2012 Electrical Code

Changes – Module 3

Sections 18 - 36

ETEL-12(02)-00 (2012-03-26)

TableofContents

Section 18 — Hazardous Locations ........................................................................................................... 2 Section 20 — Flammable Liquid and Gas Dispensing and Service Stations, Garages, Bulk

Storage Plants, Finishing Processes, and Aircraft Hangars .................................................................. 8 Section 22 — Locations in which Corrosive Liquids, Vapours, or Excessive Moisture are Likely to

be Present .................................................................................................................................................... 11 Section 24 — Patient Care Areas ............................................................................................................ 11 Section 26 — Installation of Electrical Equipment ................................................................................. 13 Section 28 — Motors and Generators ..................................................................................................... 25 Section 30 — Installation of Lighting Equipment ................................................................................... 26 Section 32 — Fire Alarm Systems, Fire Pumps, and Carbon Monoxide Alarms (See Appendix G)

....................................................................................................................................................................... 27 Section 36 — High-Voltage Installations ................................................................................................. 32 ©

British Columbia Safety Authority, 2012

1

2012 ELECTRICAL CODE CHANGES

Module 3

There have been numerous changes to the 2012 Canadian Electrical Code. The following

material only describes changes which may be considered as major. For complete Code

information, refer to the 2012 Canadian Electrical Code available at www.csa.ca.

Please note: minor electrical code changes are not covered in this material.

Section 18 — Hazardous Locations

Rule 18-052 Marking (see Appendix B)

Equipment Protection Levels are an alternative and additional specification for equipment

made in accordance with the IEC standards. Throughout Section 18, the reference to

Equipment Protection Levels (EPL) has been added where rules prescribe the type of

equipment required for a particular location.

Equipment Protection Level (EPL)

This new marking system is identified in Rules 18-090 (2) and 18-100. Since 2007, the

IEC Technical Standards have recognized that there may be occasions where it is

necessary to increase, above the normal levels, the protection against ignition sources.

This concept allows for consideration of risk (i.e. consequences of an explosion) as

opposed to just the probability of a flammable atmosphere existing - the conventional

selection criteria between the types of protection and the zone of use.

In order to introduce the concept of a declared level of safety, IEC agreed to

introduce 'Equipment Protection Levels' (EPL's). These are Ga, Gb and Gc for gas

and Da, Db and Dc for dust. These are an alternative and additional specification for

equipment made in accordance with the standards.

©

British Columbia Safety Authority, 2012

2

The following two tables show the normal relationship between EPL and zone, and the

EPL awarded to each type of protection.

Equipment Protection

Level (EPL)

Ga

Gb

Gc

©

Normal Applicable Zone(s)

0 (and 1 and 2)

1 (and 2)

2

Equipment

Code

Description

EPL

Ex ia

Ex ib

Ex ic

Ex d

Ex p

Ex px

Ex py

Ex pz

Ex e

Ex m

Ex ma

Intrinsic safety 'ia'

Intrinsic safety 'ib'

Intrinsic Safety 'ic'

Flameproof protection

Purge/pressurized protection

Purge/pressurized protection 'px'

Purge/pressurized protection 'py'

Purge/pressurized protection 'pz'

Increased safety

Encapsulation

Encapsulation

Ga

Gb

Gc

Gb

Gb

Gb

Gb

Gc

Gb

Gb

Ga

British Columbia Safety Authority, 2012

3

Class 1 Zone O Locations

Rule 18-090 Equipment and wiring (see Appendices B and F)

In Class 1 Zone 0 locations, equipment marked as providing EPL “Type Ga” will provide

protection just as equipment marked “intrinsically safe equipment Type ia”. The methods

of protection used or the design incorporated to provide the protection is not required as

the marking “Ga” alone provides the necessary certification. However, the Gas Group and

Temperature Code markings are still mandatory.

Class 1 Zone 1 Locations

Rule 18-100 Equipment in Class I, Zone 1 locations (see Appendices B and F)

Throughout Section 18, the reference to Equipment Protection Level (EPL) equipment

has been added where rules prescribe the type of equipment required for a particular

location. In Class 1 Zone 1 locations, equipment marked as providing EPL Type “Ga” or

“Gb” will provide protection equivalent to equipment identified as providing a method of

protection “d”, “e”, “o”, “p”, etc.

