Creating Tunable White Light with High Color Rendering Index

advertisement

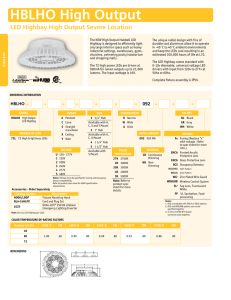

feature By Muhamad Moussa, Technical Marketing Engineer, Future Lighting Solutions Patrick Durand, Worldwide Technical Applications Manager, Future Lighting Solutions Creating Tunable White Light with High Color Rendering Index Using Color Mixing When considering white light needs for architectural lighting applications, solutions may range from a dedicated single color (e.g. warm-white, neutralwhite or cool-white) to solutions that can deliver the entire white color range within the same fixture leveraging the principle of color mixing. An important factor is how well a light source renders the true colors of objects. This factor is known as color rendering index (CRI). White LEDs provide a simple solution but they don’t provide a high CRI over a wide range of color temperatures. A preferred solution is one that provides the flexibility of dynamically changing the color temperature of the light source while maintaining a high CRI. This article introduces new design concepts to develop a 6-inch commercial recessed downlight. The solution leverages an innovative approach for color mixing to create white light at several color temperatures (tunable white) while maintaining a high CRI across the color temperature range it covers. Furthermore, the proposed solution will meet and surpass the Energy Star requirements for CRI, flux, efficacy and lifetime. Color Rendering Index CRI represents how well a light source renders the true colors of different objects and its value can range from 0 to 100. Although it is possible to calculate a negative CRI, it contains no useful information and is therefore considered irrelevant. In order to calculate the CRI of a light source, named test illuminant, there is a set of predefined light sources, named reference illuminants, which have a CRI of 100 that are compared to the test illuminant. The comparison has to be limited to a set of colors or test color samples otherwise it will be very tedious to compare for every single color that exists. Hence, the color samples are limited to the 15 Munsell Test Color Samples. Standard CRI calculations only take the first eight color samples into consideration. The reference illuminant varies depending on the target correlated color temperature (CCT). For CCTs less than 5,000 K, the reference illuminant is the black body radiator (e.g. incandescent bulb). Otherwise, it is daylight (e.g. sun light). Any variation between the spectral power distribution (SPD) of the test illuminant and the reference illuminant will result in a change in the CRI value of the test illuminant. The preferred situation is to exactly match the reference illuminant’s SPD. Being monochromatic light sources, LEDs have a spectral power distri- Figure 2a Figure 1. Relative Typical Spectral Power Distribution of a White LED bution that peaks at certain wavelengths and falls to very low values at other wavelengths. For example, in the case of white LEDs, they are created using a blue die covered with a layer of phosphor. This results in a peak in the blue region and the phosphor fills up the rest of the spectrum as shown in Figure 1. There are two peaks at the 450 nm and 550 nm regions and one valley at the 475 nm region. Such peaks and valleys may not affect the xy chromaticity coordinates of the white light nor the CCT. However, they do significantly affect the CRI of the white light. In other words, two white lights can have the same CCT and xy chromaticity coordinates, but have significantly different CRI values and SPDs. Another example is shown in Figure 2a where two normalized SPDs are plotted. One is for the test illuminant created using red, green, blue (RGB) LEDs and the other one is for the reference illuminant. Both light sources have the same CCT and xy chromaticity coordinates. The only difference is that the reference illuminant has a CRI of 100 and the test illuminant has a CRI less than 20. Clearly there is a big difference between the two SPDs that causes the degradation in CRI. In theory, the principle of color mixing can be applied in order to fill the gaps between the test and reference illuminants’ SPDs and create a white light with a high CRI. Although this might sound like an easy solution, it involves complex mathematical calculations. Figure 2b Figure 2. Test Illuminant SPD vs. Reference Illuminant SPD 22 LED Journal | March/April 2009 www.ledjournal.com feature Commercial Recessed Downlight To illustrate the concept of color mixing to