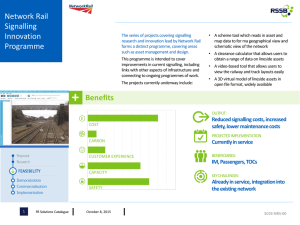

Light Signals SPS 11 - (RIC Standard: SC 07 10 00 00 SP)

advertisement