.50

2.00

J. l

22.7

15.4

0.250 2.50

11.4

3.00

3.50

4.00

9.0

7.4

o. l

5.2

AI

7.8

9.1

11.1

12.5

15 . 9

22.1

4.6

5,6

6,8

8.1

9.3

90

tJc

175 230

24.6 37.0 48.0

33.3 49.9 64.7

45,0 67.5 87.5

54.6 8 1 . 9 106.2

69,5 1 0 4 . 3

85.0

14.4 21.7 28.1

tY.l

28.7 37.2

25.5 38.3 49.6

30.6 45.9 5 9 . 5

3 4 . 8 52.2 67.6

45.0 67.5 87.5

58.8 88.2 114.4

13.7 20.5 26.6

17.0 z a . 3

JJ. I

20.1 30.2 39.1

27.3 41.0 t J . I

34.B 52.2 67.6

42.5 6 3 . 8 82.6

5 1 . 0 76.5 99.2

10.1 t 3 . I

19.6

12.1 18.2 23.6

1 6 , 3 24.4 J I . O

21.9 32.8 42.5

2 5 5 38.3 4 9 6

30.6 4 5 . 9 59.5

36.4 54.6 70.8

4 2 . 5 63.8 82.6

7.9 1.1.8 tc.J

9.6 14.3 18.6

2.0 17.7 22.9

3 7 20.5 26.6

6.6 24.5 32.3

8 . 7 28.0 36.3

23.9 35.9 46.5

33.2 49.9 64.7

6.9 0 . 3 1 a A

8.5 2.8 to.c

0.2 5 . 3 1 9 . 8

2.1

8 . 2 23.6

27.0

33.8

3 . 9 20.9

1 . 1 . 6 4 26.1

17.6 26.4 39.6

4 . 3 6 . 4 9.6

77

c. I

1.1.6

5 1. 3

12.5

15.0

300

36,9

48,9

65.2

78.2

88.8

11 5 . 0

to.c

20.1

24.4

400

500

4 8 . 1 56.1 64.2 80.2

63.8 74.4 85.0 106.3

85.0 99.1 1 1 3 . 3

600

750 1000 1250 1500 2000

96.2 120.3

102.0

34.9 45.5 c J . I

60.7 75.9 9 1. 1 11 3 , 8

43.4 56.7 o o . I

75.6 94.4 I 1 3 . 3

51.4 67.1 78.3 89.5 1 11 . 8

69.8 9 1 . 1 106.2 121.4

BB.B 11 5 . 9

108.6

33.6 3 9 . 1 44.7 55.9 6 7 . 1 83.9 1 1 1 . 8

4 0 . s 4 7 . 2 54.0 67.5 8 1 . 0 101.2

41.6 54.3 63.3 72.3 90.4 1 0 8 . 5

25.7

31.0

5 5 9 72.9 85.0 97.1

65.2 8 5 . 0 991 11 3 . 3

78.2 102.0

93.1

108.6

20.1 26.3 3 0 . 7 3 5 . 1

24.4 3 1. 9 37.2 4 2 , 5

30.1 3S.2 45.8 52.3

34.9 45.5 5 3 , 1 60.7

42.5 55.4 64.7 73.9

4 7 7 62.2 72.6 82.9

61.1 79.7 93.0 106.3

85.0 11 0 . 8

17.6 23.0 26.8 30.6

21.7 28.3 3 3 0 37.B

26.1 34.0 39.7 45.3

31,0 4 0 . 5 47.2 54.0

3 5 , 5 46.4 5 4 . 1 6 1. 8

44.4 5 8 . 0 67.6 77.3

67.4 87.9 1 0 2 . 6 117.2

2 14

io.4

25.0 28.6

19.7 25.8 3 0 . 0 34.3

6.0 9.0 1 3 , 5 | / . c 23.0 30.0

7 . 0 10.5 15.7 20.4 2 6 . 8 3 4 9

B . B 13.2 1 9 , 8 25.6 33.7 44.0

12.7 19,1 28.7 37.2 48.9 63.8

to.J

24.7 37.0 48.0 6 3 , 0 82.2

o. l

4.7 7.0 Y. I

1 1. 7 1 5 . 5

3 . 5 5 . 3 8 , 0 1 0 . 4 13.7 17.8

6.8 1 0 . 3 13.3 l a I

22.8

6.8 10.2 t c . J

1 98

zo. I

34.0

8 . 9 13.4 20.1 26.1 3 4 3 44.7

1 1 . 6 17.4 l o . l

33.8 44.4 5 8 0

1 . 7 2.6 3 9

5.0 6.6 8.6

2.2 3 . 4 c . I

6.6

8 . 6 11.2

5.0 7.5 I 0 . 0 1 2 . 8 I O . O

4 . 4 6 . 7 0 . 1 1 3 . 0 17.1 22.4

5.6 8.5

B

6.9 10.3 5.5

8.3 12.5 8 . 8

350

63.0 82.0 9 5 . 9 1 0 9 . 7

85.0 11 0 . 8

11 5 . 0

tLt.4

43.8

5 2 . 6 65.7

87.6 109.5

53.1 63.8 79.7 106,3

65,4 78.5 98.1 1 3 0 . 8

75.9

9 1. 1 11 3 . 8

s2.4 11 0 . 9

103.7

3B.3 4 5 . 9 57.4 76.6 9 5 . 7 11 4 . 9

.18.0

5 6 7 70.8 94.4 1