The following is an example of new general labelling on a distributor enclosure with

increased safety level. This sample equipment label includes:

1) the required marking to meet ATEX standards (not recognized in North America)

2) the required IEC marking, signifying the type of protection utilized and

3) the new CEC recognized Equipment Protection Level marking Gb,

1) Category 2G: Suitable for Zone 1;

2) Increased safety: Suitable for Zone 1;

3) Equipment protection level Gb: Suitable for Zone 1

Each of these markings indicate suitable for use in a Class 1, Zone 1 location

©

British Columbia Safety Authority, 2012

4

Rule 18-108 Sealing, Class I, Zone 1 (see Appendix B)

Subrule (3) has been revised to simplify the language used around the requirement for

sealing. The new wording requires a seal at the first termination inside the Class 1 Zone 1

location regardless of the type of equipment or fitting supplied and is worded like the

requirements for a conduit that leaves a Zone 1 location. This similarity is intended to

increase safety by removing the inconsistency between wiring methods.

Normal location

Sealing type connector approved

for Class 1 Zone 1 location

to be installed on the first

device in the zone

Class 1 Zone 1

Hazardous Location

Note: the rigid conduit, if smaller than 53mm, does not require a sealing fitting as the JB

does not (should not) generate arcs, sparks or high temperatures in normal operation and

does not leave the location in this diagram.

Rule 18-150 Equipment in Class I, Zone 2 locations (see Appendices B and F)

The wording “Where required by other Rules of this Code” has been added to fix an

editorial mistake. Now the wording recognizes other Rules regarding the acceptability of

equipment in Class 1, Zone 2 locations. Item (c) has been added as in Zone 0 and Zone 1

subsections recognizing equipment designed to IEC standards and labeled with an

Equipment Protection Level designation.

18-152 Wiring methods, Class I, Zone 2 (see Appendix B)

Rule 18-152 has been revised to include types RC90 and RA90 armoured cable as

acceptable for use in Class 1 Zone 2 locations

©

British Columbia Safety Authority, 2012

5

Rule 18-154 Sealing, Class I, Zone 2 (see Appendix B)

The requirement to provide sealing for a cable less than 10m in length has been removed

from the Code. Now paragraph (b) requires a sealing type fitting be installed where the

cable terminates at equipment in the Zone 2 location and the other end terminates in a

non-hazardous location where a negative pressure greater than 0.2kPa exists (0.2kPa is

equal to approximately 0.03 psi).

Rule 18-202 Wiring methods, Class II, Division 1 (see Appendix B)

The acceptable wiring methods have not been changed. The net result of the revision is

to separate the two wiring methods into items rather than leave them lumped into one

longer Subrule. The notation that cables needed to be used “with associated cable glands

approved for the particular hazardous location” has been removed. The wording was

unnecessary as the installation cannot be made to comply without using approved type

fittings.

Rule 18-252 Wiring methods, Class II, Division 2 (see Appendix B)

Subrule (d) - The previous Code recognized Type ACWU as suitable in this location. Now

additional armoured cable types are recognized.

Subrule (f) - Type CIC (control and instrumentation cable) has been added as an

acceptable wiring method but with the restrictions noted.

©

British Columbia Safety Authority, 2012

6

Rule 18-302 Wiring methods, Class III, Division 1 (see Appendix B)

Subrule 18-302(1) has been revised to clarify acceptable wiring methods within a Class 3,

Division 1 location. Each acceptable wiring method has been separately listed.

Armoured cables with overall jacket have been added and include Teck90, ACWU90,

copper-sheathed and aluminum sheathed cable. When armoured control and instrument

cable (Type ACIC) is used within a Class 3 Div 1 location, it must have interlocking armor

and a continuous jacket.

Pictured above: Armoured Control & Instrumentation Cable, 300 Volts, PVC Insulation.

This cable is suitable for installation in cable trays in dry, damp and wet locations or for

direct burial and may be extended through sealing glands without removal of the

individual shields, when installed in Hazardous Locations containing A, B, C & D

atmospheres as defined by the Canadian Electrical Code.

Rule 18-322 Electric cranes, hoists, and similar equipment, Class III, Division 1

Rule 18-322 has been re-written for clarification to the user of the requirements

surrounding system requirements and ground fault detection when installing electric

cranes, hoists, and similar equipment for operation over combustible fibres or

accumulations of flyings and similar such equipment and locations.

Rule 18-352 Wiring method, Class III, Division 2 (see Appendix B)

This Rule has been revised to separate and clarify acceptable wiring methods within a

Class 3, Division 2 location. Each acceptable wiring method has been separately listed.

