Available online at www.sciencedirect.com

CERAMICS

INTERNATIONAL

Ceramics International 41 (2015) 14157–14164

www.elsevier.com/locate/ceramint

Thermally induced crystallization of mechanically alloyed Na0.5Bi0.5TiO3

and K0.5Bi0.5TiO3 piezoelectric ceramic nanopowders

S. Baradarana,n, Bahman Nasiri-Tabrizib,nn, T.S. Velayuthamc, W.J. Basirund, Ahmed A.D. Sarhana

b

a

Department of Mechanical Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia

Advanced Materials Research Center, Materials Engineering Department, Najafabad Branch, Islamic Azad University, Najafabad, Iran

c

Low Dimensional Materials Research Centre, Physics Department, University of Malaya, 50603 Kuala Lumpur, Malaysia

d

Department of Chemistry, Faculty of Science, University of Malaya, 50603 Kuala Lumpur, Malaysia

Received 24 May 2015; received in revised form 28 June 2015; accepted 6 July 2015

Available online 15 July 2015

Abstract

Thermally induced crystallization of mechanically alloyed K0.5Bi0.5TiO3 and Na0.5Bi0.5TiO3 piezoelectric ceramic nanopowders was

investigated. The raw materials with a distinct molar ratio were initially mixed and milled in a high-energy ball mill under air atmosphere at

room temperature for 1 h. After the mechanical activation, the resultant powders were annealed between 500 and 700 1C for 1 h to crystallize the

mechanosynthesized powders. The results show that the mode of the reaction was progressive and consists of two stages: (i) the decomposition of

some reagents to oxides and (ii) the reaction of Bi2O3 and TiO2 with potassium and sodium oxides which led to the formation of fine powders.

From the structural point of view, the crystallite size and lattice strain of K0.5Bi0.5TiO3 nanopowder were 30 nm and 0.427%, respectively, while

the Na0.5Bi0.5TiO3 powder gave a crystallite size of 37 nm and lattice strain of 0.340%. In accordance with the TEM images, upon heat treatment

at 700 1C, coalescence of the grains led to the appearance of relatively large grains, with cubic (55 7 10 nm) and spheroidal (75 715 nm)

morphologies, for the K0.5Bi0.5TiO3 and Na0.5Bi0.5TiO3 powders, respectively.

& 2015 Elsevier Ltd and Techna Group S.r.l. All rights reserved.

Keywords: Piezoelectric ceramic; Crystallization; Progressive reaction; Nanopowder

1. Introduction

Lead oxide-based piezoelectric ceramics such as lead titanate

(PbTiO3) are extensively utilized for piezoelectric actuators,

sensors and transducers due to their superior piezoelectric

properties [1]. Nonetheless, the volatilization of toxic lead oxide

and its high vapor pressure during processing not only causes

environmental pollution but also degrades the composition and

their electrical properties [2]. Therefore, the development of

environmentally friendly lead-free piezoelectric materials to

replace the PZT-based ceramics has become one of the main

research focus in piezoelectric ceramics [3].

n

Corresponding author. Tel: þ98 9132275822; fax: þ98 3312291008

Correspondence to: Materials Engineering Department, Najafabad Branch,

Islamic Azad University, PO Box: 8514143131, Najafabad, Isfahan, Iran.

Tel.: þ 601 72838175; fax: þ603 79675330.

E-mail addresses: saeid_baradaran@yahoo.com (S. Baradaran),

bahman_nasiri@hotmail.com (B. Nasiri-Tabrizi).

nn

http://dx.doi.org/10.1016/j.ceramint.2015.07.038

0272-8842/& 2015 Elsevier Ltd and Techna Group S.r.l. All rights reserved.

Among the wide range of lead-free piezoelectric ceramics,

potassium bismuth titanate K0.5Bi0.5TiO3 (KBT) and sodium

bismuth titanate Na0.5Bi0.5TiO3 (NBT), are among the A-site

complex perovskite bismuth titanate compounds (generic

formula ABO3), have received much attention due to their

excellent ferroelectric properties and relatively high Curie

temperature of 653 and 593 K, respectively [4]. The pyroelectric features of KBT and NBT were investigated and a

positive temperature coefficient of resistivity (PTCR) effect

was detected in alkaline bismuth titanates. This phenomenon

was comprehensively examined by several authors [5–7].