c o ./

68.0 8s.0 1 1 3 . 3

67.5 8 1 . 0 101.2

77.3 92.7 11 5 . 9

96.6 11 5 . 9

47.2

35.7

42.9

42.9

ct.J

5 3 . 6 71.4 89.3 107.1

64.4 8 5 . 9 1 0 7 . 3

35.0 40.0 50.0 60,0 75.0 1 0 0 . 0

40.8

3t.J

74.4

95.9

18.1

20.8

25.5

39.7

52.2

46.6 58.2

58.6 73.3

85.0 106.3

109.7

20.7 25.9

23.8 29.7

30.4 37.9

45.3 56.7

59,6 74.6

77.3 96.6

1 1 . 5 14.4

tc.u

18.7

67.6

10,1

13.1

1 9 . 3 22.1

26.1 29.8

21.7 2 8 . 3 3 3 . 0 37.8

26.4 34.4 40.2 45.9

32.0 41.8 48.8 55.7

69.9 87.3 116.4

87.9 1 0 9 . 9

3 1 . 1 38.9 5 1 . 8 64.8 77.7 1 0 3 . 7

35.7 44.6 59.4 74.3 89.2 1 1 8 . 9

45.5 56.9 75.5 94.9 11 3 . 8

68.0 85.0 I I J . J

89.5 1 1 1 . 8

I tc.v

17,3 zt.o

22.5 28.1

27.6 33.1 41.4

37.3 44.7 55.9

47.2

Eat

69.7

28.8

37.4

36.0 43.2 57.6

s

56.2 74 . 9 55.2

82.8 110.4

74.6 93.2 1 1 1 . 8

56.7 70.8 s4.4 11 8 . 0

U

68.9 8 6 . 1 11 4 . 9

83.6 1 0 45

o

46.8

69,0

II

IV]ILD VEE TONS

(2000

STEEL DIE

LB)

T H I C KOPENING

.

5

NOMINAL P E R

NOMINAI

INCHESINCHESFOOT n/",

.313

.375

.438

1.50

2.00

2.50

3.00

3.50

4.00

500

2.00

2.50

.625

19.7

tc.J

12.7

10.5

4.6

5.0

4.4

5.5

5.8

t.o

1a

2.8

9.4

9.7

10.3

5.2

7.7

9.0

11.8

12.1

12.8

7.0

10.3

14.0

17.2

18"5

19.0

25.2

4.9

5.7

4.9

5.7

6.6

8.9

5.2

7.7

qn

2.9

3.2

3.4

3.6

3.8

6.0

6.3

6.6

7.9

8.3

11.0

11.7

I t.J

15.8

1.0

9.3

10.3

13.7

1 8 . 0I

20.4

23.6

25.4

27.6

8.7

140

17.2

18.5

19.0

25

6.6

8.9

9.3 1 3 . 9 1 7 . 4 23.2

20.6

18.0 27.4

20.4 32.9

23.6 35.0

26.7 3 8 . 1

tJ,/

346

448

25.7

1A e

34.0

46.9

43.9

50.8

57.1

60.5

68.1

76.2

.875

.0

13.0

14.0

7

2.3

5.8

15.3

16.4

17.3

22.6 32.9 44.1

36.8 49.0

17.2 . A E

21.7 2 8 . 1 4 5 . 6 59.5

b.u

7.5

7.8

B.B

10'5

10.9

12.3

7.8 1 1 . 6

8 , 8 14.2

10.5 15.5

I t.D

16.4

15.4 20.0

21.0 28.0 36.0

12.00

14.00

1.500 16.00

20.00

2400

16.00

676

2.2

2.3

2.4

2.5

3.9

3.9

6.0

A1

c. I

7.5

4.3

4.4

D.4

5.5

8.0

8.0

8.2

8.2

11.2 11.2

20.2

1 9 . 0 26.1

22,5 3S;tr

24.6 32.8

32.4 L + Z . J

43.4

t c .I

J,I

3.9

J.a

4.1

5.8

6.0

8.0

5.8

6.0

8.0

7.6

8r0.

;'8.6

7 . 6 1 1 . 2 16.2

8.4 12.0 1 8 . 0

20.0

, [{J.E, 14_U

16.00

2 . 0 0 0 20nft

24.00

30.00

t2

21.8

24,0

29.7

JJ.

30.3

39.2

..4s$'

54.5

69.6

76,0

I

34.9

39.9

4S.0

58.0

63.2

69.8

2.3

3.4

3.4

AE

, i", llt

4.6

5.0

ri rJ

4.8

6.2

6.9

8.0

1 0 . 3 13.7

1 3 . 0 17.0

19,3

22.8

28.0

33.8

36.7

39.3

12.0

21.0

24.9

26.0

tJ.o

17.3

r

31.6

252

1 1. 4

s1.2

12.0

76.2

tAa

44.2

35.2

29.4

97.0

75.5

61.6

5 1. 1

377

119.0

97.3

8s,6

59.5

468

19

11 8 . 0

20.00 87.5

1 . 7 5 0 24.00 68.8

30 00

32.

