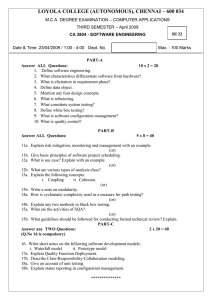

New chapter 38

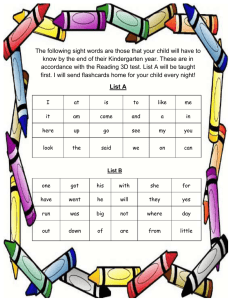

advertisement