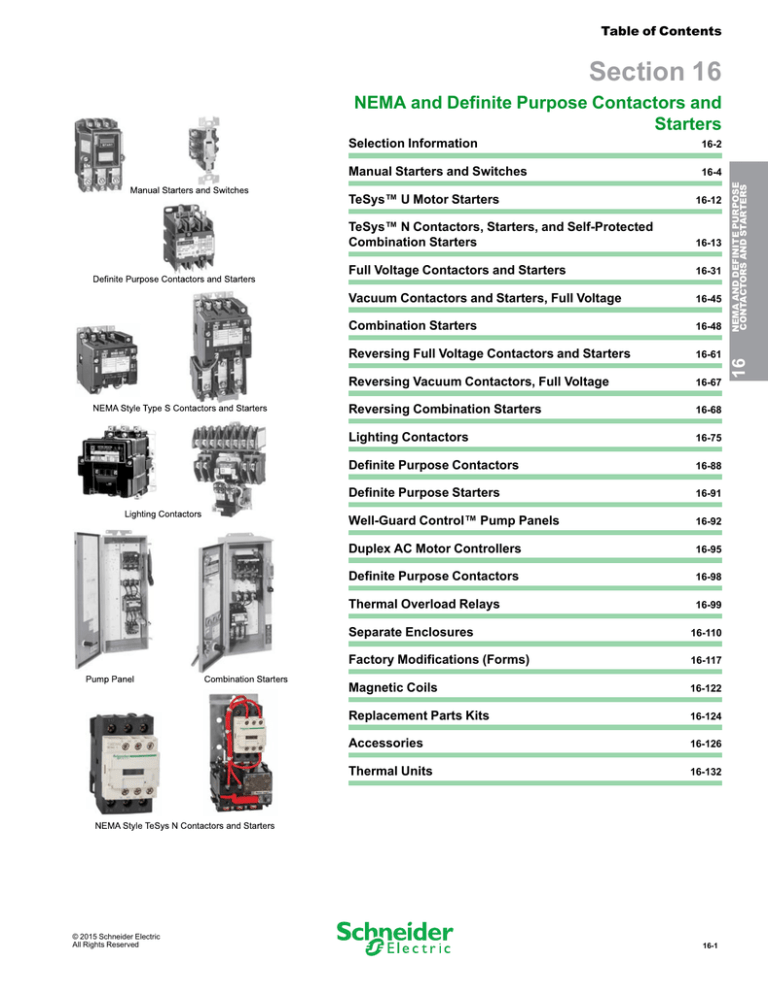

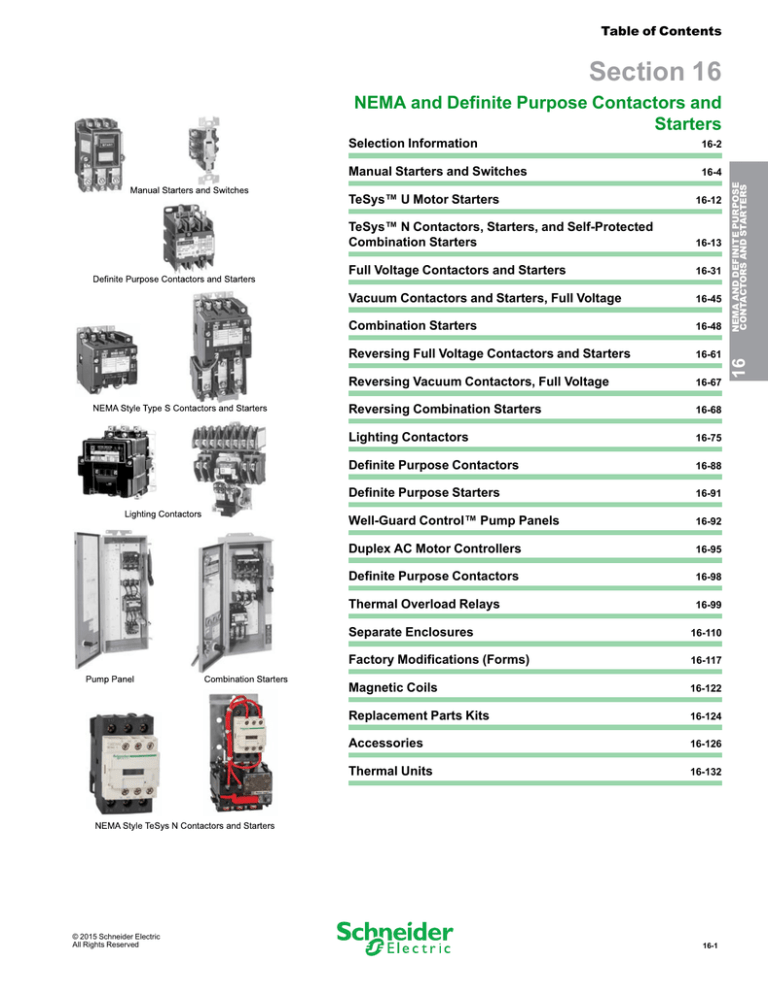

Table of Contents

Section 16

Definite Purp os e Conta ctors a nd S ta rte rs

NEMA Style Type S Conta ctors a nd S ta rte rs

Lighting Co nta ctors

Pump Panel

Combinatio n S ta rte rs

16-2

Manual Starters and Switches

16-4

TeSys™ U Motor Starters

16-12

TeSys™ N Contactors, Starters, and Self-Protected

Combination Starters

16-13

Full Voltage Contactors and Starters

16-31

Vacuum Contactors and Starters, Full Voltage

16-45

Combination Starters

16-48

Reversing Full Voltage Contactors and Starters

16-61

Reversing Vacuum Contactors, Full Voltage

16-67

Reversing Combination Starters

16-68

Lighting Contactors

16-75

Definite Purpose Contactors

16-88

Definite Purpose Starters

16-91

Well-Guard Control™ Pump Panels

16-92

Duplex AC Motor Controllers

16-95

Definite Purpose Contactors

16-98

Thermal Overload Relays

16-99

Separate Enclosures

16-110

Factory Modifications (Forms)

16-117

Magnetic Coils

16-122

Replacement Parts Kits

16-124

Accessories

16-126

Thermal Units

16-132

NEMA Style Te S ys N Conta ctors a nd S ta rte rs

© 2015 Schneider Electric

All Rights Reserved

16-1

16

Manual Start e rs a nd S witche s

Selection Information

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

NEMA and Definite Purpose Contactors and

Starters

NEMA and Definite Purpose Contactors

and Starters

Selection Information

schneider-electric.us

Selection Information

16

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Class

2510, 2511, 2512

T40

T02, T36

8502 & 8702

8536 & 8736

NEMA Style, Full Voltage Non-Reversing and Full Voltage Reversing

Type of Product

Manual Starters and

Switches,

Non-Reversing, Reversing

and Two Speed

TeSys™ N

Self-Protected Combination

Starters

TeSys™ N

Contactors and Starters

AC Magnetic Contactors

AC Magnetic Starters

Combination Magnetic

Starters with

Disconnect Switch

page 16-4

page 16-14

page 16-17

8502: page 16-31

8702: page 16-61

8536: page 16-35

8736: page 16-63

8538: page 16-48

8738: page 16-68

M-0

M-1

M-1P

00–1

00–7

00–7

00–7

8538: 0– 6

8738: 0–5

Type F: 277 Vac

Types K & M: 600 Vac

600 Vac Max.

600 Vac Max.

600 Vac Max.

600 Vac Max.

600 Vac Max.

Type F: 16 A

Types K & M: 30 A

27 A

9–810 A

9–810 A

9–810 A

8538: 18–540 A

8738: 18–270 A

Type F: 1

Type K: 20

Type M: 10

10

600

0.5–600

0.5–600

Type F: Melting Alloy

Type K: N/A

Type M: Melting Alloy

Electronic

Contactors: N/A

Starters: Bimetallic (Size 002) or Solid-State

N/A

Melting Alloy

Bimetallic (Size 00–2)

Melting Alloy

Bimetallic (Size 0–2)

Solid State

Solid State

1, Flush Mount,

3R, 4, 4X, 7 & 9

and Open

1, 12/3R, 4/4X

Open

1, 3R, 4, 4X,

12/3R, 7 & 9

and Open

1, 3R, 4, 4X,

12/3R, 7 & 9

and Open

1, 4, 4X, 12/3R

UL File E42243 NLRV

UL File E152395

CSA file LR60905

Contactors: UL File E164862

NLDX

CSA LR43364 Class 321124

Starters: UL File E152395

NKJH

CSA LR60905 Class 321124

Page

NEMA Sizes

Load

Voltage

Current Ratings

(Continuous)

Horsepower

Ratings

(Maximum)

Overload Relay

Enclosure Types

UR File E42243 NLRV2

Approvals

16-2

CSA File LR 25490

8538 & 8738

8538: 0.5–400

8738: 0.5–200

UL File E78351 NLDX

UL File E78351 NLDX

UL File E152395 NKJH7

CSA 60905 Class 321104

CSA 60905 Class 321104

CSA LR584 Class 3211

04

CE IEC 947-4-1

Sizes 00–5 Only

CE IEC 947-4-1

Sizes 00–5 Only

© 2015 Schneider Electric

All Rights Reserved

NEMA and Definite Purpose Contactors

and Starters

Selection Information

schneider-electric.us

8539 & 8739

8903L & 8903S

8903

Combination Devices

Type of Product

Combination Magnetic

Starters with

PowerPact™ Circuit

Breaker

Multipole electrically held

and mechanically held

contactors available in 30

A configurations to 12

poles and 800 A

configurations to 3 poles.

