..

..

..

..

..

KETEK GmbH

Hofer Str. 3

81737 München

Phone +49-89-673467-70

Fax +49-89-673467-77

KETEK GmbH

VITUS

Silicon Drift Detectors

.

.

.

.

User’s Manual

.

.

.

.

.

.

Steffen Pahlke

Rev. 3

Information furnished by KETEK is believed to be accurate and reliable.

However, no responsibility is assumed by KETEK for its use, nor for any

infringements of patents or other rights of third parties that may result from its

use. Specifications given in this document subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights

of KETEK. Trademarks and registered trademarks are the property of their

respective owners.

KETEK GmbH, Hofer Str. 3, D-81737 München, Germany

Tel: +49-(0)89-67346770

Fax: +49-(0)89-67346777

www.ketek.net

©2012 KETEK GmbH. All rights reserved.

KETEK VITUS SDD Manual

1. Table of Contents

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

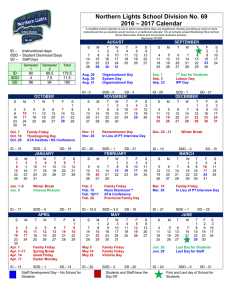

Table of Contents............................................................................................................................ 3

Revision History .............................................................................................................................. 3

Features .......................................................................................................................................... 5

Applications ..................................................................................................................................... 5

Functional Block Diagram ............................................................................................................... 5

General Description ........................................................................................................................ 5

Safety .............................................................................................................................................. 6

General Restrictions ....................................................................................................................... 7

Specifications .................................................................................................................................. 8

Absolute Maximum Ratings ........................................................................................................ 9

Ambient Conditions .................................................................................................................. 10

ESD Caution ............................................................................................................................. 10

Pin Configuration and Functional Descriptions ........................................................................ 10

Typical Performance Characteristics ........................................................................................ 11

Theory of Operation .................................................................................................................. 17

Applications and Operations Information ................................................................................. 19

16.1. Wiring ................................................................................................................................... 19

16.2. Mechanical Connection ........................................................................................................ 19

16.3. Readout Circuit for Temperature Sensor ............................................................................. 20

16.4. Operating Voltages .............................................................................................................. 21

16.5. Preamplifier Design .............................................................................................................. 22

16.6. Peltier Characteristics .......................................................................................................... 23

Collimator ................................................................................................................................. 25

Outline Dimensions .................................................................................................................. 26

Footprint ................................................................................................................................... 27

Ordering Guide ......................................................................................................................... 28

Optional .................................................................................................................................... 28

Contact ..................................................................................................................................... 29

2. Revision History

11/07 – Revision 0: Initial Version

12/03 – Revision 1: Minor textual changes, accommodation of Specifications

12/08 – Revision 2: Minor textual changes, accommodation of Specifications

12/11 – Revision 3: Update Gain of SDD, update Typical Performance Characteristics due to new FET,

update spectral definitions

Rev. 3

Page 3 of 29

KETEK GmbH

KETEK VITUS SDD Manual

Rev. 3

Page 4 of 29

KETEK GmbH

KETEK VITUS SDD Manual

3. Features

Silicon Drift Detector

energy resolution down to 123eV FWHM at Mn-Kα

excellent peak-to-background

operable at an ambient temperature of up to +80°C with excellent performance

high count rate capability up to 1,000,000 cps

efficient integrated Peltier element

no liquid nitrogen cooling required

radiation hardness during more than 10 years standard count rate exposure

easy to use

active areas from 7 to 100mm² available

4. Applications

XRF

µ-XRF

EDX

EDS

TXRF

XRD

Handheld

5. Functional Block Diagram

Fig. 1: KETEK VITUS SDD Functional Block Diagram

6. General Description

KETEK VITUS Silicon Drift Detectors (SDD) are the state-of-the-art X-ray detectors based on silicon

substrates. Their typical X-ray energy range is between 0.2keV and 30keV. They are used in

applications such as EDX, EDS, XRF, TXRF in bench top as well as in handheld based systems. Due

to their wide operating temperature range they are especially suited for industrial and automotive

applications.

Rev. 3

Page 5 of 29

KETEK GmbH

KETEK VITUS SDD Manual

7. Safety

It is strongly recommended to read this user manual carefully and completely before installing or

activating the SDD. Please keep this user manual always with the system for that any operator can get

this important information. In case of resale – even when second hand – or in case of scrapping at the

end of lifetime this manual has to be given along with the system. Please handle the attached

documents “Beryllium Material Data Sheet” and “Statement of contamination…” the same way.

