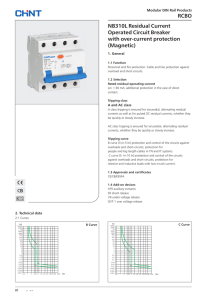

RESIDUAL CURRENT OPERATED CIRCUIT-BREAKERS

advertisement