Type S lighting contactors

electrically held and

mechanically held

available with disconnect

switches or PowerPact™

circuit breakers

8910, 8911, 8965

8940

8941

Definite Purpose nonreversing contactors

available as compact 1 or

2 pole to 40 A and 2 to 4

pole to 90 A. Reversing

and Starter

Configurations also

available.

Well-Guard Control™

Pumping Plant Panels

available

with disconnect switches

or PowerPact™ circuit

breakers.

NEMA Style AC

Duplex Motor

Controllers available as

a combination starter

or without

disconnecting means.

8539: page 16-52

8739: page 16-70

page 16-75

page 16-78

8910: page 16-88

8911: page 16-91

8965: page 16-98

page 16-92

page 16-93

page 16-95

Page

8539: 0–7

8739: 0–6

N/A

N/A

N/A

1–7

1–4

NEMA Sizes

Load

Voltage

600 Vac Max.

600 Vac Max.

600 Vac Max.

600 Vac Max.

600 Vac Max.

600 Vac Max.

Current Ratings

(Continuous)

8539: 18–810 A

8739: 18–540 A

8903L to 30 A

8903S to 800 A

300 A (Disconnect)

600 A (Circuit Breaker)

20–40 A (Compact)

27–810 A

27–135 A

Horsepower

Ratings

(Maximum)

8539: 0.5–600

8739: 0.5–400

N/A

N/A

0.5–50

0.5–600

0.5–100

Melting Alloy

Bimetallic

(Size 0–1)

Solid State

N/A

N/A

Melting Alloy (8911)

Melting Alloy

Melting Alloy

Overload Relay

Enclosure Types

1, 4, 4X, 12/3R

1, 3R, 4, 4X,

12/3R and Open

Approvals

UL File E152395 NKJH7

CSA LR584 Class 3211

04

UL File E78427 NRNT

CSA LR60905 Class

3231 01

© 2015 Schneider Electric

All Rights Reserved

20–90 A

Bimetallic

Bimetallic

Solid State

Solid State

1, 4, 4X,

12/3R and Open

1, 4, 4X, 12/3R

1

3R

UL File E16151 NRNT

cUL File E16151 NRNT

UL E3190 NLDX2

CSA LR25490 Class

3211 04

UL/cUL 152395 NKJH

UL File E152395

NKJH7

16-3

16

Class

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Selection Information

Manual Starters and Switches

Manual Starters, Type F—Fractional

Horsepower

Class 2510, 2512 / Refer to Catalog 2510CT9701

schneider-electric.us

Fractional Horsepower Manual Starters with Melting Alloy Type

Thermal Overload Relay

Table 16.1: Single-Unit Types—Class 2510—Rated 16 A—Thermal Units (see Thermal Unit Selection, page 16-132)

16

Type of

Operator

No.of

Poles

NEMA 1

General Purpose

Enclosure

Surface Mounting

Features

Standard

Oversized

Type

Type

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Basic Starter—Class 2510

Standard

FG1

1

With Red Pilot Light [2]

FG1P

Toggle

Standard

FG2

2

With Red Pilot Light [2]

FG2P

Standard

FG3

1

With Red Pilot Light [2]

FG3P

Key

Standard

FG4

2

With Red Pilot Light [2]

FG4P

Starter with Handle Guard/Lock-Off—Class 2510

Standard

FG5

1

With Red Pilot Light [2]

FG5P

Toggle

Standard

FG6

2

With Red Pilot Light [2]

FG6P

General Purpose Flush Mounting

(Without Pull Box)

Standard

Jumbo

Gray

Stainless

Stainless

Flush

Steel

Steel

Plate

Flush Plate Flush Plate

Type

Type

Type

FGJ1

FGJ1P

FGJ2

FGJ2P

FGJ3

FGJ3P

FGJ4

FGJ4P

FF1

FF1P

FF2

FF2P

FF3

FF3P

FF4

FF4P

FGJ5

FGJ5P

FGJ6

FGJ6P

FS1

FS1P

FS2

FS2P

FS3

FS3P

FS4

FS4P

NEMA Type 4 [1]

Enclosure

Watertight

and

Dusttight

—

FSJ1P

—

FSJ2P

—

FSJ3P

—

FSJ4P

Order basic starter plus

separate handle guard kit.

NEMA Types 3R, 7 & 9

Enclosure

Hazardous Locations

Div. 1 & 2

Class I Groups B, C, & D, &

Class II Groups E, F, & G

Open

Type

Number

of

Thermal

Units

Required

Type

Type

Type

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

FO1

FO1P

FO2

FO2P

FO3

FO3P

FO4

FO4P

1

1

1

1

1

1

1

1

FW1

FW1P

FW2

FW2P

FR1

—

FR2

—

[3] [4]

[3] [4]

[3] [4]

[3] [4]

1

1

1

1

Table 16.2: Duplex Units—Class 2510

Type of

Operator

No. of

Poles

NEMA 1 General Purpose

Enclosure Surface

Mounting

Features

Type

One Starter in Duplex Enclosure—Class 2510

Standard

FG02

Toggle

2

With Red Pilot Light [2]

FG02P

Key

With Red Pilot Light [2]

FG04P

2

Two Starters in One Enclosure—Class 2510

FG22

2 Each Standard

Toggle

Str.

With Red Pilot Light on Each[2]

FG22P

2 Each With Red Pilot Light on Each[2]

Key

FG44P

Str.

Starter and Auto-Off-Hand SPDT Selector Switch (AC Only)—Class 2510

Standard

FG71

1

With Red Pilot Light [2]

FG71P

Toggle

Standard

FG72

2

With Red Pilot Light[2]

FG72P

Key

With Red Pilot Light[2]

2

FG74P

Two Speed Starters (AC Only)—Class 2512

With Mechanical Interlock:

Standard

FG11

With 2 Red Pilot Lights [2]

FG11P

1

With High-Off-Low Selector Switch:

With 2 Red Pilot Lights [2]

—

Toggle

With Mechanical Interlock:

Standard

FG22

With 2 Red Pilot Lights [2]

FG22P

2

With High-Off-Low Selector Switch:

With 2 Red Pilot Lights [2]

—

General Purpose Flush Mounting (Without Pull Box)

Gray Flush Plate for Wall

Stainless Steel Flush Plate

or Cavity Mounting

for Wall or Cavity Mounting

Type

Type

Number of

Thermal

Units

Required

Replacement Starter

Class 2510

Type

—

—

—

—

—

—

—

—

—

FF22

FF22P

—

FS22P

—

—

2

FF44P

FS44P

—

2

FF71

FF71P

FF72

FF72P

FF74P

—

FS71P

—

FS72P

FS74P

FF11

FF11P

—

—

FO1T

FO1PT

—

FS101P

FO1PT

FF22

FF22P

—

—

FO2T

FO2PT

—

FS202P

FO2PT

1

1

—

1

—

—

1

—

—

1

Replacement Starter—Class 2510

2

2

Table 16.3: Horsepower Ratings, Type F (continuous current rating: 16 A)

Volts

1-Pole

1

1

115–230

277

Maximum Horsepower

AC Single Phase

2-Pole

1

1

DC

2-Pole Only

3/4

—

Table 16.4: Approvals—2510 Type F and K

Agency

UL

CSA

Open

Enclosed

UL Component Recognized

File: E42243, CCN: NLRV

UL Listed

CSA Certified File: LR25490, Class: 3211-05

File: E42243, CCN: NLRV2

Table 16.5: How to Order

To Order Specify:

Type FG2P

[1]

[2]

[3]

[4]

16-4

Type FO2

•

•

Class Number

Type Number

Catalog Number

Type

Class

2510

FG1

Furnished with one 3/4" pipe tap in the bottom (reversible for top feed). For a 3/4" pipe tap in the top and bottom, add the suffix H to the Type.

For a green pilot light, add the letter G to the catalog number (i.e. 2510FG2PG).

For a replacement starter, order the Open type above.

When replacing a starter equipped with a pilot light in NEMA 4 enclosure, retain the pilot light mounting bracket from the original device.

