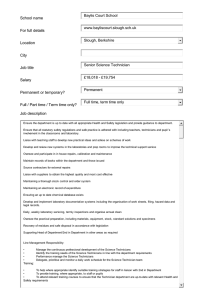

space for technicians?

advertisement