WARNING!

The detector contains a thin, fragile Be window. If this window is damaged, the detector

will be destroyed and cannot be repaired.

Be windows damaged due to improper handling are not covered under warranty.

This product uses – a very small amount - of toxic beryllium material at the inner side of

the detector foil. Beryllium is preferred as an entrance window coating because it

provides a light-tight seal and, further, does not introduce spurious peaks in the

measured spectrum. In normal operation there is no danger to get in contact with any

toxic materials. If the SDD window was destroyed by accident, follow our safety

instructions.

Scrapping at end of lifetime has to be done according to the (local) legal requirements.

Make the “Beryllium Material Data Sheet” available to your waste disposal contractor. Do

not scrap the SDD to your domestic waste.

Due to the very thin window foil you should take care neither to touch it with fingers nor

to bring other things or materials under test too near to it.

Keep away excessive dust particle streams from the SDD window.

Excessive electrostatic discharge might destroy the window. Take care ESD is well bled

off in your application.

Some of the SDD types are evacuated. A damaged entrance window may implode

scattering small beryllium particles in the immediate vicinity of the SDD. In this case,

rigorously clean the SDD and its surrounding area following all the precautions

mentioned in the “Beryllium Material Safety Data Sheet”.

Always keep the SDD protection cap with the system, even if fixed mounted. It’s

necessary for cleaning, service and shipping to be able to protect the beryllium window.

CAUTION!

High voltages need to be applied to the detector for use. To prevent electrical shock, do

not touch the detector.

Do not drop or cause mechanical shock to the detector. Components inside the detector

are mechanically fragile and may be damaged if the unit is dropped.

Avoid temperature shocks. If the detector is out of allowed temperature range, make

sure to acclimate slowly.

Avoid air pressure shocks. Especially in evacuated applications take care to ventilate

slowly.

Let the protection cap be mounted at the SDD as long as the system isn’t mounted in its

end application. Your end application has to be designed that way to make unexpected,

damaging contact with the SDD window impossible. Make sure your samples under test

might never touch the SDD window.

Do not remove the protective cap from the detector until data is to be taken. The detector

window is made from thin beryllium which is extremely brittle and can shatter very easily.

Do not have any object come in contact with the window. Do not touch the detector

because the oil from the fingers will cause it to oxidize. Use gloves. The window cannot

be repaired. If the window is damaged the detector assembly must be replaced. Be

windows damaged due to improper handling will not be covered under warranty. Keep

the protective cover nearby at all times and cover the detector when the instrument is not

in use.

Rev. 3

Page 6 of 29

KETEK GmbH

KETEK VITUS SDD Manual

Radiation damage to the detector will occur if it is exposed to a high flux environment.

Synchrotron Radiation Beams should be modified with attenuators before they are

allowed to strike the detector or the fluorescence target. Damage to the detector will be

permanent if the flux from an X-Ray Tube, a strong nuclear radiation source, or an

accelerator is not attenuated.

No user serviceable parts inside the units. Refer servicing to KETEK GmbH. To prevent

electrical shock, do not remove covers.

Keep the device dry and clean!

Warranty

KETEK GmbH warrants to the original purchaser this instrument to be free from defects in materials

and workmanship for a period of one year from shipment. KETEK GmbH will, without charge, repair or

replace (at its option) a defective instrument upon return to the factory. This warranty does not apply in

the event of misuse or abuse of the instrument or unauthorized alterations or repair. KETEK GmbH

shall not be liable for any consequential damages, including without limitation, damages resulting from

the loss of use due to failure of this instrument. All products returned under the warranty must be

shipped prepaid to the factory with documentation describing the problem and the circumstances

under which it was observed. Additionally the statement of contamination must be filled out completely

and returned with the product. KETEK must be notified prior to return shipment. The instrument will be

evaluated, repaired or replaced, and promptly returned if the warranty claims are substantiated. A

nominal fee will be charged for unsubstantiated claims. Please include the model and serial number in

all correspondence with KETEK.

Care Instructions

Do not clean the SDD under any circumstances. Do not use any alcoholic, acid or rubbing cleaning

agents.