© 2015 Schneider Electric

All Rights Reserved

Manual Switches, 30 A—Type K

Manual Starters and Switches

Class 2510, 2511, 2512 / Refer to Catalog 2510CT9701

schneider-electric.us

Table 16.6: Non-Reversing—Class 2510

Standard

With Pilot Light [6]

115 Vac

230 Vac

Standard

With Pilot Light [6]

208–277 Vac

440–600 Vac

Standard

With Pilot Light [6]

115 Vac

230 Vac

Standard

With Pilot Light [6]

208–277 Vac

440–600 Vac

Standard

With Pilot Light [6]

115 Vac

230 Vac

Standard

With Pilot Light [6]

208–277 Vac

440–600 Vac

2

3

Toggle

2

3

2

Key

3

Standard

Oversized

Gray

Flush

Plate

Type

KG1

Type

KGJ1

KG1A

KG1B

KG2

Features

NEMA Type

4 Enclosure

[5]

Watertight

and

Dusttight

NEMA Types 3R, 7 & 9

Enclosure[5]

Hazardous Locations

Div. 1 & 2

Class I Groups B, C, & D, &

Class II Groups E, F, and G

Open

Type

Type

KF1

Standard

Stainless

Steel

Flush Plate

Type

KS1

Jumbo

Stainless

Steel

Flush Plate

Type

—

Type

KW1

KR1

KO1

KGJ1A

KGJ1B

KGJ2

KF1A

KF1B

KF2

KS1A

KS1B

KS2

KSJ1A

KSJ1B

—

KW1A

KW1B

KW2

—

—

KR2

KO1A [7]

KO1B [7]

KO2

KG2B

KG2C

KG5

KGJ2B

KGJ2C

KGJ5

KF2B

KF2C

—

KS2B

KS2C

—

KSJ2B

KSJ2C

—

KW2B

KW2C

KW5

—

—

—

KO2B [7]

KO2C [7]

KO5

KG5A

KG5B

KG6

—

—

KGJ6

—

—

—

—

—

—

—

—

—

KW5A

KW5B

KW6

—

—

—

KO5A [7]

KO5B [7]

KO6

KG6B

KG6C

KG3

—

—

KGJ3

—

—

KF3

—

—

KS3

—

—

—

KW6B

KW6C

—

—

—

—

KO6B [7]

KO6C [7]

KO3

KG3A

KG3B

KG4

KGJ3A

KGJ3B

KGJ4

KF3A

KF3B

KF4

KS3A

KS3B

KS4

KSJ3A

KSJ3B

—

—

—

—

—

—

—

KO3A

KO3B

KO4

KG4B

KG4C

KGJ4B

KGJ4C

KF4B

KF4C

KS4B

KS4C

KSJ4B

KSJ4C

—

—

—

—

KO4B

KO4C

Type

Type

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

No. of

Poles

General Purpose Flush Mounting

(Without Pull Box)

16

Type of

Operator

NEMA 1

General Purpose

Enclosure

Surface Mounting

Table 16.7: Reversing—Class 2511

Type of

Operator

No. of

Poles

Motor Types

for Which Suitable

2

1Ø

3-Lead

Repulsion-Induction

3

3 Ø; Also

1 Ø Capacitor,

Split Ø, or 4-Lead

Repulsion-Induction

NEMA 1

General Purpose

Enclosure

Surface Mounting

Type

KG11

Features

(Including Mechanical

Interlock)

Standard

With Pilot Light[6]

115 Vac

230 Vac

Standard

With Pilot Light[6]

110–120 Vac

208–220 Vac

440–600 Vac

Toggle

With Flush Plate for

Cavity Mounting

(Without Pull Box)

Replacement

Switch

Class 2510

Type

Type

KF11

KO1T

KG11A

KG11B

KG22

KF11A

KF11B

KF22

KO1AT

KO1BT

KO2T

KG22A

KG22B

KG22C

KF22A

KF22B

KF22C

KO2AT

KO2BT

KO2CT

Table 16.8: Two Speed—Class 2512

Type of

Operator

No. of

Poles

Suitable for

Motor Types

2

1Ø

Two Winding

(3-Lead)

3

3Ø

Separate Winding

(Wye-Connected)

KG11

With Flush Plate

for Cavity

Mounting

(Without Pull Box)

Type

KF11

KG11A

KG11B

KG22

KF11A

KF11B

KF22

KO1AT

KO1BT

KO2T

KG22B

KG22C

KF22B

KF22C

KO2BT

KO2CT

NEMA 1 General

Purpose Enclosure

Surface Mounting

Features

(Including Mechanical Interlock)

Type

Standard

With 2 Pilot Lights [6]

115 Vac

230 Vac

Standard

With 2 Pilot Lights [6]

208–240 Vac

440–600 Vac

Toggle

Device

Motor Type

AC

1Ø

3Ø

1Ø

3 Ø,

Constant or

3

Class

Variable Torque

2512

3 Ø,

3

Constant Hp

Continuous current rating

Class

2511

2

3

2

Maximum Hp

115 V

2

2

2

230 V

2

7-1/2

2

460–575 V

3

10

3

2

7-1/2

10

2

7-1/2

10

30 A at 600 Vac maximum

Maximum DC Hp

(breaking 2 poles)

90 V

115 V

230 V

1

2

1-1/2

30 A at 24 Vdc maximum

Class

2510

No. of

Poles

Motor

Type AC

KO1

Single Ø

2

KO3

KO2

3

Three Ø

KO4

Single Ø

KO5

2

KO6

3

Three Ø

Continuous current rating

Maximum DC Hp

(breaking 2 poles)

Maximum Hp

115

V

230

V

460

V

575

V

2

2

3

3

2

7-1/2

10

10

2

3

7-1/2

10

2

7-1/2

15

20

30 A at 600 Vac maximum

Table 16.11: How to Order

To Order Specify:

•

•

[5]

[6]

[7]

Type

KO1T

Table 16.10: Class 2510 Horsepower Ratings

Table 16.9: Class 2511 and 2512 Horsepower Ratings Type K

No. of

Poles

Replacement

Switch

Class 2510

Class Number

Type Number

90 V

115 V

230 V

1

2

1-1/2

30 A at 24 Vdc maximum

Catalog Number

Type

Class

2510

KO2

Furnished with one 3/4" pipe tap in the bottom (reversible for top feed). For a 3/4" pipe tap in the top and bottom, add the suffix H to the Type.

For a green pilot light, add the letter G to the catalog number (i.e. 2510FG2PG).

When replacing a starter equipped with a pilot light in NEMA 4 enclosure, retain the pilot light mounting bracket from the original device.

© 2015 Schneider Electric

All Rights Reserved

16-5

Type F and K—Approximate Dimensions

Manual Starters and Switches

Class 2510, 2511, 2512 / Refer to Catalog 2510CT9701

schneider-electric.us

Open Type

Mtg. Holes for #6-32 Screws (2)

Pilot Light

Mtg. Holes For #6-32 Screws (2)

Pilot Light

OFF

1.69

43

2.38

60

3.28

83

4.13

105

16

1.69

43

.84

21

OFF

.84

21

2.38

3.28 60

4.13 83

105

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

2.22

56

1.59

40

1.70

43

Types FO1, 1P, 2

Fractional Hp Starter

2.34

60

Types KO1, 1A, 1B, 2, 2B, 2C

Types KO5, 5A, 5B, 6, 6B, 6C

Motor Starting Switch

NEMA 1 General Purpose Enclosure (Surface Mount)

Mtg. Holes .25 dia. (2)

6

Mtg. Holes .25 dia. (2)

6

3.00

76

2.75

70

2.88

73

0.56

14

0.41

10

3.00

76

OFF

4.25

108

1.63

41

2.44

62

Pilot

Light

2.75

70

2.88

73

0.56

14

4.25

108

OFF

1.63

41

2.88

73

Pilot

Light

4.86

123

0.69

17

0.71

18

4.35

110

OFF

1.06

27

1.06

27

1/2–3/4" Conduit

Knockout, Both Ends

1/2–3/4" Conduit

Knockout, Both Ends

Standard

(Class 2510 Types FG & KG, Single

Unit)

Oversized

(Class 2510 Types FGJ & KGJ,

Single Unit)

3.28

83

Pilot Light

2.20

56

3.09

78

Jumbo

(Class 9991Type KE2, see Table

16.29)

NEMA 1 General Purpose Enclosure (Flush Mount)

Table 16.12: General Purpose Enclosure (Flush

Mount)

Device

Type of

Operator

Toggle

Fractional

Hp Starter

Key

Toggle

Motor

Starting

Switch

Key

Class 2510 Type

FF1, 1P, 2, 2P,

FS1, 1P, 2, 2P

FSJ1P, 2P

FF3, 3P, 4, 4P,

FS3, 3P, 4, 4P

FSJ3P, 4P

KF1, 1A, 1B, 2, 2B, 2C

KS1, 1A, 1B, 2, 2B, 2C

KSJ1A, 1B, 2B, 2C

KF3, 3A, 3B, 4, 4B, 4C

KS3, 3A, 3B, 4, 4B, 4C

KSJ3A, 3B, 4B, 4C

Dimensions

A

B

C

1.44

2.75

4.5

1.44

3.5

5.25

1.44

2.75

4.5

1.44

3.5

5.25

1.75

2.75

4.5

1.75

3.5

5.25

1.75

2.75

4.5

1.75

3.5

5.25

OFF

2.56

65

C

D

.50

13 0.66

17

B

1.78

45

D

Pilot

Light

A

NOTE: These dimensions are for reference only.

If you need precise measurements, contact the

Customer Care Center at 1-888-778-2733.

