Life Cycle Cost Checklist

advertisement

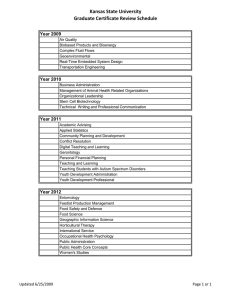

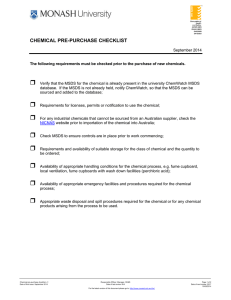

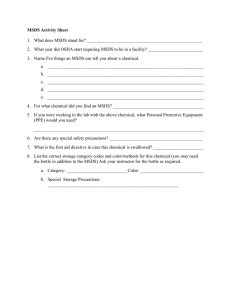

Biobased Product Life Cycle Cost Checklist and User Guide Contents Section 1 Introduction…………………………………………………………….2 Section 2 Checklist Overview.…………………………………………………...3 Section 3 User Guide Description.............……………………………………...3 Section 4 Description of Appendices…………………………………………….5 Appendices Appendix A Life Cycle Checklist Form……..……………………………………7 Appendix B Life Cycle Checklist User Guide……………………………….…..9 Appendix C Interpreting Information from a Material Safety Data Sheet…...17 Appendix D Interpreting Hazard Information from a National Fire Protection Association (NFPA) label………………………….….18 Appendix E Interpreting Hazard Information from a Hazardous Material Information System (HMIS) label……………………....19 Appendix F Examples of Filled Out Checklists FR3® Transformer fluid………………………………….…20 Bean-e-doo® Mastic remover……………………………..22 1 Biobased Product Life Cycle Cost Checklist and User Guide 1. Introduction Federal agencies are required to purchase biobased products. This requirement has been supported by The Food, Conservation and Energy Act of 2008, the Farm Security and Rural Investment Act of 2002, various Presidential Executive Orders and the Federal Acquisition Regulation (FAR). Under its BioPerferredSM Program, the U.S. Department of Agriculture (USDA) has issued rules listing product categories that identify “designated items” for biobased purchasing preference. This life cycle checklist has been developed 1 for potential buyers to better understand and evaluate the life cycle costs of using biobased products compared to non-biobased products. The selection of a product should not be based solely on the initial purchase price but rather a comparison should be made with the competing product in all aspects such as performance per unit used, safety and health, environmental impact and end-of-life fate. Very few products are equal in all these aspects and attendant costs, thus the initial purchase price is but one factor that should be considered during the procurement decision-making process. Use of a product life cycle checklist can be a useful tool for identifying and analyzing key differences between biobased and non-biobased products. The checklist can help differentiate biobased product characteristics than may not be readily apparent but, when considered over the useful product life, can frequently provide cost saving benefits. These benefits can be in the form of enhanced performance and/or worker safety, and reduced environmental impacts. The questions on the checklist are designed to identify aspects of a product that would frequently have cost implications during the use and disposal phases. These costs could then considered along with the product initial cost to arrive at an estimated “life cycle” cost. Once this information is known, the purchaser is in a better position to determine if a true cost differential exists between the biobased and non-biobased products. The checklist may also be used when different biobased products are being compared. 1 The United Soybean Board (USB) funded Omni Tech International, Ltd to develop this checklist and supporting materials. USB is made up of 68 farmer-directors who oversee the investments of the soybean checkoff on behalf of all U.S. soybean farmers. As stipulated in the Soybean Promotion, Research and Consumer Information Act, USDA's Agricultural Marketing Service has oversight responsibilities for USB and the soybean checkoff. 2 The process used to collect information for the development of this checklist utilized several sources including: 1. Published case studies of biobased product use by governmental agencies 2. Interviews with government people using biobased products 3. Vendors who are selling biobased products to governmental agencies 4. Personnel who have developed general biobased purchasing procedures for governmental rulemaking Collectively these sources provided a perspective that produced a checklist that will have applicability with any product evaluation and assessment. The checklist was “test driven” using two biobased products that successfully compete with petroleum based products having lower initial purchase costs. The checklist illustrated and verified the life cycle benefits of the biobased products in an objective and credible manner, thus supporting the decision to purchase these products. This checklist will serve as a valuable tool in supporting the choice of many biobased products when compared to nonbiobased products over the entire life cycle and thus include important aspects of safety, health and the environment in the purchasing decision. This document includes the checklist which can be used as a record for the collection of information, an accompanying guidance for how and where to gather information, appendices on how to use and interpret information from specific sources, and two examples of a filled out checklist using commercially available biobased products now being purchased by government agencies. 2. Checklist Overview The checklist is two pages and can be found in Appendix A. Copies can be photocopied for use or an electronic version can be accessed at: http://www.soybiobased.org/lifecyclechecklist The downloaded checklist may be filled out electronically and filed as a record. The checklist is designed to help identify important differences between biobased and non-biobased products. The questions contained in the checklist are based on interviews, literature searches, and actual experiences of federal government personnel who have purchased and used different types of biobased products in a wide variety of applications. Their experiences have identified the positive and negative characteristics of comparable products and, in many cases, have demonstrated that some biobased products have lower life cycle costs, although their initial cost is higher. Use of this checklist will 3 help to determine if a biobased product is the best overall choice. 