8. General Restrictions and Recommendations

Rev. 3

-

do not use detector without heat sink connection. Overheating will destroy the module

-

do not solder the pins or any other part of the detector module

-

avoid touching the detector module

-

use gloves to avoid corrosion

-

avoid touching the entrance window of the detector module. It contains hazardous materials

Page 7 of 29

KETEK GmbH

KETEK VITUS SDD Manual

9. Specifications

Parameter

VOLTAGES

R1

RX

BACK

FET-Substrate/Bulk

Drain

CURRENTS

R1 = RX

BACK*

Drain

Temp.-Sensor

PELTIER (TEC)

Voltage

Current

Voltage

Current

Gain

Conditions/Comments

measured before filtering

Min

Typ

Max

Tolerance

-25

-160

-100

-7

1

-20

-130

-65

-4

3

-5

-80

-35

-2

4

±1

±5

±2

±1

±0.1

V

V

V

V

V

10

20

at maximum cooling

1

2

2

3

4

0.1

1

5

-35°C operating temp @ 20°C heat sink temp.

H7 / H20 / H30 / H50

1.6

1.7

1.8

H7 / H20 / H30 / H50

250

300

350

maximum cooling @ 20°C heat sink temp.

H7 / H20 / H30 / H50

3.0

3.3

3.6

H7 / H20 / H30 / H50

600

650

700

0.9

±5

±0.1

±0.1

±0.1

µA

nA

mA

µA

±0.1

±10

V

mA

5

±0.1

±10

±30%

Unit

V

mA

mV/keV

* Back voltage absolute value should not exceed one half of the RX voltage absolute value by more than 10V

These specifications refer to the whole VITUS SDD class. Please refer to the individual SDD

datasheet for detailed information.

Rev. 3

Page 8 of 29

KETEK GmbH

KETEK VITUS SDD Manual

10. Absolute Maximum Ratings

Parameter

VOLTAGES

R1

RX

BACK*

FET-Substrate/Bulk

Peltier H7/H20/H30/H50

Peltier H80

Peltier H7LE/H15LE/H20LE

CURRENTS

RX

Drain

Temp.-Sensor

Peltier H7/H20/H30/H50

Peltier H80

Peltier H7LE/H15LE/H20LE

Radiation Hardness @17keV

Torque

Stresses beyond those listed under Absolute

Rating

Maximum Ratings may cause permanent

≥ -30V

≥ -180V

≥ -100V

≥ -15V

≤ 3.6V

≤ 4.5V

≤ 4V

damage to the device. This is a stress rating

only; functional operation of the device at these

or any other conditions above those indicated

in the applications and operations section of

this specification is not implied. Exposure to

absolute

≤ 1mA

≤ 10mA

≤ 50µA

≤ 700mA

≤ 1000mA

≤ 900mA

12

≤ 10 Photons

≤ 0.8Nm

maximum

rating

conditions

for

extended periods may affect device reliability.

* Back voltage absolute value should not exceed one half of

the RX voltage absolute value by more than 10V

Rev. 3

Page 9 of 29

KETEK GmbH

KETEK VITUS SDD Manual

11. Ambient Conditions

Parameter

OPERATING

Temperature

Humidity

Pressure

Pressure Change

STORAGE

Temperature

Humidity

Min

Max

Unit

0

10

0

60

80

1.1

100

°C

% RH

atm

mbar/s

0

10

60

90

°C

% RH

Conditions

non condensing

non condensing

12. ESD Caution

ESD (Electrostatic Discharge) sensitive device.

Charged devices and circuit boards can discharge without

detection. Although this product features patented or proprietary

protection circuitry, damage may occur on devices subjected to

high energy ESD. Therefore, proper ESD precautions should be

taken to avoid performance degradation or loss of functionality.

13. Pin Configuration and Functional Descriptions

VITUS H7, H20, H30, H50

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

Rev. 3

Description

Temp Sensor - /GND

Temp Sensor +

Ring 1

Back

Reset

FET-Substrate / Bulk

Source

Drain

Feedback

Peltier +

Ring X

Peltier -

VITUS H80, R100

Mnemonic

TD- /GND

TD+

R1

BK

RES

SUB / BULK

FFS

FFD

FB

P+

RX

P-

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

Page 10 of 29

Description

Peltier Ring X

Feedback

Peltier +

Drain

Source

Reset

FET-Substrate / Bulk

Back

Ring 1

Temp Sensor +

Temp Sensor - /GND

Mnemonic

PRX

FB

P+

FFD

FFS

RES

SUB / BULK

BK

R1

TD+

TD- /GND

KETEK GmbH

KETEK VITUS SDD Manual

14. Typical Performance Characteristics

Fig. 2: Typical KETEK VITUS Silicon Drift Detector Spectrum of H7 active area type SDD with an Fe-55 source,

taken with a KETEK preamplifier and a digital pulse processor.

