ULL - Mirus International Inc.

advertisement

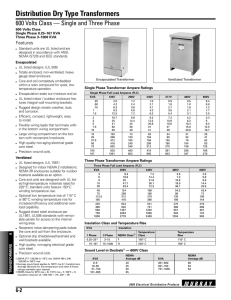

ULLTRA™ High Performance Transformers Not all Energy Efficient Transformers are created equal ULLTRA High Performance transformers are designed to deliver more energy savings than any other transformer on the market. The result is a high performing transformer that offers the highest efficiency in the industry under either linear or non-linear loading and maintains these high efficiency levels at not only 35% loading but over a wide load range. Although other energy efficient transformers on the market may meet new, more demanding standards such as NEMA Premium and CSL3, these standards only restrict losses under linear loading and at 35% load levels. When it comes to higher load levels and non-linear loading, other transformers on the market can’t offer the same high efficiencies under these conditions. ULLTRA High Performance transformers actually exceed NEMA Premium efficiency levels at their peak performance loading of 50%. Quicker PAYBACK PERIOD Applications A perfect solution for any application where energy efficiency and lower life cycle costs are critical – K-12 and Higher Education, Government, Healthcare, Commercial, Industrial and LEED buildings. Applications that expect heavier loads such as Data Centers, Solar and other Alternative Energy projects, will benefit from ULLTRA Series Transformers ability to maximize savings under ANY load and for ANY load profile. Mirus offers eVALUATOR™, a proprietary and complimentary payback analysis tool for transformers. By entering some simple data into the program it calculates accurate payback and energy savings and takes into account the effects of harmonics created by non-linear loading. ULLTRA improves paybacks by allowing for ‘Right Sizing’. Right Sizing takes into account that a transformer designed to maintain high efficiencies under heavy and non-linear loading can be significantly smaller than one optimized for light loading. The transformer can be sized to operate at heavier load levels, where it is better utilized, without sacrificing energy efficiency. This not only saves energy and the associated operating costs, but also saves on initial costs. In addition, smaller transformers require less materials, such as steel and copper, providing further environmental benefit. Paybacks are particularly good in applications where both light and heavy loading can be expected. For example, transformers used for alternative energy sources, such as Solar Power, will be nearly fully loaded during peak daylight hours but very lightly loaded at night. Often incentives associated with Utility purchase agreements include much higher rates for the electricity they buy, further justifying ULLTRA’s use. Real-world Tested. REAL-WORLD PERFORMANCE Like all of Mirus’ products, ULLTRA High Performance Transformers undergo rigorous real-world tests in Mirus’ own Harmonics & Energy Lab. Load profiles are matched to real-world conditions. With the largest non-linear load bank in the industry, Mirus can test transformers up to 225 kVA under full non-linear load conditions to ensure the promised energy savings are realized. International Inc. Features Mirus-engineered GREEN DESIGN • Highest efficiencies in the industry at any load profile and at all load levels To maximize efficiencies at any load level or load profile, Mirus’ ULLTRA High Performance Transformers feature a unique core configuration that substantially reduces the core losses without having to lower flux density and provides both low core losses and copper losses. • Lowest Life Cycle Costs for best paybacks and improved bottom line • H1E improves reliability by reducing voltage distortion • Exceeds CSL-3 and NEMA Premium requirements in a wider load range • Meets NEMA TP-1 efficiencies under non-linear loading • Lower losses minimize energy waste and protect the environment by