44

57.8

70.7

85.1

16I

.10.90r r i J 9 I

2000

21.9

29.9

1 1. 4

53.5

43.6

& 0 0 r 36.5

10"00 27.1

1 2 . 0 0 21.0

7.00 64.6

8.00 5 2 , 9

12.00

14.00

/.00

8.00

10.00

1.000

00

14.00

1600

10.00

12.00

1 . 2 5 0 14.00

16.00

34.9

51.4

70.4

90.6

728

8 . 7 1 3 . 1 16.4

1 1 . 4 17.2 22.4

6.00

7.00

.750

50

11.2

3 . 5 0 39.7

4.00 33.3

5.00 24.6

6.00 1 9 . 4

7.00 1 5 . 9

'13

1

8.00

4.00 5 8 . 3

5.00 43.1

6:00 33,3

7.00 27.4

8.00 23.3

1 00 0

3.4

4.0

4.2

2.2

2.4

36

.cn,/

'7tso

uu%oo,too%uoo

s%ss 1t%zrt tu%rrt'oYtoo 'o/*o 'u%oo'u%ooao%aoo

J. l

4.6

I

7.7

42.3

30.9

3.00 24.0

3.50 1 9 . 6

4.00 to.J

5.00 I Z . J

6.00

9.5

2.50 45.8

.00

qn

28.6

4.00 24.4

5 . 0 0 17.3

'14.8

6.00

700

.500

39.8

27.0

5AC

FEET

LINEAR

ONLY

STROKE

PRESS

BRAKES-STANDARD

MECHANICAL

al

34

I

J

1

3AC

12

12AC

9AC

q

507

165.0

122.A

96.0

70.8

F

'6

:

F

(5

@

.Pressbrake

operation.

ratings

listed

areforlowspeed

tonnage

capacity

5AC,9ACand13AC

of stroke.Series

tonnage

capacity

atmidstroke

andnearbottom

MILD

VEE

TONS

STEEL

D I E (2000

LB)