Fig. 3: Definition of Peak-to-Background (P/B) and Peak-to-Tail (P/T) of a typical spectrum

taken with a KETEK preamplifier and a digital pulse processor.

Rev. 3

Page 11 of 29

KETEK GmbH

KETEK VITUS SDD Manual

1.0

0.9

0.8

Transmission

0.7

0.6

8 µm

12.5 µm

25 µm

0.5

0.4

0.3

0.2

0.1

0.0

500

1000

1500

2000

2500

3000

Photon energy (eV)

Fig. 4: Typical transmission of KETEK Silicon Drift Detectors with different Beryllium entrance window thickness

Fig. 5: Typical transmission of KETEK Silicon Drift Detectors with low energy AP3.3 entrance window

Fig. 6: Typical absorption efficiency of KETEK Silicon Drift Detectors with a thickness of 450µm and 8µm Beryllium window

Rev. 3

Page 12 of 29

KETEK GmbH

KETEK VITUS SDD Manual

Fig. 7: Typical control range of Silicon Drift Detector chip temperature at different ambient temperatures

Fig. 8: Typical calculated energy resolutions of Silicon Drift Detectors for low energies

Fig. 9: Typical Input to Output Count Rate Ratio (Throughput) for different Peaking Times

taken with a KETEK VITUS H30 SDD and an XIA Mercury Digital Pulse Processor

Rev. 3

Page 13 of 29

KETEK GmbH

KETEK VITUS SDD Manual

H7

H20

H30

H50

H80

H7-LE

H15-LE

Fig. 10: Typical KETEK VITUS Silicon Drift Detector Spectrum with an Fe-55 source,

taken with an KETEK preamplifier and an XIA Mercury digital pulse processor for the different VITUS active areas.

Rev. 3

Page 14 of 29

KETEK GmbH

KETEK VITUS SDD Manual

H7

H15 / H20

H30

H50

H80

Fig. 11: Typical energy resolution for different chip operating temperatures dependent on the Peaking Time for different SDD

sizes.

Rev. 3

Page 15 of 29

KETEK GmbH

KETEK VITUS SDD Manual

H7

H15 / H20

H30

H50

H80

Fig. 12: Typical energy resolution for different input count rates dependent on the Peaking Time for different SDD sizes.

Rev. 3

Page 16 of 29

KETEK GmbH

KETEK VITUS SDD Manual

15. Theory of Operation

The silicon bulk of the Silicon Drift Detector (SDD) has to be depleted completely to make the sensor

sensitive for incoming photons. By applying a negative voltage to the back contact of the SDD, the

detector bulk is completely depleted. An incoming photon will generate a number of electrons and

holes dependent on its energy. The holes drift to the back side of the detector formed by the large

area back contact whereas the electrons drift to the anode where the accumulated charge can be

measured or read out. The drift field for the electrons is applied by a ring structure on one side of the

SDD with a negative voltage at the outer ring (Ring X) and a voltage close to 0V at the innermost ring

(Ring 1).

Fig. 13: Silicon Drift Detector potential diagram

The anode is connected to: a) the gate of the first field effect transistor (FET), b) the feedback

capacitance (CFB) and c) the cathode of the reset diode (D RES). The combination of a) and b), the FET

and the feedback capacitance, respectively, forms the first part of a charge sensitive amplifier, used to

read out the accumulated electrical charge. The combination forms a transimpedance (current to

voltage) and an integrator when connected to the subsequent stages of the pre-amplifier. Therefore

the source of the FET has to be connected to ground and the drain voltage and current need to be set

appropriately (typically 3V and 3mA). The operating point of the FET is optimized by setting its bulk or

substrate voltage.