From the structural point of view, KBT has a tetragonal

symmetry with a=b=3.918 Å and c=4.013 Å at room temperature and shows a phase transition into the pseudo-cubic

phase and cubic phase at nearly 270 1C and 420 1C, respectively [8]. On the other hand, the structure of NBT between 5

and 528 K is purely rhombohedral and characterized by the

polar space group R3c, with a–a–a– anti-phase tilts of the

14158

S. Baradaran et al. / Ceramics International 41 (2015) 14157–14164

2. Materials and methods

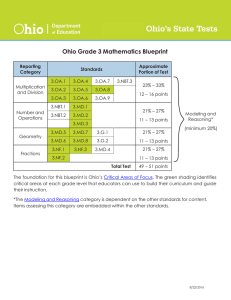

Table 1

Detailed specifications of the specimens.

Sample Powder components

S1

S2

S3

S4

S5

S6

K2CO3–Bi2O3–TiO2

K2CO3–Bi2O3–TiO2

K2CO3–Bi2O3–TiO2

Na2CO3–Bi2O3–TiO2

Na2CO3–Bi2O3–TiO2

Na2CO3–Bi2O3–TiO2

Milling time (h) Annealing temperature (1C)

1

1

1

1

1

1

–

500

700

–

500

700

2.1. Raw materials

Sodium carbonate (Na2CO3, Z 99.5%), potassium carbonate (K2CO3, 99.99%), titanium dioxide (TiO2, Z 99%), and

bismuth trioxide (Bi2O3, 99.99%) were used as reagents

without further purifications.

2.2. Mechanical activation

oxygen octahedra around the pseudo-cubic axes and parallel

cation displacements [9]. The ideal cubic perovskite structure

occurs at higher-temperatures (above 813 K). On the other

hand, the co-existence of rhombohedral and tetragonal phases

is evident between 573 and 593 K and a purely tetragonal

phase occurs at above 673 K [10]. From a synthetic perspective, piezoelectric ceramics are usually prepared by solid-state

reaction method, which consists of a calcination process below

1000 1C, where the raw materials such as Na2CO3, K2CO3,

Bi2O3 and TiO2 react with each other to form the KBT and

NBT, and a sintering process above 1000 1C [11–13]. In

accordance with previous studies, the sintering temperature of

the powders varies from 1030 to 1120 1C, which is mismatched with the report of the sample melting at 1070 1C [14].

In addition, the wet chemical synthesis techniques such as sol–

gel [3], hydrothermal [4], and molten salt methods [15] have

been developed for preparing the piezoelectric ceramics.

However, it has been reported that the hydrothermal and

sol–gel synthesis are usually long and complex processes,

involves the use of hazardous solvents such as 2methoxyethanol and expensive starting materials [15] and

often results in agglomerated particles [16]. Therefore, the

synthesis and characterization of KBT and NBT is still a

widely discussed problem. Although the optical and dielectric

properties of these ceramics, as well as structural phase

transitions have been widely studied [5,6,17], the mechanothermal synthesis and characterization of nanostructured KBT

and NBT have not been conclusively established.

From a traditional perspective of the solid-state process, the

ceramic powders are synthesized via conventional powder

processing which frequently needs high calcination temperature, long periods of milling time and repeated grindings [18].

This process can lead to an increase in the level of contamination and introduce some undesirable phases if the raw

materials are milled for extended durations [19]. It has been

shown recently that in many cases, the KBT and NBT

ceramics are not the direct products of extended milling times

(20–24 h), rather the products of high annealing temperature at

long time periods (950 1C for 10 h) [13,20,21]. Therefore, in

the present study, the influence of short-time milling (one-step

dry mechanical activation) and thermally induced crystallization on the phase transition, structural features and morphological characteristics of the KBT and NBT nanopowders were

studied with a detailed investigation on the microstructural and

chemical composition of the products.

Here, the influence of mechanical activation on mechanochemical behavior of X (Na2CO3, K2CO3)–Bi2O3–TiO2

ternary system and subsequent annealing on the crystallization

of the milled powders were studied. Therefore, the mixtures of

Na2CO3, K2CO3, Bi2O3, and TiO2 with a stoichiometric

composition were mechanically activated via high-energy ball

milling for 1 h (Table 1). It is expected that the reaction in this

system involves two steps: first, the decomposition of Na2CO3

and K2CO3 during activation and second, the reaction of Na2O

and K2O with other reagents which may lead to the formation

of the KBT and NBT nanopowders.