3. User Guide Description The Checklist User Guide can be found in Appendix B. The questions on the checklist are arranged into the following four categories: • • • • Performance Safety and health Environmental Disposal In addition, the initial purchase costs of a biobased and non-biobased product are to be listed. Some questions may not apply to every type of product use but consideration should be given to answering as many questions as possible to support the purchasing decision. The checklist provides suggestions on where to find specific information for the products being considered. Those sources of information can be: • • • • • Material data safety sheets (MSDS) from the vendor’ website or provided by the Vendor Product literature provided by the vendor Product labels provided by the vendor Case studies from government agencies http://www.biopreferred.gov/CaseStudies.aspx Case studies from other sources (e.g. http://www.soybiobased.org/profiles) Each question on the checklist is described along with guidance on how to assess the differences between products. If a difference can be identified, an “x” is to be placed in either the “YES” or “NO” box following each question. If there is no difference, an “x” is to be placed in the “ND” (no difference) box. In support of the decision, the relevant data and the source of the information can be stated in the “Product Data/Reference” column. At the end of the checklist, the number of “yes” responses is reviewed to determine if there are life cycle benefits that outweigh initial cost differences between the biobased product and the alternative product. A final comment may be added as to why these benefits did or did not make the biobased product the preferred choice for purchase. In some cases, product differences will be easy to compare while, in other cases, the differences will be more difficult to quantify or assign a monetary 4 value. The following are some potential suggestions on how to keep differences in perspective: • Information on all checklist questions may not be readily available. Suggestion: Some questions may not apply to every type of product use so do not spend much time trying to obtain an answer if the question does not appear to apply to the product application. • There appears to be much emphasis on using a Material Safety Data Sheet (MSDS) for information. How can information from the MSDS be converted to monetary value? Suggestion: The MSDS is the federal worker “right-to-know” source for product hazard and regulatory information. (See Appendix B for assistance in interpreting hazard and regulatory information from a MSDS.) Once those hazards are identified, the user can then estimate the cost of protecting the worker and nearby people from those hazards. This cost can then be added into the life cycle cost of the product. This is a situation where the procurement person should consult with the product user to assure any hazard risk is being properly recognized along with the cost of managing that risk to meet regulatory requirements. • Some environmental, health and safety (EHS) differences and benefits may be difficult to assign a monetary value. How should that situation be handled? Suggestion: This situation may best be handled by the procurement person seeking input from the person or persons who will be using the product to see how they value these differences since they most probably will know what the cost and kind of controls that will be necessary to handle those differences. If the government agency or user group has an EHS staff expert, that person should also be consulted for cost/benefit information. Finally, to derive the most benefit from this checklist evaluation tool, it is recommended that the purchasing person seek the input of those who will be using the product and fellow agency experts who are knowledgeable in health, safety and environmental regulations that could apply to the products being compared. Those aspects have been shown to cost implications and those sources can assist defining their relative importance and cost of management. To optimize the effectiveness of the life cycle checklist, make this evaluation a team exercise. 4. Description of Appendices The following appendices provide more detailed information and examples of how the checklist can be used. 5 • Appendix C describes how to use and interpret information on a MSDS. • Appendix D describes the label developed by the National Fire Protection Association (NFPA). • Appendix E describes how to use and interpret information on the Hazardous Materials Identification System label developed by the National Paint & Coatings Association (NPCA). • Appendix F includes examples of filled out checklists using two commercially available biobased products being purchased by government agencies. 6 Appendix A LIFE CYCLE CHECKLIST Product Cost ($/unit) Biobased: Alternative: Life Cycle Criteria - as compared to the alternative product: YES I. Performance A. Has the biobased product been successfully used at other federal facilities? (see case studies on "www.BioPreferred.gov/CaseStudies.aspx") B. Will the biobased product require less material to perform the job or last longer during use? (see case studies or product literature) C. Can the biobased product be used with existing equipment and procedures? (see case studies, product literature or consult with vendor) D. Will use of the biobased product lead to less equipment wear and/or reduced maintenance? (see case studies or product literature) E. Does the biobased product offer any other performance benefits such as reduced product inventory, energy to use, etc. (see case studies or product literature) II. Safety and Health A. Is the biobased product less flammable? [See flash pt. from MSDS Sec. V or (or equivalent