T H I C K . OPENING PER

NOIVIINALNOIVINAL FOOT

IN C H

E S INCHES

1.50

.313

.375

.438

2.00

2.50

3.00

3.50

4.00

5.00

2.00

2.50

3.00

3.50

4.00

5.00

6.00

2.50

3.00

3.50

4.00

5.00

6.00

7.00

3.50

4.00

.500 5.00

6.00

i.00

8.00

4.00

5.00

6.00

.625

700

8.00

10.00

6.00

7.00

.750

8.00

10.00

12.00

7.00

8.00

.875 10:00

12.00

14.00

7.00

8.00

1.000 0.00

2.00

4.00

6.00

0.00

1.250 2.00

4.00

16.00

20.00

12.00

1.500 14.00

16.00

20,00

24.00

16.00

20.00

1.750

24.00

30.00

16.00

20.00

2.000 24.00

30.00

39.8

27.0

19.7

15.3

12.7

10.5

7.7

42.3

30.9

24.0

19.6

16.3

12.3

9.5

45.8

35.4

28.6

24.4

17.3

14.8

11.2

39,7

33.3

24.6

19.4

15.9

13.1

58

LINEAR

FEET

-ONNAGE

HYDRAULIC

PRESS

BRAKE

60

90

IJJ

t/c

2.9

3.7

2.8 4.3

5.5

20

5.8

7.6

5 . 0 7.5

9.7

6.0 9 . 0 1 1 . 7

7 . 3 1 0 . 9 14.2

9.9 14.9 19.3

2.7

3.5

2.5

4.8

3.2 4.8

6.3

3.9 5 . 9

7.6

7.0

9.1

6.2

9.3 12.1

8 . 0 12.0 1 5 . 6

2.5

3.2

2.2

3.2

4.2

2.7 4.0

5.2

o. I

3.1

4.7

44

6.6

8.6

5.2

7.8 1 0 . 1

6 . 8 10.2 1 3 . 3

3.7

2.9

2.3 3 , 4 4.5

J. I

4.7

o.l

3.9 5.9

7.7

4.8

7.2

9.4

5.8

Ae1

8.8

2.7

600

750 1000 1250 1500 2000

10.7

12.8

16.0

12.6

17.3

22.2

26.8

32.4

15.7

18.9

25.5

33.3

40.2

23.6

32.4

7.2

9.9

12.8

20.1

1 8 . 6 24.3

2 5 . 4 33.1

4.6

6.0

o.J

8.3

8.3 1 0 . 0

10.0 13,0

12.0 1 5 . 6

1 5 . 9 20.7

20.6 26.8

4.3

5.6

5.5

7.2

6.8

8.0

1 1. 3

13.2

174

4.9

5.9

8.0

4.5

1 69

53.5

4.5

6.8

5.4

6.4

8.8

2.1

2.6

2.8

3.4

3.1

4.1

4.2

5.5

2.2

2.9

2.3

2.8

3.7

4.7

5.9

7.1

7.1

8.4

11 . 5

3.7

4.5

5.4

9.3

3.0

3.7

4.9

6.2

25.2

91.2

76.2

56.3

44.2

2.0

2.0

2.6

3.4

35.2

29.4

97.0

75.5

61.6

51.1

37.7

119

97.3

80.6

59.5

46.8

118

B7.5

68.8

50.7

2.0

12.9

16.7

1E I

3.4

3.4

3 1. 6

500

8.5

z.o

4.2

4.9

21.0

64.6

52.9

3S,7

400

7.5

1 1. 0

15.1

19.4

J.J

2.8

3.4

2.1

2.8

350

6.4

9.4

11.4

z.o

27.1

300

4.9

10.1

12.3

14.9

27.4

23.3

43.6

36.5

230

2.1

26

3.5

38.6

7.0

9.6

12.4

15.2

10.4

17.2

22.8

20.1

12.2

17.2

26.6

7.5

7.7

8.9

1 0 . 4 12.0

o.c

13.1

16.0

19.5

4.4

7.0

9.4

121

26.0

5.8

7.9

10.0

c. I

IL.q

14.6

20.1

6.4

8.6

tJ.c

16.1

16.9

20.2

5.6

6.7

9.1

6.7

b.4

3.7

AE

5.6

6.0

7.7

9.7

7.5

11.6

3.1

3.9

3.5

4.5

5.4

2.2

2.9

3.7

5.0

a.l

9.6

12.1

14.5

4.4

5.6

6.9

8.3

1 1. 3

11.5

14.5

J_O

^a

44

5.2

6.3

5.3

7.1

9.1

3.6

4.9

6.2

8.4

2.6

3.5

4.4

6.0

32.9 4 3 . 8

15.9

1 95

JJ.

8.4

11.0

14.4

/

cJ. I

70.8

13.9

18.9

19.2

24.0

30.2

36.1

10.9

16.9

5.4

o.o

t.5

7/

9.3

1 0 . 0 12.6

3.9

4.2

5.2

5.3

6.6

7.2

9.0

28.9

8.8

11 . 3

13.8

16.6

22.5

7.1

36.0

44.6

48.0

59;4

61.4

11.1

'15.0

18,1

5.8

I

44.3

17.5 23.3

23.5 31.4

3 0 . 4 40.5

9.9

13.2

12.1

16.1

t o .I

21.4

20.2 2 6 . 9

25.3

7.0

9 . 3 11.7

7.9

8.6

10.7

1 0 . 9 13.6

4.3

5.4

J.

53.5

64.9

14.6

19.7

1 9 . 1 25,5

23.3 31.0

27.4

36.5

377

50.3

17.3 21.7

5.3

6.6

6.8

8.4

8.3 1 0 . 3

1 0 . 0 12.5

13.5

55.0

52.3 6 9 . 7

73.7 98.3

7 1 . 8 86.1 11 4 . 9

94.9 11 3 . 8

26,8 3 2 . 1 4 2 . 8

3 1 . 9 38.9 51,1

43.2 51.8 6S,1

54.8 65.7 87.6

66.8 80.2 1 0 6 . 9

8 1. 1

97.3 1 2 9 . 8

18.2

21.9

292

24.7 2 9 6 3 9 . 4

3 1 . 9 38.9 5 1 . 1

38.8 4 6 . 5 62.0

45.6

54.7

73.0

62.9 75.4 1006

1 9 . 9 23.8 3 1. 8

2 4 . 4 29.2 39.0

29.1 34.9 46.6

39.2 47.0

62.7

50.6 60.7 8 0 9

to.q

1 9 . 7 26.3

20.1 24.1 32.1

26.8 n t . I

42.8

33.6 40.3 5 3 . 8

42.2 5 0 . 6 67.5

1 9 . 1 25.5

10.8

13.5

5.6

7.5

40.2

41.3

34.8

49.1

rc.J

1 1. 9

14.6

30.1

30.0

37.2

20.7 25.9, 34.6

8.7

11 . 8

25.1

34.4

24.0

29.7

12.8

40.1

48.7

10.9

14.8

111

54.2 6 5 . 1 86.7

52.1 65.2 78.2 1 0 4 . 3

69.1 86.4 1 0 3 . 7

89.5 1 1 1 . 8

1 8 . 6 23.2 27.8 J t . l

57.4

15.3

1 5 . 5 1 86

18.2 21.9

25.1

30.2

It.o

26.1

36.8

42.7

63.0

86.3

43.4

75.9

r3.0

7.9

9.7

22.3

27.5

35.4

ia1

24.3

7.9

9.6

12.8

4.8

4.3

7.3

I

56.9

16.1

34.4

45.5

20.2

6.6

8,0

10.7

2.7

J.t

13.9

18.0

16.2

5.3

J.O

2.6

o/.1

I1.1

1 44

17.8

20.9

1^a

7.8

9.3

5.5

6.7

9.0

2.9

3.5

4.2

5.7

7.3

2.9

3.9

4.9

6.7

2.1

2.8

3.5

6.8

2.1

51.8

15.7

3.3

3.9

5.3

5.0

41.5

29.5

4J.