2.3. Preparation of nanopowders

The Na2CO3, K2CO3, Bi2O3, and TiO2 with a molar ratio of

1:1:4 (reaction 1 and 2) were initially mixed, and the powders

were ball-milled for 1 h in a high-energy ball milling using

zirconia vials (50 ml) and balls (10 mm diameter) in air

atmosphere at room temperature. The ball-to-powder (BPR)

weight ratio, total powder mass and rotational speed were 8:1,

4 g, and 500 rpm, respectively. After the mechanical activation, the powders were annealed between 500 and 700 1C for

1 h to crystallize the mechanosynthesized powder. The heating

rate from room temperature to the desired temperature was

fixed at 10 1C min–1

Na2CO3 þ Bi2O3 þ 4TiO2-4Na0.5Bi0.5TiO3 þ CO2↑

(1)

K2CO3 þ Bi2O3 þ 4TiO2-4K0.5Bi0.5TiO3 þ CO2↑

(2)

2.4. Characterization of nanopowders

The phase compositions were analyzed by powder X-ray

diffraction (XRD) analysis with a PANalytical Empyrean Xray diffractometer (Cu–Kα radiation) over a 2θ range from 201

to 801. The XRD patterns were compared to standards

compiled by the Joint Committee on Powder Diffraction and

Standards (JCPDS), with card 036-0339 for KBT and 0360340 for NBT. To identify the functional groups of the

powders, attenuated total reflection (ATR) analysis was

performed on a Tensor 27 (Bruker FT-IR spectrophotometer)

with a frequency range of 4000 400 cm 1. The microstructure of the products was analyzed with TEM (HT-7700,

Hitachi, Japan), while Energy Dispersive X-ray Spectrometry

(EDS) and elemental mapping analysis were employed to

S. Baradaran et al. / Ceramics International 41 (2015) 14157–14164

14159

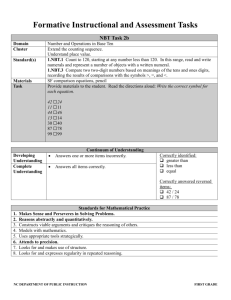

Fig. 1. (a) XRD patterns of the mechanically alloyed powder and the standard samples of the raw materials as well as (b) the milled powders after thermal treatment

at 700 1C for 1 h.

investigate the chemical constituents in the selected areas and

the spatial distribution of elements in specimens.

3. Results and discussion

3.1. Phase structure and structural features (XRD analysis)

Fig. 1a shows XRD patterns of the mechanically alloyed

powders and standard samples of the raw materials. All

diffractograms display sharp diffraction peaks with cubic,

tetragonal and monoclinic symmetries, which indicates the

presence of K2O, TiO2 and Bi2O3 after 1 h of milling time.

From this profile, no trace of KBT was detected and particle

size reduction begins after the mechanical activation. The

XRD patterns of the milled powders after thermal treatment at

700 1C for 1 h are shown in Fig. 1b. The formation and

crystallization of milled powders occurred during annealing at

700 1C and the characteristic peaks of KBT with tetragonal

symmetry are as follows: (1 0 0) plane at 2θ ¼ 22.551, (1 0 1)

plane at 2θ ¼ 32.091, (1 1 1) plane at 2θ ¼ 39.461, (0 0 2) plane

at 2θ ¼ 44.591, (2 0 0) plane at 2θ ¼ 46.221, (1 0 2) plane at

2θ ¼ 52.001, (2 1 1) plane at 2θ ¼ 57.101, and (2 2 0) plane at

2θ ¼ 67.581. On the other hand, the NBT with rhombohedral

symmetry are as follows: (1 0 1) plane at 2θ ¼ 23.141, (0 1 2)

plane at 2θ ¼ 32.861, (0 2 1) plane at 2θ ¼ 40.471, (2 0 2) plane

at 2θ ¼ 46.661, (1 1 3) plane at 2θ ¼ 52.451, (1 2 2) plane at

2θ ¼ 58.191, and (2 2 0) plane at 2θ ¼ 68.481. From the XRD

profiles, it is obvious that the preferred orientation of KBT and

NBT took place along the (1 0 1) and (0 1 2) planes, respectively. In addition, it is clear that the mechanical activation was

accompanied by the simultaneous presence of uniform

(macro-) and non-uniform (micro-) strains which resulted in

both peak shift and peak broadening, respectively. After

annealing at 700 1C, the crystallization and recovery of the

crystal lattice occurred, and thus the characteristic peaks of

KBT and NBT intensified and shifted to the standard position.