Item (d) is new. Armoured cables with overall jacket have been added and include

Teck90, ACWU90, copper-sheathed RC90 and aluminum sheathed RA90 cables.

Item (e) is new. Armoured control and instrument cable (Type ACIC) must have

interlocking armor and a continuous jacket when used within a Class 3 Div 1 location.

Item (f) reference to Type TC (tray cable) cable is new and demonstrates how the

previous Code wording has been expanded. The previous Electrical Code mentioned “or

cables approved for hazardous locations with associated cable glands approved for the

particular hazardous location”.

Item (g) is similar to item (f). When control and instrument cable (Type CIC) is used within

a Class 3, Division 2 location, the non-armoured version (Type CIC) is permitted subject

to the limitations listed.

©

British Columbia Safety Authority, 2012

7

Section 20 — Flammable Liquid and Gas Dispensing and Service

Stations, Garages, Bulk Storage Plants, Finishing Processes, and

Aircraft Hangars

Rule 20-060 Scope

A minor change has been made to the Subsection title. The word “and” was removed to

make “compressors” a stand alone category. Compressors can be found at other types of

facilities besides storage facilities.

Rule 20-062 Hazardous Areas

This rule has been extensively revised. The former Rule attempted to describe all of the

locations where a classified location could be situated. A newly expanded Table 64 “Class

I, Zone 1 space surrounding compressed natural gas (NGV) storage” has been developed

for the purpose of classifying hazardous locations. Previous Code Rule 20-064 has been

deleted and the other Rules in this sub-section have been renumbered.

Rule 20-102 Hazardous areas

Showrooms shall not be classified as hazardous areas when separated from a service

and repair area by tight-fitting barriers such as curbs, ramps or partitions at least 50mm

high.

©

British Columbia Safety Authority, 2012

8

©

British Columbia Safety Authority, 2012

9

Rule 20-110 Equipment above hazardous areas (see Appendix I)

Previous editions of the Code required fixed lighting which was subject to damage over

lanes and similar areas to be installed at least 3.6m above floor level. Where this was not

possible, luminaires of the totally enclosed type or those constructed to prevent the

escape of sparks or hot metal parts were required.

This new revision permits fixtures approved for non-hazardous locations to be installed.

To prevent fixture damage, the Rule still requires the fixture to be mounted 3.6m above

the finished floor or be mechanically protected by a guard or location where installed at

less than that height.

More than

3.6m

less than

3.6m

Lane Area

Any luminaire suitable for non hazardous location

Any Luminaire suitable for non hazardous location

with mechanical protection (wire guard or similar)

• Installed more than 3.6m, any luminaire suitable for normal locations is

OK.

• Installed below 3.6m, any luminaire suitable for normal locations

protected from mechanical injury by a guard or location.

Rule 20-506 Wiring not within hazardous areas

Rule 20-506 has been revised to recognize wiring methods using types aluminum

sheathed or copper sheathed cables as approved.

©

British Columbia Safety Authority, 2012

10

Section 22 — Locations in which Corrosive Liquids, Vapours, or

Excessive Moisture are Likely to be Present

Changes and revisions in Section 22 of the Code are editorial in nature and have been

made to recognize the selection of conductors or cables shall be made in accordance

with Rule 4-008(1) or to recognized copper–sheathed cable as an acceptable wiring

method.

Section 24 — Patient Care Areas

Rule 24-102 Circuits in basic care areas (see Appendix B)

Hospitals, doctor offices and private clinics may have more than one classified patient

care area within the premises. This can result in some wiring systems being designated

as “essential” with faster restoration times during a normal power outage.

This Subrule has been added to inform users that branch circuit wiring supplied from an

essential wiring system shall not be used to supply receptacles or permanently connected

equipment in other areas of the facility. The hospital administrator or designate

determines the classification of all patient care areas.

Rule 24-104 Bonding to ground in basic care areas (see Appendix B)

Besides communication, radio and cable TV equipment, other equipment in a patient care

area having conductive parts may come in contact with or provide a conductive path to a

patient. Medical gas, water lines and suction equipment are types of these systems.

New Subrule (8) has been provided to require these systems be bonded to ground with a

conductor sized to T16 but not smaller than #12. This bonding conductor shall be

terminated in accordance with Subrule (3).

©

British Columbia Safety Authority, 2012

11

These are examples of locations within a patient care

environment where a conductive path to ground could be found.

