EE 100-Engineering Laboratory

advertisement

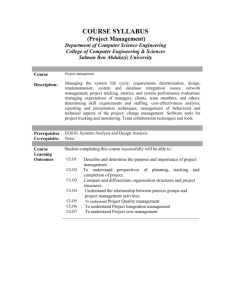

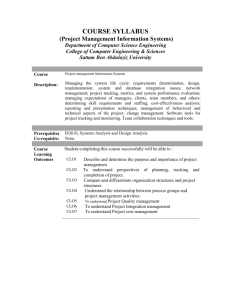

Lahore University of Management Sciences EE100: Engineering Laboratory Spring 2015-16 Course Catalog Description This course is designed for freshmen engineering and science students to provide them a basic introduction of various stages involved in an engineering product design. It will help students to interpret and create computer aided mechanical parts and assembly drawings, interpret and create schematic and layout drawings for electronic circuits, Identify materials and select manufacturing processes for engineering products. Students will also be given an opportunity to get hands on experience on conventional and non-conventional machines such as CNC and 3D printers for rapid prototyping. The course is divided into four modules each of which contains lab tasks for practice and module project to test the concepts learned. The final module is a course project in which students shall use all the concepts learned in this course in order to consolidate their learning and to give them an opportunity to work with in larger team. Course Details Credit Hours Core Elective Open for Student Category Closed for Student Category 1 Core Course for Electrical Engineering No SBASSE N/A Course Prerequisite(s)/Co-Requisite(s) Pre-requisites: None Co-requisites: None Course Offering Details Lecture(s) Number of Lecture Per Week 1 Duration Course Modules Number of Modules Per Semester 5 Duration Course Instructor Room No. Office Hours Dr. –Ing. Ahmad Kamal Nasir 9-313 Monday : 1000-1100 Wednesday : 1000-1100 ahmad.kamal@lums.edu.pk sameen.ghaffar@lums.edu.pk +92 (42) 3560 3531 Engr. Sameen Ghaffar Omer Qureshi (TBA) (TBA) Tuesday : 0000-0000 (TBA) Wednesday : 0000-0000 (TBA) LMS, http://web.lums.edu.pk/~akn/engineering_laboratory_fall_2015-16.html Email Telephone Lab Engineer Lab Technician Teaching Assistance TA Office Hours Course URL (if any) 170 min Timings and Venue Fri. 0000-0000 – Section I – EE LAB 6 Fri. 0000-0000 – Section II – EE LAB 6 Mon. 0000-0000 – Section III – EE LAB 6 Thr. 0000-0000 – Section IV – EE LAB 6 PCB : 03 Weeks CAD : 04 Weeks Electrical Wiring : 01 Weeks Machining Processes : 02 Weeks Course Project : 04 Weeks Course Learning Outcomes EE100The students should be able to: CLO1: Identify electrical/electronic devices and usage of electrical/mechanical measurement tools CLO2: Identify manufacturing process and materials in an engineering product design. CLO3: Create and interpret mechanical drawings CLO4: Create and interpret electronic schematics and layout drawings. CLO5: Use modern CAD/CAM and other rapid prototyping tools for engineering design. CLO6: Recall and demonstrate workshop/industrial safety practices. CLO7: Work within a team toward finding solutions for engineering problems. Page 1of 3 Lahore University of Management Sciences Relation to EE Program Outcomes EE-100 Related PLOs CLOs CLO1 PLO1 CLO2 PLO1 CLO3 PLO1 CLO4 PLO1 CLO5 PLO5 CLO6 PLO6 CLO7 PLO9 Levels of Learning Teaching Methods Cog-1,2 Cog-1,2 Cog-1,2 Cog-1,2 Cog-2 Cog-1,2 Cog-3 Lecture, Demo Lecture, Demo Lecture, Demo Lecture, Demo Lecture, Demo Lecture, Demo Lecture Grading Breakup and Policy Assessment Module Final Examination Lab Tasks Course Projects Numbers 1 12 5 CLO Attainment checked in Final Exam, Lab Tasks, Projects Final Exam, Projects Final Exam, Lab Tasks, Projects Final Exam, Lab