reducing greenhouse gas emissions • Energy savings are realized even during peak load conditions when environmental impact is greatest • Contributes to LEED (Leadership in Energy Efficient Design) in Energy & Atmosphere and Innovation & Design categories • Performance validated through linear and non-linear load testing in Mirus’ Harmonics & Energy Lab • Inrush magnetization currents are the lowest in the industry • Lower audible noise levels: 3dB to 5dB below NEMA ST-20 requirements Other design features include: lower audible noise well below standard limits and much lower inrush currents. Since ULLTRA Series do not need to be oversized to reach high K-Ratings, its unique core design allows for smaller cores with even lower inrush currents than standard transformers. ULLTRA™ – Ultra Low Loss TRAnsformer • Optimized for any load level making ULLTRA the only transformer ideally suited for both light or heavy loading conditions • Linear load losses are a full 30% lower than the already low levels defined by NEMA TP-1 • Efficiencies meet NEMA Premium levels at the mandated 35% loading and even exceed these levels at the transformer’s peak design loading of 50% • Harmonic losses are also reduced to ensure efficiencies meet NEMA TP-1 requirements even under ‘real world’ non-linear loading • Inrush currents (< 8x rated) and audible noise (3dB lower than standard) are extremely low • Ideal for Solar Power or other applications where transformer loading varies widely and electricity rates are high ULLTRA-H1E™ – Harmonic Mitigating Transformer In applications where non-linear loading is expected to be severe, the ULLTRA-H1E combines the proven harmonic mitigating properties of Mirus’ Harmony™ HMT line with superior energy efficiency, low inrush and low audible noise found in the ULLTRA design. • Voltage distortion (flat-topping) is minimized by cancelling zero sequence fluxes within the secondary windings and eliminating circulating currents in the primary windings • Treats triplen harmonics (3rd and 9th) within the transformer and 5th and 7th upstream • The highest efficiency harmonic mitigating transformer from the company that first introduced HMT’s to the market in the early 1990’s 75kVA Transformer Comparison under Linear Load ULLTRAtm Series Efficiency Sizes Primary Style Weight lbs [kg] 15 30 45 75 112.5 150 225 300 500 750 MT2 MT2 MT3 MT3 MT4 MT4 LT1 LT2 LT3 LT3 250 [115] 375 [170] 500 [227] 850 [386] 1000 [454] 1200 [544] 1800 [820] 2500 [1135] 3175 [1440] 4250 [1928] kVA Case Approximate Values Linear 35% Load* 50% Load 97.90% 98.25% 98.39% 98.60% 98.74% 98.81% 98.95% 99.00% 99.09% 99.16% 97.96% 98.35% 98.45% 98.65% 98.82% 98.85% 99.00% 99.07% 99.20% 99.28% * NEMA Premium & CSL3 specs Impedance K-13 Non-Linear No-Load 50% Load** Losses (W) 97.0% 97.5% 97.7% 98.0% 98.2% 98.3% 98.5% 98.6% 98.7% 98.8% 75 115 150 225 320 400 560 710 1100 1550 ULLTRA H1E Zero Sequence Zo Xo 3 Phase Short Circuit <0.95% <0.95% <0.95% <0.95% <0.95% <0.95% <1.0% <1.0% <1.5% <2.0% <0.3% <0.3% <0.3% <0.3% <0.3% <0.3% <0.5% <0.5% <0.5% <1.0% 2.0-3.5% 2.0-3.5% 2.0-3.5% 2.0-3.5% 2.5-5.0% 2.5-5.0% 3.0-6.0% 3.0-6.0% 4.5-7.0% 5.0-8.0% ** Equivalent to NEMA TP-1 'MT' Style Enclosure 'LT' Style Enclosure W W D D General Specifications: Primary 3-Phase, 3 wire, 60Hz Secondary 3-Phase, 4-wire, 60Hz Operating Temp. Rise 115oC Insulation Class 220oC Primary Taps 15kVA (and all 208V): + 1 x 5% 30kVA - 300kVA: +2 x 2.5%, - 4 x 2.5% 500kVA - 750kVA: + 2 x 2.5% K-Factor Rating (at 150oC rise) 13 Neutral Bus Ampacity 200% of phase current Energy Efficiency ( H H Mtg. W Mtg. D Mtg. W Front View Side View Front View Mtg. D Side View † see table ) Linear Load: Meets and/or exceeds the US Department of Energy Candidate Standard Level 3 (CSL-3) efficiency requirements by ensuring losses are 30% lower than NEMA TP-1. Non-Linear Load: Exceeds NEMA TP-1 efficiency requirements. Magnetizing Inrush < 8 times FL