Rule 24-106 Receptacles in basic care areas (see Appendix B)

The wording of Subrule (6) has been re-written to clarify which

receptacles must be coloured red in patient care areas.

Rule 24-306 Emergency supply

This revision has removed former Subrule (2). Information and standards around

generator installation and performance is provided in CAN Standard: C282-09 Emergency electrical power supply for buildings.

This consensus based Standard provides design, installation, operation, maintenance

and testing requirements for emergency electrical power generators and associated

equipment for use by generator set designers, manufacturers, installation contractors,

maintenance contractors, building inspectors and commissioners in buildings where

emergency power generators are mandated by the BC Building Code and local building

by-laws.

©

British Columbia Safety Authority, 2012

12

Section 26 — Installation of Electrical Equipment

The dangers of cellulose nitrate film

Cellulose nitrate film is extremely dangerous. It catches fire very easily and once alight is

difficult to put out. Fires involving cellulose nitrate burn extremely quickly with a hot,

intense flame and the smoke is particularly toxic, containing large quantities of poisonous

gases.

Any cellulose nitrate film that you come across now will be extremely old. This is a

problem because the high fire risk from cellulose nitrate film increases as it ages. Old

cinematographic film and old photographic negatives (including X-ray film) may be made

from cellulose nitrate (which means they contain nitrated cellulose or other nitrated

product). These films are sometimes referred to as ‘nitrate’, ‘nitratebased’, ‘nitro-cellulose

based’ or ‘celluloid’ film (although the term ‘celluloid’ is often used these days to refer to

film in general, it may not actually contain cellulose nitrate).

Why is cellulose nitrate film dangerous?

It is the nitro-cellulose that makes cellulose nitrate-based film so dangerous to store and

handle. It is hazardous because:

•

it can start to decompose and become unstable at temperatures as low as 38ºC,

giving off large quantities of poisonous gases, which could cause an explosion.

Warmth and humidity (moisture) accelerate this decomposition;

it catches fire very easily and burns extremely quickly, with a hot and intense flame;

it produces very dense, poisonous smoke containing copious amounts of choking

nitrogen dioxide fumes; and

unlike many other flammable materials, nitro-cellulose does not need the oxygen in

the air to keep burning and once it is burning it is extremely difficult to put out.

Immersing burning film in water may not extinguish the fire and it could actually

increase the amount of smoke produced.

•

•

•

Cellulose nitrate film should, because of its age and the likelihood that it has not been

stored in ideal conditions, be treated as being potentially dangerous. If you have film or

negatives made from cellulose nitrate (or you think they may be made from cellulose

nitrate) keep them well away from any source of heat (e.g. radiators and light bulbs). Do

not run film through a projector or put negatives on an enlarger; they can catch fire simply

by the heat from the lamp or from friction caused by the film passing over the projector

sprockets.

Above information courtesy of

www.hse.gov.uk

©

British Columbia Safety Authority, 2012

13

For longer storage, use an approved storage vault. The standards for design,

construction, and use of storage cabinets and vaults for historical nitrate films are based

on years of experience by the National Board of Fire Underwriters and are supported by

the experience of the National Archives and the National Bureau of Standards.

The important principles supporting the Underwriters' regulations are based on

•

•

•

•

•

elimination of all possible means of starting a fire

control of, and protection against, the spread of fire

segregation of large quantities of film into small protected units

ample provision for safety to human life

proper ventilation and exhaust system

These are the important reasons behind every detail of an approved building construction,

self closing fire doors, exits, vents, light fixtures, electrical systems, heating equipment,

and automatic sprinklers, etc.

Vaults for commercial storage are limited to 750 cubic feet with a vent area not less than

200 square inches per 1,000 pounds, or a total of 2,000 square inches for the standard

size vault. A sprinkler is required for every 62.5 cubic feet of space or 12 for a 750 cubic

foot vault.

Vaults for long term storage are limited to 100 cubic feet with a vent area of at least 2,670

square inches, and with no less than eight sprinklers. Both sprinklers and ventilation

provide about five times the safeguards suggested for that of commercial storage.

Shelves in long term film vaults should be divided into individual compartments with not

less than 3/4 inch thick non combustible insulating material. Each compartment should

hold only one, or at most two, film containers.

The ceiling water sprinklers should be directed so that all shelves will be drenched in the

event of fire. The individual containers will protect the film from water damage.