.75

.91 19

23

1.69

43

NEMA 4 Watertight Die-Cast Zinc Enclosure

Table 16.13: NEMA 4 Watertight Die-Cast Zinc

Enclosure

Device

Fractional Hp Starter

Motor Starting Switch

Class

2510

2510

Type

FW1, 1P, 2, 2P

KW1, 1A, 1B, 2, 2B, 2C

.25

6

(2) .22 DIA. MTG. HOLE

6

1.13

29

3

76 2.75

70

4.56

116 4.25

108

PILOT LIGHT

ON

OFF

3.75

95

4.38

111

1.13

.31

29

8

CONDUIT CENTER LINE

16-6

.28 DIA. PADLOCK HOLE

7

3" 14 PIPE TAP

4

.78

20

© 2015 Schneider Electric

All Rights Reserved

Approximate Dimensions—Type F and K

Manual Starters and Switches

Class 2510, 2511, 2512 / Refer to Catalog 2510CT9701

schneider-electric.us

NEMA 3R, 7, and 9 Aluminum Enclosure for Hazardous Locations

1.37

35

3.95

100

Table 16.14: NEMA 3R, 7, and 9 Aluminum Enclosure for Hazardous Locations

4.35

110

2X .30

8

Device

Fractional Hp Starter

Motor Starting Switch

Type

FR1, 2

KR1, 2

Class

2510

2510

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

6.36

161

ON

5.75

146

OFF

.28 PADLOCK HOLE

7

CONDUIT CENTERLINE

2X .31 MTG. HOLES

8

1.37

35

3/4-14 PIPE TAP,

BOTTOM ONLY

.70

18

1.19

30

Dimensions for Duplex Devices

NOTE: These dimensions are for reference only. If you need precise measurements,

contact the Customer Care Center at 1-888-778-2733.

.25

Dia. Mtg. Holes

6

Table 16.15: NEMA 1 General Purpose Surface Mount Enclosure for Duplex

Devices

Pilot

Light

OFF

OFF

3.00

76

Device

4.25

108

2.75

70

.38

10

2.88

73

1.88

48

4.50

114

1.88

48

One Starter

2.56

65

0.56

14

3.81

97

Two Starters

2.63

67

One Starter and

One Selector Switch[8]

Reversing Switch[9]

Two-Speed Starter

Two-Speed Switch

1.06

27

Type of

Operator

Toggle

Key

Toggle

Key

Toggle

Key

Toggle

Toggle

Toggle

Type

Class

2510

2510

2510

2510

2510

2510

2511

2512

2512

16

(4)

FGO2, 02P

FGO4P

FG22, 22P

FG44P

FG71, 71P, 72, 72P

FG74P

KG11, 11A, 11B, 22, 22A, 22B, 22C

FG11, 11P, 22, 22P

KG11, 11A, 11B, 22, 22B, 22C

0.5–0.75 Conduit Knockout, Both Ends

Table 16.16: General Purpose Flush Mounting Plate for Duplex Devices

Device

2.56

65

OFF

OFF

A

D

[8]

[9]

[10]

[11]

.75

19

.91

23

C

Pilot

Light

Two

Starters

One

Starter

and One

Selector

Switch[11]

Reversing

Switch

Two-Speed

Starter

Two-Speed

Switch

Type of

Operator

Class

Toggle

2510

Key

2510

Toggle

2510

Key

2510

Toggle

2511

Toggle

2512

2512

Toggle

Type

FF22, 22P

FS22P

FF44P

FS44P

FF71, 71P, 72, 72P

FS71P, 72P

FF74P

FS74P

KF11, 11A, 11B

KF22, 22A

KF22B, 22C

A

5.25

4.56

5.25

4.56

5.25

4.56

5.25

4.56

Dimensions[10]

B

C

3.75

5.25

3.5

4.5

3.75

5.25

3.5

4.5

0.75

5.25

3.5

4.5

3.75

5.25

3.5

4.5

D

1.44

1.44

1.44

1.44

2

2

2

2

5.25

3.75

5.25

1.75

FF11, 11P, 22, 22P

5.25

3.75

5.25

1.44

KF11, 11A, 11B,

KF22, 22B, 22C

5.25

3.75

5.25

1.75

B

Selector switch is on the left and increases the overall depth to 3.5 in.

Only one pilot light (located on right) is used on Class 2511 switches.

Dimensions include factory wired power connections.

Selector Switch is on left, extends 1-5/8" from mounting surface.

© 2015 Schneider Electric

All Rights Reserved

16-7

Manual Starters and Switches

Manual Starters, Type M and T—Integral

Horsepower

Class 2510, 2511, 2512 / Refer to Catalog 2510CT9701

schneider-electric.us

Integral Horsepower

16

Types M and T integral horsepower manual starters provide

convenient On-Off operation of small single phase, polyphase or DC

motors. Typical applications include small machine tools, pumps, fans

and conveyors.

• Push button (M) or toggle (T) operators

• Reliable overload protection

• Pilot light and auxiliary contact available

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Table 16.17: Integral Horsepower Manual Starters (see Thermal Unit Selection, page 16-132)

Ratings

No. of

Poles

NEMA

Size

M-1P

115

230

115

230

115

230

M-0

200-230

380-575

M-1

200-230

380-575

M-0

2Pole

M-1

3Pole

DC

2Pole

Motor

Voltage

M-0

M-1

115

230

115

230

All Except NEMA 7 and 9

File E42243

CCN NLRV

NEMA 7 and 9 Only

File E58760

CCN NPXZ

[12]

[13]

16-8

Max. Hp

PolySingle

Phase

Phase

—

1

—

2

—

2

3

—

3

—

5

—

—

—

—

3

5

—

—

—

7.5

—

10

—

1 hp DC

1.5 hp DC

1.5 hp DC

2 hp DC

Non-Reversing, Class 2510, Max. Voltage: 600 Vac

NEMA 1

NEMA 4/4X

Surface Mounting

Watertight,

NEMA 4/4X

Dusttight

Watertight and

and

Dusttight

CorrosionSquare

Enclosure

Toggle

Resistant

P.B.

Brushed

Operator

GlassOperator

Stainless Steel

Polyester

Enclosure

Type

NEMA 7 & 9

For

Hazardous

Locations

Class I—

Groups C, D

Class II—

Groups E, F &

G

NEMA 12

Dusttight

and

Driptight

Industrial

Use

Enclosure

Type

Type

Type [12]

Type

Open Type

Square

P.B.

Operator

Toggle

Operator

Type

MBG1

TBG1

MBW11 [13]

MBW1 [13]

MBR1 [13]

MBA1 [13]

MBO1

TBO1

MCG1

TCG1

MCW11

MCW1

MCR1

MCA1

MCO1

TCO1

MCG2

TCG2

MCW12

MCW2

MCR2

MCA2

MCO2

TCO2

MBG2

TBG2

MBW12 [13]

MBW2 [13]

MBR2 [13]

MBA2 [13]

MBO2

TBO2

MCG3

TCG3

MCW13

MCW3

MCR3

MCA3

MCO3

TCO3

MBG4

TBG4

MBW14

MBW4

—

MBA4

MBO4

TBO4

MCG5

TCG5

MCW15

MCW5

MCR5

MCA5

MCO5

TCO5

All Except NEMA 7 and 9

File LR60905

Class 3211-05

NEMA 7 and 9 Only

File LR26817

Class 3218-04

Table 16.18: How to Order

To Order Specify:

•

•

Class Number

Type Number

Catalog Number

Type

Class

2510

MCA1

NEMA 7 & 9 enclosures are cast-iron. NEMA 7 & 9 enclosures (cast aluminum) are available for outdoor use; to order these type of enclosures, replace the R in the catalog number with a T.

For additional information, contact the Customer Care Center.

Approved for group motor installations per NEC 430-53(c).

© 2015 Schneider Electric

All Rights Reserved

Manual Starters, Type M and T—Integral

Horsepower

schneider-electric.us

Manual Starters and Switches

Class 2510, 2511, 2512 / Refer to Catalog 2510CT9701

Reversing and Two Speed

Class 2511 reversing and Class 2512 two-speed manual starters consist of two

mechanically interlocked Class 2510 Types M or T manual starters.

Table 16.19: Reversing Class 2511

Description

Number

of

Poles

2511

Standard

3-Pole

NEMA

Size

M-0

M-1

Ratings

Motor

Voltage

Maximum

Hp

200-230

380-575

200-230

380-575

3

5

7-1/2

10

NEMA 1

Surface Mounting

Square

Toggle

P.B.

Operator

Operator

Open Type

Square

P.B.

Operator

Toggle

Operator

MBG1

TBG1

MBO1

TBO1

MCG1

TCG1

MCO1

TCO1

Table 16.20: Two Speed, Class 2512 (Wye-Connected Separate Winding Motors Only)

Class

Description

Number

of

Poles

2512

Standard

3-Pole

NEMA 1

Surface Mounting

Ratings

NEMA

Size

M-0

M-1

Motor

Voltage

Constant

Hp

200-230

380-575

200-230

380-575

2

3

5

7-1/2

Constant

Torque or

Variable

Torque

3

5

7-1/2

10

Open Type

Square

P.B.

Operator

Toggle

Operator

Square

P.B.

Operator

Toggle

Operator

MBG1

TBG1

MBO1

TBO1

MCG1

TCG1

MCO1

TCO1

Thermal Units

16

Starters will not operate without properly installed thermal units and device reset.

Thermal unit must be installed so that markings face the front of starter.

Application Data

Size–Available in NEMA Sizes M-0, M-1, and M-1P.

Poles–Two poles single phase; three poles polyphase; 2 poles DC.

Voltage–600 Vac max.; 250 Vdc max.

Overload Relays–Melting alloy thermal overload relays have provisions for one Type B

thermal unit for single phase starters and three Type B thermal units for three phase

starters. All thermal units must be installed and the device reset before the starter

contacts will operate. After overload relays have tripped, allow one or two minutes for

the alloy to solidify before resetting.

Operator–Available with a push button or toggle operator in open and NEMA 1 versions.