RMS Winding Material Copper Dimensions Case Style MT1 MT2 MT3 MT4 LT1 LT2 LT3 H (Height) inches [mm] 29.00 [737] 38.00 [965] 45.00 [1143] 51.50 [1308] 59.00 [1499] 66.00 [1677] 75.00 [1905] W (Width) inches [mm] 16.75 [425] 21.50 [546] 26.00 [661] 32.00 [813] 39.50 [1003] 44.00 [1118] 48.50 [1232] Mtg. Center W Mtg. Center D D (Depth) inches [mm] inches [mm] inches [mm] 13.75 [349] 13.00 [330] 15.00 [381] 17.00 [432] 17.50 [445] 19.50 [495] 21.50 [546] 19.00 [483] 21.00 [534] 23.50 [597] 23.50 [597] 25.50 [648] 24.00 [610] 32.00 [813] 30.00 [762] 26.00 [660] 36.00 [915] 34.00 [864] 27.50 [699] 41.00 [1041] 39.00 [991] Insulating Varnish Impregnation Polyester Resin Audible Sound Level 3dB to 5dB below NEMA ST-20 Enclosure Type: Nema-3R, ventilated Paint: Polyester powder coated Colour: ANSI 61 Grey Electrostatic Shield Single, [double] Product Code: Transformer Type Secondary Ultra Low Loss L-L Voltage Transformer 208, 480, 600 Applicable Standards Electrostatic Shield S = Single shield (Std. for ULL) SS = Double shield Options ULL - dd - hhh - xxx - kVA - S - TRx - t - (o) Angular Primary Primary kVA Temperature Displacement L-L Voltage 15, 30, 45, 75, Rise 30 (Std. for ULL) 208, 480, 600 112.5, 150, 225, TRB* = 115oC (Std.) [ * Leave blank for TRB] 00 (Std. for Type H1E) 300, 500, 750 Type H1E = Harmonic Mitigating [Leave blank for Std. ULL] NEMA Premium, NEMA ST20, NEMA TP1, NEMA TP2, CSA C9, CAN/CSA-C802.2, DOE CSL-3 Options: Over-Temp. Sensors [170oC], [200oC] Solid Bottom Plate Available for 'MT' case only C Mirus International Inc. All specifications subject to change without notice. MIRUS International Inc. 31 Sun Pac Blvd., Brampton, ON, Canada L6S 5P6 Tel: 905.494.1120 Fax: 905.494.1140 Toll Free: 1-888 TO MIRUS (888.866.4787) www.mirusinternational.com R ULL-PS01-A7 Effective: August 2012 MIRUS International Inc. 31 Sun Pac Blvd., Brampton, Ontario, Canada L6S 5P6 I. TYPICAL SPECIFICATION ULLTRA™ & ULLTRA-H1E™ NEMA Premium® Ultra Low Loss TRAnsformer PART 1 – GENERAL 1. SCOPE A. NEMA Premium® copper-wound ultra low loss isolation transformer with a higher efficiency than that required by NEMA Std. TP-1. Optimized for energy efficiency over a wide load range. 1. Meets NEMA Premium® and US Department of Energy proposed Candidate Standard Level CSL-3 efficiency. 2. Losses 30% lower than required at the defined NEMA TP-1 test point of 35% load. 3. Rated for K-13 load profile to supply without de-rating or significant degradation in efficiency, any typical application where non-linear loads, such as computer equipment, are present. 4. Optional harmonic mitigating model with low zero phase sequence impedance 2. APPLICABLE DOCUMENTS AND REFERENCES A. Federal Register – US Department of Energy, Office of Energy Efficiency and Renewable Energy. 10 CFR Part 430, July 29, 2004. Energy Conservation Program for Commercial and Industrial Equipment: Energy Conservation Standards for Distribution Transformers; Proposed Rule. B. NEMA Premium® Efficiency Transformer Program Guidelines C. ANSI/NEMA ST 20 – Dry Type Transformers for General Applications. D. ANSI/NEMA TP-1 – Guide for Determining Energy Efficiency for Distribution Transformers. E. ANSI/NEMA TP-2 – Standard Test Method for Measuring the Energy Consumption of Distribution Transformers. F. IEEE C57.110-1998 – IEEE Recommended Practice for Establishing Transformer Capability When Supplying Nonsinusoidal Load Currents. G. IEEE-1100 – IEEE Recommended Practice for Powering and Grounding Electronic Equipment. H. CSA C9 – Dry-Type Transformers. I. CAN/CSA-C802.2 – Minimum Efficiency Values for Dry-Type Transformers. 