Air conditioning systems in film vaults should be installed according to regulations of the

National Board of Fire Underwriters. Automatic fire dampers should be installed in the air

ducts so that a fire in one vault will not spread to another and so that the toxic gases

given off will not be distributed to other rooms, but will be vented outside. The

Underwriters' regulations do not provide for control of air temperature and relative

humidity in the storage of nitrate film other than that temperatures must not exceed 21°C

(70°F). This is a safety precaution. Additional precautions are required from the

standpoint of film preservation.

Above information courtesy of

www.motion.kodak.com

©

British Columbia Safety Authority, 2012

14

Rule 26-360 General

This new Rule defines the scope of the section.

Rule 26-362 - Equipment in film-vaults

This new rule restricts the installation to fixed lighting only. Modern film vaults store the

film canisters in smaller groups and separate them with fire-resistant shelving. Only

lighting is permitted in the vault due to the extremely flammable characteristics of nitrate

film.

Rule 26-364 - Wiring methods in film-vaults

Subrule (1) - The nature of cellulose nitrate requires wiring methods prescribed by Rules

18-152 (a), (b), and (d). These wiring methods are associated with Class 1 Zone 2

installations.

Subrule (2) - This rule is to prevent the spread of noxious gases, smoke and combustion

products from one vault to another.

Subrule (3) - The conduit between the switch and light fixture shall be “sealed off near the

switch”. No reference is made for the seal to comply with Rule 18-108 (approved sealing

fittings and sealant) as required for installations in Class1 Zone 2 locations; however an

EYS and chico shall be used unless another approved fitting and compound is available.

Rule 26-366 - Luminaires in film-vaults

Luminaires approved for Class 1 Zone 2 (or Div 2) locations shall be installed.

Rule 26-368 - Circuits in film-vaults

To ensure maximum safety for someone entering a storage vault as well as to the

equipment and contents, the switch is placed outside. A red pilot light will grab people’s

attention and all ungrounded conductors shall be de-energized when the switch is open.

©

British Columbia Safety Authority, 2012

15

Rule 26-700 General (see Appendices B and I)

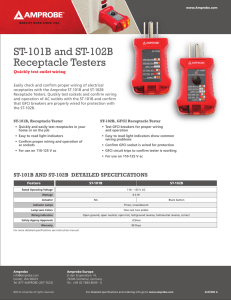

Subrule (9) – This revision is editorial in nature and describes the specific type of GFCI

protection required.

Subrule (12) - This new addition is another level of protection in a location where children

could attempt to insert conductive objects into receptacles.

Appendix B note to Rule 26-700 (12) - It is intended by this Rule that unless otherwise

designated by an authority having jurisdiction for child care facilities, a “child care facility”

is considered to be an area designed to provide care to persons 7 years of age or less.

Rule 26-702 Receptacles exposed to the weather (see Appendix B)

Currently standard C22.2 No. 42.1 which deals with cover plates for flush mounted wiring

devices recognizes that outlets may be tested for use in wet locations:

• with electrical equipment plugged in, or

• without electrical equipment plugged in

Previous versions of Rule 26-702 did not distinguish between the two possible uses. The

changes are being made to ensure that receptacle covers provide adequate weather

protection when electrical devices are plugged in or not plugged in.

Copyright © 2009, The Reader’s Digest Association, Inc. and its licensors. All rights reserved.

©

British Columbia Safety Authority, 2012

16

Rule 26-704 Receptacles for maintenance of equipment located on roof tops

Appendix B note to Rule 26-704 - The minimum distance of 7.5 m is intended to ensure

that a standard 10 m long extension cord will reach the roof top equipment. The minimum

750 mm clearance from the finished roof is intended to ensure that the receptacle

remains visible in the event of snow build up.

In this illustration, consider two separate scenarios:

•

Scenario #1 - the HVAC equipment on the right is the only unit on the rooftop. In this

case a receptacle located anywhere within the prescribed 7.5 M and elevation is

acceptable. Caution, WorkSafe BC fall protection requirements apply where a fall

hazard exceeds 3m. To avoid fall protection requirements, choose another more

suitable location, mount the receptacle more than 2m from the edge, or ensure the

pony wall exceeds 2m in height.

•

Scenario #2 - both HVAC units are installed on the roof top as shown. One rooftop

receptacle may serve more than one HVAC unit provided the receptacle is located

within 7.5m of any unit so served.

Note: If the unit comes with an integral receptacle, it does not satisfy this rule.

©

British Columbia Safety Authority, 2012

17

Rule 26-710 General (See appendix B)

Subrule (d) - The revision is new wording that describes the proper receptacle

configuration designation.