GND

UOR

Driftfield

UIR

Anode

-V

UBACK

Homogeneous thin entrance window

Fig. 14: Silicon Drift Detector schematic

Rev. 3

Page 17 of 29

KETEK GmbH

KETEK VITUS SDD Manual

The FET is operated in a common source configuration. The leakage current sensed at the FET gate

causes a ramp signal at the output of the pre-amplifier. The slope of the ramp signal, and thus its

frequency, is dependant on the operating temperature. The incoming photons generate short current

pulses, with a certain rise time (dependant on the location of interaction of the x-ray with the SDD

chip), and a certain duration and amplitude (dependent on the energy of the incoming photon). In turn,

these short pulses generate steps superimposed on the pre-amplifier’s ramped output signal. The

height of a step contains the information necessary to determine the energy of the interacting photon.

1,5

Preamp Out

Reset Out

1

Amplitude [V]

0,5

0

-0,5

-1

-1,5

0

5

10

15

20

Time [ms]

Fig. 15: Typical KETEK Preamplifier Output Signal including Preamplifier Reset Pulse Output

using a KETEK VITUS SDD irradiated with an Fe-55 Source at -35°C Operating Temperature

0,04

Amplitude [V]

0

-0,04

-0,08

Preamp

Out

-0,12

-0,16

0

20

40

60

80

100

120

Time [µs]

Fig. 16: Zoom of Figure 15, typical KETEK Preamplifier Output Signal including Preamplifier Reset Pulse Output

using a KETEK VITUS SDD irradiated with an Fe-55 Source at -35°C Operating Temperature showing step like pulses

Rev. 3

Page 18 of 29

KETEK GmbH

KETEK VITUS SDD Manual

16. Application and Operation Information

For (optimal) operation, SDDs require the application of several voltages and integration with a charge

sensitive amplifier and other pulse forming electronics (either analog or digital). Typically, a high

voltage DC power supply feeds the drift ring voltages; a high current, linearly regulated, low voltage

power supply feeds the Peltier element; and a bipolar, linearly regulated power supply feeds the

charge sensitive amplifier and pulse forming electronics.

The drift ring voltages can be generated from a filtered high voltage rail, by using several voltage

dividers. Each detector may have individual ring currents. Thus potentiometers should be used for

voltage adjustments as the voltage drop at the voltage dividers depends on the ring currents.

Fig. 17: KETEK Silicon Drift Detector connected to typical preamplifier board – block diagram

The Peltier power supply should be regulated with a PI/PID loop to keep the operating temperature of

the SDD chip stable. Therefore it is necessary to read out the temperature sensor of the SDD.

16.1.

Wiring

The SDD should be placed as close as possible to the preamplifier. It is recommended to shield at

least the preamplifier connections. It is strongly recommended using a single point ground. Please

note that also the housing of the SDD should be connected to ground.

16.2.

Mechanical Connection

WARNING: Do not operate the detector without proper heat sink connection.

Overheating of the detector will destroy the module.

It is strongly recommended to install the detector connected to a proper heat sink. Dimensioning the

heat sink is dependant on ambient temperature, air ventilation, operating temperature of the SDD,

surface area and its condition. The guaranteed operating temperature is always related to the heat

sink temperature. Therefore the minimum operating temperature can vary and is directly dependant on

the quality of the heat sink interconnection.

Rev. 3

Page 19 of 29

KETEK GmbH

KETEK VITUS SDD Manual

16.3. Read out Circuit for Temperature Sensor

a) Temperature Diode:

Using a diode as temperature sensor leads to a linear relationship between the measured voltage and

sensor temperature. The line’s slope depends on the diode bias current. For the recommended 1µA,

the slope is 2.35mV/K. It is recommended to apply a constant current.

b) Thermistor (NTC resistor):

In case of the thermistor the temperature function is given by the following equation:

1

3

1.129241 103 2.341077 10 4 ln( R) 8.775468 108 ln( R)

T

The function is shown in the following plot. At 25°C the resistance is 10kΩ.

1E7

Resistance [Ohm]

1000000

100000

10000

1000

100

-100

-50

0

50

100

150

Temperature (°C)

Fig. 18: Temperature function of a thermistor as SDD temperature sensor

To read out the temperature sensor, the following schematic is recommended. Although a diode (D1)

is shown in the schematic, it may be replaced with a thermistor (say, Rt); the equations given below

apply, if D1 is replaced with Rt. R4 limits the maximum current through the temperature sensor and

should be set as follows:

R4

U

V1

I I ( D1)

For example: The voltage V1 is +5V and the current I(D1) should be 1µA. This leads to R4=5MΩ.

R1 and R2 form a voltage divider representing the offset voltage. They can be used to set the circuit’s

signal swing, given the operational demands on the SDD, e.g. if an ADC is used to digitize the voltage,

tuning R1 and R2 would ensure the desired temperature range corresponds to voltage values in the

ADC’s range.

R1, R2 and R3 determine the gain of the circuit. The gain can be calculated as follows:

A 1

Rev. 3

R3

( R1 R 2)

Page 20 of 29

KETEK GmbH

KETEK VITUS SDD Manual

Fig. 19: Typical Read out Circuit for temperature sensors with linearization, offset correction and gain.

16.4.

Operating Voltages

Several voltages are needed for operating the detector (exact values are given in each detector data

sheet), for example:

1.

Ring 1

= approx. -20V

2.

Ring X

= approx. -130V

3.

Back

= approx. -65V

The detector voltages should be filtered using the following combinations of resistors and capacitors

providing low pass filters:

1.

Ring 1:

RR1 = 15kΩ,

CR1 = 220nF

2.

Ring X:

RRX = 500kΩ,

CRX = 47nF/250V

3.

Back:

RBack = 1MΩ,

CBack = 47nF/250V

Fig. 20: Operating voltages filtering block diagram

Rev. 3

Page 21 of 29

KETEK GmbH

KETEK VITUS SDD Manual

Before switching on the system, the output-signal of the preamplifier and the shaped signal should be

connected to an oscilloscope.

The preamplifier operating voltage must be switched on first.

The detector voltages should be switched on in the following order:

R1 – RX – Back

The voltages to be applied must be set according to the detector datasheet. Typical currents flowing

are several μA through Ring 1 and Ring X (voltage divider) and approx. 1nA for the back contact if the

back voltage is applied. R1 and RX currents should be equal!

After switching on the detector voltages the signal of the preamplifier should show a ramp. The ramp

period depends on the chip temperature. At -35°C the ramp period should be in the range of several

microseconds.

16.5.

Preamplifier Design

For the design of the preamplifier it is recommended to use the FET in the common source

configuration. Therefore the source of the FET can be connected directly to signal ground. The drain

drives the signal. The substrate or bulk should be adjusted to the value given in the datasheet of each

single SDD. Also a low pass filter should be used to suppress any noise. Typical values are:

Substrate/Bulk: RSUB = 10kΩ,

CSUB = 4.7µF/16V Tantalum, low ESR

The drain can be driven by a simple current source formed by a resistor. Additional low pass filtering is

mandatory. Tantalum capacitor with low ESR of at least 100µF should be chosen.

The Drain and Feedback lines should be well separated to avoid any ringing or crosstalk. It is

recommended to shield at least one of the above lines.

The Reset circuit should include a current limiter. This will protect the sensitive reset diode mechanism

inside the SDD. It is recommended to use an in-line resistor of at least 2kΩ.

Fig. 21: Preamplifier connection block diagram

Rev. 3

Page 22 of 29

KETEK GmbH

KETEK VITUS SDD Manual

16.6.

Peltier Characteristics

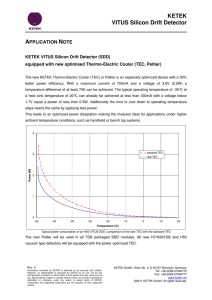

The KETEK Silicon Drift Detectors are provided in three different performance grades, based on the

package’s internal atmosphere and size: evacuated TO-8 packages (H7, H20, H30, and H50);

evacuated non-TO-8 packages for larger devices (H80, R100); and, low-energy, nitrogen filled TO-8

packages (H7-LE, H15-LE). The three types have different cooling capabilities because of the

different internal atmosphere (vacuum or nitrogen) and different sizes.

4

H7-LE

3

H80

Power [W]

H7

2

1

0

-60

-50

-40

-30

-20

-10

0

10

20

Temperature [°C]

Fig. 22: Typical power consumption of the three different KETEK VITUS SDDs

It is strongly recommended to limit the current as mentioned in chapter “10. Absolute Maximum

Ratings”. Stresses above those listed under “Absolute Maximum Ratings” may cause permanent

damage to the device. Functional operation of the device at these or any other conditions above those

indicated in the applications and operations section of this specification is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Please note that the behaviour of the Peltiers can vary with changed ambient temperatures. The

efficiency of the Peltier elements is increasing approximately by 0.5K for each Kelvin of increasing

ambient temperature. Additionally the step response factor will change which will influence the

parameters of the control loop for the regulation of the operating temperature.