Several theoretical models have been developed to obtain

structural information through mathematical analysis of the

XRD profiles [19,22]. Among them, the Williamson–Hall

equation is a simplified integral breadth method which is

based on the broadening of the diffraction lines due to the

strain and crystallite size. The equation is as follows:

B cos θ ¼

0:9λ

þ η sin θ

D

ðIÞ

where λ, D, η and θ are the wavelength of the X-ray

(0.154056 nm), crystallite size, internal micro-strain and the

Bragg angle (1), respectively. Note that B in the equation is the

peak width (in radians) after subtracting the peak width due to

the instrumental broadening. Therefore, when B cosθ is

plotted against sinθ, straight lines were obtained for samples

with slope η and the intercept 0.9 λ/D. Moreover, if we

assume that a crystallite is a sphere of diameter D surrounded

by a shell of grain boundary with thickness t, then the volume

14160

S. Baradaran et al. / Ceramics International 41 (2015) 14157–14164

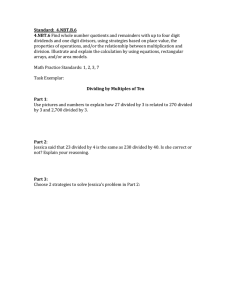

Table 2

Crystallite size and lattice strain of the milled samples after annealing at 700 1C for 1 h.

Sample

Powder components

Annealing temperature (1C)

D (nm)

η (%)

f (%)

S3

S6

K2CO3–Bi2O3–TiO2

Na2CO3–Bi2O3–TiO2

700

700

30 72

37 72

0.427

0.340

9.36

7.68

fraction of the grain boundary (f) is approximately [23]

3

D

f ¼ 1

ðD þ tÞ

ðIIÞ

Here, the values of f were calculated by substituting the values

of the crystallite size obtained from the Williamson–Hall plots

with D with an assumption of t¼ 1 nm. The crystallite size, lattice

strain and volume fraction of the grain boundary of the milled

samples after thermal treatment at 700 1C are summarized in

Table 2. For the KBT powder, the crystallite size and lattice strain

are 30 nm and 0.427%, respectively, while the NBT nanopowder

exhibited a crystallite size and lattice strain of 37 nm and 0.340%,

respectively. Furthermore, from the obtained data, the volume

fraction of grain boundary of KBT and NBT powders is 9.36%

and 7.68%, respectively. This behavior suggests that the structural

features of the mechanosynthesized lead oxide-based piezoelectric

ceramics were influenced by the chemical composition of the

reagents. From a comparative view, this variation in percentage of

volume fraction of grain boundary resulted mainly from the

differences in crystallite size of the samples after annealing. This

indicates that by choosing the appropriate milling and annealing

conditions, different piezoelectric nanopowders with various

nanostructural features may be generated, where each of them

could be used for specific applications.

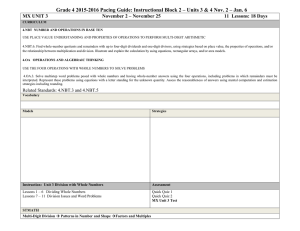

3.2. Evaluation of the functional groups (FT-IR analysis)

The FT-IR spectra of the milled samples before and after

thermal treatment at 700 1C were recorded in the range of

4000–400 cm–1 (Fig. 2). As can be seen, the milled powders

before thermal treatment show several bands especially above

1000 cm–1, which shows that no chemical reaction occurred during

the mechanical activation. In contrast, the annealed specimens

did not demonstrate any bands above 1000 cm–1. It should be

mentioned that, the intermediate band at approximately 2350 cm–1

is not a characteristic of the specimens; but belongs to the KBr

itself [24]. For the annealed samples, single broad bands were

observed in the range of 1000–400 cm–1, which belongs to the

stretching vibration of Ti–O [25]. From the FT-IR spectra, the

synthesized nanopowders showed high chemical purity which is

very important in piezoelectric applications.