Subrule (e) - This Rule applies to receptacles installed in all residential occupancies

including dwelling units and single dwellings. In previous Codes, item (ii) used the

wording “or area”. This wording resulted in inconsistent application of the requirements.

Subrule (o) - Appendix B note to Rule 26-710 (o):

It is intended by this requirement to recognize a need for additional EV charging

infrastructure in residential occupancies only in those cases when such EV charging

infrastructure is mandated by the provincial/territorial building codes or local building or

zoning regulations.

Rule 26-712 Receptacles for dwelling units (see Appendices B and G)

Subrule (d)(iii) has been revised to clarify receptacles are required along counter work

surfaces whether there is a wall behind the counter or not. Previous editions of the Code

required receptacles along the wall “behind counter work surfaces”. This caused

confusion for Users and AHJ’s when the counter work surface abutted glass windows or

other non-traditional “wall” surfaces which did not provide a means to locate a receptacle.

Compliance with this rule may require a receptacle to be mounted in the counter work

surface along the wall using pop-up or pedestal mount receptacles which are available

at this time.

©

British Columbia Safety Authority, 2012

18

•

The receptacle on the left is not approved for use in Canada. It is shown as a means

of meeting the new requirements where a wall is not provided behind the counter

space. Any receptacle intended for use must bear acceptable evidence of approval.

•

The receptacle on the right is fully approved.

©

British Columbia Safety Authority, 2012

19

Rules 26-712(d)(iv) and (v)

Appendix B Note - It is intended by this Rule that a continuous counter surface is one

which is not interrupted by sinks, ranges and other built in equipment.

Where there is a sink, range or other built in equipment such as a gas cook top installed

in a counter surface, new measurements shall be taken to determine if additional

receptacles are required. This may result in more than one receptacle on an island work

space.

600mm or

greater

continuous counter surface

300 mm

or greater

If less than

300mm

receptacle

not required

600 mm

or greater

•

Where a sink or appliance interrupts a counter surface, a new counter work surface

begins. If this new work surface meets the minimum dimensions specified, an

additional receptacle will be required.

•

In this example, a receptacle is NOT required to the left of the sink as the minimum

300mm dimension is not met.

©

British Columbia Safety Authority, 2012

20

600mm or

greater

continuous counter surface

280 mm

600 mm

or greater

600 mm

or greater

600mm or

greater

300 mm

or greater

600 mm

or greater

600 mm

or greater

300 mm

or greater

•

Where a sink or appliance interrupts a counter surface, a new counter work surface

begins. If measurements determine it meets the minimum dimensions specified, an

additional receptacle will be required.

•

In the upper island example, one of the minimum dimensions is not met; therefore a

receptacle is not required.

•

In the lower island example, both dimensions are met and there are two counter work

surfaces, one on each side of the sink, therefore a receptacle is required at each

location.

•

In the peninsula example, both dimensions are met and there are two counter work

surfaces, one on each side of the sink, therefore a receptacle is required at each

location.

©

British Columbia Safety Authority, 2012

21

Rule 26-712(h) – Appendix B Note:

The intent of Rule 26-712(h) is to protect children from shock where they may tamper with

receptacles accessible to them. For those situations where the receptacle is inaccessible,

a non-tamper proof receptacle may be used.

Examples of such situations where the receptacle is inaccessible are microwaves in

cabinets, refrigerators, freezers, washing machines, those located in an attic or crawl

space, or those installed above 2 m from the floor or finished grade.

Cabinet lighting power above 2 meters

Clock outlet above 2 meters

Microwave

TR

TR

TR

Fridge or

Freezer

Dishwasher

TR

TR

Wine

cooler

TR

Washer

Dryer

Garburator ,

Hot Water Dispenser

Tamper Resistant receptacle required

Standard receptacle OK to use

©

TR

British Columbia Safety Authority, 2012

22

TR Receptacles

not required

in attic space

Areas

requiring

tamper

resistance

receptacles

2M

Tamper

TR

resistant

receptacle

Balconies

or decks

interior

TR

TR

Standard

receptacle

TR

exterior

interior

TR

TR

TR Receptacles not required

in crawl space

©

British Columbia Safety Authority, 2012

23

Rule 26-714 Receptacles for single dwellings (see Appendices B and G)

Previously the Code was silent in regard to the requirement to install a receptacle

for the overhead garage door opener.

