product data sheet TGL ISO SLP BT 60

advertisement

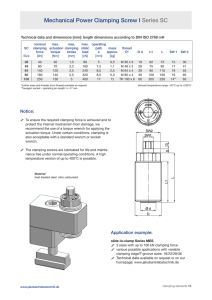

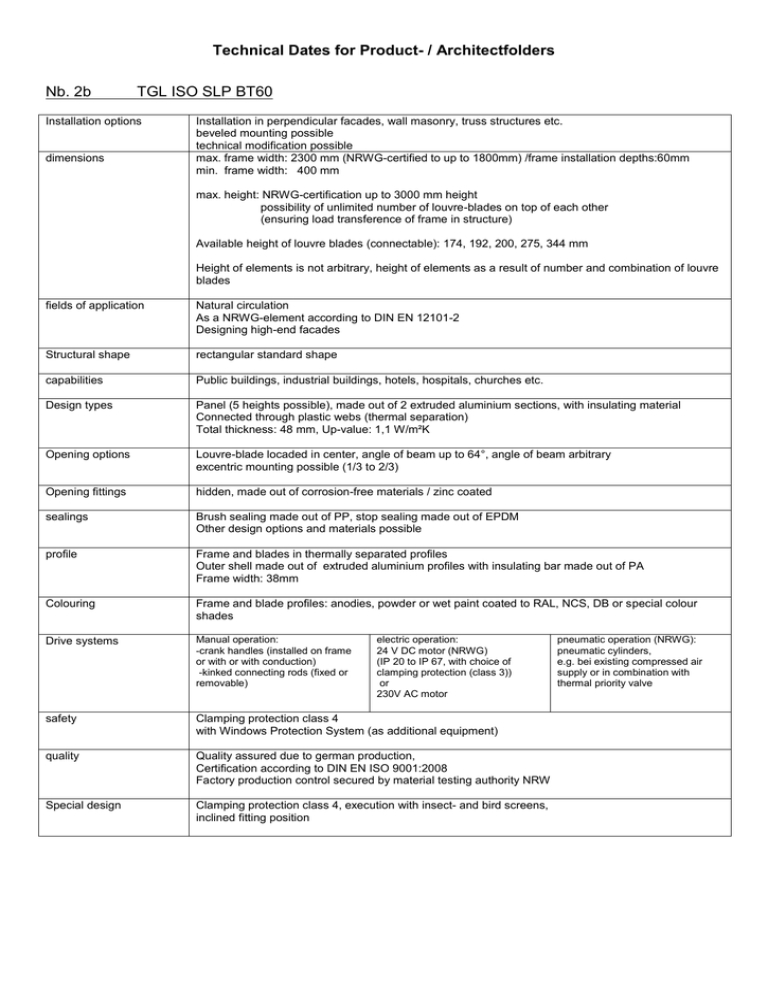

Technical Dates for Product- / Architectfolders Nb. 2b TGL ISO SLP BT60 Installation options dimensions Installation in perpendicular facades, wall masonry, truss structures etc. beveled mounting possible technical modification possible max. frame width: 2300 mm (NRWG-certified to up to 1800mm) /frame installation depths:60mm min. frame width: 400 mm max. height: NRWG-certification up to 3000 mm height possibility of unlimited number of louvre-blades on top of each other (ensuring load transference of frame in structure) Available height of louvre blades (connectable): 174, 192, 200, 275, 344 mm Height of elements is not arbitrary, height of elements as a result of number and combination of louvre blades fields of application Natural circulation As a NRWG-element according to DIN EN 12101-2 Designing high-end facades Structural shape rectangular standard shape capabilities Public buildings, industrial buildings, hotels, hospitals, churches etc. Design types Panel (5 heights possible), made out of 2 extruded aluminium sections, with insulating material Connected through plastic webs (thermal separation) Total thickness: 48 mm, Up-value: 1,1 W/m²K Opening options Louvre-blade locaded in center, angle of beam up to 64°, angle of beam arbitrary excentric mounting possible (1/3 to 2/3) Opening fittings hidden, made out of corrosion-free materials / zinc coated sealings Brush sealing made out of PP, stop sealing made out of EPDM Other design options and materials possible profile Frame and blades in thermally separated profiles Outer shell made out of extruded aluminium profiles with insulating bar made out of PA Frame width: 38mm Colouring Frame and blade profiles: anodies, powder or wet paint coated to RAL, NCS, DB or special colour shades Drive systems Manual operation: -crank handles (installed on frame or with or with conduction) -kinked connecting rods (fixed or removable) safety Clamping protection class 4 with Windows Protection System (as additional equipment) quality Quality assured due to german production, Certification according to DIN EN ISO 9001:2008 Factory production control secured by material testing authority NRW Special design Clamping protection class 4, execution with insect- and bird screens, inclined fitting position electric operation: 24 V DC motor (NRWG) (IP 20 to IP 67, with choice of clamping protection (class 3)) or 230V AC motor pneumatic operation (NRWG): pneumatic cylinders, e.g. bei existing compressed air supply or in combination with thermal priority valve