3.3. Morphological characterization (TEM analysis)

The performances of nanostructured ceramics for piezoelectric applications are strongly dependent on their morphological

features [26]. However, particle shape analysis is one of the

most difficult problems in powder technology because there is

no general shape factor available that clearly differentiates all

possible kinds of morphologies [27,28]. Here, for a better

understanding of the effect of mechanothermal process on the

morphological features, TEM analysis was carried out at low

and high magnifications. Fig. 3 shows the morphology and

particle size distribution of the 1 h milled samples after thermal

annealing at 700 1C. At the beginning of milling, the above

mentioned system involves three types soft powders. With the

increase of the milling time (continued deformation), this soft

system may be transformed to the ductile-brittle system with

brittle components. Due to the distribution of these brittle

phases, the work hardening and transformation of ductile

particles into the lamellar shapes were the dominant phenomena.

With continued deformation, the lamellae and brittle particles

are further refined, the interlamellar spacing decreased, and the

brittle components are uniformly dispersed. Finally, a balance

between fracturing brittle particles by trapping and ductile

constituents by work hardening caused the formation of fine

powders [29].

A redistribution of defects and the formation of areas with

different concentrations of vacancy-type defects as well as the

release of internal strain may be the main reasons for the

formation of KBT and NBT nanopowders after annealing at

700 1C. From the high magnification TEM images, the

coalescence of the grains occurred upon heat treatment at

700 1C, which led to the appearance of relatively large grains

with cubic (55 7 10 nm) and spheroidal (75 7 15 nm)

morphologies, for the KBT and NBT nanopowders, respectively. In fact, during annealing at 700 1C, the fine particles

convert into individual grains, therefore the grain boundary

energy is minimized by thermal grooving; i.e., grain boundary

grooving to achieve the equilibrium of cubical and spheroidal

shapes. This phenomenon is in good agreement with previous

studies [20].

In addition, severe agglomerations occurred for both

mechanochemical reactions as observed in Fig. 4. This

behavior was due to the relatively large specific surface area

which is associated with the van der Waals interactions. From

a mechanochemical perspective, when two adjacent primary

particles collide, the coalescence may occur on the premise

that these two particles share a common crystallographic

orientation. Accordingly, two primary particles attach to each

other and combine to form a secondary particle. Since the sizes

of the secondary particles are still very small, it is reasonable

that they will continue to collide and coalesce, which may

ultimately lead to particle agglomeration [22]. Thereafter, the

substantial growth of agglomerates/nanoparticles was dominant during the annealing, therefore the KBT and NBT

nanopowders composed of both fine grains and large agglomerates at 700 1C.

S. Baradaran et al. / Ceramics International 41 (2015) 14157–14164

Fig. 2. FT-IR spectra of the milled samples before and after thermal treatment at 700 1C; (a) KBT and (b) NBT nanopowders.

Fig. 3. TEM images of (a,b) KBT and (c,d) NBT nanopowders after thermal treatment at 700 1C for 1 h at low and high magnifications.

Fig. 4. TEM images of agglomerated particles of (a) KBT and (b) NBT nanopowders after thermal treatment at 700 1C for 1 h.

14161

14162

S. Baradaran et al. / Ceramics International 41 (2015) 14157–14164

Fig. 5. EDS spectra and elemental mapping images of (a) KBT and (b) NBT nanopowders after thermal treatment at 700 1C for 1 h.

3.4. EDS analysis and elemental mapping

To achieve a better understanding of the XRD patterns, the

EDS analysis and elemental mapping are presented in Fig. 5.

From the EDS spectra, potassium, sodium, titanium, oxygen and

carbon are the major elements and contamination due to the

excessive wearing of the vial and balls was absent. This confirms

that the samples had an appropriate chemical purity owing to the

absence of chemically stable contaminants. These results are in

accordance with the XRD results, which show that the formation

of KBT and NBT nanopowders with high phase purity. On the

other hand, the similarity of the recorded data over three different

points on the samples revealed that the products had homogenous

microstructures. From the elemental mapping images in Fig. 5, an

appropriate spatial distribution of elements in the samples was

observed with the formation of homogenous microstructures after

the mechanothermal process. It is obvious that K, Na, Ti, Bi and

O as representatives of the KBT and NBT phases, had proper

distribution patterns.