Rule 26-720 General

Subrule (b) applies to branch circuits for all residential occupancies including dwelling

units and single dwellings. In previous Codes, the wording “or area” was used. This

wording resulted in inconsistent application of the requirements. The subrule now clearly

defines when that branch circuit is required. Note that the wording “receptacles” has not

changed which still allows all receptacles in a laundry room to be supplied by the laundry

room circuit.

Subrule (g) is a new item added to require a separate branch circuit.

Rule 26-722 Branch circuits for dwelling units (see Appendices B and I)

Some electrical equipment is subject to nuisance tripping due to the nature of the

equipment design or sometimes the nature of the location. Both AFCI and GFCI

protection may be undesirable where the consequences of nuisance tripping cause

unwanted conditions.

Revisions to Rule 26-722(g) help clarify that a receptacle installed for the dedicated use

of a sump pump, does not require AFCI protection. To help ensure the receptacle is not

used for unintended purposes and AFCI protection is maximized within the sleeping area,

a single (not duplex) receptacle properly identified and on a separate circuit from other

receptacles in the bedroom is required.

Image courtesy of

www.visual.merriam-webster.com

©

British Columbia Safety Authority, 2012

24

Rule 26-744 Supply connections for appliances

In previous editions of the Code, Rule 8-300 required branch circuit conductors to be

sized to 8kw for a range up to 8kw. This resulted in a conductor sized smaller than the

rating of the range receptacle (14-50R/50a). This revision now recognizes and accepts

the smaller conductor to supply this receptacle configuration.

Rule 26-760 - Special terminology

Bare element water heater - a self contained factory assembled water heater that heats

water by direct contact with the uninsulated heating element wire.

CSA Standard C22.2 No. 64 requires that bare element water heaters be marked "BARE

ELEMENT WATER HEATER" and "CHAUFFE-EAU À ÉLÉMENT NU". The requirements

for bare element water heaters in CSA Standard C22.2 No. 64 apply to permanently

connected heaters and do not apply to cord-connected equipment.

Rule 26-762 – General

The previous wording “A water heater with a bare heater element immersed in water” has

been deleted.

Section 28 — Motors and Generators

Rule 28-308 Overload protection not required (see Appendix B)

The revision to 28-308 (a) is strictly editorial. The previous (a) has been split into items (i)

and (ii). The net result is no change in intent, just easier reading and therefore clarification

of the requirements where overload protection is not required.

Subrule (c) has not been revised and still references the types of motors which conform to

CSA C22.2 No.77. These motors are typically fractional HP with electronic control

systems which monitor speed, direction and overload situations. They are used

extensively in plenum, duct and damper control of HVAC systems (servo motors).

©

British Columbia Safety Authority, 2012

25

Section 30 — Installation of Lighting Equipment

Rule 30-308 Circuit connections

Safety during maintenance remains the foremost reason for requiring a disconnecting

means for fluorescent fixtures rated more than 150 volts to ground. This rule has been

revised to recognize other acceptable means to provide the required disconnecting

means.

Rule 30-310 – Luminaire as a raceway

The former references to Table 19 and Table 11 have been replaced by the references to

select the conductors in accordance with Rule 4-008 and 4-012 respectively.

Rule 30-410 - Wiring of show window luminaires

The former reference to Table 11 has been replaced by the reference to select the

conductors in accordance with Rule 4-012(1).

Rule 30-912 - Wiring of recessed fluorescent luminaires

The former reference to Table 11 has been replaced by the reference to select the

conductors in accordance with Rule 4-012(1).

Rule 30-1004 - Wiring methods — Underground

The former reference to Table 19 has been replaced by the reference to select the

conductors in accordance with Rule 4-008 (1).

Rule 30-1102 –Conductors

The former reference to Table 19 has been replaced by the reference to select the

conductors in accordance with Rule 4-008 (1).

©

British Columbia Safety Authority, 2012

26

Section 32 — Fire Alarm Systems, Fire Pumps, and Carbon

Monoxide Alarms (See Appendix G)

Rule 32-100 Conductors

As with other revisions throughout the Code, the User of the Code must ensure the

selection of conductors used for the Fire Alarm wiring are approved and suitable for the

intended purpose.

Rule 32-102 Wiring method

The requirement to encase rigid PVC conduit in 50mm of concrete or masonry has been

removed. Now an exposed surface run of Rigid PVC is an acceptable wiring method in a

non-combustible building.

Note that the ENT provision in item (d) has additional text added in RED. A CSA errata

has been made, requiring type ENT to be embedded in at least 50mm of concrete when

used in non-combustible construction.