60.7

82.8 11 0 . 4

1 5 . 1 20.1

53.7

21.9

26.3

26.7 3 2 . 1

32.4 3 8 . 9

9.9

50.2

26.0

31.3

Z I.J

12.5

8.5

2.8

3.3

4.1

14.9

17.4

24.6

41.7

20.6

26.6

32.5

39.1

11.0

94

2.0

2.6

48.6

66.2

1 0 . 0 12.1

tJ.d

16.5

9.5

1 17

14.0

18.8

6.8

8.1

10.1

7.2

8.7

2.6

3.4

40.5

55.2

28.7

379

8.6

10.7

1 0 . 0 12.8

1 3 . 8 17.3

22.7

4.6

4.5

5.8

33.5

230

30.4

175

3.9

4.8

6.4

4.4

11.9

13.9

19.7

15.3

18.7

5.9

6.9

7.7

8;9

9.3 1 09

1 0 . 9 12.8

1 5 . 1 17.6

4.8

5.6

5.8

44.1

8.0

11.0

27.8

14.2 17.7

17.3 21.7

1 8 . 3 20.9 26.1

24.2 27.6 J 4 . b

3 1 . 3 35.8 4 4 /

6.5

I

8.4

9.6 12.0

8,9

10.5

14.7

165

122

96.0

70.8

23.4

28.3

21.6

26.7

39.3

53.9

32.0

47.2

64.7

55.6 69.4 8 3 . 3

6 6 . 9 83.7 100.4

8 1. 0 101.2

21.4

31.5

14.0

16.7

22.6

28.8

36.2

18.6

22.3

30.2

38.5

48.3

43.4

13.1

57.8

169

17.0 20.7

20.8 24.9

28.2 33.8

8.9

10.7

22.5

27.6

33.3

1/ I

|/.3

45.1

14.3

1 3 . 1 17.5

1 6 . 0 21.1

8.7 1 0 . 9

10.5 13.2

t4.J

17.9

28.6

1 8 . 2 22.7 27.2 36.3

7.2

9.0 1 0 . 8 1 44

9.7 12.1 1 4 . 6 1 9 . 4

12.4

16.8

21.0

5.2

7.0

8.7

8.9

12.0

1q A

6.4

1 1. 1

15.0

18.5

25.1

3

ee 6

7.7 1 0 . 3

1 0 . 5 13.9

1 3 . 3 17.7

1 8 . 0 24.0

O

o

I3

ASTM

SPTCITICAIIOI{

TYPT

SIEIIA"36 STRUCTUMI

l{0.

GRADT

rtil)|lt

STRTl{GTH

K.5.1.

YITTD

STRENGIH

t(.s.1.

?t-4'l

58t0

51-65

A-t

3r

IOR

St|IPS

STRUCTURAL

STEEI.

I.OW.AI"IOY

A-242 t|IG||-STREi'IGTH

ST[[L

STRUCIURAL

IENSILI

STRINGTH

INTTRMEDIATE

AND

A-283 LOW

PLA][S

OISTUCTURAT

CARBON

SIEEL

OUAIITY

ALL

70MrN.

A

50MtN.

24Min.

50"60

2/ Min.

t

55-65

30MtN.

60-72

33MIN

rr{cHts

.lB0-.500

r.000

.500. .500

.180

- 1.000

.500

.l80- .500

500-1000

.tB0".250

.2s0-.500

.180-.500

500- I .000

. l8 0 .-5 0 0

- r.000

.500

.t80- .500

500- I.000

.r80-.500

r.000

.500.180. .500

. I .000

500

A

4t65

24MrN.

B

50t0

27MtN.

c

55-/5

30MrN.

.l 80- .500

500- 1.000

.180-.500

.500-1.000

S]EEL

PI.ATI

MANGANISI

SILI(ON

N299 CARBON

FOR

PRESSURE

VESSII.S

AND

IEMPERED

HIGH.YIIO

SNINGTH,

A-51

4

OUENCt|ID

WETDING

SUITABI.I

IOR

AI.IOY

SNI PUTE

INTTRMEDIATI

ANI]

PLA]ES

IOR

A5l5

CARBON

STEEI

55

FOR

l|IGHER

TIMPERATURE

SERVICI

VESSEI.S

PRISSURE

60

75-95

42MtN.

.t80-1.00

A51

6

MODERATI

AND

IOR

CARBON

$EEtPI.ATIS

F0R

TEIIIPERATURl

SIRVICE

t0WtR

PRISSUREVESSI$

5t75

100MtN.

30MtN.

32MtN.

65

65.85

35MIN.

t0

/090

38MIN

55

60.

7.0

AND

ALLOY

STIIL

OUTNIt|ID

A-5t

/

HIGH

SIRINGTIT,

ftMPERID

PI,AIES

FOR

PRESSURE

VTSSILS

MANGAl.|ESFSII.ICOl'l

CAIBON

A-537 ||IAITREATED,

ctAss

I

VESSIL

STEEL

PI.ATE

FOR

NESSURT

tl

ctASs

IOW.AI.LOY

IOIUMBIUM.VANADIUM

A-572 HIGH.STRENGTH

42

55-75

'60t0

65.85

7&90

ilfl35

70-90

80r00

30MIN:

32MIN

35'lllN.

38MrN.

100

MtN.

50i4rN.

60MtN.

60MIN

42MtN.

50

65MtN.

50^ lN.

60

/5 MIN

60l tN.

S]EEtS

OISTRUCTURAi

OUALITY

65

'/VITH

I.OW.AI.IOY

SIRUCTIJAT

STEEL

4588 HIGl|.$R|l'lOTII

Ar.t

YIITD

POINT

IO4' T||I[K

5O.OOO

PSI

MINIMUM

ROLLTD

AND

IOLD

AND

STRIP,

||OT

A-606 STITL

SHIIT

H.R.

IOW.AI.LOY

WITH

ROLtID,

t]IGH.SIRINGTH,

RESISTANCI

IMPROVED

CORROSION

BO

MIN.

65MtN.

70MIN

50[4rN.