NEMA 4/4X (stainless) and 12 versions utilize a direct acting push button only.

NEMA 4/4X (polyester) and 7/9 versions utilize an external toggle to actuate a push

button device inside.

Maintenance of Equipment

For proper performance, all equipment should be periodically inspected and maintained.

Replacement contacts and interlocks are available in kit form to facilitate servicing and

stocking. In addition, the service bulletin contains an exploded view of the device with

components clearly marked for easy identification by description and part number.

Mechanism Lock Off – Both open devices and starters in NEMA 1 surface and flush

mounting, and NEMA 4, 4X, 7 & 9, and 12 enclosures can be locked in the Off or Stop

position.

The NEMA 1 surface mounting, 4, 4X, 7 & 9, and 12 enclosures can also be locked

closed to prevent unauthorized entry.

Table 16.21: Terminal information and Replacement Contact Kits

Power Terminals

NEMA

Size

Type of

Lug

Wire Size

(Solid or

Stranded

Copper Wire)

Min.-Max.

14–8

M-1

Pressure

Wire

Pressure

Wire

M-1P

Box Lug

14–6

M-0

14–8

Auxiliary Interlock

Terminals

Wire Size

(Solid or

Type of

Stranded

Lug

Copper Wire)

Min.-Max.

Pressure

16–12

Wire

Pressure

16–12

Wire

Pressure

16–12

Wire

Replacement

Contact Kit

Number of

Poles

Service

Bulletin

Class

Type

2 or 3

312AS

9998

ML1

2 or 3

312AS

9998

ML2

2

312AS

9998

ML2

Accessories and Modification Kits

One auxiliary contact, either N.O. or N.C. can easily be added internally to any open or

enclosed Type M or T manual starter. It occupies the space provided in either the upper

right hand or left hand corners of the device. These contacts are for AC loads only. For

electrical ratings, refer to page 16-127, Class 9999 Types SX11 or SX12.

A unique red pilot light assembly that clips into place is available factory installed on

NEMA 1, 4, 4X, 12 and flush enclosures or as a field modification kit on the NEMA 1

surface or flush mounting enclosures. See page 16-11. The color cap assembly snaps

into a knockout in the enclosure cover on the NEMA 1 enclosures. Pilot light kits are

available for use on Various voltages (110-600 V). Pilot light assemblies are not available

for NEMA 7 and 9 enclosures.

© 2015 Schneider Electric

All Rights Reserved

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Class

16-9

Manual Starters and Switches

Manual Starters, Type M and T—Integral

Horsepower

Class 2510, 2511, 2512 / Refer to Catalog 2510CT9701

schneider-electric.us

Approximate Dimensions

.28

3.50

1.75 89

4.03

7

102

44

1.25

32

START

16

5.13

130

STOP

RESET

5.72

1.13

145

29

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

.69

NEMA 1

General Purpose Surface Mounting

NEMA 12

Dusttight and Driptight

Industrial Use

NEMA 4/4X

Watertight and Dusttight

Stainless Steel

START

STOP

STOP

RESET

29

11 Reset

3.97

101

Class 2510 Type M

Sizes M-0, M-1 and M-1P, Open Style

Approximate Shipping Weight: 3 lb

.22

(3) .5 -.75 K.O.

Top and Bottom

.28 Dia.

Mtg. Holes

START

RESET

.44 Travel to

Prov. for

(3) #10

Mounting

Screws

1.13

18

6

9.34

237

4.25

7.88

108

200

7.25

184

.75

8.94

NEMA 4/4X

Watertight, Dusttight

and Corrosion Resistant

Glass Polyester

3.38

.94

24

1.69

.22

.88

86

6

22

43

NEMA 7 & 9

Hazardous Locations

Cast Iron

5.00

.22

54

27

99

26

.22 Dia.

(3) Mounting

Holes

1.00

.94

24

105

6.00

152

5.75

RESET

.47

.31 Dia.

(2) Mounting

Holes

12

10.75

273

START

10.92

10.00

STOP

RESET

3.00

1.02

(2) .50 - .75 K.O.

Top and Bottom

76

5.00

26

277

254

2.89

Class 2510 Types M & T Sizes M-0 and M-1

NEMA 1 General Purpose Enclosure

Approximate Shipping Weight: 5 lb

6.50

.75

19

(2) .31 Wide Slots

73

127

Class 2510 Type M & T Size M-1P

NEMA 1 General Purpose Enclosure

Approximate Shipping Weight: 5 lb

147

33

37

25

27

5.78

83

1.44

1.00

1.06

32

1.31

.38

3.25

146

25

(1) .50 - .75 K.O.

(2) .75 - 1.00 K.O.

Top and Bottom

.50 - .75 K.O.

Each Side

219

STOP

1.00

25

4.13

.75 Conduit Hub

Top and Bottom

NEMA 4/4X

10

147

1.27

1.14

8.63

START

.22 Dia.

(4) Mounting

Holes

207

33

29

.50 - .75 K.O.

(2) Each Side

254

8.13

STOP

RESET

5.78

1.02

27

1.00

10.00

START

1.28

21

3.91

6

1.06

25

.50 - .75 K.O.

(2) Top Back

43

86

Classes 2511, 2512, Types M & T

Sizes M-0 and M-1 NEMA 1

General Purpose Enclosure

Approximate Shipping Weight: 9 lb

2.13

127

1.06

19

.84

227

1.69

3.38

163

19

1.28

127

33

1.69

146

Class 2510 Type M Sizes M-0, M-1 and M-1P

NEMA 4/4X Watertight Stainless Steel Enclosure

NEMA 12 Dusttight Industrial Use Enclosure

Approximate Shipping Weight: 9 lb

6.00

6.41

.75

165

5.00

5.76

152

.66

.34

9

4.69

17

119

6.13

156

43

R

E ON

S

E

T

OFF

8.75

R ON

E

S

E

T

OFF

222

7.31 10.34

186

263

3.69

94

5.13

130

.72

18

.81

.75 Conduit Hub

Top and Bottom

21

Class 2510 Type M Size M-0 (AC–DC)

and Size M-1 (DC) NEMA 4/4X

Watertight Corrosion-Resistant

Glass Polyester Enclosure

Approximate Shipping Weight—6 lb

16-10

OFF

12.13

(2) .31 Dia.

Mtg. Holes

18

8.75

222

(2) .31 Dia.

Mtg. Holes

.72

R ON

E

S

E

T

36

2.19

56

267

252

308

(4) .13 Wide

Mtg. Slots

1.69

43

1.41

10.50

9.94

.75 Conduit Hub

In Top and Bottom

Class 2510 Type M Sizes M-1 and M-1P (AC)

NEMA 4/4X Watertight Corrosion-Resistant

Glass Polyester Enclosure

Approximate Shipping Weight—6 lb

2.34

59

(1) .75 Conduit Top and Bottom (Std.)

(1) 1.50 Conduit Top and Bottom (Max.)

Class 2510 Type M Sizes M-0, M-1 and M-1P

NEMA 7 & 9 Hazardous Location

Cast Iron Enclosure

Approximate Shipping Weight—18 lb

© 2015 Schneider Electric

All Rights Reserved

Accessories, Modifications, and

Replacement Parts

schneider-electric.us

Manual Starters and Switches

Class 2510, 2511, 2512 / Refer to Catalog 2510CT9701

Accessories, Modifications, and Replacement Parts

Voltage

120 V

200/208 V

230 V

460 V

575 V

Code

V02

V08

V03

V06

V07

Table 16.23: Modifications (Types M & T only)

Description

Factory Modifications (Forms)

Red Pilot Light [14]

P11[15]

Auxiliary Contacts [16]

Jumper Straps [17]

Contactor only

X1 (1 N.O.)

X2 (1 N.C.)

N/A

Y76

Table 16.25: Pilot Light Kits—Class 2510 Types F and K

Table 16.24: Accessories—Class 2510

Types F and K

Description

Handle Guard Kit with Padlock Provision [18]

Emergency Off Actuator

Additional Key for Key Operated Devices

Field Modification Kits, Class &

Type

9999MP1 (110–120 V )

9999MP2 (208–240 V )

9999MP3 (440–600 V )

9999SX11 (N.O.)

9999SX12 (N.C.)

9998SO31

N/A

Application

Class & Type

2510FL1

2510PB1

2510FK1

Type KF, KG, KW [19]

Type FF, FG, FW [19]

Red Pilot Light

Class & Type

9999PL11

9999PL12

9999PL13

9999PL10

Voltage

110–120 Vac

208–277 Vac

440–600 Vac

115–240 Vac/dc

Green Pilot Light

Class & Type

9999PL11G

9999PL12G

9999PL13G

9999PL10G

Table 16.26: Replacement Nameplates—Class 2510 Types F and K

Nameplate Type Number—Class 2510

For Type F Starter

(includes Reset indication)

Without

With

Without

With

Pilot Light

Pilot Light

Pilot Light

Pilot Light

For Type K Switch

Application

1-3/4" x 2-13/16" Nameplate

with Embossed Mounting Holes

for #6 Oval Head Screws

Standard commercial switch

box cover or flush plate, including

Square D stainless steel plates

(Blank)

FN1

—

FN2

—

(Special marking –specify the marking desired)

FN5

—

FN6

—

(Blank)

High

Low

Forward

Reverse

(Special marking—specify the marking desired)

FN10

FN11

FN12

FN13

FN14

FN15

FN20

FN21

FN22

—

FN24

FN25

FN30

FN31

FN32

—

—

FN35

FN40

FN41

FN42

—

—

FN45

1-29/32" x 3-27/32"

Flat Nameplate

with Mounting Holes

for #6 Pan Head Screws

Square D NEMA 1

surface mounted enclosure

or gray flush plate

16

Description

Nameplate

Marking

Contact Kits

See page 16-124 for Class 9998 Replacement Contact Kits.

