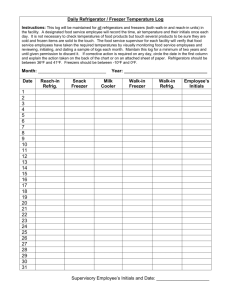

AIR-CONDITIONING, HEATING AND REFRIGERATION

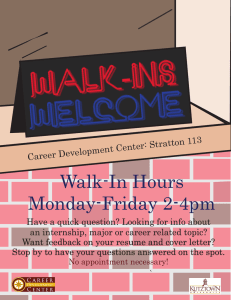

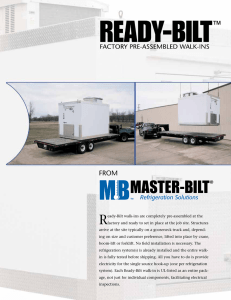

advertisement