/0 MtN.

50MtN.

65MtN.

45'1llN.

63-83

/s90

80,100

42^4tl'l.

50iUlN

60MtN.

s0MtN.

60

/0 MtN.

60MtN.

t0

80MlN.

70MIN

ANNIAL.

T.R.

NORM.

||I6H.S]RIN6TlJ

LOW-ALIOY

A-633 NORMALIZID

SIRUOUMTSTEET

1r0.130

60-80

65

A-b

CD

E

HIGH.STRINGTH

I.OW.

SNUCTUMI.

STEEL,

A-656 HOT.ROLTED

50

FORMABITITTY

PLATI

WITH

IMPROVED

AttOY

SIEEL

t4

4t55

34Min.

B

D

STRENO]I|

INIERMIOAII

TIN$I"E

AND

A-285 I.OW

VISSEI.S

FOR

PRISSURI

CARBON

STEIL

PI.ATIS

58fl

thATEtilAt

THICKilTSS

80

90MtN.

6n iitN

80MtN.

l{0ilIt1{At

UPPIR

DIE FORMABIlITY

RADIIJS TAfiOR

OPENII{G

8I

IT

1.3

1.51

t0T

N0Mtl{At

vtt Dtt

l0T

21

?1

t.l

IT

t5I

1.0

dl

r0r

BT

tnT

8T

I

1.51

8T

t0T

UI

107

0l

oT,

rl

0t

3t

.l80-.500

.500-1.000

.t80. .500

- 1.000

.500

UI

l0T

?\0.7{0

0-.250

.250-./50

tl

BT

r0T

8T

I0T

r0T

t2I

t4T

0-.250

?{n-750

0-.250

.250-./50

0-.250

1T

t.5T

IT

r.5I

IT

r5T

IT

l.5T

1T

I .5r

IT

1.51

.180..500

.500"

1.000

0t.00

01.00

0t.00

1.6

1.2

8T

l0I

BT

107

.t80t.250

0vER

1.250

.t80-.250

()VER250

.tB0-.250

.250-.500

.l 80-.250

.250-.500

.l 80-.250

.250.500

.t80-.250

250-.500

.1B0-.250

.25S.500

0-.062

.062-.250

.250".500

0-.062

OVER.062

1I

t.5r

180-1.000

0\/ER

1.000

.l80- .500

500-1000

.t80- .500

- 1.000

.500

.180-.500

s00r.000

.r80-.500

"1.000

500

.180-.500

.5001.000

.t80 000

000

OVER

t.ll

121

BT

l0T

UI

2I

t.5T

lI

I .57

l.5T

2I

2I

7t

tl

8T

l0T

l.5T

1T

I5T

tul

l2t

2I

.51

1.0

t.l

1.2

1.0

t.l

t.2

1.5

3.1

1.2

1.3

I .45

1.6

1.2

1.3

1.45

t2T

147

2I

6T

6T

4T

6T

2T

3T

3.1

3T

4I

1.9

6T

6T

4l

1T

5T

t.5T

1.6

2.0

0I

2T

2I

2I

4T

4T

2I

2.57

1.6

3T

3.51

t.8

4l

J . 5|

11

1.4

1.9

6T

OT

2I

4T

21

3T

|.l

UI

lI

21

3T

1.7

2I

II

2l

}I

1.6

1.7

1(r

101

l2T

UI

t0T

ltl

121

T2I

8T

101

8T

lnT

8T

107

8T

t0l

tl

l.5T

]T

t{T

IT

I .5r

IT

I .5r

1.6

1.5

E

1.6

1.8

O

2.1

Thischartis

Thetensileand/oryieldstrengthof manyASTMsteelsarespecifiedasminimumvalueswith no limit on the maximum,

yieldstrengths15,000

thisvalue

PSIabovethe specifiedminimumvalues.Steelexceeding

basedon the actualtensilestrengthand./or

mustbe Iimitedto thinnermaterialthanshownin the chart.Theactualphysicalpropertiesandchemicalanalysisof a steelmaymeet

gradewithin a specification.

and/orgradewith the

for the specification

and,/or

In this casethe capacities

morethanonespecification

properties

1,2000.

listedarethosein effect0nJanuary

highestmechanical

mustbeused.TheASTMspecifications

ASIMSPT(ITICATION

No.

TYPT

t5 lypeA,B,&C

DSTypeA&B

uu5

EODS

55:(jrode

25

Grode

30

SS:

55:Gmde

33ivpeI & 2

SS:Grode

40lypeI & 2

SS:Grode

80

Ar008

STEEI.,

S||EEI

COLD

ROLLED,

CARBON,

SIRUCTURAT,

HIOH.

SIRINGT|l

LOW.AI.tOY

AND

HIGH.

SIRINGI|I

LOW.AI-LOY

WIT|l

IMPROVTD

FORMABILITY

||S|AS:

45(loss

I

Grode

MATTRIAI. 1{0MrNAr. N0illtNAr.

TENSil.t

YIEI.D

DIE

DIT FORMABITITY

UPPER

STREI{GTH STRTNGTH THICKNISS VTE

RlDiltq

FAfTON

0PEl,lll'lG

K.S.t.

K.S.t.