Table 16.27: Replacement Part Kits

Enclosure

Replacement Toggle Kits

Product Description

Kit Catalog No.

NEMA 4

NEMA 7 & 9

Replacement Handle Kits

Type FW and KW

Type FR and KR

9998HW1

9998HR2

Type MBA, MCA (Ser. A & B)

Type MBA, MCA (Ser. C)

Type MBW, MCW (Ser. A & B)

Type MBW, MCW (Ser. C)

Type MBW (Size 0)

Type MCW (Size 1)

Type MBR, MCR

9998HWA1

31085-381-50

9998HWA1

31085-381-50

9998HWA1

9998HR3

9998HR3

Kit Catalog No.

9998IL1

NEMA 12

NEMA 4/4X (Stainless)

NEMA 4/4X (Polyester)

NEMA 7 and 9

Description

Internal Lever

Table 16.28: How to Order

To Order Specify:

•

•

Class Number

Type Number

Table 16.29: Enclosures

Catalog Number

Type

Class

9991

KE1

For use with Class 2510 Type

F and K

M: Sizes M-0 & M-1

M: Size M-1P

MBO and MCO

FO1, FO1P, FO2, FO2P, FO3, FO3P, FO4, FO4P

KO1, KO1A, KO1B, KO2, KO2B, KO2C,

KO3, KO3A, KO3B, KO4, KO4B, KO4C,

KO5, KO5A, KO5B, KO6, KO6B, KO6C

[14]

[15]

[16]

[17]

[18]

[19]

Enclosure

NEMA 1 Standard

NEMA 1 Flush Mount

(with pull box and plaster adjustment)

NEMA 1 Flush Mount

(without pullbox but with mounting strap)

NEMA 4X (Polyester)

NEMA 4 (Stainless Steel)

NEMA 1 Oversized

NEMA 1 Oversized

NEMA 1 Jumbo

NEMA 3R

Catalog No.

9991EN1

9991MG1

9991MG2

9991MF1

9991MF2

9991MW1

9991MW11

9991FE1

9991KE1

9991KE2

9991KE3

May only be field-added to NEMA 1 enclosures. For green pilot light, order 9999SPG1 additionally.

Form P11 pilot lights require a voltage code. Refer to Table 16.22. Catalog number example: 2510MBG1V02P11.

For proper operation, only one auxiliary contact kit per device may be added.

Used to control a single phase motor utilizing a three phase starter.

Standard on Type K devices.

The lens cannot be replaced. The pilot light kits for NEMA 4 enclosed units are for replacement only.

© 2015 Schneider Electric

All Rights Reserved

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Table 16.22: P11 Pilot Light Voltage Codes

16-11

TeSys™ U Motor Starters

TeSys™ U Starter Components

Refer to Catalog MKTED210011EN

schneider-electric.us

TeSys U Selection

The NEMA style TeSys U motor starter is an integrated product—simple to choose and

to install—consisting of a control unit snapped into a power base. TeSys U can be

configured to fit specific applications as well. The NEMA style TeSys U starter uses the

same optional accessories—reverser, current limiter, predictive maintenance options,

and communication options—as the IEC TeSys U.

For detailed information about TeSys U,

visit www.schneider-electric.com/us.

16

Selecting a NEMA TeSys U Motor Starter in Three Steps

Step 1

Power Base

Step 2

Control Unit

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

=

Step 3

NEMA TeSys™ U Motor Starter

Function Modules

Auxiliary Contacts

Table 16.30: Step 1. Select Power Base

Control

Connection

NEMA

Size

With screw

terminations

1

Power Base

24

BL[1]

B

—

220/240

V

7.5

7.5

460 V

575/600

V

120 V

240 V

10

10

2

3

Power

Bases

Catalog

Number

LUB32NR

Table 16.32: Step 2. Select Control Unit [3]

Table 16.31: Voltage Codes

Volts

DC

AC

DC or AC

Max. hp, Single

Phase

Max. hp, Three Phase

200/208

V

48–72

—

—

ES[2]

110–240

—

—

FU

Setting Range

A

0.15–0.6

0.3–1.4

1.25–5.0

3–12

4.5–18

8–32

Standard

3-phase

Class 10 trip [4]

LUCAX6••

LUCA1X••

LUCA05••

LUCA12••

LUCA18••

LUCA32••

Advanced

3-phase

Class 10 trip [4]

LUCBX6••

LUCB1X••

LUCB05••

LUCB12••

LUCB18••

LUCB32••

Advanced

single-phase

Class 10 trip [4]

LUCCX6••

LUCC1X••

LUCC05••

LUCC12••

LUCC18••

LUCC32••

Advanced

3-phase

Class 20 trip [4]

LUCDX6••

LUCD1X••

LUCD05••

LUCD12••

LUCD18••

LUCD32••

Table 16.33: Step 3. Select Auxiliary Contacts (optional)

Auxiliary Contact Blocks

Contact State for Each Mode [5]

Terminals

Ready

condition

Fault

condition

Ready

condition

Fault

condition

Screw

Control Unit

Contact

Indicates

Auxiliary Contact

Screw

Contact

Normal

Status

Off

Ready

Run

Short

Circuit

Trip

Overload

Trip

(Manual

Reset)

Overload

Trip

(Remote/

Auto

Reset) [6]

N.O.

O

I

I

O

O

I

N.C.

I

I

I

O

O

I

N.O.

O

I

I

O

O

I

N.O.

O

O

O

I

I

O

Catalog

Number

LUA1C11

LUA1C20

Table 16.34: TeSys U Auxiliary Contact Function Modules

Terminals

Contact

Normal

Status

Contact

Indicates

Screw

Screw

Screw

Power pole status

Power pole status

Power pole status

2 N.O.

1 N.O. and 1 N.C.

2 N.C.

Catalog

Number

LUFN20

LUFN11

LUFN02

Table 16.35: TeSys U Accessories

E164862

CCN NLDX

LR43364

Class 3211 08

Accessories for LUB32NR

Current limiter

Reverser

Line phase barrier

Multifunction control unit

Function modules

Communication modules

Soft starter + TeSys U

Powerbus

Configuration and connection

accessories

Quick Description

For details & selection,

see pages:

Increases the breaking capacity to 130kA @ 460 V

Stacked or side mounted (LU6MB0•• [4] only)

Required for use as a self-protected combination

starter (UL508 Type E)

Has functions for monitoring and predictive

maintenance

Fault differentiation, thermal overload, motor load

indication

Integrates into existing networks, major protocols

available

Use Altistart U01Soft Starter with TeSys U

Use TeSys U with a prewired system

18-30

18-30

SoMove software, busbar, external handle

18-31

18-30

18-30

18-30

18-31

18-32

18-31

Accessories and Dimensions: See Section 18.

[1]

[2]

[3]

[4]

[5]

[6]

DC voltage with range of 0.90 to 1.10 of nominal.

48–72 Vdc; 48 Vac

The control unit contains solid-state overload relay and control power source for TeSys U. For more details on the different control units, their functions, and placement on the power base

see Section 18.

Complete the catalog number by adding the appropriate voltage code from Table 16.31. For example: LUCAX6FU.

I = closed contact; O = open contact

Requires a multifunction or advanced control unit, plus fault differentiation module LUFDDA10.

16-12

© 2015 Schneider Electric

All Rights Reserved

Catalog Numbering System: T02, T36, and

T40

TeSys™ N Contactors, Starters, and SelfProtected Combination Starters

Refer to Catalog MKTED210011EN

schneider-electric.us

Interpreting the Catalog Number

Device Type

02: Contactor, page 16-17

36: Starter, page 16-19

40: Self-Protected Combination Starter, page 16-14

NEMA Size

T02 and T36

devices

A: Size 00

B: Size 0

C: Size 1

D: Size 2

E: Size 3

F: Size 4

G: Size 5

H: Size 6 [2]

J: Size 7 [2]

Enclosure Type

T02 and T36

devices

N: No enclosure

T40 devices

A: Size 00

B: Size 0

C: Size 1

T40 devices

A: NEMA 12/3R Industrial Use

G: NEMA 1 General Purpose,

Surface Mounting

W: NEMA 4/4X Stainless Steel

Direction

1: Non-reversing

2: Reversing

Numerals

Used to define specific, physical arrangements such as

number of poles for devices type T02 or protection type

for devices type T36 and T40. Numbering varies with type

of device. Consult the Digest listings for specific device

numbers.

[1]

[2]

T

40

C

A

1

3

V80

M

Forms

Most Common Forms

A: Start-Stop pushbutton

AP1: Abbreviated Forms: Form A + Form P51 [1]

C: Hand-Off-Auto selector switch

CP1: Abbreviated Forms: Form C + Form P51 [1]

P51: Red LED Light On

P52: Green LED Light Off

S: Separate control circuit

This is only a partial listing. Consult the specific

Digest pages for more information.