3.5. Formation mechanism of KBT and NBT nanopowders

Depending on the mechanical activation conditions, the

mechanical attrition processes fall into two categories: progressive reaction and mechanically induced self-sustaining

reaction (MSR) [30]. In the first method, the reaction may

S. Baradaran et al. / Ceramics International 41 (2015) 14157–14164

extend to a very small volume during each collision, resulting

in a gradual transformation. In the second style, if the reaction

enthalpy is sufficiently high, a self-propagating combustion

reaction can be initiated after a certain time. In the selfpropagating mode, the occurrence of the combustion reaction

causes a rapid increase in temperature of the milling media,

and provides suitable conditions for a quick transformation.

This type of reaction mechanism can be predicted by calculating the adiabatic temperature (Tad). The value of Tad, the

maximum temperature which could be attained as a result of

the reaction heat, can be calculated using the following

equation [31]:

Z Tad X

Q ¼ ð ΔH 298 1Þ ¼

Cp ðProductsÞdT

ðIIIÞ

298

where Cp, ΔH 298 1 and Q are specific heat capacity, standard

enthalpy changes of formation at 298 K and heat of reaction,

respectively.

It has been reported that the reaction can be a self-sustained

combustion, when the adiabatic temperature of the reaction is

higher than 1800 K [31]. Here, due to the unavailability of

KBT and NBT thermodynamic data, the calculation of Tad is

not possible. However, owing to the lack of high exothermic

reactions, it seems that the Tad value is lower than 1800 K,

suggesting that the mode of the reaction in the above

mentioned system is a progressive reaction which involves

two stages: (i) the decomposition of Na2CO3 and K2CO3 to

Na2O and K2O, respectively, and (ii) the reaction of Bi2O3 and

TiO2 with K2O and Na2O which may lead to the formation of

KBT and NBT nanopowders, respectively. This can be

explained by the reactions shown in Eqs. (3)–(6).

14163

the combination of mechanochemical and thermal processing

methods. In this method, due to the subsequent thermal

treatment, various milled systems may be activated, which

can lead to the formation of a wide range of advanced

materials such as nanostructured compounds, nanocomposites

etc [32]. Hence, this approach is not only an interesting

method from a theoretical point of view, but also has many

attractive features for industrial applications, where simplicity

and high productivity are of prime importance.

4. Conclusion

The effect of short-time milling (one-step dry mechanical

activation) and thermally induced crystallization on the phase

transition and structural features of the KBT and NBT

nanopowders were studied by a detailed investigation of the

microstructural and chemical composition of the products.

From the XRD profiles, traces of KBT and NBT phases were

absent after the mechanical activation. During annealing at

700 1C for 1 h, crystallization of milled powders occurred and

consequently the characteristic peaks of KBT with tetragonal

and NBT with rhombohedral symmetries were identified. The

substantial growth of agglomerates/nanoparticles was dominant during the annealing, therefore the KBT and NBT

nanopowders composed of both fine grains and large agglomerates at 700 1C. From the elemental mapping images, an

appropriate spatial distribution of elements in the samples was

observed, which showed the formation of homogenous microstructures after the mechanothermal process. In a nutshell, the

above mentioned approach is not only an interesting method

from a theoretical point of view, but also has many attractive

features for industrial applications.

Na2CO3-Na2O þ CO2

(3)

K2CO3-K2O þ CO2

(4)

Acknowledgment

Na2O þ Bi2O3 þ 4TiO2-4Na0.5Bi0.5TiO3

(5)

K2O þ Bi2O3 þ 4TiO2-4K0.5Bi0.5TiO3

(6)

This work has been supported by the University of Malaya,

Grant No. UM.C/625/1/HIR/166 and FP033 2013A. The

authors are also grateful to Research Affairs of Islamic Azad

University, Najafabad Branch for supporting of this research.

This assessment was achieved from the following assumptions: (a) milling vial was sealed and isolated (b) all the

reactions occurred in the standard conditions (ΔG=ΔG1)

(c) the activity coefficient of raw materials was equal to 1,

and (d) the reactions occurred in the same physical conditions.