create a high CRI tunable white light, a specific application will be analyzed. The application is a 6inch commercial recessed downlight. Energy Star lists the following requirements for this application: • Minimum Light Output = 575 lumens • Allowable CCTs: 2,700 K, 3,000 K, 3,500 K, 4,000 K, 4,500 K and 5,000 K • Minimum Efficacy = 35 lm/W • Minimum CRI = 75 The resulting CCTs can be a subset of the allowable CCTs specified by Energy Star. Hence, 3,000 K, 3,500 K, 4,000 K and 4,500 K will be used in this example. Although Energy Star lists a minimum CRI of 75, this example will provide a CRI of 90 throughout the selected CCTs. Target CCT (Kelvin) Minimum Light Output (Lumens) Target CRI Efficacy (lm/W) 575 90 35 3,000 3,500 4,000 4,500 Table 1. Summary of Requirements and Target Values Colors and Number of LEDs The first step is to determine the LEDs combination that will result in 575 lumens at the given CCT values with a target CRI of 90. Leveraging a proprietary CRI Optimization Tool developed by Future Lighting Solutions, the color combination consists of red, green, amber and coolwhite. Luxeon Rebel LEDs will be leveraged for this application. The tool provides the minimum number of LEDs needed to achieve the target CCTs and CRI while maximizing the luminous flux in order to enhance the system's efficacy as specified by Energy Star. In order to achieve the target light output, three clusters of the four-LED color combination are used. Controlling the forward current of each LED will result in controlling the number of lumens from each LED hence, the target CCTs can be reached while maintaining the target CRI value. Each CCT relates to a specific forward current ratio relationship between the LEDs. A controlled change in the ratios results in a change in the CCT (tunable white) while maintaining the same target CRI value. Figure 2b shows the SPD for the reference illuminant at 3,500 K and the SPD of the white light generated using the four-LED combination, which provides a CRI of 90. When compared to Figure 2a, it is noticeable that the gaps between the test illuminant and the reference illuminant have been reduced. This results in a higher CRI value. Adding more colors will further reduce the gaps and enhance the CRI; however, there will be a point at which adding more colors (LEDs) will significantly increase the system cost without a major change in CRI. The goal is to minimize the number of LEDs (colors) used to achieve the target requirements. It is important to note that a CCT of 3,500 K is specified just as an example and the principle applies to all target CCTs outlined in Table 1. Thermal Analysis and Design In order to have a comprehensive solution, the system must be thermally managed. LED manufacturers publish datasheets that contain information on the performance of LEDs at a junction temperature of 25°C. In reality, LEDs will rarely operate at such a low junction temperature. Therefore, analyzing the system's performance at elevated junction temperatures is more realistic in order to ensure that the lighting system performs as expected and meets Energy Star requirements. As the LED junction tem- www.ledjournal.com perature increases, the LED experiences three short-term phenomena: 1. Reduction in light output 2. Color shift 3. Degradation in lifetime Since the four LEDs consist of four different colors, the reduction in the light output will not be consistent amongst them. For example, at a given junction temperature, one LED may lose 15 percent of its initial light output while another LED may lose 8 percent of its initial light output. This results in an uncontrolled change in the relative ratios among the four LEDs. If this is not managed appropriately, the color point, CCT and CRI values will change. It is very critical to make sure that the ratios stay constant with respect to each other. This can be achieved by optimizing the thermal design to make sure that the LEDs do not reach extreme junction temperatures. The optimization will also help in maintaining the color point within acceptable ranges (non-visible change). The thermal design and optimization includes heat sink design as well as a continuous thermal feedback loop that monitors the LEDs junction temperature and de-rates the forward current values accordingly. Thermal simulation software, QLED, is used to perform such analyses and optimize the heat sink design. It provides the junction temperature results along with light output and power consumption of all the LEDs. These results are used to ensure that the LED-based lighting system