3. SUBMITTALS A. Submit product specifications including the following: 1. Data sheets including a. construction details with enclosure dimensions, b. kVA rating, primary and secondary nominal voltages, voltage taps, unit weight, c. basic performance characteristics with insulation class, temperature rise, core and coil materials, d. impedances, e. audible noise levels 2. Dimensional drawings, 3. Inrush current (typical 3 cycle recovery) 4. Short circuit current data 5. Efficiency data a. no load and full load losses per NEMA ST20, b. efficiency data at 35%, 50%, 75% and 100% of nominal linear load, Mirus International Inc. [2012-08-13] 1-888-TO MIRUS www.mirusinternational.com Page 1 of 5 ULL-TS003-A0 MIRUS International Inc. 31 Sun Pac Blvd., Brampton, Ontario, Canada L6S 5P6 c. TYPICAL SPECIFICATION ULLTRA™ & ULLTRA-H1E™ NEMA Premium® Ultra Low Loss TRAnsformer efficiency data at 35% of nominal linear load tested per NEMA TP-2, d. efficiency data at 50% of nominal load with K-13 load profile. B. Submit copy of non-linear test program description and sample test report for approval before manufacturing. C. Submit certified copies of the standard production tests required by NEMA standards ST-20 and TP2 for each transformer for approval before shipment. D. Submit certified type test results for non-linear load testing for each size of transformer ordered on the project for approval before shipment II. PART 2 PRODUCTS 1. REQUIREMENTS A. Acceptable Product and Manufacturer: 1. ULLTRA™ Isolation Transformer made by MIRUS International Inc. 2. No alternates or substitutions will be permitted unless they meet all the requirements of this specification, including document submittal requirements and that they are submitted in sufficient time to receive written approval by the engineer at least 10 days before bid closing. B. Voltage and kVA Requirements: 1. Primary Voltage: [480][600][other] Volts 2. Secondary Voltage: [120/208][other] Volts 3. kVA rating: [15][30][45][75][112.5][150][225][300][500][750][other] kVA 4. System Frequency: 60 [50][other] Hertz C. Basic Requirements: 1. Three-phase isolation transformer built to NEMA ST20 and relevant NEMA, UL, CSA and ANSI/IEEE standards. 2. UL listed and CSA approved. 3. Common core construction. 4. Convection air-cooled. 5. Copper Windings. 6. Insulation Class: 220°C system, (15 kVA and 30 kVA transformers have 200°C insulation class). 7. Temperature rise: 115°C, [80°C] in a 40 degrees C maximum ambient. 8. K-rating: K-13 at 150°C rise. 9. Maximum magnetizing inrush current: < 8x full load rms 10. Taps: for 15kVA and all 208V primary: ±1 x 5% (1FCAN, 1FCBN); for 30kVA up to 300kVA: + 2 x 2.5%, - 4 x 2.5% (2FCAN, 4FCBN); for 500kVA to 750kVA: ±2 x 2.5% (2FCAN, 2FCBN). 11. Sound levels 3dB below NEMA Std. ST-20: max. 42dB up to 45 kVA, 47 dB from 75 to 150 kVA, 52 dB from 225 to 300 kVA, 57dB for 500 kVA, and 61 dB for 750 kVA. 12. Enclosure: NEMA 3R, ventilated, sprinkler-proof. [Other]. Colour: Grey 13. Anti-vibration pads shall be used between the core and the enclosure. 14. Single electrostatic shield: 60dB attenuation. D. Key Requirements: Mirus International Inc. [2012-08-13] 1-888-TO MIRUS www.mirusinternational.com Page 2 of 5 ULL-TS003-A0 MIRUS International Inc. 31 Sun Pac Blvd., Brampton, Ontario, Canada L6S 5P6 TYPICAL SPECIFICATION ULLTRA™ & ULLTRA-H1E™ NEMA Premium® Ultra Low Loss TRAnsformer 1. Secondary neutral connection rated at 200% of the rated secondary phase current 2. Maximum No Load losses shall not exceed: 15 kVA: 75 watts, 30 kVA: 115 watts, 45 kVA: 150 watts, 75 kVA: 225 watts, 112.5kVA: 320 watts, 150 kVA: 400 watts, 225 kVA: 560 watts, 300 kVA: 710 watts, 500 kVA: 1100 watts, 750 kVA: 1550 watts. Submit for approval before shipment certified type test results for maximum no load losses for each size of transformer ordered on the project. 