In the progressive reaction systems, heavy deformation is

introduced into the particles as a result of the presence of a

variety of crystal defects like dislocations, vacancies, stacking

faults, and increased number of grain boundaries. The high

defect densities induced by ball milling and the refined

microstructural features accelerates the diffusion process and

decreases the diffusion distance, respectively. Besides, the

slight increase in temperature during processing is a contributing factor for the acceleration of the diffusion process [30].

However, the KBT and NBT ceramics are not directly

produced by ball milling, but only after a proper thermal

treatment due to the redistribution of defects and the liberation

of internal strain during the annealing. This shows that the

mechanothermal method is a complex process which involves

References

[1] M. Zannen, M. Dietze, H. Khemakhem, A. Kabadou, M. Es-Souni, The

erbium's amphoteric behavior effects on sodium bismuth titanate properties, Ceram. Int. 40 (2014) 13461–13469.

[2] Y. Lia, W. Chen, Q. Xu, J. Zhou, X. Gu, Piezoelectric and ferroelectric

properties of Na0.5Bi0.5TiO3–K0.5Bi0.5TiO3–BaTiO3 piezoelectric ceramics, Mater. Lett. 59 (2005) 1361–1364.

[3] L. Hou, Y.D. Hou, X.M. Song, M.K. Zhu, H. Wang, H. Yan, Sol–gelhydrothermal synthesis and sintering of K0.5Bi0.5TiO3 nanowires, Mater.

Res. Bull. 41 (2006) 1330–1336.

[4] M.M. Lencka, M. Oledzka, R.E. Riman, Hydrothermal synthesis of

sodium and potassium bismuth titanates, Chem. Mater. 12 (2000) 1323–

1330.

[5] F. Bo, C. Zhixiong, B. Tiecheng, L. Meidong, PTCR effect in ferroelectric semiconducting ceramics with bismuth perovskite structure,

Ferroelectrics 101 (1990) 219–222.

[6] S.B. Vakhrushev, V.A. Isupov, B.E. Kvyatkovsky, N.M. Okuneva,

I.P. Pronin, G.A. Smolensky, P.P. Syrnikov, Phase transitions and soft

modes in sodium bismuth titanate, Ferroelectrics 63 (1985) 153–160.

14164

S. Baradaran et al. / Ceramics International 41 (2015) 14157–14164

[7] Q. Yuan, Y. Pu, J. Wei, Effect of reoxidation on positive temperature

coefficient of resistance behavior for BaTiO3–K0.5Bi0.5TiO3 ceramics, J.

Electroceram. 30 (2013) 98–101.

[8] X. Jing, B. Huang, X. Zhang, X. Qin, J. Wei, X. Wang, S. Yao, Z. Xu,

Z. Wang, P. Wang, Structural and electrical properties of K0.5Bi0.5TiO3

thin films for ferroelectric field effect transistor applications, J. Phys. D

Appl. Phys. 42 (2009) 045421.

[9] A.M. Glazer, Simple ways of determining perovskite structures, Acta

Crystallogr. Sec. A 31 (1975) 756–762.

[10] G.O. Jones, P.A. Thomas, The tetragonal phase of Na0.5Bi0.5TiO3—a

new variant of the perovskite structure, Acta Crystallogr. Sect. B 56

(2000) 426–430.

[11] S. Zhao, G. Li, A. Ding, T. Wang, Q. Yin, Ferroelectric and piezoelectric

properties of (Na, K)0.5Bi0.5TiO3 lead free ceramics, J. Phys. D Appl.

Phys. 39 (2006) 2277–2281.

[12] J. König, M. Spreitzer, B. Jancar, D. Suvorov, Z. Samardzija, A. Popovic,

The thermal decomposition of K0.5Bi0.5TiO3 ceramics, J. Eur. Ceram.

Soc. 29 (2009) 1695–1701.

[13] M. Davies, E. Aksel, J.L. Jones, Enhanced high-temperature piezoelectric

coefficients and thermal stability of Fe- and Mn-substituted Na0.5Bi0.5TiO3 ceramics, J. Am. Ceram. Soc. 94 (2011) 1314–1316.

