Wiring Instructions for StreetHawk Light Assembly

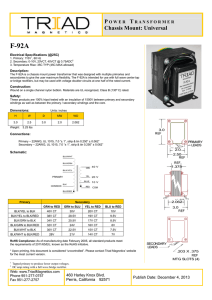

advertisement

2561268B REV. B 702 Printed in U.S.A. WIRING AND MAINTENANCE FOR FEDERAL STREETHAWK® LIGHT ASSEMBLY SAFETY MESSAGE TO INSTALLERS WARNING People’s lives depend on your safe installation of our products. It is important to read, understand and follow all instructions shipped with this product and the related add-on products. In addition, listed below are some other important safety instructions and precautions you should follow: • • • • • When drilling into a vehicle structure, be sure that both sides of the surface are clear of anything that could be damaged. Remove all burrs from drilled holes. To prevent electrical shorts, grommet all drilled holes through which wiring passes. A light system is a high current device. In order for it to function properly, a separate ground connection must be made. If practical, it should be connected to the negative battery terminal. At a minimum, it may be attached to a solid metal body or chassis part that will provide an effective ground path as long as the light is to be used. This product may contain high intensity LED devices. To prevent eye damage, DO NOT stare into the light beam at close range. High voltages are present inside the strobe light equipped models during and after operation. Ensure that power is disconnected and wait at least ten minutes before removing the dome. Locate light system controls so the VEHICLE and CONTROLS can be operated safely under all driving conditions. • You should frequently inspect the light to ensure that it is operating properly and that it is securely attached to the vehicle. GENERAL. The Light Assembly comes from the factory with six (6) stationary light lenses, gaskets and mounting hardware in kit form. This enables the user to choose and install the color combination that best suits the application. The Light Assembly comes from the factory with six (6) black lenses, gaskets and mounting hardware in kit form which enables the user to cover the pod openings when optional lighting is not desired. To properly install this light: you must have a good understanding of automotive electrical procedures and systems, along with proficiency in the installation and use of safety warning equipment. • • I. WARNING Using a lens colored differently than an LED will greatly reduce the light output, thereby reducing the effectiveness of the light for emergency signaling purposes. Either use a clear lens or match the color of the lens with the LED. Federal recommends that lenses be installed prior to mounting the light assembly on the vehicle. To install a lens in any position, proceed as follows (see figure 1): A. Install gasket on rim of lens. B. Insert lens and gasket into lens opening. Secure with two #6 screws. Tighten to 10-15 in./lbs. of torque. II. ELECTRICAL WIRING. A. General. WARNING To prevent personal injury and/or damage to vehicle components, in the event of a shortcircuit in the power cable, install a fuse in each incoming cable conductor. LENS GASKET BASE REF. File these instructions in a safe place and refer to them when maintaining and/or reinstalling the product. Failure to follow all safety precautions and instructions may result in property damage, serious injury, or death to you or others. #6 SCREWS 290A2893 Figure 1. NOTE FRONT DRIVER'S SIDE Any of the light assembly functions can be activated by applying 12VDC to the appropriate control line. The heavy black lead (-) must be connected to vehicle ground, to perform a function check. PASSENGER SIDE STROBE, TAKEDOWN OR END LAMP C OF L LIGHT BAR ROTATING OR OMNI-DIRECTIONAL STROBE 1 2 3 4 5 6 7 8 9 10 11 STROBE, ROTATING TAKEDOWN OR OR END LAMP OMNI-DIRECTIONAL STROBE SPEAKER The Light Assembly is completely wired at the factory and does not require any additional internal wiring. (If desired, to allow Intelli-Flash Mode 2, connect the wht/red Intelli-Flash wire to an unused power cable wire or a usersupplied wire.) The cable connected to the Light Assembly contains all the conductors necessary for proper control of all basic and optional functions. Figure 2 illustrates the function of each conductor in the cable. Be sure to use fuses (current ratings shown in figure 2), wire and switches with adequate current capacity for each function. ROTATING DYNARAY DYNARAY ALLEY LIGHT END LAMP OR DIRECTIONAL STROBE END LAMP OR DIRECTIONAL STROBE ROTATING ALLEY LIGHT 11 10 9 8 7 6 5 4 3 2 1 CHASSIS GROUND SCREW INTERNAL WIRING EXTERNAL WIRING Figure 2 illustrates the external/internal Light Assembly wiring by function. Using figures 2 and 3 as a guide, make the appropriate electrical connections. Be sure to use fuses (current ratings shown in the diagram in figure 2), wire and switches with adequate current capacity for each function. ACCESSORY CABLE GROUND (-) BLK 15A DYNARAY RED/WHT BLK/WHT NOT USED NOTE DIRECTIONAL STROBES(1 & 2) 10A DUAL DIRECTIONAL STROBES (4) 20A When takedown lights or directional strobe lights are not used in the front and rear secondary light positions, alternating flash end lamps (35-watt halogen lamps) will be found in these positions. GRA OMNI-DIRECTIONAL STROBES (2) 10A PRIMARY ROTATING LIGHTS (4) 25A RED BRN/WHT SPEAKER B. Programming the Intelli-Flash (see figure 3). BRN SPEAKER TAKEDOWN (1) 8A, (2) 15A To operate the flasher in Mode 1, close SW1. To operate the flasher in Mode 2, close SW1 and SW2. 15A FLASHING END LAMPS (2) 5A, (3) 10A, (4) 15A Turn on the flasher in Mode 1. Short across the programming pins until the desired pattern is running. Allow the pattern to run for at least 15-seconds to program Mode 1. 15A BLU 8A LEFT ALLEY LIGHT ORN 8A GRN CUSTOMER SUPPLIED SUPPLIED W/LIGHTBAR RIGHT ALLEY LIGHT POWER (+) Turn on the flasher in Mode 2. Short across the programming pins until the desired pattern is running. Allow the pattern to run for at least 15-seconds to program Mode 2. YEL TO POWER/IGNITION 290A2898 Figure 2. B. Lamp Replacement. 1. Dome Removal (see figure 4). III. MAINTENANCE. a. A. Cleaning the Plastic Domes and Lenses. Turn-off power to Light Assembly. b. Remove three #10 type “B” hex washer head thread-forming screws which secure the upper speaker grille to the lower speaker grille. Lift upper grille away from lower grille. WARNING Crazing (cracking of domes or lenses) will cause reduced effectiveness of the light. Do not use cleaning agents (which will cause crazing) such as strong detergents, solvents, or petroleum products. If crazing of domes or lenses does occur, reliability of light for emergency signaling purposes may be reduced until domes or lenses are replaced. c. Remove the eight (four on each side) #8-32 x 7/8" hex head screws and #8 flat washers from the front and rear edges of the dome. d. Carefully remove the domes. Ensure that the bulkhead gasket remains tucked in its groove. Ordinary cleaning of the plastic domes and lenses can be accomplished by using mild soap and a soft rag. Should fine scratches or a haze appear on the domes, they can ordinarily be removed with a non-abrasive, high quality, one-step, automotive paste cleaner/wax and a soft cloth. e. The domes and upper speaker grille can be replaced by reversing the procedure. Torque dome screws to 14-18 in./lbs and grille screws to 20-25 in./lbs. -2- PRIMARY ROTATING LIGHTS DOMESTIC RED RED INCOMING 1 2 3 4 5 6 7 8 9 10 11 CABLE RED INCOMING CABLE 1 2 PRIMARY ROTATING LIGHTS INTERNATIONAL 3 4 5 6 7 8 9 10 11 RED R M M R BLK BLK BLK PASSENGER SIDE BLK RF BLK R - 4 5 R 2 1 BLK PASSENGER SIDE INCOMING CABLE ORN GRN BLK BLK PASSENGER SIDE BLU INCOMING 1 2 CABLE BLK Y D BLK 11 10 9 8 7 6 5 4 3 2 1 RE BLK YEL ORN BLK D BLU BLU BLK BLK BLK BLK F RF BLK BLK POWER F BLU BLU 11 10 9 8 7 6 5 4 3 2 1 TD TWO REAR FLASHING NOTE: 35W LAMPS ONLY 3 4 5 6 7 8 9 10 11 BLK FE DRIVER SIDE FRONT BLU BLK ONE TAKEDOWN PASSENGER SIDE 1 2 3 4 5 6 7 8 9 10 11 BLK 11 10 9 8 7 6 5 4 3 2 1 INCOMING 1 2 CABLE BLK RF PASSENGER SIDE DRIVER SIDE FRONT INTELLI-FLASH * * SW1 INCOMING CABLE SW2 1 BLK 4 A 1 2 3 4 5 6 7 8 9 10 11 PASSENGER SIDE FRONT YEL INCOMING CABLE B DRIVER SIDE 1. POWER CABLE WIRE COLOR (TYP. BLUE OR WHT/RED) AND LOCATION OF FLASHING LIGHTS DEPENDENT UPON CONFIGURATIION. DUAL TAKEDOWN (NON-FLASHING) 1 2 3 4 5 6 7 8 9 10 11 * BLK RED BLK RED 11 10 9 8 7 6 5 4 3 2 1 G A DRIVER SIDE FRONT YEL BLK PASSENGER SIDE BLK BLK YEL YEL BLK PASSENGER SIDE INCOMING CABLE BLK E ORN WHT/RED BLK BLK BLK ALLEY LIGHTS AND/OR DYNARAY RE BLK BLK POWER F 3 11 10 9 8 7 6 5 4 3 2 1 THREE FLASHING END LAMPS (TWO REAR AND ONE FRONT) 3 4 5 6 7 8 9 10 11 2 1RED DRIVER SIDE FRONT FF DRIVER SIDE FRONT BLK BLK + 4 - BLK A BLK BLK C BLK 11 10 9 8 7 6 1 2 3 4 5 6 7 8 9 10 11 BLK FF + RED BLK RF BLK BLU BLK M BLK 5 B FRONT AND REAR FLASHING LIGHTS NOTE: 35W LAMPS ONLY BLU BLK R 3 BLK BLK + - - DRIVER SIDE FRONT BLK - M + M M - BLK BLK R + + RED BLK POWER F BLK BLK + BLK 11 10 9 8 7 6 BLU INCOMING 1 2 3 4 5 6 7 8 9 10 11 CABLE M + RED RED A + - + - - M + + R RED + BLK D Y RED + BLK RED R + BLK RED/GREEN LED GRN RED ORN RED BLK PROGRAMMING PINS 2. UNUSED POWER CABLE WIRE OR USER-SUPPLIED WIRE TO BE CONNECTED TO MODE 2. YEL YEL BLK TD H RED/WHT (MODE 2) RED (MODE 1) 1110 9 8 7 6 5 4 3 2 1 TD PASSENGER SIDE FRONT BRN/WHT INCOMING CABLE BLK 11 10 9 8 7 6 5 4 3 2 1 BLK 3. SOLID GREEN LED INDICATES SAE APPROVED PATTERN. SOLID OR INTERMITTENT RED LED INDICATES UNAPPROVED SAE PATTERN. BLK DRIVER SIDE 4 SPEAKER 58 OR 100 WATT 1 2 3 4 5 6 7 8 9 10 11 1 PASSENGER SIDE FRONT DRIVER SIDE BRN BRN PATTERN BRN OUTSIDE ALL WIRE NUTS PASSENGER SIDE FRONT PATTERN 1 PATTERN 2 PATTERN 3 PATTERN 4 PATTERN 5 PATTERN 6 PATTERN 7 PATTERN 8 11 10 9 8 7 6 5 4 3 2 1 L POSITION 1 2 3 4 A A A B A A A A 75 FPM ALTERNATING 95 FPM ALTERNATING 115 FPM ALTERNATING 4 @ 120 FPM ALTERNATING THEN 4 @ 120 FPM SIMULTANEOUS 180 FPM ALTERNATING ALTERNATING 260 FPM DOUBLE ALTERNATING 300 FPM TRIPLE 300 FPM TRIPLE/60 FPM SINGLE 290A2899B DRIVER SIDE Figure 3. -3- DOME #10 TYPE "B" HEX HEAD SCREW, THD. FORMING (3) UPPER GRILLE DOME 8-32 x 7/8" HEX HD. SCREWS(8) (4 ON EACH DOME SECTION) LOWER GRILLE BULKHEAD GASKET 290A2892 Figure 4. CAUTION WARNING A serious injury may result if lamp is touched when hot. Always allow lamp to cool before removing. Halogen lamps are pressurized and if broken can result in flying glass. Always wear gloves and eye protection when handling the lamps. 2. When installing a new lamp, do not touch the glass portion. If the glass has been touched, shortened lamp life will result. If the glass end has been handled, it should be carefully cleaned with a grease solvent. c. Replace the defective lamp with a new H-1 halogen lamp (Part No. 8440A265A). When reassembling, ensure that the lamp is secured to the connector and that the clip is properly seated in the grooves on the lamp socket. Primary Rotating Lamps. To replace the halogen lamp, proceed as follows (see figure 5): 3. CAUTION Omni-Directional Strobe Tube. Remove fresnel lens from base. Pull defective flash tube from mounting socket. Replace with Part No. 8422A420 flash tube. Forced rotation of the light mechansim will cause damage to the worm gear. ALWAYS rotate the light mechansim by rotating the motor shaft. 4. a. Rotate the reflector unitl the lamp clip (located at the base of the lamp) can be removed, and remove the clip by sliding it away from the reflector. Secondary Lamps. To replace lamps in the secondary light positions (six locations), proceed as follows (see figure 1): b. Note the lamp’s orientation and pull the defective lamp and connector out of the socket. a. Remove the two #6 pan head screws. b. Remove lens by pulling straight out. Remove lens gasket. H-I HALOGEN LAMP c. Replace defective lamp with proper lamp only. Refer to Table 1, Secondary Lamp Replacement Guide. DO NOT TOUCH GLASS PORTION OF LAMP LAMP BASE d. Reinstall lens and gasket . Secure with two #6 screws removed in step a. ORIENTED PARALLEL TO GROVES IN LAMP SOCKET 5. SLIDE CLIP OVER LAMP BASE INTO GROOVES ON LAMP SOCKET CONNECTOR LAMP SOCKET Gen III PCB Assembly Replacement. a. Remove the domes. GROOVES(2) b. See figure 6. Disconnect the electrical connector from the PCB assembly. GEAR AND REFLECTOR ASSEMBLY c. Gently pry the PCB assembly from the snap-top standoffs on the backplane. d. Remove the two heat sink retaining screws and the heat sink. 290A2600-01 Figure 5. -4- Table 1. Secondary Lamp Replacement Guide. RIVSCREWS FUNCTION DESCRIPTION Part No. Alley Light (right and left) 50W Halogen, Sylvania #795 8107A119 End Lamps (right and left,front and rear) 35W Halogen, Sylvania #796 8548A028A Takedown Lights (front only) SEE NOTE 50W Halogen, Sylvania #795 8107A119 Directional Strobe (front and rear) Flash Tube Assy. 8107A127 Brake/Tail Light (rear only) Incandescent Lamp #1157 BACKPLANE ASSEMBLY LED MODULE FRESNEL LENS 290A4532 Figure 7. Gen III PC Board PCB Assembly Red/Amber Blue e. Assembly is the reverse of disassembly. Prior to installation of the PCB assembly, ensure that the LED connector pins on the PCB are not bent or damaged. 8107A095 6. Z2005175-N Z2005175-02N Gen III LED Module Replacement. a. Remove the domes. Gen III LED Module LED Module Assy. Amber Blue Red Z8625106-AS Z8625106-BS Z8625106-RS b. See figure 6. Disconnect the electrical connector from the PCB assembly. Gen III Lens Lens, Fresnel 8625101 c. Gently pry the PCB assembly from the snap-top standoffs on the backplane. NOTE: If the alternating flash feature is desired, the flasher supplied with the Alternating Flasher Kit is required. d. e. See figure 7. Remove and discard the Rivscrews retaining the LED module to the backplane. Remove the LED module. HEAT SINK RETAINING SCREWS HEAT SINK Remove the device from the light bar. f. Unlatch the Fresnel lens from the LED module. PCB ASSEMBLY g. Snap the Fresnel lens onto the new module. Make sure the rectangular recess in the lens aligns with the black connector on the new LED module. h. Position the LED module on the backplane, aligning the black connector on the LED with the large clearance hole in the backplane. Secure the module with the 2 #6-32 screws provided. i. ELECTRICAL CONNECTOR 7. BACKPLANE ASSEMBLY Remainder is the reverse of disassembly. Fresnel Lens Replacement. Same as LED Module Replacement above, except that the Rivscrews must be retained for reuse if a new LED module is not being installed. 290A4531 Figure 6. -5- C. Worm Gear and Bearing. GEAR AND REFLECTOR ASSEMBLY H-1 HALOGEN LAMP All gears should be greased at least twice a year. Use medium consistency Dow Corning DC33 or equivalent type grease. Proceed as follows (see figure 8): CLIP 1. Remove lamp and clip from rotating light. LAMP SOCKET 2. Lift-off reflector and worm gear. Lubricate with grease as shown in figure 8. 3. Replace parts by performing the above procedure in reverse order. GROOVE APPLY GREASE HERE (3 PLACES) NOTE When reassembling, ensure that the lamp is secured to the connector and that the clip is properly seated in the grooves on the lamp socket. MOTOR D. Motor. 290A2600-03B 1. Before attempting to service the motor, ensure that the worm gear and worm are free of binding. Figure 8. 2. There should be a small amount of gear backlash for proper motor operation. 3. Replace motor if operation is sluggish or intermittent, after it has been determined that there is no binding and that all electrical connections are correct. E. Service Parts Kits. Service Parts Kits and Instructions are available for these lights. Contact your local Distributor for more information. -6-