Rev. 3

Page 23 of 29

KETEK GmbH

KETEK VITUS SDD Manual

20

10

0

100mA

Temperature [°C]

-10

-20

200mA

-30

300mA

-40

400mA

-50

500mA

700mA

-60

0

50

100

150

200

250

300

350

400

Time [s]

Fig. 23: Typical H7 step response functions for different Peltier currents

using a diode as temperature sensor with 1µA operating current and 10V compliance voltage.

20

10

100mA

0

Temperature [°C]

200mA

-10

300mA

-20

400mA

500mA

-30

600mA

700mA

-40

800mA

900mA

-50

1000mA

-60

0

50

100

150

200

250

300

350

400

Time [s]

Fig. 24: Typical H80 step response functions for different Peltier currents

using a diode as temperature sensor with 1µA operating current and 10V compliance voltage.

20

100mA

Temperature [°C]

0

200mA

300mA

400mA

-20

500mA

600mA

700mA

900mA

-40

-60

0

50

100

150

200

250

300

350

400

Time [s]

Fig. 25: Typical H7-LE step response functions for different Peltier currents

using a diode as temperature sensor with 1µA operating current and 10V compliance voltage.

Rev. 3

Page 24 of 29

KETEK GmbH

KETEK VITUS SDD Manual

17. Collimator

The KETEK Multilayer Collimator consists of a Tantalum (Ta) foil covered with stacked layers of

Chromium (Cr), Titanium (Ti) and Aluminium (Al). The purity of the layers is ≥99%.

All collimators are mounted on-chip.

Fig. 26: KETEK multi-layer collimator

Optionally, KETEK offers an external outer clip-on collimator VPROTECT. Depending on the

application, the geometry of the x-ray beam can differ. To avoid any foreign absorption or fluorescence

the additional collimator can optimize the beam geometry.

Fig. 27: KETEK additional external clip-on collimator

Rev. 3

Page 25 of 29

KETEK GmbH

KETEK VITUS SDD Manual

18. Outline Dimensions

H7LE

H15LE

Ø

4.78

H7

H20

H30

H50

H80

R100

Fig. 28: Outline dimensions of the different KETEK VITUS Silicon Drift Detector types

Rev. 3

Page 26 of 29

KETEK GmbH

KETEK VITUS SDD Manual

19. Footprint

For H7, H20, H30, H50 SDDs: (Bottom View), M4x6 Screw

Mating connectors:

-

Type Tyco Electronics/AMP 6-5330808-5

For H80 and R100 SDDs: (Bottom View), M6x8 Screw

Mating connectors:

Rev. 3

-

Type Tyco Electronics/AMP 2-5331272-3

-

Type Tyco Electronics/AMP 2-5331272-7

Page 27 of 29

KETEK GmbH

KETEK VITUS SDD Manual

20. Ordering Guide

Encapsulation

Window

Cap

material

Collimator

-

Active area

-

window

Chip entrance

O

Temp. Sensor

2

Peltier

F

FET

5

450µm

Chip thickness

Product VITUS

V

Example:

V5F2T0-H30-ML8BEV: VITUS 450µm SDD Chip with low capacitance FET and a Thermistor as

temperature sensor, active area of 30mm² with high peak-to-background ratio, multilayer collimator in

a bevelled cap with a Be window sealed under vacuum.

21. Optional

Optional available are different KETEK products in combination with the VITUS Silicon Drift Detector:

-

KETEK Preamplifier: High performance stand-alone preamplifier for SDD applications

-

KETEK VICO: VITUS Components, -PA: Preamplifier, -TC: TEC/Peltier Controller, -HV: High

Voltage Power Supply, -DP: Digital Pulse Processor, -EV: Evaluation Board

-

KETEK VIAMP: VITUS SDD in combination with preamplifier

-

KETEK AXAS: Analytical X-ray Acquisition System

-

KETEK VPROTECT: external collimator

For detailed information please contact KETEK Sales and Marketing Office.

Rev. 3

Page 28 of 29

KETEK GmbH

KETEK VITUS SDD Manual

22. Contact

KETEK Headquarter Sales Office

KETEK GmbH

Hofer Str. 3

81737 München

Email

info@ketek.net

Phone +49 (0) 89 673467 75

Fax

+49 (0) 89 673467 77

www.ketek.net

Rev. 3

Page 29 of 29

KETEK GmbH