When more than one form is applied to a single

device, arrange forms in alphabetical order.

Communication Code

– Mandatory for T40 devices

– Not applicable to T02 and T36 devices

C: CANopen

D: DeviceNet

M: Modbus

N: No communication

P: Profibus

This only a partial listing. Consult the specific

Digest pages for more information.

Voltage Code

B7: 24 Vac, 50/60 Hz

BD: 24 Vdc coil

BD4: 480 Vac/24 Vdc power supply

G7: 120 Vac, 50/60 Hz

LE7: 208 Vac, 50/60 Hz

U7: 240 Vac, 50/60 Hz

T7: 480 Vac, 50/60 Hz

V81: 480/120 Vac Control Power Transformer

V83: 480/24 Vac Control Power Transformer

V89: 120/24 Vac Control Power Transformer

CPT includes fuse protection on

primary and secondary as standard.

This is only a partial listing. Consult the

specific Digest pages for more information.

Abbreviated Forms cannot be used with other Forms (with the exception of Form S). To use other forms, non-abbreviated forms must be used (for example, CP51P68).

Not available for reversing Type T36 devices.

© 2015 Schneider Electric

All Rights Reserved

16-13

16

Product Family

T: TeSys N

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Table 16.36: TeSys N Catalog Numbering System

TeSys™ N Contactors, Starters, and SelfProtected Combination Starters

Self-Protected Combination Starters

Refer to Catalog MKTED210011EN

schneider-electric.us

Choosing a Configuration

TeSys N self-protected combination starters combine the requirements of motor overload

and short-circuit protection into one smaller package. These next-generation starters are

manufactured in accordance with NEMA standards and are UL listed. They offer superior

performance and efficiency and are easier to install and maintain.

16

To select a TeSys N self-protected combination starter, follow the 5-step process

described below.

1. Choose a base configuration.

Table 16.37: Base Configurations

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Ratings

Motor

Voltage

(V)

115

230

200

230

460

575

115

230

200

230

460

575

115

230

200

230

460

575

Max. HP

Single

phase

1/3

1

Threephase

1.5

1.5

2

2

NEMA Size

Type 1 enclosure

Non-reversing

Reversing starter

starter

Base Configuration Base Configuration

Number

Number

Type 12/3R enclosure

Non-reversing

Reversing starter

starter

Base Configuration Base Configuration

Number

Number

Type 4/4X enclosure

Non-reversing

Reversing starter

starter

Base Configuration Base Configuration

Number

Number

00

T40AG1

T40AG2

T40AA1

T40AA2

T40AW1

T40AW2

0

T40BG1

T40BG2

T40BA1

T40BA2

T40BW1

T40BW2

1

T40CG1

T40CG2

T40CA1

T40CA2

T40CW1

T40CW2

1

2

3

3

5

5

2

3

7.5

7.5

10

10

2. Choose the thermal overload relay

(plug-in control unit)

The thermal overload relay is a control unit that plugs into the TeSys U

starter. No tool is needed to install or remove the control unit.

If you do not wish to select the thermal overload relay at this time, select

Thermal Overload Relay Type codes N1 or N3 in function of the motor

configuration (single phase or 3-phase) in Table 16.38. A thermal overload

relay can be selected and ordered later on independently before

installation.

To select a thermal overload relay, you must follow the next 2 steps. First,

select the thermal overload protection type code in Table 16.38. Secondly,

select the full load amperage code inTable 16.39.

Advanced Control Unit

2.1 Choose the thermal overload protection type.

A control unit can be ordered with the base unit, or it can be ordered

separately. Some control unit functions are built-in, while others are

available when combined with the appropriate function module.

Table 16.38: Thermal Overload Protection Types

Thermal Overload Protection

Type Code[3]

Protection Type

Single phase, Class 10

3-phase, Class 10

3-phase, Class 20

3-phase, Selectable Class 5–30

Protection Functions

Short circuit

Over current

Thermal overload

Phase loss

Phase imbalance

Ground fault

Underload, long start, jam

Advanced

Control Unit

Multifunction

Control Unit

4

1

2

3

built in

—

—

—

—

built in

—

—

—

—

built in

—

—

—

—

built in

built in

built in

built in

—

—

built in

w/function

module

built in

built in

built in

built in

built in

built in

w/function

module

built in

built in

built in

built in

built in

built in

w/function

module

built in

built in

built in

built in

built in

built in

w/function

module

w/function

module

w/function

module

w/function

module

—

—

built in

w/function

module

w/function

module

w/function

module

w/function

module

—

—

built in

w/function

module

w/function

module

w/function

module

w/function

module

—

—

built in

built in

Control Functions

Automatic or local/remote reset

Fault differentiation

Multifunction Control Unit

Thermal alarm

Motor load display

Fault history

Alarm threshold adjustment

Tripping test

[3]

built in

built in

built in

built in

built in

built in

built in

Complete the overload relay selection by adding the full-load amperage code after the thermal overload protection type code.

16-14

© 2015 Schneider Electric

All Rights Reserved

Self-Protected Combination Starters

schneider-electric.us

TeSys™ N Contactors, Starters, and SelfProtected Combination Starters

Refer to Catalog MKTED210011EN

2.2 Choose the motor full-load amperage (FLA).

3 Choose the power source.

0.15–0.6

0.3–1.4

1.25–5.0

3–12

4.5–18

8–27

Full Load Amperage

Code

5

6

9

8

0

1

Table 16.40: Control Power Source Code

Control

Circuit

Source

System

Type

Motor

Voltage

Control

Voltage

Control Power

Source Code

Common

Control

Single

Phase

ThreePhase

120 Vac

240 Vac

208 Vac

240 Vac

120 Vac

120 Vac

120 Vac

240 Vac

240 Vac

240 Vac

208 Vac

208 Vac

208 Vac

240 Vac

240 Vac

240 Vac

480 Vac

480 Vac

480 Vac

600 Vac

600 Vac

600 Vac

120 Vac

240 Vac

240 Vac

208 Vac

208 Vac

240 Vac

240 Vac

480 Vac

480 Vac

600 Vac

600 Vac

120 Vac

240 Vac

208 Vac

240 Vac

480 Vac

600 Vac

120 Vac

240 Vac

208 Vac

240 Vac

24 Vac

24 Vdc

120 Vac

24 Vac

24 Vdc

120 Vac

24 Vac

24 Vdc

120 Vac

24 Vac

24 Vdc

120 Vac

24 Vac

24 Vdc

120 Vac

24 Vac

24 Vdc

120 Vac

24 Vac

120 Vac

24 Vac

24 Vac

120 Vac

24 Vac

120 Vac

24 Vac

120 Vac

24 Vac

120 Vac

24 Vdc

24 Vdc

24 Vdc

24 Vdc

24 Vdc

24 Vdc

G7

U7

LE7

U7

B7[4]

BD[4]

G7[4]

B7[4]

BD[4]

G7[4]

B7[4]

BD[4]

G7[4]

B7[4]

BD[4]

G7[4]

B7[4]

BD[4]

G7[4]

B7[5]

BD[5]

G7[5]

V89

V80

V82

V90

V84

V82

V80

V83

V81

V91

V86

BD1

BD1

BD1

BD1

BD4

BD6

Single

Phase

Separate

Control

ThreePhase

Single

Phase

Factory

Installed

Control

Power

Transformer

[6]

Factory

Installed

Power

Supply [7]

[4]

[5]

[6]

[7]

ThreePhase

Single

Phase

ThreePhase

4 Choose the communication type.

If a Communication protocol is selected (that is, a communication code other than N), the

control voltage must be 24 Vdc (control power source code BD, BD1, BD4, or BD6 only

—refer to Table 16.40).

Table 16.41: Communication Code

Communication Protocol

No Communication

Advantys STB

AS-interface

AS-interface V2

Beckoff

CANopen

DeviceNet

Modbus

Modbus TCP/IP

Profibus

5 Choose factory modifications.

Communication Code

N

A

J

K

B

C

D

M

E

P

When choosing Factory modifications, add the Form code to the end of the catalog

number. If several Forms are selected, arrange them in alphabetical order. There are two

types of Forms: Abbreviated and Standard.

5.1 Abbreviated Forms

Abbreviated Forms are defined combinations of the most commonly ordered Standard

Forms. They are part of the profiled configurations with short lead times. For example,

Abbreviated Form CP1 is a combination of Standard Forms C and P51.

Abbreviated Forms cannot be mixed with other Standard Forms, with the exceptions of

Forms S and S6. If your combination of Forms is not available as an Abbreviated Form,

use only Standard Forms and arrange them in alphabetical order. For example,

T40CG1CFG7NCP1S is a valid catalog number with the Abbreviated Form CP1. If you

want to add Form P68, the valid catalog number is T40CG1CFG7NCP51P68S.

T40CG1GFG7NCP1P68S is invalid because Abbreviated Form CP1 cannot be used

with Standard Form P68.

