SPD Section 16289 3rd Edition Spec June 2014

advertisement

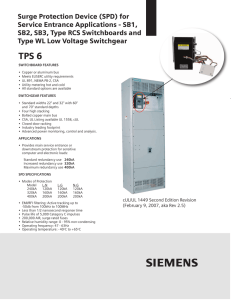

SECTION 16289 - SURGE PROTECTION DEVICES PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section. SUMMARY A. This Section includes Surge Protection Devices for low-voltage power, control, and communication equipment. B. Related Sections include the following: 1. 2. 3. 1.3 1.4 Division 16 Section "Wiring Devices" Surge Protection Devices Division 16 Section "Panel boards" Surge Protection Devices Division 16 Section "Switchboards" factory-installed Surge Protection Devices SUBMITTALS A. Must have fifteen day prior approval to bid on project. Request for submittal must be in writing and attached with independent documentation of the following items. B. Drawings: Electrical and mechanical drawings shall be provided by the manufacturer which show unit dimensions, weights, mounting provisions, connection notes, wire size and wiring diagram. C. Equipment Manual: The manufacturer shall furnish an installation manual with installation notes, start-up and operating instructions for the specified system. Installation instructions shall clearly state whether the system requires an external over current device to maintain the system’s UL 1449 listing. D. National Electrical Code (2008) Article 285 - Installation requirements for SPD. 1. Article 100, SPD must limit transient voltage by diverting or limiting surge current; it also should prevent continued flow of follow current while remaining capable of repeating these functions. SPD that utilize fuses must have repetitive surge capability that can survive its surge rating and meet UL 1449. 2. Article 285.6, SPD shall be marked with a short circuit current rating and shall not be installed at a point on the system (ex. service, distribution or branch panels) where the available fault current (AIC rating) is in excess of that rating. E. UL 3 Edition Suppressed Voltage Rating (SVR) shall test using the combination wave generator rd at a setting of 6kV, 3kA. SPD shall pass UL 1449 3 edition Nominal Discharge Current Rating (In) 20kA. rd STANDARDS SURGE PROTECTION DEVICES 16289-1 rd A. Underwriters laboratories 1449 - (UL 1449 3 Protection Devices ) B. National electrical code 2008 rev. - (NEC article 285 SPD installation practice/NEC article 250.56 grounding) NFPA-78 and CSA - (National Fire Protection Association and Canadian Standards Associations) ISO 9001:2000 - quality standard / military standards (mil-std 220a) C. IEEE (Institute of Electrical and Electronic Engineering Inc.) C62.41.1 and C62.41.2 – 2002 rev. - (system shall be designed to meet C62.41) 1. IEEE C62.45 – 2002 rev. - (system shall be tested to meet the C62.45) 2. Category A & B - (0.5 s x 100 kHz ring wave) 3. Category B3 bi-wave - (8 x 20 s at 3,000 amperes and 1.2 x 50 s at 6,000 volts) 4. Category C3 bi-wave - (8 x 20 s at 10,000 amperes and 1.2 x 50 s at 20,000 volts) D. All manufacturers must comply with above listed standards and any additions current revisions of industry standards. All products that do not comply with current industry standards will not be accepted. 1.5 QUALITY ASSURANCE A. 1.6 Source Limitations: Obtain suppression devices and accessories through one source from a single manufacturer. PROJECT CONDITIONS A. Placing into Service: Do not energize or connect service entrance equipment, panel boards, control terminals, or data terminals to their sources until the surge protective devices are installed and connected. B. Protection modes: The SPD shall provide Line to Neutral (L-N) (Wye), Line to Ground (L-G) (Wye or Delta), Line to Line (L-L) (Delta) and Neutral to Ground (N-G) (Wye) protection. C. Existing Utilities: Do not interrupt utilities serving facilities occupied by Owner or others unless permitted under the following conditions and then only after arranging to provide temporary utility services according to requirements indicated: 1. 2. D. Notify Architect not less than two days in advance of proposed utility interruptions. Do not proceed with utility interruptions without Architect's written permission. Service Conditions: Rate surge protective devices for continuous operation under the following conditions, unless otherwise indicated: 1. 2. 3. 4. 1.7 edition or current safety standard for Surge Maximum Continuous Operating Voltage: Not less than 115 percent of nominal system operating voltage. Operating Temperature: 30 to 120 deg F (0 to 50 deg C). Humidity: 0 to 85 percent, non-condensing. Altitude: Less than 20,000 feet (6000 m) above sea level. COORDINATION SURGE PROTECTION DEVICES 16289-2 A. Coordinate location of field-mounted surge suppressors to allow adequate clearances for maintenance. B. Coordinate surge protective devices with Division 16 Section "Electrical Power Monitoring and Control." 1.8 WARRANTY A. General Warranty: Special warranties specified in this Article shall not deprive Owner of other rights Owner may have under other provisions of the Contract Documents and shall be in addition to, and run concurrent with, other warranties made by Contractor under requirements of the Contract Documents. B. Manufacturer shall provide a product warranty for a period of not less than ten (10) years from date of installation. Warranty shall cover unlimited replacement of SPD modules during the warranty period. Those firms responding to this specification shall provide proof that they have been regularly engaged in the design, manufacturing and testing of SPD for not less than twenty (25) years. C. Special Warranty for Plug-in Cord-Connected Surge Suppressors: Written warranty, executed by manufacturer agreeing to repair or replace electronic equipment connected to circuits protected by surge suppressors. PART 2 - PRODUCTS 2.1 SERVICE ENTRANCE SUPPRESSORS A. Acceptable Manufacturers and Models: a. PQ Protection PQS400 No other Manufacturers will be accepted. 