3. Linear load efficiency at 35% shall ensure 30% less losses than that required by NEMA Std TP1 meeting NEMA Premium and DOE 10 CFR Part 430 CSL-3 efficiency requirements as tested per NEMA TP-2. To ensure high efficiency over a wide load range, linearl load efficiency at 50% load shall be higher than the efficiency at 35% load. a. The following efficiency levels shall be met at 35% load: 15 kVA: 97.9%, 30 kVA: 98.25%, 45 kVA: 98.39%, 75 kVA: 98.6%, 112.5kVA: 98.74%, 150 kVA: 98.81%, 225 kVA: 98.95%, 300 kVA: 99.0%, 500 kVA: 99.09%, 750 kVA: 99.16%. b. The following efficiency levels shall be met at 50% load range: 15 kVA: 97.96%, 30 kVA: 98.35%, 45 kVA: 98.45%, 75 kVA: 98.65%, 112.5kVA: 98.82%, 150 kVA: 98.85%, 225 kVA: 99.0%, 300 kVA: 99.07%, 500 kVA: 99.20%, 750 kVA: 99.28%. Submit for approval before shipment certified type test results for linear load efficiency at 35% and 50% load for each size of transformer ordered on the project. 4. Non-linear load efficiency under K-13 non-linear load at 50% load of nameplate rating shall meet efficiency levels defined by NEMA TP-1: 15 kVA: 97.0%, 30 kVA: 97.5%, Mirus International Inc. [2012-08-13] 1-888-TO MIRUS www.mirusinternational.com Page 3 of 5 ULL-TS003-A0 MIRUS International Inc. 31 Sun Pac Blvd., Brampton, Ontario, Canada L6S 5P6 TYPICAL SPECIFICATION ULLTRA™ & ULLTRA-H1E™ NEMA Premium® Ultra Low Loss TRAnsformer 45 kVA: 97.7%, 75 kVA: 98.0%, 112.5kVA: 98.2%, 150 kVA: 98.3%, 225 kVA: 98.5%, 300 kVA: 98.6%, 500 kVA: 98.7%, 750 kVA: 98.8%. Submit for approval before shipment certified type test results for non-linear load testing including efficiency of 50% and full load for each size of transformer ordered on the project. 5. Positive & negative sequence impedance at 60Hz: 2.0% to 3.5% (up to 75 kVA), 2.5% to 5% (112.5 kVA to 150 kVA), 3.0% to 6% (225 kVA to 300 kVA), 4.5% to 7% (500kVA) 5% to 8% (750 kVA to 1000kVA). E. Other Requirements: 1. [OPTION] For harmonic mitigating model (ULL-H1E), zero sequence impedance and reactance at 60Hz shall not exceed: Zo < 0.95%, Xo < 0.3% for sizes up to 150 kVA, Zo < 1.0%, Xo < 0.5% for sizes 225 kVA and 300 kVA, Zo < 1.5%, Xo < 0.5% for 500 kVA and Zo < 2.0%, Xo < 1.0% for 750 kVA. 2. [OPTION] [Dual electrostatic shields.] 3. [OPTION] Over-Temperature switch[es] wired to internal terminal strip. Temperatures specified for use with class 220°C insulation systems. Standard configuration is N.C. opening [N.O. closing] on high temperature. Number of switches: [one switch: 170°C or 200°C on center coil] [two switches: 170°C and 200°C on center coil] [six switches: one 170°C and one 200°C on each of the 3 coils.] 4. [OPTION] Submit for approval before shipment certified production test results with serial numbers for linear load efficiency at 35% load for one of each size of transformer manufactured for the actual project. 5. [OPTION] Submit for approval before shipment certified production test results with serial number for non-linear load testing up to the lesser of either full load or 225kVA for one of each size of transformer manufactured for the project. 2. VERIFICATION A. Non-linear Load Testing Capability: 1. Manufacturer must have a non-linear load testing program operating in the production environment. A detailed description of the program and a sample non-linear test report must be submitted to the Engineer in sufficient time for him to issue his written approval at least 10 days before bid closing. The non-linear load bank shall consist of three single-phase power electronic rectifier loads that present the same current harmonics (fundamental plus 3rd, 5th, 7th, 9th, 11th, etc.) as the 120VAC personal computer power supply loads present in workplaces today. The non-linear load bank shall be capable of presenting current distortion levels up to 100% and a load of up to 75 kVA on each phase-to-neutral leg in order to test a 225 kVA transformer at full load and larger transformers at a reduced load. Dual wattmeters and CT sets shall be used to monitor transformer input and output power with revenue class accuracy. Measurements shall include input and output power, kVA, and efficiency plus input and output current and voltage distortion and k-factor. This information shall be presented in graphical form. 3. WARRANTY A. