Huntsman Metalworking Brochure

advertisement

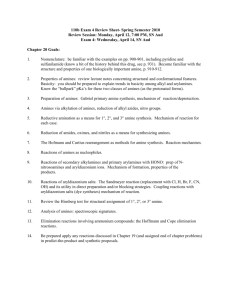

Performance Products Metalworking Chemicals Product Information Huntsman Metalworking Chemicals Table of Contents Page Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Huntsman Capabilities Huntsman Products Amines for the Metalworking Industry . . . . . . . . . .4 Comparison of Important Properties DIGLYCOLAMINE® Agent Bis-(hydroxyethyl) methyl amine (BHEMA) SURFONAMINE® MW-781 Amine XTA-771 Ethanolamines Other Amines Surfactants for the Metalworking Industry . . . . . .29 Alkylphenol Ethoxylates Alcohol Alkoxylates EO/PO Block Copolymers Alcohol Ethoxylates Fatty Acid and Castor Oil Ethoxylates Phosphate Esters Formulated Emulsifiers Other Products for the Metalworking Industry . . .45 Alkylate H-230L JEFFOX® WL-series Functional Fluids Glycols Regional Product Offerings . . . . . . . . . . . . . . . . .50 Contact Information . . . . . . . . . . . . . . . . . . . . . .54 DEHSCOFIX®, DGA®, DIGLYCOLAMINE®, EMPICOL®, EMPILAN®, EMPIPHOS®, JEFFAMINE®, JEFFOX®, LAUREX®, POGOL®, SURFOL®, SURFONAMINE®, and SURFONIC® are registered trademarks of Huntsman Corporation or an affiliate thereof in one or more, but not all, countries. DMDGA™ is a trademark of Huntsman Corporation of an affiliate thereof in one or more, but not all, countries. CORFREE® is a trademark of Invista North America. TEFLON® is a trademark of E. I. DuPont de Nemours & Company. VITON® is a trademark of DuPont Dow Elastomers LLC. 1 SECTION 1 Introduction Huntsman Capabilities Huntsman is committed to producing a broad range of the highest quality amines, surfactants and related chemicals for the metalworking industry, and is the logical choice to be your key supplier for the formulation of your metalworking fluids. Huntsman is an integrated supplier, producing not only the finished amines and surfactants but many of the basic raw materials used to manufacture those products. Huntsman is a global supplier, manufacturing products for the metalworking industry in the United States, Australia, and multiple European countries. Our skilled and knowledgeable sales force markets 2 our products worldwide, assisted by an extensive distributor network. Huntsman is an innovative supplier. With the support of state of the art research, development and pilot facilities we will work closely with you to help formulate products that meet your exacting needs. Huntsman Products Huntsman manufactures a broad range of amines, surfactants, and related products essential in formulating metalworking fluids. Table 1.1 lists primary application areas for each of the product types. Similar tables including trademarked product names by region can be found in Section 5. Introduction Intermediates Anti-mist Additives Hard Water Tolerance Aids Metal Cleaning Aids Anti-Foamants Coupling Agents Lubricity Additives Emulsifiers Corrosion Inhibitors Product Alkalinity Control Table 1.1 - Huntsman Products for the Metalworking Industry Primary Amines Tertiary Amines Polyetheramines Linear Alcohols Alcohol Ethoxylates Alcohol Alkoxylates Alkylphenol Ethoxylates Fatty Acid Ethoxylates Castor Oil Ethoxylates EO/PO Block and Reverse Block Copolymers Phosphate Esters Sodium Isethionate Functional Fluids Glycols Glycol Ethers 3 SECTION 2 Amines for the Metalworking Industry Huntsman is a major integrated supplier of amines, many of which have application in the metalworking industry. We have developed and continue to support our amine process technologies in fully equipped laboratories and pilot facilities in the United States and Europe. This section demonstrates our ongoing commitment to our amine customers in the metalworking industry. metalworking. A comparison of cobalt leaching by commonly used metalworking amines is plotted in Figure 2.2. Included in Section 2 is information on various amines commonly used in the metalworking industry. The first part of this section contains comparison data for these amines while the last part of this section individually discusses several Huntsman amines used in the metalworking industry. These products include DIGLYCOLAMINE® Agent, bis(hydroxyethyl) methyl amine (BHEMA), SURFONAMINE® MW-781 amine, triethanolamine (TEA), diethanolamine (DEA), and others. MIPA. It is somewhat more alkaline than either DEA or DIPA (diispropanolamine). Comparison of Important Properties A list of amines commonly used in metalworking is given in Table 2.1, with Huntsman product offerings highlighted. Table 2.2 further discusses commonly used amines in metalworking, listing the CAS numbers, as well as regulatory information. Volatility is an important consideration in metalworking applications where misting is a concern. Data included in Table 2.3 and Figure 2.1 illustrate the low volatility of Huntsman products, such as DIGLYCOLAMINE® Agent, monoethanolamine (MEA), DEA, TEA and BHEMA, relative to other amines commonly used in metalworking applications. Cobalt leaching is another important factor in 4 The pH measurements on solutions of various amines at several different concentrations in water are given in Table 2.4. These data are indicative of the relative efficiency of the amines as alkalinity control agents. Generally, DIGLYCOLAMINE® Agent is less alkaline than MEA and Titration curves are presented for several of the more common metalworking amines with some of the more common metalworking acids in Figures 2.3, 2.4 and 2.5. Boric acid is a well-known component of metalworking fluids, which imparts both corrosion resistance and enhanced biostability. Both salts and condensates of boric acid with a variety of amines have been employed. Data in the literature suggest that the boric acid adduct of DIGLYCOLAMINE® Agent is quite effective in maintaining pH and resisting biodegradation (Table 2.5). Published information (Table 2.6) comparing the tendency to form N-nitrosoamines in prototype synthetic and semisynthetic cutting fluids shows a pronounced tendency to form these carcinogenic materials from secondary amines like DEA and diisopropanolamine (DIPA). Primary amines, like DIGLYCOLAMINE® Agent, do not show this tendency. Another important aspect in metalworking is corrosion. Aluminum staining/corrosion data is compared in Tables 2.7, 2.8, and 2.9. Figure 2.6 compares magnesium staining by various amines. Amines for the Metalworking Industry Table 2.1 - Amines for Metalworking Physical Properties Amine Type DGA® Agent MEA AMP MIPA Primary Primary Primary Primary Appearance DEA DIPA TEA Secondary* Secondary* Tertiary BHEMA APM Tertiary Prim/Tert Clear and free of suspended material Color, Pt-Co <15 <15 <15 <15 <15 <15 <15 <15 <15 Equivalent Weight 105 61 94 75 105 133 149 119 144** pKa, 20°C 9.45 10.03 9.82 9.40 8.88 8.70 7.76 8.59 10.04 pH, 5% aqueous solution 11.30 11.56 11.46 11.40 10.98 10.84 10.38 10.79 11.59 Boiling Point, °C, 760 mmHg 223 171 165 158 268 246 340 247 224 Vapor Pressure, 20°C, mmHg 0.004 0.4 0.7 0.6 <0.01 <0.01 <0.01 <0.01 <1 Freezing Point, °C -12.5 10 30 (dry) 25 28 44 21 -21 <-45 Flash Point, °C 124 95 78 71 149 260 202 126 86 Viscosity, cSt, 30°C 20 18.9 90 23 352 870 429 56 Dermal LD50, mg/kg >3000 1025 >2000 1600 >3000 >3000 Oral LD50, mg/kg 2560 2100 2900 2700 1410 >2000 Acute Fish LC50, mg/l 460 >500 331 220-460 0.1 >450 Acute Daphnia EC50, mg/l 190 >100 193 108 55 1530 Acute Algae IC50, mg/l 160 7.5–75 520 23 >10 169 Mutagenic No No No No (*) (*) No No Dermal Sensitizer No No No No No No No No 1 1 — 1 1 1 1 1 Environmental, Health & Safety Concerns WGK Classification * Secondary amines prone to N-nitrosamine formation **Equivalent weight is for primary amine function only Data sources: Huntsman, literature Huntsman products in bold type. 5 SECTION 2 Amines for the Metalworking Industry Table 2.2 - Common Amine Components of Metalworking Fluid Formulations 6 CAS# European Classification U.S. DOT Classification Packing Group Exposure Limits Authority DIGLYCOLAMINE® Agent 2-(2-aminoethoxy)ethanol 929-06-6 Corrosive Corrosive III None — MIPA Isopropanolamine 78-96-6 Corrosive Corrosive II None — AMP amino methyl propanol alternative 124-68-5 Irritant None — None — BHEMA Bis-(hydroxyethyl)methylamine 105-59-9 Irritant None — None — TEA Triethanolamine 102-71-6 None None — 5 mg/m3 TWA ACGIH TLV DEA Diethanolamine 111-42-2 Irritant None — 15 mg/m3 TWA ACGIH TLV MEA Monoethanolamine 141-43-5 Harmful Corrosive III 6 mg/m3 TWA OSHA PEL Amines for the Metalworking Industry Table 2.3 - Relative Volatility of Selected Amines Used in Metalworking Vapor Pressure, mmHg 20°C 100°C 150°C DIGLYCOLAMINE® Agent Boiling Point,°C, 760 mmHg Flash Point, °C 0.004 5.5 68.5 223 124 MEA 0.2 48.2 387 171 95 MIPA 0.5 79.8 560 158 71 AMP 0.7 59 457 165 — Amine in Vapor Phase (Wt%) Figure 2.1 - Volatility of Some Common Metalworking Amine Solutions* *Plots correspond to a 10 wt% aqueous amine sample and were constructed using data obtained in vapor-liquid equilibrium determinations. 7 SECTION 2 Amines for the Metalworking Industry Figure 2.2 - Cobalt Leaching by Commonly Used Metalworking Amines* *Samples are 1 wt% aqueous solutions of amine containing 1500 ppm cobalt powder. The pH of each solution is adjusted to the desired pH level with acetic acid. Dissolved cobalt is measured after 21 days. 8 Amines for the Metalworking Industry Table 2.4 - pH of Metalworking Amines as a Function of Concentration at 25°C1 Amine Concentrate (wt%) 1 5 10 15 20 DIGLYCOLAMINE® Agent 2-(2-aminoethoxy)ethanol 11.30 11.57 11.74 11.86 MEA Monoethanolamine 11.56 11.79 11.94 12.03 JEFFAMINE® D-400 Polyetheramine 11.00 11.19 11.27 11.35 AMP amino methyl propanol alternative 11.40 11.69 11.84 11.95 MIPA Monoisopropanolamine 11.40 11.66 11.81 11.95 DEA Diethanolamine 10.98 11.18 11.31 11.38 DIPA Diisopropanolamine 10.84 10.90 10.97 11.02 TEA Triethanolamine 10.38 10.61 10.73 10.80 BHEMA Bis-(hydroxyethyl)methylamine 10.79 10.97 11.07 11.13 DMDGATM Aminoalcohol N,N-dimethyl-2-(2-aminoethoxy)-ethanol 11.12 11.87 11.47 11.58 APM Aminopropylmorpholine 11.59 11.87 12.05 12.23 pH data was determined using a pre-calibrated Beckman 12pH Meter and Cole Parmer sealed combination electrode with a silver/silver chloride reference electrode. Solutions were allowed to equilibrate 10 minutes prior to measurement. 9 SECTION 2 Amines for the Metalworking Industry Figure 2.3 - Titration Curves of Various Metalworking Amines with Decanoic Acid Figure 2.4 - Titration Curves of Metalworking Amines with Isononaoic Acid 10 Amines for the Metalworking Industry Figure 2.5 - Titration Curves of Metalworking Amines with CORFREE® M1 Corrosion Inhibitor mL of 5% amine solution Table 2.5 - pH Stability of Boric Acid Derivative of Aminoalcohols1 pH Initial 6 days 12 days 18 days 30 days % Change Adduct with DIGLYCOLAMINE® Agent Odor 10.20 none 10.18 none 10.08 none 10.05 none 10.01 none -1.9 Adduct with MEA Odor 10.0 none 9.98 none 9.80 none 9.70 weak 9.60 weak -10.0 Adduct with DEA Odor 10.41 none 10.36 none 10.21 none 10.07 none 9.99 none -4.0 Adduct with TEA Odor 10.10 none 10.08 none 10.05 none 10.02 none 9.80 none -2.2 “Antimicrobial Properties of the Products from the Reaction of Various Aminoalcohols and Boric Anhydride” S. Wantanabe, T. Fujita, M. Sakamoto, and W. Aono Materials Chemistry and Physics, Volume 19 (1988), pp 191-195 1 11 SECTION 2 Amines for the Metalworking Industry Table 2.6 - Nitrosoamine Formation in Synthetic and Semi-Synthetic Cutting Fluids Semi-synthetic Cutting Fluid1 ppb Nitrosoamine Secondary Amine DEA Diisopropanol Amine 336 414 Primary Amine MEA Monoisopropanol Amine DIGLYCOLAMINE® Agent 14 18 24 Tertiary Amine TEA 113 Control Synthetic Cutting Fluid2 9 ppb Nitrosoamine Secondary Amine DEA Primary Amine MEA DIGLYCOLAMINE® Agent 1 2 609,000 None detected None detected Conditions: 5% emulsion, 50 ppm Na nitrite, 60°C, 1 week Reference: J. Hübner in T + S Tribologie und Schmierungstechnik, 3, 1996 Literature: R.N. Loeppky, T.J. Hansen, and L.K. Keefter, Food and Chemical Toxicology, Vol. 21, 607-613, 1993 Nitrite-free cutting fluid after exposure to nitric oxide in air for three hours Table 2.7 - Aluminum Staining/Corrosion Summary of Results • • • • • • 12 Aluminum staining/corrosion is pH dependent Aluminum staining/corrosion is also dependent on the presence of other common additives (such as fatty acids) Tests run at pH=8.8 suggest that DGA® Agent may provide an advantage over other amines Solutions of TEA showed much more significant staining/corrosion than any other amines tested Test time was 24 hours at ambient temperature Corrosion documented by weighing the test coupons before and after the test; dissolved Al in solution measured by ICP Amines for the Metalworking Industry Table 2.8 - Aluminum Staining/Corrosion Dissolved Al (ppm) Al 6061 Al 2024 Amine* Al 7075 Al 390 DGA® Agent 5 5.5 7.6 9 AMP 9 7.9 12 11.5 TEA 155 195 235 215 XTA-771 11 9.3 14 14 BHEMA 7.2 4.8 8.6 9 DEA 7.9 9.3 10 11 MEA — — — 10 Blank <1 <1 <1 <1 * 2.5 weight % aqueous solution of amine; pH adjusted with acetic acid 13 SECTION 2 Amines for the Metalworking Industry Table 2.9 - Aluminum Staining/Corrosion with Fatty Acid Amine Isononanoic acid salt* Al 7075 Dissolved Al (ppm) Al 6061 Al 2024 DGA® Agent 2.6 3.4 5 3.9 AMP 3.6 3.4 3.7 2.2 TEA 10 30 3.7 2.2 XTA-771 3.0 2.6 2.7 2.2 BHEMA 2.2 3.0 <1 <1 DEA 2.5 <1 1.2 <1 MEA 1.9 <1 2.6 <1 Blank 4.1 <1 6.7 6.0 * 2.5 weight % aqueous solution of salt (1:1); pH adjusted with KOH Figure 2.6 - Effect of Amines on Magnesium % Wt Loss From Coupons 14 Al 390 Amines for the Metalworking Industry DIGLYCOLAMINE® Agent Table 2.13 lists the countries with DIGLYCOLAMINE® DIGLYCOLAMINE® Agent is an essentially colorless, slightly viscous liquid. The product is a non-volatile primary amine with a low tendency to leach cobalt, aluminum, or copper. Features and benefits of DGA® Agent are listed in Table 2.10. Agent registrations. Table 2.14 lists TSCA registrations for amides and salts of DGA® Agent. A comparison of hard water tolerance of salts of neodecanoic acid with either DGA® agent or DEA is presented in Table 2.15. DIGLYCOLAMINE® Agent has an excellent toxicity profile as summarized in Table 2.11. Numerous physical properties of DGA® Agent are listed in Table 2.12. Table 2.10 - Features and Benefits of DIGLYCOLAMINE® Agent in Metalworking Features • • • • • • • • • • • • • Primary Amine Isomeric with DEA Inventory listed (TSCA, EINECS, MITI, DSL, AICS) Used commercially in U.S. and Europe as DEA replacement Huntsman manufactures in U.S. and Europe Low toxicity profile Non-mutagenic Non-dermal sensitizer Lower volatility, higher boiling and flash points than other DEA substitutes Lower freezing points than other DEA substitutes Provides buffering and corrosion protection Lime-tolerant Readily forms amides Benefits • • • • • • • • DEA free Reacts readily with acids to form amides and salts Stoichiometrically equivalent to DEA Readily available globally Minimal disposal problems Reduced volatility and respiratory concerns; Good cold weather handling Similar to DEA in providing buffering capacity Amides provide lubricity, emulsification, hard water stability 15 SECTION 2 Amines for the Metalworking Industry Table 2.11 - DIGLYCOLAMINE® Agent Toxicity Profile Mammalian Toxicity Oral LD50 2.56 g/kg in rats; considered slightly toxic by ingestion (1991). Dermal LD50 Greater than 3.0 g/kg in rabbits; considered practically non-toxic by dermal absorption (1990). Dermal Irritation Draize dermal irritation score in rabbits is 8.0 of 8.0; considered to be a dermal corrosive (1992). Ocular Irritation Due to dermal corrosivity, an ocular irritation study is considered to be inappropriate and has not been performed. Draize ocular irritation score (rabbit) is estimated to be 50 to 80/100; considered to be severely irritating/corrosive to the eyes. Dermal Sensitization Not a sensitizer in guinea pigs when induced and challenged at 105 using the Beuhler study protocol (1991). Genetic Toxicity Ames Assay Negative with and without metabolic activation in a plate incorporation assay, using concentrations up to 10,000 ug/plate in Salmonella tester strains TA 98, TA 100, TA 1535, TA 1537, and TA 1538 (1982). UDS Assay Negative at culture concentrations up to 1% in DMSO. This concentration was the maximum non-cytotoxic dosage under the test protocol (1982). Cell Transformation Test Negative at culture concentration up to 1563 nl/ml. This concentration was the maximum non-cytotoxic dosage under the test protocol (1982). 16 Amines for the Metalworking Industry Table 2.12 - Physical Properties of DIGYCOLAMINE® Agent Boiling point, °C , 760 mmHg 221 Critical constants* Critical temperature, °C Critical pressure, psi Critical density, g/cc 401.40 42.98 0.322 Density, g/ml 60°F 77°F 1.0585 1.0508 Flash point, °F, PMCC 255 Freezing point, °C -12.5 Heat of vaporization, 760 mmHg, Btu/lb 219.14 Ionization constant, 25°C, KD 3.6 x 10-5 Refractive index, nD, 20°C 1.4598 Specific gravity, 20/20°C 1.0560 Specific heat of liquid, Btu/lb/°F 60°F 180°F 0.571 0.623 Thermal conductivity, 68°F, Btu/hr, sq ft, °F/ft 0.121 Vapor pressure, 68°F, mmHg 0.004* Viscosity, 60°F, cp 40 Weight, 60°F, lb/gal 8.8 * calculated Table 2.13 - DIGLYCOLAMINE® Agent Registrations Country United States Europe Canada Australia Japan Korea Inventory CAS# TSCA EINECS DSL AICS MITI ECL 929-06-6 213-195-5 929-06-6 929-06-6 (2)-3202 2-709 17 SECTION 2 Amines for the Metalworking Industry Table 2.14 - DIGLYCOLAMINE® Amide and Salt Registrations Inventory PMN# Amides CAS# TSCA 99-350 DGA® Amide of Neodecanoic acid 212335-62-1 TSCA 99-351 DGA® Amide of Coco Fatty acid 212335-59-6 TSCA 99-352 DGA® Amide of Dodecanoic acid 20138-28-7 TSCA 99-353 DGA® Amide of Decanoic acid 158948-13-1 TSCA 99-358 DGA® Amide of Castor-oil Fatty acid 212335-58-5 Testing Required 99-354 DGA® Amide of Tall Oil Fatty acid 213702-37-5 Testing Required 99-355 DGA® Amide of Octadecanoic acid 32425-87-9 Testing Required 99-356 DGA® Amide of Isooctadecanoic acid 212335-61-0 Testing Required 99-357 DGA® Amide of Soya Fatty acid 212335-57-4 Salts 18 TSCA 99-544 DGA® Salt of Tall Oil Fatty acid 216593-48-5 TSCA 99-545 DGA® Salt of Octadecanoic acid 216583-60-7 TSCA 99-546 DGA® Salt of Isooctadecanoic acid 216583-91-4 TSCA 99-547 DGA® Salt of Soya Fatty acid 216593-49-6 TSCA 99-548 DGA® Salt of Castor-oil Fatty acid 216593-54-3 TSCA 99-583 DGA® Salt of Coco Fatty acid 216593-55-4 TSCA 99-584 DGA® Salt of Dodecanoic acid 78543-39-2 TSCA 99-585 DGA® Salt of Neodecanoic acid 216853-95-8 TSCA 99-586 DGA® Salt of Decanoic acid 216583-94-7 TSCA 99-587 DGA® Salt of Nonanoic acid 216583-66-3 TSCA 99-588 DGA® Salt of Boric acid 124756-59-8 TSCA 01-308 DGA® Salt of Dodecanedioic acid 292601-80-0 TSCA 01-309 DGA® Salt of Undecanedioic acid 292601-81-1 TSCA 01-310 DGA® Salt of Decanedioic acid 292601-82-2 TSCA 01-307 DGA® Salt of CORFREE® M1 inhibitor 292849-36-6 TSCA 01-311 DGA® Salt of 3,5,5-Trimethyl-hexanoic acid 292601-83-3 Amines for the Metalworking Industry Table 2.15 - Hard Water Tolerance of Neodecanoic Acid Salts of DIGLYCOLAMINE® Agent vs. DEA Hardness, ppm 0 114 342 1000 Temperature, 25°C DIGLYCOLAMINE® Agent DEA C C C C C SH C SH Temperature, 60°C DIGLYCOLAMINE® Agent DEA C C C SH C SH C SH Notes: Salts used at 1% level Acid type influences hard water tolerance C = Clear SH = Slight Haze 19 SECTION 2 Amines for the Metalworking Industry DIGLYCOLAMINE® Agent Data comparing the physical properties of DGA® Agent and another commonly used metalworking amine are given in Table 2.16. Both products are relatively strong amines with about the same equivalent weight. The boiling point, flash point, and vapor pressure of DGA® Agent indicate DGA® Agent is a less volatile amine. This could be an important factor where misting and odor are concerns. Both amines have similar toxicity profiles. Table 2.16 - DGA® Agent Physical Properties Physical Properties DGA® Agent AMP Primary Primary Equivalent weight 105 93.7 Boiling point, °C, 760 mmHg 223 165 Vapor Pressure, 20°C, mmHg 0.004 0.08 Freezing Point, °C -12.5 -2 63 27 561 147 pH, 5% aqueous solution 11.3 11.4 Flash point, °C 124 78 Dermal LD50, mg/kg >3000 >2000 Oral LD50, mg/kg 2560 2900 Acute fish LC50, mg/l 460 331 Acute daphnia EC50, mg/l 190 193 Acute algae IC50, mg/l 160 520 Mutagenic No No Dermal Sensitizer No No Amine type Viscosity, cSt, 10°C 25°C Environmental, Health, and Safety 20 Amines for the Metalworking Industry Because AMP is a slightly stronger amine than DGA® Agent, it gives a directionally higher pH in solution (Table 2.17). When these amines are used to provide reserve alkalinity (buffering), we recommend the inclusion of a weaker amine like TEA (Triethanolamine). Reserve alkalinity is a function of the amount of amine present. With strong amines, less amine is required to reach a given pH target, hence reducing the amount available for buffering. Inclusion of TEA will increase the amount of amine present without appreciably increasing the pH. The effect of blending TEA with either DGA® Agent or AMP on pH and alkalinity of 5% aqueous solutions is given in Table 2.17. The data indicate AMP is a more basic amine giving a directionally lower reserve alkalinity with TEA than DGA® Agent with TEA. Table 2.17 - pH and Reserve Alkalinity of 5% Aqueous Amine Solutions 1 pH Reserve Alkalinity 1 TEA 10.4 — DGA® Agent 11.3 17.8 AMP 11.4 16.8 DGA® Agent/TEA (2.5%/2.5%) 11.1 21.6 AMP/TEA (2.5%/2.5%) 11.3 20.6 As neodecanoic acid salt (ASTM D1121) The breakpoints obtained from iron chip corrosion tests on borate salts of DGA® Agent and AMP are provided in Table 2.18. DGA® Agent and AMP are seen to be equivalent in their effect on corrosion of cast iron chips as defined by the ASTM D4627 test. The test solutions were made up of 1:1 amine/boric acid, at 1.5M concentration. This corresponds to 15.75 weight % DGA® Agent, 13.35 weight % AMP, and 9.27 weight % boric acid. The pH of all solutions was 10.1. The tests were run according to ASTM D4627-92, utilizing 10 dilutions of the test solutions in calcium chloride water. A second set of tests were also performed by making the dilutions using calcium chloride water containing 10 times the standard method concentration. There was no observable effect on the breakpoints. Table 2.18 - Amine Borate Chip Rust Test Results Amine Breakpoint Breakpoint (10X) DGA® Agent/Borate 4.0 4.0 DGA® Agent/Borate - repeat 4.0 4.0 AMP/Borate 4.0 4.0 AMP/Borate - repeat 4.0 4.0 21 SECTION 2 Amines for the Metalworking Industry DGA® Agent and AMP have a similar cobalt leaching profile, while DGA® Agent is better toward copper (Table 2.19). Foam properties, as measured on 1% solutions of the neodecanoic acid salts of both amines, are essentially equivalent. Table 2.19* - Cobalt and Copper Leaching Comparison Co Cu DI water (control) 11.0 0 DGA® Agent 24.4 107.5 AMP 17.8 207.5 *Angus Chemical Company data Electrochemical tests1 were performed to measure the corrosion rate of aluminum and carbon steel in amineborate solutions. The corrosion rate of aluminum in the presence of only the amine borates or amine borates and KOH, used to adjust to a constant pH, was moderate, in the range of 2.4 to 6.0 mpy. There was essentially no difference among the three amines. Corrosion of carbon steel was very low, at an average of 0.05 mpy. The data are given in the table below. We conclude on the basis of this testing there are no difference in the corrosion protection for aluminum and steel provided by the amine borates prepared from DGA® Agent, DEA, and AMP. Table 2.20 - Aluminum Corrosion Rates 1 Amine Salt pH Aluminum (mpy) Steel (mpy) DGA® Agent Borate 9.6 4.9 ± 0.3 0.040 ± 0.012 DEA Borate 9.3 2.7 ± 0.3 0.060 ± 0.016 AMP Borate 9.8 5.4 ± 0.6 0.040 ± 0.0006 DGA® Agent Borate 10.1 3.2 ± 0.9 Not determined DEA Borate 10.1 5.8 ± 1.9 Not determined AMP Borate 10.1 3.8 ± 1.2 Not determined The amines were prepared as 1:1 mole ratio salts with boric acid at a concentration of 0.1M. The solutions were tested at the as-prepared pH (shown in Table 2.20) and also at a pH value of 10.1, adjusted using KOH. The corrosion rates were measured using electrochemical polarization resistance over a four-hour period. Aluminum alloy 7075 (UNS A97075) and 1020 carbon steel were freshly polished before each test. All tests were performed at room temperature (22°C) under continuous aeration and with moderate stirring. 22 Amines for the Metalworking Industry Handling, Storage and Shipping of DIGLYCOLAMINE® Agent General The handling and storage of DIGLYCOLAMINE® Agent present no unusual problems. Huntsman Corporation’s Technical Services team is available to assist those persons desiring additional information. Maintaining Specifications DIGLYCOLAMINE® Agent is hygroscopic and will absorb water vapor when exposed to a moist atmosphere. If water content is to be minimized, a dry inert gas pad under a few ounces of pressure should be used on the storage tanks. A gas pad should also be used if low color is important, since absorbed atmospheric oxygen and carbon dioxide will cause DIGLYCOLAMINE® Agent to develop color. Since DIGLYCOLAMINE® Agent is basic, it will react with acidic gases; hence carbon dioxide and natural gas containing acidic sulfur compounds cannot be used. Nitrogen is quite suitable. The solvent properties and alkaline nature of DIGLYCOLAMINE® Agent should also be considered when installing handling and storage facilities. DIGLYCOLAMINE® Agent may react with copper to form complex salts. The use of copper and alloys containing copper should be avoided in equipment that will contact DIGLYCOLAMINE® Agent or its aqueous solutions. Carbon steel storage tanks constructed according to a recognized code are generally satisfactory. In cases where low color is important, stainless steel is preferred. DIGLYCOLAMINE® Agent is not compatible with phenolic resin linings. Steam coils with sufficient surface area to heat the tank contents using low-pressure steam should be built into the tank about six inches above the floor. The coils should be constructed in such a manner as to allow the condensate to drain. Stainless steel coils are preferred, particularly when low color DIGLYCOLAMINE® Agent is important. If steam heat is to be used continuously to prevent high viscosities or freezing, a temperature regulator that throttles either the steam or condensate should be installed. In situations where the ambient temperature is low, tank insulation is desirable. Asphalt-cork or urethane foam insulation sprayed onto the outer wall is satisfactory. If a nitrogen pad is used, pressure relief and vacuum relief valves of a suitable capacity should be installed. The system may consist of a cylinder of nitrogen, a pressure reducing valve, a pressure relief valve, and a line to the top of the storage tank. Tankage should be diked and electrically bonded and grouped. Transfer Lines Carbon steel transfer lines at least two inches in diameter and joined by welds or flanges are suitable. Screwed joints are subject to failure unless back-welded because DIGLYCOLAMINE® Agent will leach conventional pipe dopes. U.S. Rubber 899 gasket material, polypropylene, Teflon® elastomer, or their equivalents are satisfactory for use with flanged connections in DIGLYCOLAMINE® Agent service. Avoid the use of nitrile rubbers such as neoprene, Buna-N or Viton® rubber. If the ambient temperature is below 20°F, the transfer line for the pure product should be steam traced and insulated. Steam tracing can be accomplished by affixing copper tubing of approximately 3/8-inch 23 SECTION 2 Amines for the Metalworking Industry diameter to the underside of the line, insulating the tube to the line, and using low-pressure steam in the tubing. For flexible connections, stainless steel hose is preferred to rubber since rubber will generally deteriorate in DIGLYCOLAMINE® Agent service and increase the color of the product with time and temperature. Systems that are insulated and steam traced should be preheated in cool weather before being put into service. Normally, 15 to 30 minutes of applying steam to the tubing will adequately warm, but not overheat, the system. Transfer piping and pumps may be equipped with a nitrogen padding system so the DIGLYCOLAMINE® Agent can be pressured out of the lines when an extended idle period is contemplated. This practice will help losses and color increases that would result if the DIGLYCOLAMINE® Agent were allowed to remain in the lines. constructed of welded carbon steel and have bottomunloading fittings and steam coils. Deliveries can also be made in insulated, stainless steel, full or compartmented tank wagons with steam coils. If requested, tank wagons can be equipped with unloading pumps and hoses. Drums of DIGLYCOLAMINE® Agent can be shipped in truckload or less-than-truckload quantities. The net weight of a drum is 480 pounds; the gross weight is approximately 519 pounds per drum. Drums are UN1A1 or UN1H1, nonreturnable. Under U.S. Department of Transportation (DOT) and Canadian Transportation of Dangerous Goods (TDG) regulations, the proper shipping name for DIGLYCOLAMINE® Agent is “2-(2-aminoethoxy)ethanol”, identification number UN 3055. This product is considered a corrosive material (TDG hazard class 8) and requires a “CORROSIVE” label for shipping. Shipping Information DIGLYCOLAMINE® Delivery of Agent can be made in 10,000 and 20,000-gallon tank cars. These cars are 24 For further information, please refer to the Material Safety Data Sheet (MSDS). Amines for the Metalworking Industry BHEMA BHEMA is a low-volatility tertiary amine which may be useful as an alternative to TEA. It has low acute toxicity, and low nitrosamine potential. These features, as well as other features of BHEMA are summarized in Table 2.21. Toxicity and environmental profiles are presented in Tables 2.22 and 2.23. Registration information for salts of BHEMA are listed in Table 2.24. Table 2.21 - Features and Benefits of BHEMA Features • • • • Benefits Alternative to TEA Low mammalian and aquatic toxicity Low potential for nitrosamine formation Effective in single amine formulations • • • • Low volatility, which reduces airborne exposure Not classified as corrosive under DOT Shows lower tendency to stain than TEA Slightly stronger base and lower molecular weight than TEA, so less amine is required for pH development • Good reserve alkalinity • Good copper and cobalt leaching characteristics Table 2.22 - BHEMA Toxicity Profile Test Result Interpretation Dermal LD50 - Rabbit >2000 mg/kg Practically nontoxic Dermal Irritation - Rabbit None -> slightly irritating Eye Irritation - Rabbit Irritating BHEMA is alkaline. 90-day subchronic dermal study - rat LOAEL: 250 mg/kg/d NOAEL: 100 mg/kg/d Effects limited to skin effects from irritation Genotoxicity Negative In-vivo and in-vitro studies Data Source: IUCLID monograph 25 SECTION 2 Amines for the Metalworking Industry Table 2.23 - BHEMA Environmental Profile Test Value Interpretation Octanol:water partition coefficient (log Kow) -1.08 Very water soluble; low bioaccumulation potential Fish Toxicity 3 species LC50 760-2000 mg/l Practically nontoxic Invertabrate Toxicity (Daphnia) EC50 230 mg/l Practically nontoxic Algal Tox EC50 26-45 mg/l EPA slightly toxic Data Source: IUCLID monograph Table 2.24 - BHEMA Salt Registrations TSCA, DSL and EINECS Registrations Pending Inventory PMN# Salts CAS# TSCA P-05-782 BHEMA Salt of CORFREE® M1 inhibitor 843644-84-8 TSCA P-05-787 BHEMA Salt of Tall Oil Fatty Acids 843644-82-6 TSCA P-05-789 BHEMA Salt of Neodecanoic Acid 842129-84-4 TSCA P-05-786 BHEMA Salt of Nonanoic Acid 842126-27-6 TSCA P-05-788 BHEMA Salt of Decanoic Acid 842126-13-0 Data Source: IUCLID monograph 26 Amines for the Metalworking Industry SURFONAMINE® MW-781 Amine SURFONAMINE® MW-781 amine is butoxypropyl amine. It is a water white liquid with a low viscosity and very low molecular weight. More features and benefits are discussed in Table 2.25. Figure 2.7 displays the physical properties for SURFONAMINE® MW-781 amine. Table 2.25 - Features and Benefits of SURFONAMINE® MW-781 Amine Features • • • • Strong primary amine (7.6 meq/g total amine) Possible candidate for Borate production Very low molecular weight (131 g/mol) Inventory listed (TSCA, ENICS, NDSL) Figure 2.7 - Benefits • Multipurpose additive for synthetic and semi-synthetic formulations • Viscosity is 2 cSt; Melting point is -47oC • Has surfactant properties; coupling agent/solubilizer (somewhat foamy if neutralized to a low pH) • Possible vapor-phase corrosion inhibitor SURFONAMINE® MW-781 Amine Physical Properties 27 SECTION 2 Amines for the Metalworking Industry Ethanolamines The ethanolamines used for metalworking are MEA (Monoethanolamine), DEA (Diethanolamine), and TEA (Triethanolamine). DEA has been used for a number of years in metalworking applications. MEA and TEA are often used in combination with each other. MEA has a high pH and TEA has a low pH. Other Amines Some other metalworking amines that can be used include XTA-771, JEFFAMINE® D-2000 polyoxypropylenediamine, JEFFAMINE® D-230 polyoxypropylenediamine, JEFFAMINE® D-400 polyoxypropylenediamine, and JEFFAMINE® T-403 polyetheramine. XTA-771 XTA-771 is a polyoxyalkylene amine with three primary amine groups per molecule. The features and benefits are listed in Table 2.26. Table 2.26 - Features and Benefits of XTA-771 • • • • Low tendency to leach cobalt from tooling Low tendency to leach copper Provides added lubricity Three primary amine groups per molecule JEFFAMINE® D-2000 Polyoxypropylenediamine JEFFAMINE® D-2000 polyoxypropylenediamine acts as a defoamer in metalworking applications. The features and benefits are listed in Table 2.27. Table 2.27 - Features and Benefits of JEFFAMINE® D-2000 Amine • Hydrophobic amine • Gives defoaming performance in semi-synthetic, but especially synthetic formulations • Fatty acids amides of JEFFAMINE® D-2000 amine may work even better 28 SECTION 3 Surfactants for the Metalworking Industry Alkylphenol Ethoxylates Nonylphenol Ethoxylates – SURFONIC® N Series Surfactants The main area of application in metalworking fluids for the SURFONIC N series surfactants is in the emulsification of oils. Nonylphenol ethoxylates (NPEs) are highly effective materials for formulating soluble oil, semisynthetic and metal cleaning compounds. These surfactants have excellent emulsification properties when used with naphthenic and paraffinic oils. In general two or three ethoxylates of different Hydrophile/Lipophile Balance (HLB) are blended in order to get the best emulsification, especially when formulating products for high hard water tolerance. Higher HLB products will improve hard water tolerance and hinder soft water tolerance. Combinations of NPEs such as SURFONIC products N-95 with N-40 or N-102 with N-60 are excellent starting points for formulation work. The nonylphenol ethoxylates tend to have lower foam and lower pour points than the equivalent alkyl alcohol ethoxylates. The SURFONIC N series products are biodegradable and are compatible with sulfonates, fatty acid salts and most other metalworking additives. To complete a formulation, products such as an amide based on DIGLYCOLAMINE® Agent for corrosion control and lubricity, PEG esters for lubricity, phosphate esters for extreme pressure (EP) enhancement and amines for alkalinity enhancement can be added. Nonylphenol ethoxylates are also widely used in metal cleaning compounds, where they act to scavenge residual fluids, to enhance wetting and rinsing of parts, and to disperse swarf left on parts. Formulations based on NPEs can be used to clean parts from stamping and forming operations where they help to disperse waxy carriers left from the lubricant. The wetting performance of the SURFONIC N series products as a function of ethylene oxide (EO) content is illustrated in Figures 3.1 and 3.2. The maximum wetting performance of the water-soluble SURFONIC N series products is seen with products containing 8.5 - 9.5 moles of EO per mole of nonylphenol. (Fig. 3.1) Products containing 15 or more moles of EO are useful as dispersants for graphite, metal cuttings and the like. Many cleaning formulations use caustic additives to help saponify fatty materials on the substrate. In order to make NPEs soluble in potassium hydroxide (KOH), for instance, a phosphate ester can be used. Figure 3.2 shows the effectiveness of a phosphate ester at solubilizing SURFONIC N-95 surfactant in KOH solutions. The physical and surfactant properties of the SURFONIC N series products are shown in Table 3.1. 29 SECTION 3 Surfactants for the Metalworking Industry Table 3.1 - SURFONIC® N-Series Nonylphenol Ethoxylates SURFONIC Product Appearance at 25°C HLB Specific Gravity, 25/25°C Viscosity, cPs, 25°C Cloud Point Wetting Time1, seconds CMC, ppm Ross Miles Foam2, 100 SUS mm, Initial Naphthenic Solubility 100 SUS Paraffinic Water Function Clear liquid 7.7 -4 1.01 294 243 8 S S I Emulsifier for soluble oils and semisynthetics N-40 Clear liquid 8.9 -7 1.026 255 343 10 S S I Emulsifier for soluble oils and semisynthetics N-60 Clear liquid 10.9 -7 1.041 239 843 12 S I D Emulsifier for soluble oils and semisynthetics N-85 Clear liquid 12.6 10 1.056 251 444 6.3 47 14 I I S Emulsifier for soluble oils and semisynthetics N-95 Clear liquid 13.1 4 1.061 293 544 6.4 48 80 I I S Emulsifier for soluble oils & semisynthetics, metal cleaners N-100 Clear liquid 13.3 3 1.064 250 654 7.9 50 85 I I S Emulsifier for soluble oils & semisynthetics, metal cleaners N-102 Clear liquid 13.5 6 1.065 290 714 10.5 54 85 I I S Emulsifier for soluble oils & semisynthetics, metal cleaners N-120 Clear liquid 14.1 3 1.070 308 525 17.1 57 110 I I S Emulsifier for soluble oils & semisynthetics, metal cleaners 23 1.065 306 655 52 100 120 I I S Improves hard water tolerance of soluble oil and semisynthetics I I S Improves hard water tolerance of soluble oil and semisynthetics I I S Improves hard water tolerance of soluble oil and semisynthetics White semisolid 15 NB-307 Clear liquid 17.1 2 1.02 785 NB-407 Clear liquid 17.8 5 1.022 765 0.1% solution, 25°C 30 Pour Point, °C N-31.5 N-150 1 ® 2 0.1% solution, 120°F 3 Water titration, mls H2O to cloud 500 4 °C, 1% aqueous solution 5 °C, 1% surfactant in 10% NaCl Surfactants for the Metalworking Industry Figure 3.1 - Draves Wetting Times for Water-Soluble SURFONIC® N Series Products Figure 3.2 - Effect of Phosphate Ester on Solubility of SURFONIC® N-95 surfactant KOH Solutions 4% SURFONIC® N-95 surfactant in KOH solutions 31 SECTION 3 Surfactants for the Metalworking Industry Octylphenol Ethoxylates – SURFONIC® OP Series Surfactants The SURFONIC OP series surfactants are ethoxylates of octylphenol. The properties of octylphenol ethoxylates (OPEs) are similar to those of nonylphenol ethoxylates of similar HLB. and semisynthetic formulations. The SURFONIC OP series products are stable in dilute hydrochloric and phosphoric acids. This characteristic suggests usefulness in acid cleaning, pickling and phosphating formulations. Three main application areas exist in metalworking for OPEs: acid-based cleaners, emulsifiers for soluble oils, The physical and surfactant properties of the SURFONIC OP series products are shown in Table 3.2. Table 3.2 - SURFONIC® OP Series Octylphenol Ethoxylates HLB Pour Point, °C Specific Gravity, 25/25°C Viscosity, cPs, 25°C Cloud Point Liquid 5.1 -9 0.985 790 OP-35 Liquid 8.6 -23 1.023 OP-70 Liquid 12.0 -26 OP-100 Liquid 13.6 OP-120 Liquid 14.4 1 ® Appearance at 25°C OP-15 SURFONIC Product 0.1% solution, 25°C 32 2 100 SUS Naphthenic Solubility 100 SUS Paraffinic Water Function 152 S S I Oil soluble coupler and defoamer for semisynthetic and soluble oil formulations 370 242 S S I Emulsifier for soluble oil formulations 1.054 260 233 3.5 90 S S S Emulsifier for semisynthetic formulations 2 1.065 240 663 3.6 200 I I S Emulsifier for semisynthetic formulations. Wetting agent for phosphoric and hydrochloric acids 16 1.071 330 584 250 I I S Improves hard water tolerance of soluble oil and semisynthetic formulations Water titration, mls H2O to cloud 3 Wetting Time1, seconds °C, 1% aqueous solution CMC, ppm 4 °C, 1% surfactant in 10% NaCl Surfactants for the Metalworking Industry Alcohol Alkoxylates – SURFONIC® LF, P and JL Series Surfactants The SURFONIC® LF and P product families are made up of ethoxylated, propoxylated linear alcohols. The choice of alcohol and the addition patterns for ethylene oxide (EO) and propylene oxide (PO) give the alkoxylated products their unique properties. The alcohol alkoxylates are ideally suited for metalworking operations. They tend to have low foam generation characteristics and some products can act as defoamers in water-based systems. All of the surfactants in this group will solubilize the components of carboxylate-based corrosion inhibitors in water. These surfactants are best suited to synthetic and semisynthetic formulations. Several products such as SURFONIC P1 surfactant are also used in soluble oil formulations. SURFONIC LF-18 surfactant is useful in low-foam semisynthetic cutting fluids. SURFONIC P5 surfactant is used in some acid cleaners and in rinse aid applications. Several of the SURFONIC LF series products, particularly SURFONIC LF-37 and LF-18 surfactants are useful as rinse aid and cleaning actives in metal cleaning operations. SURFONIC LF-18 surfactant is used in the production of low-foaming, highly effective microemulsion cleaners using d-Limonene as the solvent phase. Formulations of this type can be used to remove a variety of metalworking compounds from metal parts. The formulations have very low foam and can be used in spray applications. The SURFONIC LF and P series products offer a boost in lubricity, making them multifunctional in semisynthetic and synthetic formulations. Falex wear data are offered on a simple formulation containing several of these products. When the formulation is changed to include a phosphate ester (SURFONIC PE-2258 surfactant), dramatically improved Falex wear performance is observed. The synergy between the alkoxylated nonionic surfactant and the anionic phosphate ester is also observed with the SURFONIC POA block copolymer surfactants. By careful selection of the phosphate ester and the SURFONIC LF or P series product, it is possible to get emulsification, solubilization, lubricity, extreme pressure characteristics and corrosion protection in one pair of surfactants. The multifunctional nature of these products makes them ideal candidates for many metalworking formulations. SURFONIC® JL-80X surfactant is used in some metal cleaning operations. The unique structure of this product eliminates the gel phase common to alcohol ethoxylates in aqueous solutions. This characteristic allows the formulator to blend the surfactant into a formulation without regard to any gelling problems. The physical and surfactant properties of the SURFONIC LF and P series products are shown in Table 3.3. A comparison of the dynamic surface tension characteristics of the SURFONIC alcohol alkoxylates is presented in Figure 3.3. 33 SECTION 3 Surfactants for the Metalworking Industry Table 3.3 - SURFONIC® LF, P and JL Series Alcohol Alkoxylates SURFONIC Product 1 ® Appearance at 25°C HLB Pour Point, °C Specific Gravity, 25/25°C Viscosity, cPs, 25°C Cloud Point, °C 1% aq. Wetting Time1, seconds 4.8 LF-17 Clear liquid -12 0.998 96 34 LF-18 Clear liquid -6 1.013 240 17 LF-37 Clear to hazy liquid -12 0.9904 at 100°F 96 17 LF-41 Clear to hazy liquid 1.0343 260 P1 Clear to hazy liquid 7.0 -30 0.975 P3 Clear to hazy liquid 9.0 -30 P5 Clear to hazy liquid 10.0 P6 Falex Wear, 875 pounds Formulation A Formulation B Teeth Wear (T) Teeth Wear Torque in-lbs (IP) 65 T 15 IP Ross Miles Solubility CMC, Foam Height2, 100 SUS 100 SUS ppm mm, Initial/ 5 Min. Naphthenic Paraffinic Water Function 6.6 6/0 I I D Wetting agent for acid cleaning operations, low foam emulsifier/rinse aid 22 T 21 IP 63 5 0/0 I I D Low foam additive for semisynthetic and synthetic formulations, active defoamer in metal cleaning operations 18 26 T 29 IP 82 30 0/0 S I S Low foam emulsifier for semisynthetic and synthetic formulations 37 9.3 75 T 17 IP 66 34.2 0/0 I I S 90 25 26.9 19 T 19 IP 89 4.8 0/0 S S S Solubilizer/emulsifier for semisynthetic formulations. Emulsifier/ rinse aid for metal cleaners. Low foam. Wetting agent in dilute acid. 0.973 56 35 13.7 13 T 22 IP 125 4.5 66/11 S I S Rinse aid for cleaners/ secondary emulsifier for semisynthetic, wetting agent in dilute acid. -26 0.985 85 45 15.7 16 T 20 IP 55 6.2 75/5 S I S Hydrophilic emulsifie for semisynthetic, soluble in dilute acid Clear to hazy liquid 4 1.018 353 26.8 31 T 15 IP 61 4.9 0/0 I I D Low foam additive for semisynthetic and synthetic formulations, active defoamer in metal cleaning operations. L4-29X Solid 37 1.018 596 at 100°F 75 10 T 15 IP 84 3.9 I I S High molecular weight emulsifier for semisynthetic and soluble oils, offers some thickening JL-80X Clear liquid -5 1.003 51 59 18 T 22 IP 83 I I S Prime surfactant in cleaners 0.1% solution, 25°C 2 0.1% solution, 120°F 3 9.8 75/70 °C, 10% in 25% butyl diglycol Formulation A: 1% TEA, 1% SURFONIC PE-2258 phosphate ester, 1% SURFONIC surfactant, 97% water. Formulation B: 0.17% TEA. 0.15% CORFREE® M-1 inhibitor, 0.07% DGA® Agent, 0.6% SURFONIC surfactant, 99% water. 34 Surfactants for the Metalworking Industry Surface Tension, mN/m Figure 3.3 - Dynamic Surface Tension of SURFONIC® Alcohol Alkoxylates Bubble rate, bubbles/second 35 SECTION 3 Surfactants for the Metalworking Industry EO/PO Block Copolymers – SURFONIC® POA Series Surfactants The SURFONIC® POA block copolymers are very useful in a variety of metalworking operations. These products are made by the sequential addition of ethylene oxide and propylene oxide. The functional attributes of these products — defoaming, wetting, lubricity, solubilization, emulsification, thickening and dispersion — all depend on the ratio of ethylene oxide to propylene oxide, the molecular weight of the product and the blocking pattern of the molecule. Properties of the SURFONIC POA products are given in Table 3.4. Soluble Oils Small amounts of low HLB products such as SURFONIC POA-L101 and POA-L61 surfactants can be used in soluble oils to promote solubilization of the oil in the concentrate. Under actual use conditions, these products can act as defoamers and can boost lubricity, especially in the presence of a phosphate ester. Higher HLB products will improve removal of the soluble oil formulation from parts and equipment. Semisynthetic Formulations SURFONIC POA-25R2 surfactant is an excellent choice for use in semisynthetic formulations. It will tend to lower the foam of the system, promote good lubricity, and help to solubilize naphthenic oil and carboxylate corrosion inhibitors. If fine particles are present in the system, POA-25R2 can form a weak association with the particles and produce a thickening effect, which can lead to reduced misting and “sling.” In semisynthetic formulations, SURFONIC POA-L61 and POA-L101 surfactants offer reduced foam and improved lubricity. SURFONIC POA-L62 surfactant helps with wetting of metal parts. 36 Synthetic Formulations Synthetic formulations depend on products like the SURFONIC POA block copolymers for low-foam characteristics, enhanced solubilization of the corrosion inhibitor salts, and a major part of the system lubricity. The SURFONIC POA products have an inverse solubility coefficient, which means that at some temperature, known as the cloud point, the nonionic surfactant will come out of solution and act as an oil. When the temperature drops below the cloud point, the surfactant becomes soluble again and redissolves into the water. The lubricity offered by many nonionic surfactants is partly due to the “oiling out” phenomenon. The SURFONIC LF and P series products also show lubricity effects above the cloud point. Careful selection of SURFONIC POA surfactants for a particular application can give formulations with low foam, high lubricity and high stability. Forming Lubricants In many forming operations it is possible to replace an oil-based lubricant with a simple synthetic formulation. This formulation might contain a SURFONIC POA copolymer, a phosphate ester for extreme pressure activity and corrosion protection, and water. This type of formulation offers several advantages: the number of parts that can be formed between die service is increased, the parts have better surface finish and the formed parts are easier to clean. Many metalworking operations using oil-based fluids can benefit from substitution with water-based synthetic formulations using the SURFONIC POA series of materials. Surfactants for the Metalworking Industry Table 3.4 - SURFONIC® POA Series Block Copolymers Appearance at 25°C HLB POA-L61 Liquid 3 -30 1.017 360 24 POA-L62 Liquid 7 -4 1.04 150 32 60.7 11 T 24 IP POA-L62LF Liquid 6.6 -10 1.04 460 28 27.7 POA-L101 Liquid 1 -23 1.02 800 15 POA-17R2 Liquid 1.03 2053 35 POA-25R2 Liquid 1.02 570 30 SURFONIC Product 1 0.1% solution, 25°C 6.3 2 -5 Specific Gravity, 25/25°C Viscosity, cPs, 25°C Cloud Point, °C 1% aq. 0.1% solution, 120°F 3 Wetting Time1, seconds Falex Wear, 875 pounds Formulation A Formulation B Ross Miles Solubility Teeth Wear (T) Foam Height2, 100 SUS 100 SUS Teeth Wear Torque in-lbs (IP) mm, Initial/5 Min. Naphthenic Paraffinic Pour Point, °C ® 10 T 22 IP 117 Water Function 6/0 I I D Defoamer for synthetic and semisynthetic fluids. Lubricity enhancement. 40/10 I I S Active for cleaners. Lubricity enhancement. 11 T 22 IP 43/5.5 I I S Defoamer and lubricant additive. 12 T 24 IP 0/0 I I S Solubilizer for semisynthetic and synthetic fluids. 0/0 I I S Lubricant in synthetic fluids and solubilizer in semisynthetic fluids. 15 T 22 IP 138 57 37.8°C Formulation A: 1% TEA, 1% SURFONIC PE-2258 phosphate ester, 1% SURFONIC POA surfactant, 97% Water. Formulation B: 0.17% TEA, 0.15% CORFREE® M-1 inhibitor, 0.07% DGA® Agent, 0.6% SURFONIC POA surfactant, 99% Water. 37 SECTION 3 Surfactants for the Metalworking Industry Linear Alcohol Ethoxylates – SURFONIC® L Series Surfactants The SURFONIC® L series linear alcohol ethoxylates are biodegradable, nonionic surfactants produced by the addition of ethylene oxide to linear, primary alcohols. Their physical appearance at room temperature varies from clear liquids to white waxy solids, depending on the alcohol used and the degree of ethoxylation. The Huntsman line of linear alcohol ethoxylates is made from alcohols containing only even carbon numbers in the alkyl groups; the structure of these alcohols closely matches that of alcohols from natural sources. Ethoxylates are made from a blend of the alcohol homologues. It is possible to deduce the product composition from the product name; for instance, SURFONIC L24-3 surfactant is a blend of C12, C14 and C16 linear alcohols reacted with three moles of ethylene oxide. Properties of the SURFONIC L series products are listed in Table 3.5. The SURFONIC L series linear alcohol ethoxylates are widely used as emulsifiers, cleaners, penetrants and wetting agents in metalworking formulations. Appropriate selection of the alcohol chain length and degree of ethoxylation can provide the surfactant properties required for a particular application. Products with a short alcohol chain and low degree of ethoxylation, such as SURFONIC L12-3 surfactant, are good solubilization agents. In microemulsion cleaners and semisynthetic cutting fluids, they help to dissolve or “couple” oily materials into the water-based formulation. In some applications they can serve the same function as a glycol ether with the added advantage of having low vapor pressure. In metal cleaning operations, low-mole alcohol ethoxylates are often blended with higher-mole ethoxylates to give a formulated product with enhanced oil removal, dispersant and emulsification properties. 38 Alcohol ethoxylates with 10-12 or 12-14 carbons and about 6 EO units are prime cleaning agents for metalworking operations. Products in this range, like SURFONIC L12-6 surfactant, have the fastest surface dynamics; their nature allows them to migrate to and stabilize new surfaces quickly. This property is illustrated by the dynamic surface tension measurement (Figure 3.4). Alcohol ethoxylates with 12-14 carbons and 7-12 moles of EO are used in soluble oil and semisynthetic cutting fluids, particularly in paraffinic systems. Typically two alcohol ethoxylates are used in a formulation to give a wide range of good emulsification performance. Certain pairs of surfactants compliment each other well in emulsification applications. A blend of SURFONIC L249 and SURFONIC L24-4 surfactants in a 1:2 ratio is often an optimal system. Higher EO products like SURFONIC L24-22 surfactant can be used to improve the hard water tolerance of a formulation and can improve the dispersibility of graphite or other particles in a metal cleaning formulation. At certain water/surfactant ratios, approximately in the 30-70% surfactant range, the alcohol ethoxylates exhibit a gel phase. In this range, an aqueous surfactant system will be a gel at room temperature but will become an isotropic solution at temperatures above the gel temperature. Glycol ethers, ethanolamines and some anionic materials can be added to the system to reduce the gel phase. When formulating with alcohol ethoxylates, one can avoid extended mixing times by selecting an appropriate order of addition (add surfactant to water) and by using heat during blending. Surfactants for the Metalworking Industry Table 3.5 - SURFONIC® L Series Linear Alcohol Ethoxylates SURFONIC Product 6 Appearance at 25°C HLB Pour Point, °C Specific Gravity, 25/25°C Viscosity, cPs, 25°C Cloud Point Wetting Time1, seconds CMC, ppm Ross Miles Foam Height2, 100 SUS mm, Initial/5 Min. Naphthenic Solubility 100 SUS Paraffinic Water S S I 111/9 S I S Prime wetting agent for water-based metal cleaners. 118/8 I I S Prime wetting agent in metal cleaners. S S I Oil soluble additive for water-based cleaners. Additive for rolling oils. Function L12-3 Clear to hazy liquid 9.0 -9 0.932 35 453 L12-6 Clear to hazy liquid 12.4 10 0.9820 43 505 4.0 L12-8 Clear to hazy liquid 13.6 18 1.004 98 805 8.4 L24-2 Clear to hazy liquid 6.2 10 0.903 25 L24-3 Clear to hazy liquid 8.0 4.4 0.9239 25 453 S S I Oil soluble additive for water-based cleaners and hydrophobic esters. L24-4 Clear to hazy liquid 9.4 4.4 0.9432 31 813 S S I Oil soluble additive for water-based cleaners and hydrophobic esters. L24-5 Clear to hazy liquid 10.6 10 0.9626 44 734 S S D Emulsifier for soluble oils. 15.6 0.9824 47 505 8.7 16 98/15 S S S Emulsifier for soluble oils. L24-7 1 ® Clear to slightly 11.9 turbid liquid 91 L24-9 White semisolid 13 21 0.9935 61 755 13.9 25 104/10 S I S Emulsifier for semisynthetic formulations. L24-12 Waxy solid 14.4 29.4 1.0075 at 100°F 47 at 140°F 686 35.1 29 113/11 I I S Improves hard water tolerance of soluble oils. L24-22 Waxy solid 16.6 39 1.0309 at 140°F 46 at 140°F I I S Improves hard water tolerance of soluble oils. Good dispersing. L46-7 White semisolid 11.6 21.1 0.979 63 S S S 0.1% solution, 25°C 2 0.1% solution, 120°F °C, 1% surfactant in 10% NaCl 3 505 20.6 Water titration, mls H20 to cloud 12 4 76/25 °C, 10% in 25% butyl diglycol 5 °C, 1% aqueous solution 39 SECTION 3 Surfactants for the Metalworking Industry Figure 3.4 - Dynamic Surface Tension of SURFONIC® L Series Alcohol Ethoxylates 40 Surfactants for the Metalworking Industry Fatty Acid Ethoxylates – SURFONIC® E Series Surfactants Castor Oil Ethoxylates – SURFONIC® CO Series Surfactants The SURFONIC® E series fatty acid ethoxylates and the SURFONIC CO® series castor oil ethoxylates produced by Huntsman are important groups of products in the formulation of metalworking lubricants. The SURFONIC CO series castor oil ethoxylates are excellent emulsifiers for many oils used in metalworking. The large size of the castor oil hydrophobe helps the ethoxylated castor oil stay partially in the oil phase even when highly ethoxylated or used in formulations with high water/oil ratios. The castor oil ethoxylates are generally low foaming. (especially the dioleates) generally are soluble in the kerosene-type cuts used in traditional cold rolling lubricants. The PEG esters are also stable in the fatty alcohol products used in the same application. Excellent aluminum rolling oils can be produced using blends of PEG diesters, castor oil ethoxylates, fatty alcohols such as SURFOL® 1416 alcohol and phosphate esters like SURFONIC PE-2258 surfactant with alkanolamines such as DIGLYCOLAMINE® Agent. Properties of the SURFONIC E series PEG ester and the SURFONIC CO series castor oil ethoxylates are shown in Table 3.6. Typically, PEG esters offer lower staining potential on aluminum than straight fatty acids. The PEG esters Table 3.5 - SURFONIC® E Series Fatty Acid Ethoxylates SURFONIC® CO Series Castor Oil Ethoxylates Appearance at 25°C HLB Specific Gravity, 25/25°C E400-MO Liquid 11.8 1.013 CO-15 Liquid 8.2 1.04 CO-25 Liquid 10.7 CO-30 Liquid 11.7 SURFONIC Product 1 2 ® Falex Wear1, Ross Miles # teeth at Foam Height2, Viscosity, 875 lbs mm, Initial/ 100 SUS cPs, 25°C direct load 5 minute Naphthenic Solubility 100 SUS Paraffinic Water Function 40 5/0 I I D Emulsifier and lubricity additive. 59 64 2.5/2 I S I Emulsifier for oil-based formulations. 1.03 66 55 4.4/3 I S I Emulsifier for oil-based formulations. 1.04 71 80 5.1/3 I S I Hydrophilic emulsifier for oil-based formulations. Formulation: 3% surfactant, 1% TEA-99 in water 0.1% solution, 120°F 41 SECTION 3 Surfactants for the Metalworking Industry Phosphate Esters – SURFONIC® PE Series Surfactants Phosphate esters provide extreme pressure properties to water-based and semisynthetic formulations. Additionally they provide lubricity and emulsification of other actives in metalworking formulations and they solubilize nonionic surfactants into caustic- or silicatecontaining metal cleaning formulations. Many of the phosphate esters also offer some cleaning activity in metal cleaning operations. The phosphate esters in the SURFONIC® PE product family also provide corrosion resistance in many formulations. Properties of the SURFONIC PE series products are given in Table 3.7. SURFONIC PE-2258 phosphate ester gives excellent extreme pressure (EP) performance. Micrographs showing actual Falex pin-and-vee blocks from several EP tests are presented in Figures 3.5a and 3.5b. SURFONIC PE-1218 phosphate ester is able to solubilize nonionic surfactants in high electrolyte solutions such as those containing sodium silicate; this is particularly useful in cleaner formulations where the silicate is added to increase alkalinity and to provide corrosion inhibition. Table 3.7 - SURFONIC® PE Series Phosphate Esters 2 Falex EP in 100 SUS Naphthenic Oil (2% Surfactant in 100 SUS Naphthenic Oil) Max Load1, Torque at Carried, psi 4500 psi Hydrophobe Acid # at pH 5-5.5 Acid # at pH 9-9 PE-1198 Aromatic 68 103 80/40 85/32 4700 41 750 59 at 750 psi Hydrotrope in cleaners, EP in water-based systems PE-2258 Aliphatic 83 135 97/53 91/53 4700 61 4700 48 Solubilizer in semisynthetics, offers mild EP, good lubricity PE-1218 Aromatic 115 220 98/53 95/52 2700 90 750 19 at 750 psi Hydrotrope for cleaners PE-1265 Aliphatic 76 135 PE-2852 Aliphatic 97 142 PE-533 Aliphatic 65 100 PE-BP2 Aliphatic PE-2200 Aliphatic SURFONIC Product 1 Foam Height2, mm, Initial/5 min., 114 PPM Hardness (response to nonionic) Foam Height1, mm, Initial/5 min., 114 PPM Hardness ® Falex EP in water (1.5% Surfactant 2% TEA-99) Max Load Torque at Carried, psi 4500 psi Function 310 Neutralized Neutralized Formulation for foam height test: Phosphate ester (1.5%), TEA-99 (3.0%), Water 114 ppm hardness (94.5%). Formulation for foam height test for response to nonionic: Phosphate ester (1.5%), TEA-99 (3.0%), SURFONIC® LF-18 surfactant (1.5%), Water (94%). 42 Surfactants for the Metalworking Industry Figure 3.5a - Micrograph of Vee Block from Pin-and-Vee Test with SURFONIC® PE-2258 Phosphate Esters Figure 3.5b - Micrograph of Pin from Pin-and-Vee Test with SURFONIC PE-2258 Phosphate Esters 43 SECTION 3 Surfactants for the Metalworking Industry Formulated Emulsifiers – SURFONIC® MW-100 Additive SURFONIC® MW-100 additive is a single-component emulsifier for vegetable oil. This emulsifier is designed to enhance the metalworking properties of vegetable oilbased lubricants. Table 3.8 - Features and Benefits of SURFONIC® MW-100 Additive • • • • • 44 Inherently low-foaming Compatible with phosphate esters for extreme pressure service Useful in formulating stable macro- or microemulsions Low pour point (-2°C) for easy handling Low toxicity SECTION 4 Other Products for the Metalworking Industry Huntsman produces a number of other chemicals useful in the metalworking industry, from chemical intermediates to functional fluids to various glycols. Linear Alkylbenzene Highboiler for Sulfonation Feedstock – Alkylate H-230L Alkylate H-230L, a synthetic sulfonation feedstock widely used in the metalworking industry to augment natural sodium petroleum sulfonate, is produced by the alkylation of benzene with olefins using an HF-catalyzed process. The product is a blend of alkyl tetralins, dialkyl benzenes, and alkyl naphthalenes and diphenyl alkanes. The carbon number distribution peaks at C23. diphenylalkanes is shown in Table 4.1; structures are illustrated in Figure 4.2. The structures for the important constituents of this product are shown in Figure 4.1. The typical carbon distribution of the dialkylbenzenes, tetralins, and Sulfonation can be accomplished using air/SO3 or oleum. The actual reaction conditions will vary according to the desired product and process used for sulfonation. The actual level of each chemical species depends on the alkylation feedstock. The average molecular weight of Alkylate H-230L varies from 315-320, giving average sulfonic acid molecular weights of 413-418 g/mole. Table 4.1 - Distribution of Chemical Types in Alkylate H-230L Component Percent Alkyl- and Dialkylbenzenes 74.2 Tetralins/Indanes 10.3 Dihydronaphthalenes/Indenes 1.8 Alkylnaphthalenes 3.9 Diphenylalkanes 6.5 Diphenylalkenes 3.2 Anthracenes 0.2 45 SECTION 4 Other Products for the Metalworking Industry Figure 4.1 - Carbon Number Distribution of Alkylate H-230L 46 Other Products for the Metalworking Industry Figure 4.2 - Alkylate H-230 L Constituents Alkyltetralins Alkylindanes Alkyldehydro naphthalenes Alkylindenes Alkylnaphthalenes Condensed Aromatics Diphenylalkanes 47 SECTION 4 Other Products for the Metalworking Industry JEFFOX® WL Series Functional Fluids The JEFFOX® functional fluids are alkoxylates of mono-, di- or tri-functional starting materials. These versatile fluids have varying degrees of solubility in water and oil. As lubricants, the fluids possess many desirable properties of natural lubricants and have distinctive properties of their own which recommend their use in difficult applications such as metalworking fluids and machine lubricants. The JEFFOX fluids have good lubricating ability, even under high pressure, and high viscosity indexes, which enable them to be used over a wide range of temperatures. In metalworking applications, the fluids permit high production rates, excellent finishes and longer tool life. Water-soluble fluids are especially convenient because they may be washed from the work piece with cool water to permit finishing operations. The higher molecular weight JEFFOX WL fluids exhibit inverse solubility behavior with respect to temperature. This property can be used advantageously in water-based metalworking fluids. When the water-based fluid comes in contact with the hot tool and work piece, the lubricant drops out of the solution and coats the metal surface. This behavior takes full advantage of the cooling capability of water and the excellent lubricity of the base fluid. Because the JEFFOX fluids are transparent liquids, they allow delicate operations on small metal pieces to be observed easily. Typical applications include: • steel deep drawing • tempered spring steel pressing • nickel-plated steel drawing • copper drawing The fluids can also act as carriers for diamond powder cutting or polishing agents. Properties of the JEFFOX functional fluids are listed in Table 4.2. Table 4.2 - JEFFOX® Functional Fluids JEFFOX® Product Average Molecular Weight Functionality Appearance at 25°C Viscosity, SUS, 100°F WL-440 488 Tri Clear liquid WL-590 990 Tri WL-660 1800 WL-1400X2 WL-5000 48 150°F Density, lb/gal 20°C Flash Point, COC, °F Pour Point, °F 100 30 9.6 545 -30 508 135 43 9.3 500 0 660 471 158 60 8.7 475 -45 Clear amber liquid 1400 970 299 109 9.2 595 0 Clear amber liquid 5000 3556 1107 409 8.8 460 -10 60°F Viscosity, cSt 100°F 440 386 Clear liquid 590 Mono Clear liquid 2500 Di 4365 Mono Other Products for the Metalworking Industry Polyethylene Glycols -- POGOL® Series PEGs Huntsman manufactures a number of polyethylene glycol products. The POGOL product family has numerous uses in metalworking and allied industries. The largest use of the POGOL products is the manufacture of PEG esters; through reaction of polyethylene glycol with fatty acids such as lauric, oleic, tall oil, castor and soya fatty acids, very useful lubricants can be produced. Typically the reaction is carried out between 140°C and 250°C with a nitrogen purge. Catalysts are not necessary but they do substantially increase the reaction rate. For the lightest color products, noncatalytic procedures are used. Color inhibitors can be added to the product to give yet lighter products. Typical catalysts, such as pTSA, methane sulfonic acid and tin-based catalysts can be used or sodium bisulfite can also be used. Typical levels of catalyst are from 0.1% to 1% of the raw materials. The POGOL polyethylene glycols are also useful additives in hydraulic fluids where they offer suitable lubricity and compatibility and can be conveniently formulated with phosphate esters for extreme pressure (EP) properties. The products act as thickening agents and can be used for viscosity control. POGOL 200 polyethylene glycol can be used as a dispersant and carrier in the production of silicon carbide slurries by attrition grinding. Typically a 35% aqueous suspension can be produced, stabilized by about 3% of POGOL 200 glycol. POGOL products can also be used in the machining of silicon wafers or for other semiconductor uses. Lapping compounds to polish metal or semiconductor surfaces are produced using POGOL polyethylene glycols; the polyethylene glycol products help to disperse the lapping abrasive. The high water solubility of the POGOL products makes it easy to rinse the polished substrate cleanly. Some POGOL products are used as carrier solvents for release agents in aluminum die cast operations. Characteristics and properties of the POGOL® polyethylene glycols are shown in Table 4.3. Table 4.3 - POGOL® Polyethylene Glycols POGOL® Product Average Molecular Weight Molecular Weight Range Average EO Units Density, g/ml at 20°C Melt/Freeze Range, °C Viscosity, cSt at 37.8°C Flash Point, PMCC °F Pt-Co Color pH, 5% aqueous 200 200 190-210 4.2 1.124 - 25 >300 <50 5.5 - 7.0 300 300 285-315 6.4 1.125 -15 to -8 37 >350 <50 5.5 - 7.0 400 400 380-420 8.7 1.125 4 to 8 42 390 <50 5.5 - 7.0 600 600 570-630 13.2 1.126 20 to 25 64 410 <50 5.5 - 7.0 49 SECTION 5 Regional Product Offerings Primary Amines Monoethanolamine DIGLYCOLAMINE® Agent SURFONAMINE® MW-781 amine Tertiary Amines Triethanolamine BHEMA Alkoxylated Amines SURFONIC® PEA-25 surfactant SURFONIC® T amine surfactants Polyetheramines JEFFAMINE® D series amines JEFFAMINE® T-403 amine SURFONAMINE® MNPA-1000 amine Linear Alcohols SURFOL® 1214 fatty alcohol SURFOL® 1416 fatty alcohol Alcohol Ethoxylates SURFONIC® L series surfactants Alcohol Alkoxylates SURFONIC® LF series surfactants SURFONIC® P series surfactants Alkylphenol Ethoxylates SURFONIC® N series surfactants SURFONIC® OP series surfactants Fatty Acid Ethoxylates SURFONIC® E400-MO surfactant 50 Intermediates Anti-mist Additives Hard Water Tolerance Aids Metal Cleaning Aids Anti-Foamants Coupling Agents Lubricity Additives Emulsifiers Corrosion Inhibitors Product Alkalinity Control Table 5.1 - Huntsman Products for the Metalworking Industry – North America Regional Product Offerings Intermediates Continued Anti-mist Additives Hard Water Tolerance Aids Metal Cleaning Aids Anti-Foamants Coupling Agents Lubricity Additives Emulsifiers Corrosion Inhibitors Product Alkalinity Control Table 5.1 - Huntsman Products for the Metalworking Industry – North America Castor Oil Ethoxylates SURFONIC® CO series surfactants EO/PO Block and Reverse Block Copolymers SURFONIC® POA series surfactants Phosphate Esters SURFONIC® PE-1198 surfactant SURFONIC® PE-BP2 surfactant Sodium Isethionate Functional Fluids JEFFOX® functional fluids Glycols Diethylene glycol Propylene glycol POGOL® polyethylene glycols 51 SECTION 5 Regional Product Offerings Primary Amines DIGLYCOLAMINE® Agent SURFONAMINE® MW-781 amine Monoethanolamine Tertiary Amines BHEMA Alkoxylated Amines EMPILAN® AMT series surfactants Triethanolamine Polyetheramines JEFFAMINE® D series amines JEFFAMINE® T-403 amine SURFONAMINE® MNPA-1000 amine Linear Alcohols LAUREX® fatty alcohols Alcohol Ethoxylates EMPILAN® K series surfactants Alcohol Alkoxylates EMPILAN® PF series surfactants SURFONIC® LF series surfactants SURFONIC® P series surfactants Alkylphenol Ethoxylates EMPILAN® NP series surfactants EMPILAN® OPE series surfactants Fatty Acid Ethoxylates EMPILAN® BQ series surfactants 52 Intermediates Anti-mist Additives Hard Water Tolerance Aids Metal Cleaning Aids Anti-Foamants Coupling Agents Lubricity Additives Emulsifiers Corrosion Inhibitors Product Alkalinity Control Table 5.2 - Huntsman Products for the Metalworking Industry – Europe Regional Product Offerings Intermediates Anti-mist Additives Continued Hard Water Tolerance Aids Metal Cleaning Aids Anti-Foamants Coupling Agents Lubricity Additives Emulsifiers Corrosion Inhibitors Product Alkalinity Control Table 5.2 - Huntsman Products for the Metalworking Industry – Europe Castor Oil Ethoxylates DEHSCOFIX® CO series surfactants EO/PO Block and Reverse Block Copolymers EMPILAN® P series surfactants Phosphate Esters EMPIPHOS® O3D surfactant EMPIPHOS® A5D surfactant EMPIPHOS® DF series surfactants Functional Fluids JEFFOX® functional fluids Ether Carboxylates EMPICOL® C series surfactants Fatty Alkanolamides EMPILAN® alkanolamides 53 SECTION 6 Regional Contact Information HUNTSMAN PERFORMANCE PRODUCTS Americas Europe Asia-Pacific Business Offices 10003 Woodloch Forest Drive The Woodlands, TX 77380 281-719-6000 281-719-6416 fax Huntsman Belgium BVBA Everslaan 45 B-3078 Everberg, Belgium Huntsman (Singapore) Pte Ltd 150 Beach Road #14-05/08 Gateway West Singapore 189720 +65 6390 0371 +65 6296 3368 fax Huntsman Belgium BVBA Everslaan 45 B-3078 Everberg, Belgium Huntsman Corporation Australia Pty Ltd 61 Market Road Brooklyn, Victoria 3012 Australia +61 3 9933 6633 +61 3 9933 6600 fax Marketing 281-719-6000 281-719-6055 fax +44-1946-694108 +44-1946-694891 fax +60 3 7954 0842 +60 3 7958 1677 fax Research & Development 281-719-7400 281-719-7555 fax +44-121-550-6187 +44-121-550-1765 fax 281-719-7400 281-719-7555 fax Technical Services 281-719-7780 281-719-7555 fax +44-121-550-6187 +44-121-550-1765 fax +61 3 9933 6666 +61 3 9933 6600 fax Technology Center Huntsman Advanced Technology Center 8600 Gosling Road The Woodlands, TX 77381 281-719-7400 281-719-7500 fax Customer Service 800-852-4957 54 +65 6390 0371 Copyright ©2005 Huntsman Corporation Huntsman Corporation warrants only that its products meet the specifications stated herein. Typical properties, where stated, are to be considered as representative of current production and should not be treated as specifications. While all the information presented in this document is believed to be reliable and to represent the best available data on these products, NO GUARANTEE, WARRANTY, OR REPRESENTATION IS MADE, INTENDED, OR IMPLIED AS TO THE CORRECTNESS OR SUFFICIENCY OF ANY INFORMATION, OR AS TO THE SUITABILITY OF ANY CHEMICAL COMPOUNDS FOR ANY PARTICULAR USE, OR THAT ANY CHEMICAL COMPOUNDS OR USE THEREOF ARE NOT SUBJECT TO A CLAIM BY A THIRD PARTY FOR INFRINGEMENT OF ANY PATENT OR OTHER INTELLECTUAL PROPERTY RIGHT. EACH USER SHOULD CONDUCT A SUFFICIENT INVESTIGATION TO ESTABLISH THE SUITABILITY OF ANY PRODUCT FOR ITS INTENDED USE. Products may be toxic and require special precautions in handling. For all products listed, user should obtain detailed information on toxicity, together with proper shipping, handling, and storage procedures, and comply with all applicable safety and environmental standards. 10003 Woodloch Forest Drive The Woodlands, Texas 77380 281-719-6000 Technical Services Section 8600 Gosling Rd. The Woodlands, Texas 77381 281-719-7780 www.huntsman.com/metalworking NYSE: HUN ©2005 HUNTSMAN CORPORATION