2.2 B. Equipment shall be a multi-stage parallel protector rated for [480Y/277] or [208Y/120]. Please see contract drawings and panel board schedule to confirm voltages. The equipment’s minimum surge current capacity shall be 400kA per phase (L-N plus L-G) and 200kA per mode (L-N, L-G, LL and N-G). C. Each protection module shall have a visual indicator that signifies that the protection circuitry is on line. The unit shall not be taken off line to verify integrity of system. Redundant status indicators shall be mounted on the front of the door that monitors the system protection circuitry. D. The system shall be modular design with field replaceable modules and shall have an integral disconnecting means E. Equipment shall provide the following monitoring features: dry contacts, surge counter and audible alarm Equipment shall utilize a NEMA 4 or NEMA 12 enclosure. F. SPD SVR shall not exceed the follow: L-N-1200V, L-G-1200V, N-G-1000V for 480V systems and L-N-800V, L-G-800V, N-G- 700V for 208V systems DISTRIBUTION PANEL SUPPRESSORS SURGE PROTECTION DEVICES 16289-3 A. Acceptable Manufacturers and Models: PQ Protection- PQM200 No other Manufacturers will be accepted. B. Device shall meet all specification requirements in section 2.1 except as follows: Equipment shall be a multi-stage parallel protector rated for [480Y/277] or [208Y/120]. Please see contract drawings and panel board schedule to confirm voltages. The equipment’s minimum surge current capacity shall be 200kA per phase (L-N plus L-G) and 100kA per mode (L-N, L-G, LL and N-G). 1. Equipment shall provide the following monitoring features: dry contacts and audible alarm. Equipment shall utilize a NEMA 4 or NEMA 12 enclosure. 2. The system shall be modular design with field replaceable modules and shall have an integral disconnecting means 3. SPD SVR shall not exceed the follow: L-N-1000V, L-G-1200V, N-G-1200V for 480V systems and L-N-600V, L-G-600V, N-G- 600V for 208V systems 2.3 PANELBOARD SUPPRESSORS C. Acceptable Manufacturers and Models: PQ Protection – PQC100 No other Manufacturers will be accepted. D. Device shall meet all specification requirements in section 2.1 except as follows: Equipment shall be a multi-stage parallel protector rated for [480Y/277] or [208Y/120]. Please see contract drawings and panel board schedule to confirm voltages. The equipment’s minimum surge current capacity shall be 100kA per phase (L-N plus L-G) and 50kA per mode (L-N, L-G, L-L and N-G). 1. Equipment shall provide the following monitoring features: dry contacts and audible alarm. Equipment shall utilize a NEMA 4 enclosure. 2. SPD SVR shall not exceed the follow: L-N-1000V, L-G-1200V, N-G-1200V for 480V systems and L-N-600V, L-G-600V, N-G- 600V for 208V systems PART 3 - EXECUTION 3.1 INSTALLATION OF SURGE PROTECTIVE DEVICES A. The specified unit shall be installed external to switchboard/panel board as stand alone. Internal products will not be accepted. B. The specified service entrance/switchboard/switchgear system shall be installed with the shortest lead length possible, and must have a grounding of 25 Ohms (NEC Article 250.56) or SURGE PROTECTION DEVICES 16289-4 less and shall avoid any unnecessary or sharp bends. Utilize a 3 pole 30 amp breaker for connection means. See manufacturer’s installation manual at www.pqprotection.com C. 3.2 The specified distribution and branch panel board system shall be installed with the shortest lead length possible must have a grounding of 25 Ohms (NEC Article 250.56) or less and shall avoid any unnecessary or sharp bends. Utilize a 3 pole 30 breaker for connection means. See manufacturer’s installation manual at www.pqprotection.com CONNECTIONS A. 3.3 Tighten electrical connectors and terminals according to manufacturer's published torquetightening values. If manufacturer's torque values are not indicated, use those specified in UL 486A and UL 486B. FIELD QUALITY CONTROL A. Testing: Owner will engage a qualified testing agency to perform the following field qualitycontrol testing: B. Testing: Perform the following field quality-control testing: 1. 2. 3. After installing surge protective devices, but before electrical circuitry has been energized, test for compliance with requirements. Complete startup checks according to manufacturer's written instructions. Perform each visual and mechanical inspection and electrical test stated in NETA ATS, Section 7.19. Certify compliance with test parameters. C. Repair or replace malfunctioning units. Retest after repairs or replacements are made. D. Manufacturer's Field Service: Engage a factory-authorized service representative to inspect field-assembled components and equipment installation, including piping and electrical connections. Report results in writing. 1. Verify that electrical wiring installation complies with manufacturer's installation requirements. END OF SECTION 16289 SURGE PROTECTION DEVICES 16289-5