section of MSDS) or number in red section of NFPA label or HMIS label or product literature] B. Does the biobased product pose less exposure risk to employees in the form of irritation to skin, lungs or eyes? [Find acute health effects from MSDS Sec. 3 or 8 (or other equivalent sections of MSDS) or blue section of NFPA or HMIS labels] C. Can the biobased product be used with less restrictive requirements for personal protective equipment (PPE)? [see case studies or control measures from MSDS Sec. 8 (or equivalent section of MSDS) or verify with vendors] D. Is biobased product less volatile (less likely to evaporate) leading to less inhalation and/or odor irritation exposure to employees? [volatile content or odor information - MSDS Sec. 3 or 9 (or equivalent sections of MSDS), product literature or product label] E. Are there any other known or perceived safety and health benefits of the biobased product such as the absence of toxic, hazardous or carcinogenic chemicals, etc.? [see MSDS Sec. 3 or 11 (or equivalent sections of MSDS), product literature or case studies] 7 NO N/D Product Data/Reference Appendix A LIFE CYCLE CHECKLIST Product Cost ($/unit) Biobased: Alternative: Life Cycle Criteria - as compared to the alternative product: YES NO N/D III. Environmental A. In the event of a spill to the environment, will the biobased product have less costly cleanup requirements and have less impact due to more rapid biodegradibility and less toxicity? [see case studies, MSDS Sec. 6 or 12 (or equivalent sections of MSDS) or product literature] B. Does the biobased product contain any or lower levels of ozone depleting substances (ODS) or hazardous air pollutants (HAPs) compared to the alternate product? [see MSDS Sec. 2 or 15 (or equivalent sections of the MSDS) or verify with supplier or see product literature] C. Will the biobased product have less smog forming potential due to lower volatile organic compound (VOC) content? [see product literature or product label for VOC content or MSDS Sec. 9 (or equivalent section of the MSDS)] D Will use of the biobased product support your agency's stated environmental procurement policies and objectives? IV. Disposal A. At the end of its usable life, will the biobased product be more readily recyclable than the alternate product? (see case studies or ask vendors) B. If the used product cannot be recycled, will the biobased product qualify to be handled under less stringent disposal requirements or other regulated management options such as waste fuel blending for energy recovery? [verify with vendor, see case studies or MSDS Sec. 15 (or equivalent section in the MSDS) for RCRA classification, if applicable. YES V. Summary Does the value of the life cycle benefits outweigh any initial purchase cost difference? 8 NO Product Data/Reference Appendix B: The Life Cycle Checklist Guide I. Performance Questions A. Has the biobased product been successfully used at other federal facilities? The USDA BioPreferred website has many case studies describing where biobased products have been successfully used by federal agencies. See www.biopreferred.gov/CaseStudies.aspx B. Will the biobased product require less material to perform the job or last longer during use? Many biobased products have shown enhanced performance towards a specific task by either requiring less material per application or lasting longer. Biobased parts cleaning solutions frequently last longer on an equal weight basis compared to petroleum based solvents. Vegetable based transformer oil has provided longer transformer life as the oil provides better insulation paper thermal stability. Less biobased mastic remover is required because it evaporates much less slowly than a hydrocarbon based remover and, therefore, stays in contact with the adhesive longer. The above performance metrics illustrate potential life cycle cost savings. C. Can the biobased product be used with existing equipment and procedures? Some biobased products may require different rubber gaskets or other fittings to be used in existing equipment while others may not require any changes. For example, when Brookhaven National Lab updated their older and leaking hydraulic vehicle lifts systems, they replaced the rubber gaskets and seals with Teflon® and Rulon® to assure full compatibility with the biobased hydraulic fluid. A “no” response here should not prohibit the purchase of a biobased product, but the cost of retrofitting equipment or changing a procedure will have to be balanced against the other identified life cycle benefits. D. Will the use of the biobased product lead to less equipment wear and/or reduced maintenance? Some biobased products (especially hydraulic and cutting fluids) have been shown to produce less wear on metal parts and tools. Biobased products such as lubricants have extended the maintenance schedule needed to maintain equipment. These two attributes result in cost savings. See case studies or product literature for claims or consult with a user of the biobased product under consideration. 9 E. Does the biobased product offer any other performance benefits such as reduced product inventory, energy to use, etc? Some federal agency users have reported that their purchasing and use of biobased cleaning products have enabled them to substantially reduce the number of cleaning products needed to maintain their facilities resulting in cost savings. This reduction is possible due to the fact that some biobased cleaning products can perform on many different types of surfaces rather than have a different cleaner for each type of surface. See case study of Yellowstone and Grand Teton National Parks: www.cleanenvironmentco.com/success/index.htm. II. Safety and Health Questions A. Is the biobased product less flammable? The flammability of a product is a measure of how easily it can ignite and burn. Highly flammable products give off fumes which, in the presence of a spark source, can