INCHES

BT

.0

NOT

SPETIFIED

20-40

ALL

B]

.0

ALL

NOT

SPEcIFIED 22-35

.0

N0tsPtltftill

l:19

ALL

8I

B]

.0

NOT

ALL

SPEIIFIED 15-25

AtL

8I

.0

2 MIN.

25MtN.

45MIN

30MtN.

ALL

B]

.0

48MIN,

33MtN.

ALL

8l

I.0

ALL

B]

1.0

52MIN

40MtN.

82MIN

BOMIN.

60MIN

45MtN.

||S|AS:

Grode

45Clos

2

55MIN

HSLAS:

Grode

50tlos 1

65MIN

HSLAS:

Grode

50tlos2

60MrN.

HSLAS:

Grode

55ClosI

/0 MtN.

I]S[-AS:

Gmde

55CIos2

65MtN.

[|S|AS:

Gmde

60Closs

I

75MtN.

50MtN.

55MtN.

60MtN.

HS|AS:

0rode

60tloss

2

/0 MlN.

650osI

|ISI,AS:0rode

BO

MIN.

65MIN

flSLAS:

Grode

650oss

2

75MrN.

I1S|AS:

Grode

/0 Closs

I

85MtN.

HSI-AS:

Grode

70tloss

2

80MrN.

[|S|AS'F:

Grode

50

60MtN.

50MIN

I|SI"AS{:

60

Grode

/0 MlN.

60MtN.

HSLAS{:

Grode

70

BO

MIN.

/0 MtN.

90MIN

0-.1

B0

.r80-.230

0 t80

.tB0-.230

0-.i80

.180-.230

B0

0".1

.rB0-.230

0-.1

B0

.r80".230

0-.r

B0

I B0-.230

0-.1

B0

I 80-.230

0-.rB0

IB0-.230

B0

0-.1

I 80'.230

180

/0 MtN.

HSl,ASf:

B0

Gmde

0-.r

80

.t80.230

80MIN

IB0-.230

0-.1

80

.180.230

0-.230

0-.1

80

O\/ER

.t80

0.B

10

0vtR.180

0-.1

B0

0v[R.t80

BT

107

8T

I0T

OT

2I

OT

2T

2I

2I

2I

2I

2I

4l

2I

4T

4T

4I

4T

4I

r6l

161

167

167

t0T

8T

t0T

OT

OT

OT

2I

'IT

I .57

IT

1.57

L5T

2I

1.5T

2T

2I

2.51

21

2.51

2.51

3T

2.51

3T

3T

3.57

3T

3.sT

1.5

1.6

1.7

LB

l9

4l

51

41

5T

t.5T

t.5T

2T

I

2I

2.51

2.0

1.5

1.6

t.B

E

c

O

2.0

o

NOTE:1.Theformability

factorslistedin the chartarebasedona factorof 1.0for mildsteelwith a tensilestrengthof 60,000

p.s,i,

p.s.i.

anda yieldstrengthof 40,000

2.TheASTMspecifications

listedarethosein effectJanuary

1,2000.

3.Highstrengthlowalloysteelandstainless

steelshouldnotbeformedat temperatures

below50"F(10"C).

t5

ASTM

SPTCITIftTION

l{0.

IYPE

(STvpe

A,B,&C

DSTvoeA&B

)): br00e

JU

SS:Grode

33

36lvoe1

SS:

Grode

2

36Tvpe

SS:

Grode

Grode

40

SS:

45

SS:Grode

50

SS:Grode

55

SS:Grode

A-t

0tI

S]FFIqHFFT

AND

STRIg

ROILED,

HOT

TARBON,

STRUCTURAL,

t|IGH.STRENGTH

AND

LOW-ALI-OY

HIGH.STRINGTt|

LOWAIIOY

WITI

IMPROVED

FORMABLITY

YIEI.D

TENSil.I

STRTI{GTH STRTNGTH

K q-t-

lLs.l.

NOT

SPICIfIED 30-50

NOT

SPEt|FITD 30-45

30MIN

49MtN.

33MtN.

52MIN

s3MtN.

36MlN.

36MtN.

58-80

40MtN.

55MtN.

45MtN.

60MlN.

50MrN.

65MlN.

55MtN.

/0MrN.

45Clos1

HSLAS:

Grode

60MtN.

45tlos2

HSI"AS:

Grode

55MlN.

I

Grode

50Closs

HS|AS:

65MrN.

50Clos2

HS|AS:

Grode

60MtN.

55ClosI

HS|AS:

Grode

/0 MtN.

2

HSLAS:

Grode

55Closs

65MtN.

HSIAS:

Grode

60[losI

/5 MlN.

2

HSLAS:

Grode

60tloss

/0 MlN.

liSI-AS:

Grode

65tlosI

BO

MIN.

HSI,AS:

Grode

65tlos2

75MlN.

/0 (losI

HSLAS:

Grode

85MrN.

70Clos

2

HS|AS:

Grode

BO

MIN.

50

I1S|AS{;

Gmde

60MtN.

45MtN.

50MtN.

55MIN

60MIN

65MrN.

/0MrN.

MATTRIAI

S]AINLESS

STIIL

AIUMINUM

50MtN.

60

llS|AS-F:

0rode

/0 MtN.

60MtN.

||S|AS{:

Grode

70

80MtN.

70MtN.

80

HSLASf:

Grode

90MIN

80MrN.

TYPT

302

304.3041.316.

