Smoke Evacuation System

advertisement

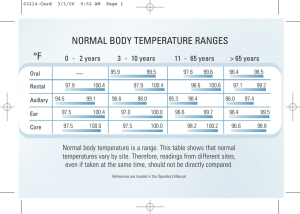

One Year Limited Warranty On New Instruments Instrumentation purchased new from Welch Allyn, Inc. (Welch Allyn) is warranted to be free from original defects in the material and workmanship under normal use and service for a period of one year from the date of first shipment from Welch Allyn. This warranty shall be fulfilled by Welch Allyn or its authorized representative repairing or replacing at Welch Allyn’s discretion, any such defect, free of charge for parts and labor. Welch Allyn should be notified via telephone of any defective product and the item should be immediately returned, securely packaged and postage prepaid to Welch Allyn. Loss or damage in shipment shall be at purchaser’s risk. Welch Allyn will not be responsible for loss associated with the use of any Welch Allyn product that (1) has had the serial number defaced, (2) has been repaired by anyone other than an authorized Welch Allyn Service Representative, (3) has been altered, or (4) has been used in a manner other than in accordance with instructions. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR OTHER WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED. WELCH ALLYN WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES. Smoke Evacuation System Model No. 88550 If you have questions regarding any Welch Allyn products, please call Customer Service at (800) 535-6663, 315-685-4560, or FAX:315-685-4653. To Obtain Warranty Service First contact the Service Department at Welch Allyn to obtain a Return Authorization Number. This Return Authorization Number must appear on all correspondence regarding your warranty claim and Welch Allyn is not required to accept a Product returned without a Return Authorization Number. Return the Product to Welch Allyn together with proof of date of purchase. Properly disinfect all products prior to returning for service. Insure and safety/securely package all shipments to Welch Allyn, preferably in the original shipping carton. Include a letter explaining the problem and a reference to the Return Authorization Number. The customer must prepay all return transportation and insurance charges and the customer will bear all risk of loss. If Welch Allyn determines that the Product requires repair under this Limited Warranty, then Welch Allyn will repair or replace the Product as provided above and will return the repaired or replacement Product to the customer, freight prepaid with the risk of loss passing to the customer upon delivery to common carrier. If Welch Allyn determines that the Product requires a repair which is not covered by this Limited Warranty, then Welch Allyn will contact the customer for further instructions. Welch Allyn will either return the Product to the customer at the customers expense or if instructed by the customer, Welch Allyn will repair the Product and return the Product to the customer freight prepaid. The risk of loss passing on the customer upon delivery to the common carrier. Welch Allyn is entitled to invoice the customer for the reasonable cost of non-warranty inspection and repair of the Product and the cost of the return freight. Note: SMOKE EVACUATION SYSTEM There are no user-serviceable parts (excluding intermittent filter changes). Only authorized Welch Allyn service personnel can carry out repairs. Manufactured for: Min. Max. 882 667 Rev. A 4341 State Street Road Skaneateles Falls, NY 13153 USA Tel: 315-685-4560 OR 800-535-6663 Fax: 315-685-4653 Part No. 882663 Rev. E Printed in the USA Operating Manual System Description The Welch Allyn Smoke Evacuation system three-stage air filtration system is used to remove airborne particulate plume produced during office and surgical procedures and has the following features— Symbols Caution: Consult Users Manual Do not use in the presence of flammable anesthetics. AP • Low noise level. • Triple filtration of air provides efficiency level for 0.014 microns rated at 99.999%. This includes a pre-filter, a charcoal filter for odor removal, and a final safety filter placed after the charcoal filter. Protective Earth Terminal • Adjustable high air flow for effective collection of plume. US • Conveniently attaches to the Welch Allyn Electrosurgical Unit WorkStation. ON (power connection to mains) OFF (power disconnected from mains) Caution: Excessive Heat With respect to electric shock, fire mechanical and other specified hazards only in accordance with UL 2601-1, CAN/CSA C22.2 NO. 601.1. 3AG 5A 250V~ 2GA2 Medical equipment Initial System Set-Up You have received one carton which contains the Vacuum Unit. Purchase the disposable accessories necessary to conduct procedures separately from Welch Allyn. ULPA Filter Installation Insert the large ULPA Filter cylinder with the air-flow arrow pointing down (See Photo A). ~ Alternating Current Warnings and Cautions This device produces a strong vacuum force. Exercise care to ensure that the suction control and the position of the inlet end of the suction tubing are adjusted properly to prevent injury to the patient or inadvertent damage to surgical materials. Operating Instructions Prepare the unit for use by inserting a clean, disposable pre-filter onto the ULPA Filter cylinder. (See Photo B). Verify this device is firmly seated. For procedures requiring close proximity plume removal (i.e., vaginal speculum) The materials removed from the plume by this device are potentially hazardous. Handle according to 29 CFR 1910.1030 and OSHA 3127.1992 (Occupational Exposure to Blood Borne Pathogens) guidelines. To prevent a fire or explosion hazard, do not use the system in the presence of flammable or potentially flammable materials. Assemble the 3/8” reducer (part # 88290) onto the port of the disposable pre-filter top with a slight twisting motion. Attach one end of an appropriate length of 3/8” ID evacuation tubing (part # 88292) to the reducer connector and direct the other end to the patient and any appropriate device that is used, such as a vaginal speculum equipped with a smoke evacuation adapter. (See Photo C) Do not allow the system to pull fluid inside. Plug the unit into an appropriate wall outlet. (See Warnings and Cautions) Replace fuses only as marked. Push the POWER switch to the “On” position to start the unit and adjust the suction control knob to the desired level. Grounding reliability can only be achieved when the equipment is connected to an equivalent receptacle marked “hospital only” or “hospital grade”. At the completion of each procedure activate the system to insure safe particle containment. Using gloves and a mask, remove the pre-filter, the reducer, and the used section of suction tubing and discard into an infectious waste receptacle. (See Cautions) Store the Smoke Evacuation System with a new pre-filter and reducer in place on the ULPA filter. NOTE: The expected life of the ULPA filter is 3-6 months depending on usage. Discard into an infectious waste receptacle if plume odor is detected or the suction is diminished. Photo A Photo B Photo C Maintenance Procedures No maintenance is required during normal operation other than making sure that ample space is maintained around the unit to allow for free air flow and adequate cooling. To prevent premature failure of the ULPA filter cylinder, do not operate this device without a disposable pre-filter in place. Specifications Electrical: Fuse: Size: Weight: Air Flow: Classification: Intermittent Operation: Filter: 115V~, 60 Hz, 5 A 3AG 5A 250V~ 9” Width x 9” Depth x 21” Height 21 Pounds 35 CFM minimum at maximum setting Class 1 15 minutes on, 30 minutes off Pre-filter, charcoal filter for odor removal and hydrophobic ULPA filter rated at 99.999% efficiency level for 0.014 micron particles. (Based on Standard CNC evaluations) Environment: Operating: Temperature: 32°F to 104°F (0°C to 40°C) / Humidity:0 to 95%rh Non Condensing Storage: Temperature: -10°F to 140°F (-23°C to 60°C) / Humidity: 30 to 95%rh Non Condensing Atmospheric Pressure: 700hpa to 1060hpa Reordering Information Cleaning Procedures Clean the outside of the unit as necessary with a soft cloth dampened (not wet) with isopropyl alcohol. Do not allow liquid to get inside the unit. Product #88288 Product #88290 Disposable Pre-Filter Reducer Product #88289 Product #88292 ULPA Filter Disposable Tubing • 3/8” ID