lead to an explosion or fire. Flammability hazard is expressed as the “flash point” temperature at which the product will readily ignite. When comparing two materials, the one with a higher flash point is less flammable. The Department of Transportation (DOT) defines a flammable liquid as having a flash point of less than 100°F. For example, a biobased paint remover like Soy Strip, which is used at the Portsmouth Naval Shipyard, has a flash point of over 200°F while a petroleum counterpart such as Strypeeze, has a flash point of less than 20°F, therefore, the biobased product can be used with less potential for causing a fire in the presence of a spark source or heating device. Many petroleum based solvents, including gasoline, do have flash points below 100°F and those product containers must be marked with a red diamond indicating that hazard. A combustible liquid has a flash point range between 100° and 200°F as defined by DOT. Diesel fuel or heating oil falls into this flash point range. Many biobased products have flash points above 200°F. Products having higher flash points offer the following advantages: • • • • Reduced fire hazard Better dissipation of heat (important for cutting fluids and hydraulic fluids) Less smoke and fumes when exposed to higher temperatures Less inhalation risk Flammability and flash point information can be found in the Material Safety Data Sheet (MSDS) under the Fire Fighting Measures which is usually Section 5 but may be found elsewhere on the MSDS. The MSDS will also provide either a National Fire Protection Association (NFPA) fire hazard rating of 0-4 with “4” being the most flammable. Try to avoid selecting a product with a NFPA rating of 10 3 or 4. Another flammability rating system found in a MSDS is the Hazardous Material Information System (HMIS). HMIS was developed by the National Paint & Coatings Industry and it also uses a numbering system of 0-4. See Appendix D and E, respectively, for more information on how to interpret the NFPA and HMIS numbering systems. Other sources where flammability or flash point information can be found are product literature, product labels and product shipping papers. If these sources are not readily available, ask the vendor for the information. B. Does the biobased product pose less exposure risk to employees in the form of irritation to skin, lungs or eyes? Human exposure to products is an important concern especially when considered over the life cycle of product use. That exposure risk can be from the inhalation of vapor or direct contact with the skin or eyes. Most biobased products such as cleaning agents, paint strippers, mastic removers and lubricants have a more favorable exposure risk profile when compared to their petroleum based counterparts. To compare exposure risk, one can view the MSDS for inhalation and skin contact severity. This information is usually located in the Hazards Identification or Exposure Limits sections. For inhalation risk, it will be expressed as PEL (permissible exposure limit) and Time Weighted Average (TWA) expressed in parts per million or mg per cubic meter of air volume. Time Weighted Average is measured over an eight hour work shift. When possible, select the product that has a higher PEL-TWA number as this means a person can normally breathe a higher concentration of the product vapor without suffering adverse irritation or health effects. The NFPA diamond and HMIS label also include a health rating numbering system. The blue diamond within the larger NFPA diamond provides a 0-4 rating for health exposure. Any number 2 or greater requires protection from the vapor. The HMIS label also contains a blue colored bar with a number from 0-4. Avoid selecting a product with a HMIS health number 3 or 4 since those products can pose major health risk. NFPA and HMIS numbers can usually be found in the MSDS or product label. The life cycle cost of adverse human health exposure can be significant. Examples of those costs can include: • • • Lost work time for the employee to recover Medical costs for treatment Overtime cost to cover for the absence of the injured employee C. Can the biobased product be used with less restrictive requirements for personal protective equipment (PPE)? 11 Many products require the use of PPE either because of the potential effects of direct product exposure or because of related exposures that can be caused by the way the product is used or performs. Depending on exposure risk, PPE can be in the form of gloves, eye protection, aprons, safety shoes, breathing masks and respirators. The level or type of PPE is determined by information on the MSDS, usually in Sec. 8. Normally a worker prefers to wear as little PPE as required since it can restrict movement, vision or body cooling in a warm environment. PPE requirements can also add to the cost of using a product, so when less PPE is required, there should be less cost incurred from using that product. PPE information can also be found on the bottom of the HMIS label where a lettering system (A-K) will define the level of PPE required. The letter “A” means minimal PPE (safety glasses) required while “K” will require full body and breathing PPE. An example of where a biobased product requires less stringent PPE is the soy based paint stripper used at the Portsmouth Naval Shipyard. The previous paint and adhesive remover required extensive sanding which, in turn, required the maintenance workers to wear respirators. The previous product also contained an acid which required extra skin protection PPE. With the soy based stripper, employees are able to eliminate the use of respirators and acid resistant PPE. D. Is the biobased product less volatile (less likely to evaporate) leading to less inhalation and/or odor irritation exposure to employees? Volatile products give off vapors that may pose an inhalation risk as described in question “B” above. These vapors can pose acute or chronic