Ferrite-based micro-inductors for Power Systems on Chip - Tel

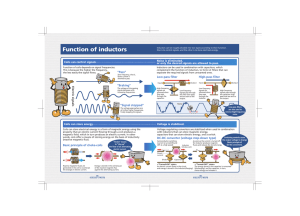

advertisement