[14] Y. Himura, R. Aojagi, H. Nagata, T. Takenaka, Ferroelectric and

piezoelectric properties of (Bi1/2K1/2)TiO3 ceramics, Jpn. J. Appl. Phys.

44 (2005) 5040–5044.

[15] L. Li, J. Deng, J. Chen, R. Yu, L. Qiao, X. Xing, Piezoelectric and

ferroelectric properties of 0.96(Na,K)(Nb0.9Ta0.1)O3–0.04LiSbO3 ceramics synthesized by molten salt method, J. Alloy. Compd. 471 (2009)

428–431.

[16] F. Bortolani, R.A. Dorey, Molten salt synthesis of PZT powder for direct

write inks, J. Eur. Ceram. Soc. 30 (2010) 2073–2079.

[17] J. Suchanicz, J. Kwapulinski, X-ray diffraction study of the phase

transitions in Na0.5Bi0.5TiO3, Ferroelectrics 165 (1995) 249–253.

[18] T. Lu, J. Dai, J. Tian, W. Song, X. Liu, L. Lai, H. Chu, X. Huang, X. Liu,

Synthesis of Na0.5Bi0.5TiO3 powders through hydrothermal method, J.

Alloy. Compd. 490 (2010) 232–235.

[19] C. Suryanarayana, Mechanical alloying and milling, Prog. Mater. Sci. 46

(2001) 1–184.

[20] D. Maurya, V. Petkov, A. Kumar, S. Priya, Nanostructured lead-free

ferroelectric Na0.5Bi0.5TiO3–BaTiO3 whiskers: synthesis mechanism and

structure, Dalton Trans. 41 (2012) 5643–5652.

[21] S. Zhang, T.R. Shrout, H. Nagata, Y. Hiruma, T. Takenaka, S. Member,

Piezoelectric properties in (K0.5Bi0.5)TiO3–(Na0.5Bi0.5)TiO3–BaTiO3,

IEEE Trans. Ultrason. Ferroelectr. Freq. Control 54 (2007) 910–917.

[22] P. Balaz, Mechanochemistry in Nanoscience and Minerals Engineering,

1st ed., Springer, Berlin Heidelberg, 2008.

[23] F. Sun, F.H.S. Froes, Synthesis and characterization of mechanicalalloyed TixMg alloys, J. Alloy. Compd. 340 (2002) 220–225.

[24] B. Nasiri-Tabrizi, A. Fahami, Synthesis and characterization of fluorapatite–zirconia composite nanopowders, Ceram. Int. 39 (2013)

4329–4337.

[25] R. Velchuri, B. Vijaya Kumar, V. Rama Devi, G. Prasad, M. Vithal,

Solid state metathesis synthesis of BaTiO3, PbTiO3, K0.5Bi0.5TiO3, and

Na0.5Bi0.5TiO3, Ceram. Int. 36 (2010) 1485–1489.

[26] V. Cauda, G. Canavese, S. Stassi, Nanostructured piezoelectric polymers,

J. Appl. Polym. Sci. 132 (2015) 41667.

[27] P. Pourghahrsamani, E. Forssberg, Review of applied particle shape

descriptors and produced particle shapes in grinding environments: part 1:

particle shape descriptions, Miner. Process. Extr. Metall. Rev. 26 (2005)

145–166.

[28] B. Nasiri-Tabrizi, A. Fahami, Synthesis and characterization of fluorapatite–zirconia composite nanopowders, Ceram. Int. 39 (2013)

4329–4337.

[29] A. Fahami, B. Nasiri-Tabrizi, G.W. Beall, B. Pingguan-Murphy, Effect of

ion concentration on mechanosynthesis of carbonated chlorapatite nanopowders, Mater. Lett. 146 (2015) 16–19.

[30] C. Suryanarayana, N. Al-Aqeeli, Mechanically alloyed nanocomposites,

Prog. Mater. Sci. 58 (2013) 383–502.

[31] L. Takacs, Self-sustaining reactions induced by ball milling, Prog. Mater.

Sci. 47 (2002) 355–414.

[32] M. Jalaly, M.S. Bafghi, M. Tamizifar, F.J. Gotor, Mechanosynthesis of

nanocrystalline ZrB2-based powders by mechanically induced selfsustaining reaction method, Adv. Appl. Ceram. 112 (2013) 383–388.