Design Guide for Connector Polarizing and Guidance Systems

advertisement

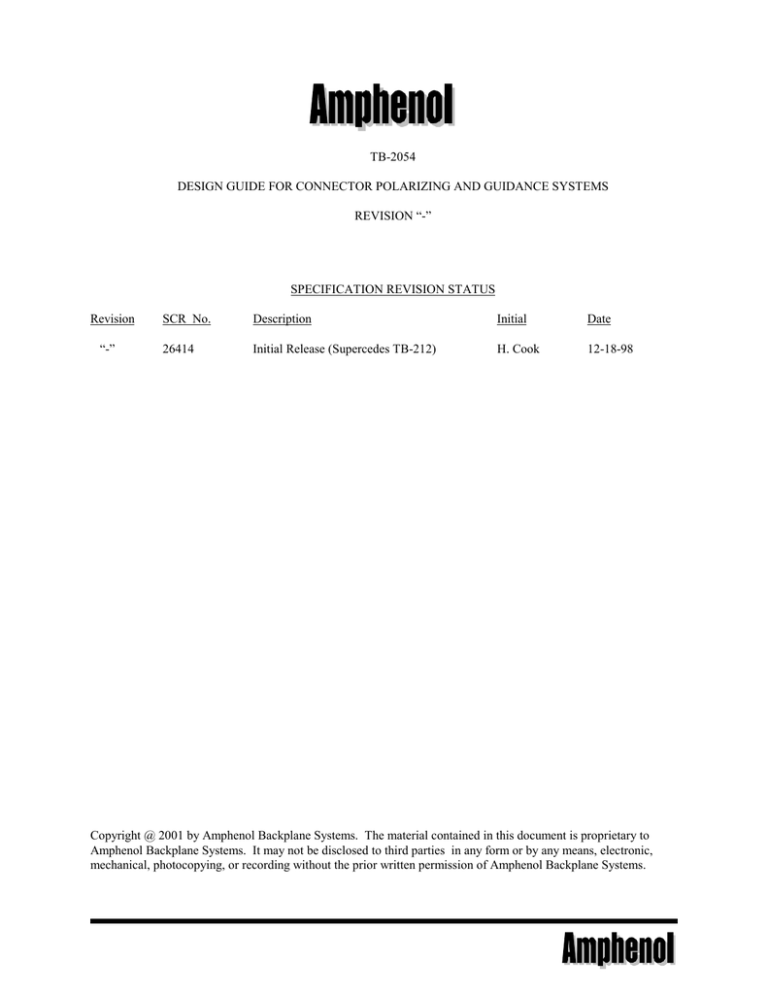

TB-2054 DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS REVISION “-” SPECIFICATION REVISION STATUS Revision “-” SCR No. Description Initial Date 26414 Initial Release (Supercedes TB-212) H. Cook 12-18-98 Copyright @ 2001 by Amphenol Backplane Systems. The material contained in this document is proprietary to Amphenol Backplane Systems. It may not be disclosed to third parties in any form or by any means, electronic, mechanical, photocopying, or recording without the prior written permission of Amphenol Backplane Systems. TB-2054 1.0 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 2 OF 10 SCOPE 1.1 This technical bulletin describes available polarizing pins, keys, guide pins, and mating guide bushings. 2.0 PROCEDURE 2.1 The polarizing and guidance systems described in this technical bulletin are primarily for male blade and tuning fork connector systems but may be used with other product lines. 2.2 A proven method of polarizing and guidance is the “SEM” (Standard Electronic Module) or otherwise known as the “NAFI” (Naval Avionics Facility, Indianapolis) System. The polarizing and/or guide pins are provided in the male blade connector and the mating polarizing keys and/or guide bushings are provided in the female tuning fork connector backplane. 2.3 Another popular polarizing method is to provide a polarizing post on the backplane and a clearance slot in the PC daughterboard. 2.4 3.0 The backplane material may be aluminum or PC board where applicable. APPLICABLE CONNECTOR SERIES Aluminum Backplane Aluminum Header PC Backplane 3.1 S1000 S1001 S1200 S1201 S1500 M1001 KS1000 S1501 M1000 M1200 M1500 M1201 For information on any of the above connector series, please consult our Sales or Engineering Staff for desired data sheets. 3.2 This document is intended to serve as a guide in the selection and specification of components to meet your requirements. Amphenol Engineering drawings take precedence over dimensions specified herein and must be referred to when specific dimensions, tolerances, materials and finishes are required. TB-2054 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 3 OF 10 Typical Male Blade Connector Assembly and Female Tuning Fork Connector Pattern PC Daughterboard Series M1001 Series KS1000 For Use With PC Backplane Polarizing Pin See Note Below Polarizing Key PC Backplane Series S1000 For Use With Aluminum Backplane Aluminum Backplane Polarizing Pins - Material: Stainless Steel .075 (1.91) .017 (0.43) .278 (7.06) .100 Dia. (2.54) .405 (10.29) .125 (3.18) .02 (.51) x 45º (.79) Rad. Chamfer Typical .050 (1.27) .100 (2.54) Part No. 564-0023-000 (Standard) Mounting Hole: .096 Diameter x .140 Deep Polarizing Keys - Material: Polycarbonate .050 (1.27) .410 (10.41) 45º (.79 Rad) 45º (.79 Rad) .192 (4.88) .144 (3.98) .160 (4.06) Figure 1 .14 (3.55) Dia. X .06 (1.52) Deep FS .118 .093 (2.99) (2.36) Figure 2 Figure 3 (Otherwise Same as Figure 1) 2.35 (5.97) Spherical Radius .040 (1.02) Part No. 564-0041-000 Mounting Hole: .096 Diameter x .140 Deep .090 (2.28) .090 (2.29) Straight Knurl Typical .103 Dia. (2.62) .315 (8.00) .078 (1.98) Part No. 564-0001-000 Mounting Hole: .096 Diameter x .110 Deep Part No. Fig Type Nav Mating Ord No. Polarizing Pin 516-0005-001 1 “D” 2648706-2 564-0023-000 516-0006-001 2 “V” 2648706-1 564-0041-000 516-0023-001 3 “O” 2648706-3 564-0001-000 516-0010-001 4 “D” 2300799-2 564-0023-000 516-0011-001 5 “V” 2300799-1 564-0041-000 516-0026-001 6 “O” 2300799-3 564-0044-000 45º (.79 Rad) .192 (4.88) .144 (3.98) NOTE: To increase the “polarizing feel” when engaging connectors which should not mate (especially those with large numbers of contacts), special stainless steel keys are available. 45º (.79 Rad) .160 (4.06) Figure 4 .118 .072 (2.99) (1.83) Figure 5 Figure 6 (Otherwise Same as Figure 4) Type “D” - Part No. 516-0035-000 - Figure 4 Type “V” - Part No. 516-0036-000 - Figure 5 The polarizing keys shown are designed to be installed into the appropriate insulator shown in the above pictorial. These keys may be used when contacts are on .100 x .100 grid. The dimension from the centerline of the last contact to the centerline of the polarizing pin/key is to be .150. A .142 diameter clearance hole must be provided in the backplane for the protruding polarizing pin. TB-2054 REVISION “-” 3.3 DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 4 OF 10 If a tighter tolerance is required when mating the male blade connector and the female tuning fork connector, the polarizing pin shown is available. This pin is larger in diameter than the standard pin (Part No. 516-0023-000). .270 .080 .100 Dia .225 .134 Dia .385 Polarizing Pin Part No. 564-0031-000 Material: Cres 416 Mounting Hole: .096 Diameter x .130 Deep 3.4 The suggested method of designating this polarizing system is as shown. The pin and key are indexed in one of eight positions. This construction will yield 64 positions for a given connector using two polarizing pins. For more positive alignment, it is recommended that pin and key be indexed in four positions (90° increments). A H A B G C F E D Polarizing Pin Mate Blade Connector Mating View A C E C B A H C E G D E F Polarizing Pin Connector Backplane Mating View TB-2054 3.5 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 5 OF 10 When a skirted header body is used for the male blade connector, clearance must be provided as shown for the width of the insulator in which the polarizing key is installed. See technical bulletin M1001, KS1000 and S1000 for additional data. .080 .010 Maximum .010 Minimum .020R Maximum .050 Minimum .285 .200 .150 3.6 When polarization is required on connectors having a contact grid of .125 x .125, .150 x .150, or staggered .100 centers, the following system may be used: Polarizing Pin Part No. 536-0014-000 Polarizing Key Part No. 516-0018-000 Aluminum Backplane NOTE: This polarization system is presently designed for connectors using an aluminum backplane only. TB-2054 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 6 OF 10 199 Typ .134 Dia. .095 Dia. .080 Mounting Hole .058 .230 .383 .121 Dia. .253 Dia. .119 .503 Polarizing Pin Part No. 536-0012-000 Material: Cres 416 Mounting Hole: .091 Diameter x .140 Deep 3.7 .203 A.F. Octagon Polarizing Key Part No. 516-0018-000 Material: Polymide (Nylon) The dimension from the centerline of the last contact to the centerline of the polarizing pin/key is to be .200. .200 .200 TB-2054 3.8 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 7 OF 10 Alternate methods of providing an effective polarizing system are illustrated. PC Daughterboard Module Contact/Insulator Aluminum Backplane Polarizing Pin Clearance Area Must Be Provided PC Board or on PC Backplanes Aluminum Backplane 3.9 A polarizing post is provided on the backplane adjacent to the connector. A typical design is to install a press fit polarizing pin as shown. An alternate method of polarizing is to use the same tuning fork contact and insulator as is used for the connector pattern. The polarizing pin method may be used for an aluminum or PC board backplane. The contact/insulator method is recommended to be used on aluminum backplanes only. 3.10 Polarization of the daughterboard module is obtained by providing a clearance slot in the PC board which allows the proper module to mate with the appropriate backplane connector. TB-2054 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS Part No. Typical Polarizing Pins PAGE NO. 8 OF 10 Dim. A Dim. B Dim. C Dim. D 564-0009-505 .095 .205 .115 .076 564-0014-505 .100 .190 .090 .075 Material: Aluminum 2025-T4 C B A D 3.11 Finish: Gold Chromate Mounting Hole: .074 Diameter x .130 Deep This illustration shows a typical design for the guidance of connectors using Amphenol’s standard hardware. Guide Pin Guide Bushing (Bonded in PC Backplanes) Backplane Clearance Area Must Be Provided on PC Backplanes NOTE: This guidance system may be used with either aluminum or PC board backplanes. .075 Dia. 60º .131 Dia. .210 .181 Dia. .187 .090 .375 Guide Pin Part No. 564-0010-505 Material: Aluminum 2024-T4 Finish: Gold Chromate Mounting Hole: .074 Diameter x .110 Deep .147 Dia. .100 .187 Guide Bushing Part No. 516-0019-505 Material: Aluminum 2024-T4 Finish: Gold Chromate Mounting Hole: .175 Diameter Thru TB-2054 3.12 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 9 OF 10 The dimension from the centerline of the last contact to the centerline of the guide pin/bushing is to be .150 minimum for contacts on .100 x .100 grids. .150 Minimum 3.13 .150 Minimum Typical guide pin/bushing system. 60º .081 Dia. .123 Dia. .330 .13 Guide Pin Part No. 564-0030-000 Material: Cres 303 Mounting Hole: .077 Diameter x .150 Deep .136 Dia. A Dia. .188 Dia. .225 .100 Guide Bushing Part No. 516-0025-000 - Dia. A = .225 Part No. 516-0077-000 - Dia. A - .200 Material: Cres 303 Mounting Hole: .183 Diameter Thru TB-2054 3.14 REVISION “-” DESIGN GUIDE FOR CONNECTOR POLARIZING AND GUIDANCE SYSTEMS PAGE NO. 10 OF 10 The dimension from the centerline of the last contact to the centerline of the guide pin/bushing is to be .200. .200 .200