Tasks, Projects Final Exam, Lab Tasks, Projects Final Exam, Projects Lab Tasks, Projects Weightage 38 % 1 x 12% (8 x 4 + 18 x 1) 50 % Textbook(s)/Supplementary Readings Textbook: Lectures and handouts will be provided where necessary Supplementary Reading: A- Design and Technology, 2nd Edition, James Garratt, Cambridge University Press B- Creo Parametric 2.0 Introduction, Christopher F. Sikora C- Basic Engineering Drawing, R.S. Rhodes & L.B. Cook COURSE OVERVIEW Week No. Module Topic 1 PCB 2 3 4 CAD 5 6 Introduction to the course and its contents Introduction to basic electronics components Circuit Design Principles Lab Task: Draw schematic circuit for simple problem PCB Fabrication: Introduction to conventional/nonconventional PCB fabrication process. Demonstration: Etching and soldering Demonstration: PCB CNC milling and drilling Introduction to Proteus ISIS Circuit Design and Simulation Tutorials: Create computer schematic and simulate circuit Lab Task: Create layout in Proteus ARES Introduction to Proteus ARES Circuit Layout Design Tutorials: Create computer PCB layout for electronic circuits Module Project : PCB Fabrication and Soldering Design methodology for scientists and engineers Introduction to Engineering Drawing Engineering Drawings o Projections, Dimensions, Drawing interpretation Workshop / Industrial Safety Practices Lab Task: Sketch orthographic projections of solid objects Lab Visit: Overview of workshop facilities Computer Aided Modeling o Intro to PTC Creo and its features o 2D sketching o Basics of 3D object modeling Lab Task: 3D part modeling. Advanced features of PTC Creo Parametric 2.0: Lab Task: 3D part modeling Reference Related CLOs & Additional Remarks A-Ch6 Lecture Notes CLO1 CLO4 Lab Tasks (3) Project deadline (2 Weeks) Lecture Notes A- Ch2 C- Ch1,2 CLO3 CLO6 Lab Tasks (8) Project deadline (2 Weeks) B B Page 2of 3 Lahore University of Management Sciences 7 8 Electrical Panel and Wiring Assembly Lab Task: Assembly task Module Project: Parts and Assembly Model Design Wiring systems and their uses Module Project: Electrical Wiring and Fitting Introduction to Workshop Facilities Workshop Technologies o Conventional: (Introduction to the Process and basic tools) (Casting, Forging ,Welding, Molding, Machining, Fitting ) o Non –Conventional Prototyping Techniques/Additive manufacturing (3D Printing, Selective Laser Sintering,) Introduction to engineering materials and their properties Introduction to Machining Lathe and Milling Machine Operations Demonstration: Conventional Machining Operations Fabrication of a CAD model using traditional workshop operations Lab Task: G-Codes for a part file Demonstration: 3D Printer based prototyping Demonstration: CNC Milling machine Module Project: Machining a part on Lathe Course Project: Robot Competition Creo Parametric 2.0 part and assembly drawings of a wall follower robot 9 Machining Processes 10 11 Course Project Circuit fabrication, testing and debugging 13 System Integration and final testing 14 Robot Competition and Project Report 15 Final Examination 12 B Lecture Notes Lecture Notes CLO7 Project deadline (In Lab) CLO1 CLO2 CLO5 Lab Tasks (1) Project deadline (2 Weeks) Lecture Notes CLO3 CLO4 CLO7 Project deadline (2 Weeks) 100 mins Examination Details Final Examination Prepared by: Date: Yes/No: Yes Combine/Separate: Combine Duration: 100 minutes Exam Specifications: MCQ, Short Questions and Answers Dr. –Ing. Ahmad Kamal Nasir 10 November 2015 Page 3of 3