Studies have shown that PVC provides an equivalent level of protection as EMT or similar

wiring methods when exposed to a building fire. However, users are cautioned that for

some buildings, the BC Building Code requires additional protection from fire exposure for

some portions of a fire alarm system which cannot be met by RPVC conduit alone. I.e.

Tall buildings. See Appendix B notes for further information.

©

British Columbia Safety Authority, 2012

27

©

British Columbia Safety Authority, 2012

28

Rule 32-200 Conductors (see Appendices B and G)

The intent of this Rule is to protect the feeder conductors between a fire pump and an

emergency power source from fire damage. The BC Building Code and Local Bylaws

requires that conductors supplying a life and fire safety equipment be protected against

exposure to fire to ensure continued operation of this equipment for a period not less than

1 h. NFPA 20 also mandates protection of circuits feeding fire pumps against possible

damage by fire.

The following examples illustrate acceptable methods for achieving this protection:

Regardless of the method chosen, verification by the Building official or a fire protection

engineer is required

(a) Using mineral-insulated cables conforming to fire rating requirements as specified in

Clause 5.3 of CSA C22.2 No. 124;

(b) Embedding the raceway containing fire pump feeder conductors in not less than 50

mm of concrete in compliance with the BC Building Code and local building by-laws.

Encasing conventional wiring in concrete is a traditional method for addressing fire

protection. 50mm of concrete has historically been considered adequate for one-hour fire

resistance; approximately 100mm are required to protect conductors for two hours.

However, this is a general statement and an engineers report confirming compliance must

be provided to the Building Official who has jurisdiction in this matter.

©

British Columbia Safety Authority, 2012

29

(c) Installing the raceway containing fire pump feeder conductors in a shaft enclosure or

service space of at least 1 h fire resistance construction.

Specific requirements pertaining to the fire resistance rating of a material or an assembly

of materials can be found in subsection 3.1.7 of the BC Building Code and Local Bylaws

or in the appropriate provincial/territorial legislation. Gypsum fire shaft assemblies are

highly complex and difficult to make properly, professional design and certification is

required.

32-202 Wiring Method

Rule 32-202 applies to both the normal power for the fire pump and portions of

emergency power that exit the concrete (if so protected) or portions that exit the fire shaft

(if so protected).

©

British Columbia Safety Authority, 2012

30

32-208 Transfer switch (see Appendix G)

The revision to Rule 32-208 is editorial in nature and clarifies the requirements that where

a transfer switch is used to supply emergency power to a fire pump, the transfer switch

shall be used solely for the fire pump. Other systems may be supplied but must be

controlled by their own transfer switches.

Further information can be found in the BC Building Code, see Section 46 3.2.7.9,

Emergency power supply for building services (elevators, fire pumps, fans, etc.).

Normal power

Emergency power

Transfer

Switch

Fire Pump

Controller

Other

emergency

loads

X

Fire Pump

Controller

X

In the illustration above, this installation is not compliant as each pump and controller

must be separately controlled as shown in illustration below.

This illustration above shows a compliant installation. Each fire pump is supplied by its

own transfer switch.

©

British Columbia Safety Authority, 2012

31

Section 36 — High-Voltage Installations

Rule 36-100 Conductors (see Appendix B)

Subrule (1) (c) - This revision is editorial only, the previous Code made reference to

Subrule (2) (d), armoured cable. This was incorrect as insulated conductors in armoured

cable are enclosed in grounded metal (the sheath).

Subrule (2) (e) - Type TC tray cable is available in Canada in medium voltage classes up

to 46 kV armoured and non-armoured.

Rule 36-214 Disconnecting means

Subrule (2) – Previously, the Code required the ability to see the switch contacts in “both

the open and closed position”. With the advent of new HV switch and circuit breaker

designs where visible inspection of the closed contacts is not possible, the Rule has been

revised. It is important that the switch contacts be visible in the open position for safety to

electrical workers. Where the contacts are not visible in the open position, this Rule

applies.

Rule 36-302 Station ground electrode

Subrule (3) - The revision clarifies that where conditions do not permit the grounding

electrode system to be adjacent to the station, a remote grounding installation must

comply with Subrule 1(a) and 1(b).

The previous Code required compliance with all of Subrule (1) which included connecting

all the metal parts within the station to the ground grid and having the remote ground form

a loop around the station. This is not possible by the very definition of a “remote Station

ground”.

©

British Columbia Safety Authority, 2012

32