exposure risk. The employee using a volatile product may be protected from adverse exposure by using required PPE. Other employees who are in the vicinity of where the product is being used may not be so protected and thus be at risk. An example is carpet tile adhesive remover. Some adhesive, mastic and paint removers have high volatility and odor characteristics. The use of these products may require the shutdown of the facility when this removal work is done. The U.S. Postal Service (USPS) tested a soy based mastic remover named BEAN-e-doo® that performed well and, due to the low volatility and lack of odor, the facility did not have to restrict operating hours during the work. Due to this and other favorable aspects of the product, the total cost to remove floor covering was reduced by 2/3. The volatility of a product can be determined from the Physical and Chemical Properties or equivalent section of the MSDS. When comparing products, a higher number means it is more volatile. Volatility is can be expressed in “grams per liter”, “percent volatile content” or by “mm of Hg vapor pressure”. E. Are there any other known or perceived safety and health benefits of the biobased product such as the absence of toxic, hazardous or carcinogenic chemicals? 12 The MSDS must identify any hazardous component if it exceeds 1%, or 0.1% if it is a carcinogen (cancer causing agent). A hazardous or carcinogenic component can pose a human health risk. When comparing products, give preference for those which contain lower levels of hazardous or carcinogenic components. This information can be found in Sections 3 or 11 (or other equivalent sections) of the MSDS (Hazard Identification and Toxicological Information) III. Environmental Questions A. In the event of a spill to the environment, will the biobased product have less costly clean-up requirements and have less impact due to more rapid biodegradability and less toxicity? One of the major life cycle cost advantages of a biobased product is its potential environmental and toxicity profile when compared to petroleum based products. Some State environmental regulatory agencies have recognized that profile by reducing the clean-up requirements for biobased products such as hydraulic fluids, transformer cooling fluid and lubricants. For example, when Brookhaven National Lab in New York State lost petroleum based hydraulic fluid to the ground from a corroded piping system, the Lab had to pay $22,000 in clean-up costs. Following a switch to a biobased fluid, New York required a simplified clean-up procedure which cost less than $1,000 since the biobased fluid was shown to biodegrade well before it could reach a groundwater drinking supply. This type of environmental benefit will be State and situational-specific. Facilities should discuss potential clean-up requirements with their cognizant State and local agencies. See product literature, case studies or the MSDS for biodegradability data and recommended spill response requirements. B. Does the biobased product contain a lower level or no ozone depleting substances (ODS) or hazardous air pollutants (HAPs)? The release of ODS to the atmosphere can result in the loss of high elevation ozone which can lead to more harmful ultraviolet radiation reaching the earth. The use of ODS is restricted by Federal law to meet U.S. obligations under the Montreal Protocol. Products containing ODS should not be purchased unless there is no feasible alternative. To see if a product contains ODS check the Regulatory Information section (15) or equivalent section in the MSDS or verify with the vendor. Hazardous Air Pollutants (HAPs), also known as toxic air pollutants or air toxics, are those pollutants that cause or may cause cancer or other serious health effects, such as reproductive effects or birth defects, or adverse environmental and ecological effects. EPA has designated 188 chemicals as HAPs. To see if a 13 product contains a HAP, check the MSDS Composition/Information on Ingredients section (2) or equivalent section to see if the term “hazardous” is listed after the ingredient name. If it is, it will be a HAP and the content will be listed. The vendor can also provide this information. For example, methylene chloride which is present in some paint strippers is a listed HAP. C. Will the biobased product have less smog forming potential due to lower volatile organic compound (VOC) content? VOC content in a product can potentially be released to the atmosphere during use or disposal, thus contributing to the formation of smog. Smog contributes to health problems of susceptible people. Biobased products such as cleaners, paint removers and coatings typically will have less VOC content compared to their petroleum based counterparts. When applicable, VOC content of products can be found in the MSDS or in product literature. D. Will the use of the biobased product support your agency’s stated environmental procurement policies and objectives? Governmental agencies are required to have a proactive affirmative procurement program for procuring biobased products. For more information on the federal BioPreferredSM program and designated biobased products, go to: www.biopreferred.gov/ IV. Disposal Questions A. At the end of its useful life, will the biobased product be more readily recyclable than the alternate product? Products which there are established recycling opportunities offer a cost savings since the cost of disposal is reduced or avoided. In instances where the facility revenue from recycling may have a negative cost, the recycled biobased materials may serve as feedstock for other products which may be purchased by federal agencies under the direction of Resource Conservation and Recovery Act (RCRA) and Executive Order 13423. For example, “used oils” that meet EPA criteria can be recycled. See case studies or ask vendor if the used product can be recycled. 