delivers the required minimum number of lumens (575 lumens) at the operating temperature rather than 25°C. They are also used to calculate the efficacy of the LED-based lighting system. Efficacy (lm/W) is calculated by taking three losses into consideration: • Optical losses due to the secondary optics • Power losses due to the power solution • Thermal losses (calculated in QLED) Table 2 shows QLED numerical results and efficacy calculations at CCT = 3,500 K assuming 80 percent optical solution efficiency and 80 percent power solution efficiency resulting in an equivalent efficiency of 64 percent (losses of 36 percent). The three clusters consume 14 watts of power after thermal stabilization. Total Light Output from QLED After Thermal Losses Total Light Output After Thermal and Optical Losses Total LED-Based Lighting System Efficacy After Thermal, Optical and Power Losses 811 Lumens 648 Lumens 36 Lumens/W Table 2. QLED Light Output Results and Efficacy LED Lifetime The overall lifetime analysis of the LED-based lighting system must include all the components used and their expected lifetime and performance standards. Such components include LEDs, power ICs, resistors, capacitors, etc. Any failure in one or more component will result in a system failure. The LED Reliability Tool (LRT) is used to estimate the lifetime of the Luxeon Rebel LEDs. All InGaN LEDs will attain a lifetime of 60,000 hours under the operating conditions (forward current and junction temperature). AlInGaP LEDs lifetime is more sensitive to junction temperature; therefore, lifetime is at 56,000 hours. Figure 3 shows the output of the LRT at a sample forward current and junction temperature for both LEDs (InGaN and AlInGaP). Article continued on page 25 March/April 2009 | LED Journal 23 feature Article continued from page 23 Muhamad Moussa is the team leader of the technical marketing team at Future Lighting Solutions. He is focused on LED-based lighting systems design and application support. His areas of expertise include color mixing and thermal management. He is a co-inventor of a patent pending tool and concepts for high CRI color mixing and optimization. Muhamad has earned his MS in Electrical Engineering from Concordia University, Montreal, Canada. He can be reached at muhamad.moussa@future.ca. Figure 3. LED Reliability Tool Lifetime Output Table 3 shows a comparison between Energy Star requirements and the proposed high CRI tunable white commercial recessed downlight. The Energy Star requirements are met using the proposed high CRI color mixing approach. Higher light output and higher efficacy can be achieved by increasing the number of LEDs used in the application. CCT (Kelvin) Light Output (Lumens) All 575 Efficacy (Lumens/W) CRI LED Lifetime (Hours) =75 35,000 Patrick Durand has the global responsibility of enabling adoption of high power LEDs at Future Lighting Solutions. His role includes creating training programs for field engineers and customers, developing tools and solutions to simplify LED designs, partnering with semiconductor manufacturers to define and launch new LED associative products and working directly with customers to solve application challenges. Patrick has received a Bachelor of Electrical Engineering from Carleton University as well as a Bachelor of Commerce and an MBA from the University of Ottawa. He can be reached at patrick.durand@future.ca. ENERGY STAR 35 6-inch Commercial Recessed Downlight 3,000 588 36 =90 56,000 3,500 648 36 =90 56,000 4,000 670 38 =90 56,000 4,500 641 38 =90 56,000 Table 3. Energy Star Requirements vs. Commercial Recessed Downlight Performance In conclusion, the market demand toward having high CRI white or tunable white luminaires that meet Energy Star requirements is increasing significantly. Hence, a solution that overcomes the challenges (optical, thermal and power) is of great importance to the solidstate lighting industry. It is now possible to achieve any CCT at high CRI values by leveraging the principle of color mixing. The conventional RGB, RGBW or RGBA doesn’t provide the optimal solution in terms of light output, number of LEDs, and efficacy. Other combinations using three or more LEDs are showing great potential and are enabling intelligent lighting applications that meet regulatory targets such as Energy Star for solid-state lighting. For more information on Future Lighting Solutions’ QLED or LRT visit www.futurelightingsolutions.com. Have an idea for a contributed article? Send abstracts to Heather Krier at heatherk@infowebcom.com www.ledjournal.com March/April 2009 | LED Journal 25