Table 16.42: Abbreviated Forms

Factory Modifications

Hand/Off/Auto selector switch + Red On LED standard pilot light

Hand/Off/Auto selector switch + Green On LED standard pilot light

Hand/Off/Auto selector switch + Red On LED standard pilot light + Green Off LED standard pilot light

Hand/Off/Auto selector switch + Green On LED standard pilot light + Red Off LED standard pilot light

Start/Stop Push Buttons + Red On LED standard pilot light

Start/Stop Push Buttons + Green On LED standard pilot light

Start/Stop Push Buttons + Red On LED standard pilot light + Green Off LED standard pilot light

Start/Stop Push Buttons + Green On LED standard pilot light + Red Off LED standard pilot light

On/Off selector switch + Red On LED standard pilot light

On/Off selector switch + Green On LED standard pilot light

On/Off selector switch + Red On LED standard pilot light + Green Off LED standard pilot light

On/Off selector switch + Green On LED standard pilot light + Red Off LED standard pilot light

Red On LED standard pilot light + Green Off LED standard pilot light

Green On LED standard pilot light + Red Off LED standard pilot light

Form

CP1

CP2

C12

C21

AP1

AP2

A12

A21

C61

C62

C66

C67

P12

P21

Add Form S to the end of the catalog number.

Add Form S6 to the end of the catalog number. A current limiter comes factory installed.

Comes standard with two fuses in the primary and one fuse in the secondary.

Comes standard with a fuse holder and two fuses.

© 2015 Schneider Electric

All Rights Reserved

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Full Load Amperage Setting Range (A)

16-15

16

Table 16.39: Full Load Amperage Code

TeSys™ N Contactors, Starters, and SelfProtected Combination Starters

Self-Protected Combination Starters

Refer to Catalog MKTED210011EN

schneider-electric.us

Factory Modifications

5.2 Standard Forms

Table 16.43: Push Button Forms

Factory Modifications

16

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Start/Stop

Forward/Reverse/Stop

On/Off

Miscellaneous

Stop

Start push button + Stop mushroom head

Emergency Stop mushroom head

Turn-to-release Emergency Stop mushroom head

Table 16.44: Selector Switch Forms

Factory Modifications

Hand/Off/Auto

Start/Stop

On/Auto

On/Off

Hand/Auto

Forward/Off/Reverse

Forward/Reverse

Three position

Two position

Keyed Hand/Off/Auto

Keyed Start/Stop

Keyed On/Auto

Keyed On/Off

Keyed Forward/Off/Reverse

Keyed Forward/Reverse

Table 16.47: Separate Control Forms

Form

A

A1

A3

A11

A13

A22

A31

A32

Form

C

C1

C2

C6

C8

C14

C20

C34

C35

C36

C37

C38

C39

C43

C47

Table 16.45: 30mm Standard LED Pilot Light

Forms

Factory Modifications

Red On

Green Off

White—Not factory wired

Blue—Not factory wired

Amber overload trip

Yellow SSC trip

Red Off

Green On

Green Forward/Reverse

Red Forward/Reverse

Form

P51

P52

P54

P56

P68

P69

P91

P92

P95

P96

Table 16.46: 30 mm Push-To-Test LED Pilot Light

Forms

Factory Modifications

Red On

Red Off

Green On

Green Off

Blue—not factory wired

White—not factory wired

Green Forward/Reverse

Red Forward/Reverse

Amber overload trip

Yellow SSC trip

[8]

[9]

Form

P42

P43

P45

P46

P66

P67

P79

P80

P88

P89

Factory Modifications

Separate control for starters with line voltage less than or equal to 480 V

Separate control for starters with line voltage equal to 600 V: current limiter is factory installed.

Form

S

S6

Table 16.48: Additional Capacity Forms

Factory Modifications

Form

T10

T11

50 VA additional capacity

100 VA additional capacity

NOTE: Fuses are included: two fuses in the primary and one in the secondary.

Table 16.49: Auxiliary Contact Forms

Factory Modifications

2 N.O.

1 N.O. and 1 N.C.

2 N.C.

1 N.C. fault signaling contact and 1 N.O. contact indicating that the starter is in the Ready state

1 N.O. fault signaling contact and 1 N.O. contact indicating that the starter is in the Ready state

Form

U8

U9

U10

U6

U7

NOTE: Auxiliary relays are not factory wired.

Table 16.50: Auxiliary Relay Forms

Factory Modifications

4 poles screw clamp control relay—4 N.O.

4 poles screw clamp control relay—3 N.O. and 1 N.C.

4 poles screw clamp control relay—2 N.O. and 2 N.C.

Programmable timer relay

Table 16.51: Enclosure Forms

Factory Modifications

Type 12/3R enclosure, factory modified for a Type 3R application

Oversized enclosure

Plain blank door—no covered, prestamped holes

Table 16.52: Miscellaneous Forms

Factory Modifications

Function nameplate

Non-standard control unit marking

Unwired terminal block

Wired terminal block

Space heater—thermostat control

Wire markers

Padlock attachment

Transient suppressor

Special factory orders

Custom control wiring

Solid neutral terminal block

Form

R1740

R1731

R1722

K1070

Form

G26

G28

G30

Form

G11

G12

G50[8]

G56[9]

G55

G105

G122

U11

SPL

Y217

N

Table 16.53: Increase Short Circuit Current Rating Forms

Factory Modifications

130 kA @480 V: current limiter factory installed

Table 16.54: Starter Status Indication Forms

Factory Modifications

Fault differentiation module—manual reset

Fault differentiation module—automatic or remote reset

Thermal overload alarm module

Motor load indication module

Form

Y1261

Form

U1

U2

U3

U4

Add the number of terminal block points required, in increments of 5.

The wiring diagram must be provided by the customer.

16-16

© 2015 Schneider Electric

All Rights Reserved

Non-Reversing Contactors

schneider-electric.us

TeSys™ N Contactors, Starters, and SelfProtected Combination Starters

Refer to Catalog MKTED210011EN

TeSys N Non-Reversing Contactors

TeSys N contactors are used to switch heating loads, capacitors, transformers and

electric motors where overload protection is provided separately. TeSys N contactors are

available in NEMA Sizes 00–7. Target market segments include hospitals; retail; food

and beverage; marine; oil and gas; and mining, metals, and minerals.

Continuous

Current

Rating (A)

00

9

0

18

1

27

2

45

3

90

4

135

5

270

6

540

7

810

Motor Voltage

Max HP

200

230

460

575

200

230

460

575

200

230

460

575

200

230

460

575

200

230

460

575

200

230

460

575

200

230

460

575

200

230

460

575

200

230

460

575

1.5

1.5

2

2

3

3

5

5

7.5

7.5

10

10

10

15

25

25

25

30

50

50

40

50

100

100

75

100

200

200

150

200

400

400

—

300

600

600

TeSys N non-reversing contactor, Size 1

TeSys N non-reversing contactor, Size 3

Open

Catalog No. [10]

T02AN13●●

T02BN13●●

T02CN13●●

T02DN13●●

T02EN13●●[11]

T02FN13●●[11]

T02GN13●●[11]

T02HN13●●[11]

T02JN13●●[11]

Table 16.56: TeSys N Non-Reversing Contactors, 3-Pole Single Phase, 600 Vac

Max.

(replace ●● with the coil voltage code)

NEMA Size

Continuous

Current

Rating (A)

00

9

0

18

1

27

2

45

Motor Voltage

Max HP

115

230

115

230

115

230

115

230

1/3

1

1

2

2

3

3

7.5

Open

Catalog Number

T02AN13●●

T02BN13●●

T02CN13●●

T02DN13●●

Table 16.57: TeSys N Coil Voltage Codes

Voltage

24 Vac

24 Vdc

120 Vac

208 Vac

240 Vac

480 Vac

Size 00

B7

BD

G7

LE7

U7

T7

Size 0

B7

BD

G7

LE7

U7

T7

Size 1

B7

BD

G7

LE7

U7

T7

Voltage Code by NEMA Size

Size 2

Size 3

Size 4

B7

B6

B6

BD

BD

BD

G7

G6

G6

LE7

L6

L6

U7

U6

U6

Q5

Q5

T7

Size 5

G7

L7

U7

S7

Size 6

n/a

n/a

F7

L7

U7

N7

Size 7

F7

L7

U7

N7

Dimensions: page 16-25 to page 16-29

Accessories: page 16-21 to page 16-23

Replacement Parts: page 16-24

Lugs: page 16-23

[10]

[11]

Replace the bullets (●●) in the catalog number with the coil voltage code. Refer to voltage codes shown in Table 16.57.

Order lugs separately. See Table 16.79. The mounting hardware (screws, washers, and nuts) comes with the contactors, not the lugs. Starters Sizes 3–7 come with lugs.

© 2015 Schneider Electric

All Rights Reserved

16-17

16

NEMA Size

NEMA AND DEFINITE PURPOSE

CONTACTORS AND STARTERS

Table 16.55: TeSys N Non-Reversing Contactors, 3-Pole Polyphase, 600 Vac Max.

(replace ●● with the coil voltage code)

TeSys™ N Contactors, Starters, and SelfProtected Combination Starters

Reversing Contactors

Refer to Catalog MKTED210011EN

schneider-electric.us

TeSys N Reversing Contactors

TeSys N reversing contactors are used for starting, stopping and reversing AC motors

where overload protection is provided separately. TeSys N reversing contactors are

mechanically and electrically interlocked and are available in NEMA Sizes 00–7. Target

market segments include hospitals; retail; food and beverage; marine; oil and gas; and

mining, metals, and minerals.

16

Table 16.58: TeSys N Reversing Contactors, 3-Pole Polyphase, 600 Vac Max.

(replace ●● with the coil voltage code)

NEMA AND DEFINITE PURPOSE