14 B. If the used product cannot be recycled, will the biobased product qualify to be handled under less stringent disposal requirements or other regulated management options such as waste fuel blending for energy recovery? Products classified as “non-hazardous waste” when discarded are less expensive to dispose than those classified as “hazardous waste.” The MSDS should state if the liquid or solid product should be managed as a (RCRA) “hazardous waste” in the Regulatory Information section. There will be no listing in the MSDS if the product does not meet hazardous waste criteria. For liquid, non-hazardous biobased products such as many cleaners, disposal may be as simple as flushing them to a sewer system due to the product biodegradability and non-toxic characteristics. This option may be identified in the product literature or by asking the vendor. Some used liquid products may be suitable for waste fuel blending which is a form of recycling. See case studies or ask vendor if this option is available. V. Summary Does the value of the combined life cycle benefits of the biobased product outweigh any initial purchase cost difference? Once you have checked all the appropriate boxes, you now need to determine if the value of the identified life cycle benefits for the biobased product are great enough to overcome any significant initial purchase cost differential. To aid in this determination, you may wish to confer with those employees who will be using the product and/or those who have set specifications for the product application. Such a conference should enable your group to quantify some or all of these benefits in terms of cost savings over the life cycle of the product. For example, assume that a gallon of a biobased floor cleaner costs $10/gallon and the currently purchased cleaner costs $5/gallon, a 100% purchase cost differential. Once filling out the checklist and conferring with your colleagues, you determine the following: • • • A gallon of the biobased cleaner will clean twice the area as a gallon of the current cleaner The employee using the current cleaner had to wear a respirator due to strong odor and the cleaning had to be done after normal working hours as nearby employees objected to the odor and did not want to wear respirators The biobased cleaner and residue could be safely rinsed to the sewer due to its biodegradability and low toxicity whereas the other cleaner had to be picked up with a vacuum machine and put into a holding tank for offsite disposal. Based on this discussion and review, the overall life cycle benefits more than offset the initial $5/gallon cost differential. The performance of the biobased 15 cleaner alone offset the $5/gallon cost differential while the other two benefits provided additional savings in the form of less overtime for after hours cleaning, no breathing respirator needed for the employee, improved productivity and morale from nearby employees as some employees left their work area if cleaning was done during their shift and a much lower disposal cost for the cleaning solution residue. 16 Appendix C: Interpreting Information from a Material Safety Data Sheet A Material Safety Data Sheet (MSDS) is a key component of the federal Occupational, Health and Safety Administration (OSHA) Hazard Communication Standard 29 CFR 1910.1200 (g). This standard requires a vendor to provide a MSDS for each product that contains a hazardous constituent greater than 1% or a carcinogen greater than 0.1%. The MSDS is a form containing data regarding the properties of a particular substance. As an important component of product stewardship and workplace safety, it is intended to provide workers and emergency personnel with procedures for handling or working with that substance in a safe manner, and includes information such as physical data (flash point, etc.), toxicity, health effects, first aid, storage, disposal, protective equipment, spill handling procedures, and regulatory information. The exact format of an MSDS can vary. The OSHA format has 8 required categories while the American National Standards Institute (ANSI) has prescribed a format with 16 sections which include more information. Since the ANSI format is more commonly used now, this checklist and guidance document reference those section titles and Arabic numerical designations. To view these two formats, go to: www.msdswriter.com/learn_writer.cfm 17 Appendix D: Protection Interpreting Hazard Information from a National Fire Association (NFPA) label The National Fire Protection Association (NFPA) has developed a diamondshaped diagram of symbols and numbers to indicate the degree of hazard associated with a particular chemical or material. Most MSDSs will include the NFPA hazard numbers in the Fire or Health sections. For a full description of the NFPA diamond hazard system, go to: http://www.nmsu.edu/~safety/programs/chem_safety/hazcom_NFPA_labels.htm 18 Appendix E: Interpreting Hazard Information from a Hazardous Material Information System (HMIS) label • The Hazardous Materials Identification System (HMIS) was developed by the National Paint & Coatings Association (NPCA) to help employers comply with OSHA’s Hazard Communication Standard 29 CFR 1910.1200. This system uses colored bars and symbols to communicate hazards of chemicals in the workplace. The HMIS and NFPA labeling systems appear quite similar. Both have four sections colored blue, red, yellow and white. HMIS used colored bars while NFPA uses colored diamonds. The HMIS label differs from the NFPA diamond by indicating what personal protective equipment should be used. Most MSDSs will include the HMIS numbers in the Fire or Health sections. For a full description of the HMIS numbering and PPE designations, go to a website such as: www.ilpi.com/msds/ref/hmis.html. 19 Appendix F LIFE CYCLE CHECKLIST Product Cost ($/unit) Biobased: Bean-e-doo ® Mastic Remover $27.95/gal Alternative: Petroleum distillates/naptha $24.95/gal Life Cycle Criteria - as compared to the alternative product: YES I. Performance A. Has the biobased product been successfully used at other federal facilities? (see case studies on "www.BioPreferred.gov/CaseStudies.aspx") X B. Will the biobased product require less material to perform the job or last longer during use? (see case studies or product literature) X C. Can the biobased product be used with existing equipment and procedures? NO N/D Product Data/Reference Portsmouth Naval Air Station; US Postal Service; Cherokee Nation Hospital. All found at http://soybiobased.org/profiles Bean-e-doo Mastic Remover has 25% greater coverage. Compared various product data sheets to Bean-e-doo data sheet Bean-e-doo is applied in same manner but does not require a machine buffing step to clean floor before new covering. Most petro products require machine buffing which is an extra step. Vendor literature. (see case studies, product literature or consult with vendor) X D. Will use of the biobased product lead to less equipment wear and/or reduced maintenance? No machine buffing or scaping needed but some petro based mastic removers do need. Literature & case studies at http://soybiobased.org/profiles (see case studies or product literature) X E. Does the biobased product offer any other performance benefits such as reduced product inventory, energy to use, etc. (see case studies or product literature) X II. Safety and Health A. Is the biobased product less flammable? [See flash pt. from MSDS Sec. V or (or equivalent Bean-e-doo works without having to periodically aggitate the mastic, allowing workers to perform other tasks while the mastic is being dissolved/lifted. Vendor info. Bean-e-doo flashpoint = 425F vs. FP range of 140F 152F for petroleum distillate based products. section of MSDS) or number in red section of NFPA label or HMIS label or product literature] X B. Does the biobased product pose less exposure risk to employees in the form of irritation to skin, lungs or eyes? [Find acute health effects from MSDS Sec. 3 or 8 (or other equivalent sections of MSDS) or blue section of NFPA or HMIS labels] X C. Can the biobased product be used with less restrictive requirements for personal protective Bean-e-doo can be used without respirator while petro & citrus based products require respirator or extra ventilation. Skin and eye contact risks are the same. MSDS & case studies at http://soybiobased.org/profiles Bean-e-doo can be used without respirator while petro & citrus based product requires respirator or extra ventilation. MSDSs, product literature, case studies at http://soybiobased.org/profiles. HMIS for Bean-e-doo is 1,0,0. equipment (PPE)? [see case studies or control measures from MSDS Sec. 8 (or equivalent section of MSDS) or verify with vendors] X D. Is biobased product less volatile (less likely to evaporate) leading to less inhalation and/or odor X Bean-e-doo has low odor & VOC of 23.7g/l (< 3%). Petro product (Chemispere) VOC 95% & Pure Citrus product VOC 100%. MSDSs & http://soybiobased.org/profiles X Bean-e-doo MSDS: no toxic, hazardous, or carcinogenic components. Petro product MSDS says "Prolonged exposure leads to brain, liver, kidney effects/ damage. irritation exposure to employees? [volatile content or odor information - MSDS Sec. 3 or 9 (or equivalent sections of MSDS), product literature or product label] E. Are there any other known or perceived safety and health benefits of the biobased product such as the absence of toxic, hazardous or carcinogenic chemicals, etc.? [see MSDS Sec. 3 or 11 (or equivalent sections of MSDS), product literature or case studies] 20 Appendix F LIFE CYCLE CHECKLIST Product Cost ($/unit) Biobased: Bean-e-doo ® Mastic Remover $27.95/gal Alternative: Petroleum distillates/naptha $24.95/gal Life Cycle Criteria - as compared to the alternative product: YES NO N/D III. Environmental A. In the event of a spill to the environment, will the biobased product have less costly cleanup Product Data/Reference Bean-e-doo is biodegradable according to vendor literature. Petro based products take longer to biodegrade according to published articles. Both products should be cleaned -up ASAP to avoid messy conditions. requirements and have less impact due to more rapid biodegradibility and less toxicity? [see case studies, MSDS Sec. 6 or 12 (or equivalent sections of MSDS) or product literature] X B. Does the biobased product contain any or lower levels of ozone depleting substances (ODS) or MSDS says no ODS or HAPs in Bean-e-doo . Some petroleum distillates are listed as HAPs. Check specific product MSDS to verify. hazardous air pollutants (HAPs) compared to the alternate product? [see MSDS Sec. 15 (or equivalent sections of the MSDS) or verify with supplier or see product literature] X C. Will the biobased product have less smog forming potential due to lower volatile organic compound (VOC) content? [see product literature or product label for VOC content or MSDS Sec. 9 (or equivalent section of the MSDS)] Bean-e-doo has significantly lower VOC content than any petroleum distillate based mastic remover MSDS comparison. X D Will use of the biobased product support your agency's stated environmental procurement Bean-e-doo is derived from soybean oil whereas petroleum based products are not renewable. Bean-edoo is on BioPreferred product list. policies and objectives? X IV. Disposal A. At the end of its usable life, will the biobased product be more readily recyclable than the Neither product can be recycled after use as both are sticky pastes when combined with removed mastic. alternate product? (see case studies or ask vendors) X B. If the used product cannot be recycled, will the biobased product qualify to be handled under Both used products when mixed with removed mastic are usually handled in same manner - either mixed with absorbent and sent to landfill or waste fuel blended. Vendor information. less stringent disposal requirements or other regulated management options such as waste fuel blending for energy recovery? [verify with vendor, see case studies or MSDS Sec. 15 (or equivalent section in the MSDS) for RCRA classification, if applicable. X YES NO V. Summary Yes. Same amount of biobased mastic remover covers more floor area, requires less PPE, and work area does not require employees or the public to be absent during removal work. Does the value of the life cycle benefits outweigh any initial purchase cost difference? X 21 Appendix F LIFE CYCLE CHECKLIST Product Cost ($/unit) Biobased: EnviroTemp FR3 Transformer oil $12.75/gal Alternative: Mineral oil $9.60/gal YES Life Cycle Criteria - as compared to the alternative product: NO N/D I. Performance A. Has the biobased product been successfully used at other federal facilities? (see case studies on "www.BioPreferred.gov/CaseStudies.aspx") Norfork Naval Station http://www.soybased.org/resources/ProfileTransforme rUSapproved.pdf X B. Will the biobased product require less material to perform the job or last longer during use? (see case studies or product literature) FR3 filled transformer should last longer - Cooper Power literature X C. Can the biobased product be used with existing equipment and procedures? (see case studies, product literature or consult with vendor) X D. Will use of the biobased product lead to less equipment wear and/or reduced maintenance? (see case studies or product literature) E. Does the biobased product offer any other performance benefits such as reduced product X Increased ability to withstand overloads for FR3 due to enhanced paper stability-Cooper Power literature X FR3 Flash point = 330C vs. 145C for mineral oil MSDS II. Safety and Health A. Is the biobased product less flammable? [see flash pt. from MSDS Sec. V or (or equivalent section of MSDS) or number in red section of NFPA label or HMIS label or product literature] B. Does the biobased product pose less exposure risk to employees in the form of irritation to skin, lungs or eyes? [find acute health effects from MSDS Sec. 3 or 8 (or other equivalent sections of MSDS) or blue section of NFPA or HMIS labels] FR3 health NFPA = 0 vs. 1 for mineral oil - MSDS X C. Can the biobased product be used with less restrictive requirements for personal protective equipment (PPE)? [see case studies or control measures from MSDS Sec. 8 (or equivalent section of MSDS) or verify with vendors] Less stringent PPE for FR3 due to its lower irritant properties - MSDS X D. Is biobased product less volatile (less likely to evaporate) leading to less inhalation and/or odor Little difference in evaporation rates irritation exposure to employees? [volatile content or odor information - MSDS Sec. 3 or 9 (or equivalent sections of MSDS), product literature or product label] X E. Are there any other known or perceived safety and health benefits of the biobased product such as the absence of toxic, hazardous or carcinogenic chemicals, etc.? [see MSDS Sec. 3 or 11 (or equivalent sections of MSDS), product literature or case studies] 22 No modifications necessary-Cooper Power representative 5-21-08 Better insulation paper thermal stability with FR3 than mineral oil suggests longer transformer life-Cooper Power literature X inventory, energy to use, etc. (see case studies or product literature) Product Data/Reference X FR3 has no hazardous or toxic components; CA has raised carcinogenic concerns for mineral oil MSDS/Cooper Power literature Appendix F LIFE CYCLE CHECKLIST Product Cost ($/unit) Biobased: EnviroTemp FR3 Transformer oil $12.75/gal Alternative: Mineral oil $9.60/gal YES Life Cycle Criteria - as compared to the alternative product: NO N/D III. Environmental A. In the event of a spill to the environment, will the biobased product have less costly cleanup requirements and have less impact due to more rapid biodegradibility and less toxicity? [see case studies, MSDS Sec. 6 or 12 (or equivalent sections of MSDS) or product literature] Aquatic biodegradation rate 2-4 times higher and more complete for FR3 vs mineral oil - ETV report Cal/EPA. Major reason FR3 chosen for Norfolk Naval Station X B. Does the biobased product contain any or lower levels of ozone depleting substances (ODS) or Neither product has ODS or HAPs hazardous air pollutants (HAPs) compared to the alternate product? [see MSDS Sec. 15 (or equivalent sections of the MSDS) or verify with supplier or see product literature] X C. Will the biobased product have less smog forming potential due to lower volatile organic Both products have very low VOC content compound (VOC) content? [see product literature or product label for VOC content or MSDS Sec. 9 (or equivalent section of the MSDS)] X D Will use of the biobased product support your agency's stated environmental procurement policies and objectives? Product Data/Reference FR3 sourced from commodity seed oil vs. mineral oil sourced from petroleum. FR3 is on USDA BioPreferred product list X IV. Disposal A. At the end of its usable life, will the biobased product be more readily recyclable than the Both products can be recycled alternate product? (see case studies or ask vendors) X B. If the used product cannot be recycled, will the biobased product qualify to be handled under less stringent disposal requirements or other regulated management options such as waste fuel blending for energy recovery? [verify with vendor, see case studies or MSDS Sec. 15 (or equivalent section in the MSDS) for RCRA classification, if applicable. When discarded, FR3 is not classified as "used oil" per 40CFR279, mineral oil is so classified- MSDS. Both products could be waste fuel blended if recycling option is not selected X YES NO V. Summary Does the value of the life cycle benefits of the biobased product outweigh any initial purchase cost difference? 23 X Enhanced fire safety, longer transformer life, less cost in handling spills and reduced PPE requirements should more than offset higher initial purchase cost.