&316t

YITTD

Iil{Sil.1

STRTlIGTH SIRTNGTH

K.S.t.

K.S.t.

80"90

30-40

3004-1134

35TYP

2I TYP

5052-H32

33TYP

28TYP

606r{6

42IYP

37TYP

MATERIAI. N0mtilAr. iloM[{At

UPPTR

DIE f0RillABil.rTY

THI(KNESS vtt Dlt

t1{ftts

OPEI{ING RADIIIS TACTOR

1.0

IT

BT

0-.230

IT

1.0

8I

0-.230

1.1

IT

8i

0,.230

l.t5

t.5T

t0l

0-.230

t.l5

l.5T

l0T

0-.230

1.3

r.5T

l0T

0-.230

1.25

2t

21

0-.230

1.5

21

l2I

0-.230

1.6

2.57

2I

0-.230

1.7

3T

127

0-.230

IT

8T

0-.1

80

1.51

t0T

.r80-.230

t.5

II

8T

80

0-.1

t.5r

l0T

.180-.230

t.5t

OT

80

0-.1

21

2T

.t80-.230

1.6

t.ll

OT

B0

0-.t

2I

2l

.r80-.230

21

2I

80

0-.1

21

2.sI

.180-.230

1.7

21

2T

0-.1

80

2.51

21

.t80-.230

121

2.5r

0.180

3T

l4r

.180-.230

LB

t2T

2.51

80

0-.1

31

t4r

180.230

t4T

3T

B0

0'.1

3.57

t4T

.tB0-.230

1.9

4T

3T

0-.1

80

4T

3.51

rB0-.230

0-.r

80

.180-.230

0-.1

80

.rB0-.230

0-.230

0.180

OVER

.IBO

B0

0-..l

0\/[R

.180

80

0-.1

.t80

o\/ER

6T

6i

4T

5T

6T

6T

OT

8T

l0T

t0T

r0T

l0T

l2l

4T

5I

2.0

I .5I

1.5

r.5l

2t

1.6

2I

2.51

1.8

2I

2.57

2.0

MATERIAT N0illrt{At iloffi1{Ar

UPPTR

DII FORMABII.ITY

THICKlITSS vtt Dlt

0Pt1{lNG RADIUS FAOOR

[{(Hts

II

8T

0-.500

t.3

1.57

t0I

.s00t.000

3

II

25

8T

0-.1

0.6

t0T

1.5-37

.r25-.r

88

IT

8T

0-.03r

0.7

tr

t0T

2I

.031-.062

O

IT

8T

0-.031

0.8

l0I

2I

.03r-.062

o

T6

The

41008 & A1011 replacedseveralold ASTM Specifications.

ln Jan of 2000 new ASTM Specifications

chart shown here is a cross referencebetweenthe old and the new specifications.

aslt sPtc

l{0.

GRADI

CS

lype

A

tSType

B

CS

lype

C

DS

Type

A

DS

Type

B

DDS

EDDS

)5: br00e

l5

Ar008

COLD

R0U.ED

Sl|ETT

SS:

Grode

30

SS:

Orode

33Type

I

SS:

Grode

33Type

2

55:Grode

40Type

I

SS:

Grode

40Type

2

SS:

Orode

80

HS|AS:

45ilosI

Gmde

tiSIAS:

Grode

45Clos

2

'l

HS|AS:

Grode

50tloss

HS|^AS:0rode

50Clos

2

HSLAS:

Grode

55CIos

I

I1S|AS:

Gmde

55Closs

2

HSLAS:

Grode

60ClosI

l|SLAS:0rode

60Clos

2

HSLAS:

Grude

65Clos1

|"IS|AS:

Grode

65(los2

HSLAS:

Grode

70ClosI

[|S|AS:

Grode

/0 Closs

2

HStASf:

Grode

50

HS|AS-F:

Gmde

60

tlS|AS.F:

70

Grode

HSLAS-F:

Orode

80

cSTvpe

A

B

[S.lype

CSlwe(

3ivrl

u) typo

u

55:Oiode

30

)): t f00eJJ

SS:

Grode

36Type

1

SS:

Grode

36Type

2

SS:

Grode

40

55:0rode

45

5S:

Grode

50

At0ll

HOT

R0u.ED

St|EET

)): trlooe))

HS|AS:

Grode

45ClosI

HS|"AS:

Grode

450oss

2

l|SLAS:

Orode

50Closs

I

I|SI,AS:

Grode

50(los2

HSLAS:

Grode

55Clos1

HSLAS:

Grode

55Closs

2

[|S|AS:

Grode

60[|osI

H5LA5:

Orode

60Closs

2

HSTAS:

Grode

65(losI

HSIAS:

Orode

65Clos

2

HSLAS:

Grode

/0 ClosI

||SLAS:

Orode

70Closs

2

HSTAS{:

Grode

50

HSLAS-F:

6rode

60

HSLAS-F:

Grcde

i0

H(l [(-F' Grnrlc80

T7

PRtvtous

sPEc

4.366

A-620

A-963

Ar69

A T 1G1R A

A T IG

I R

B

A-61

I 6RClypeI

A-61

I GR

CType

2

A-61

I 6R0Type

I

A.5lI GR

DType

2

A.6I

I GR

E

A-607

GR

45flosI

A.607

45tloss

GR

2

A-60/

GR

50ClosI

A-607

6R500oss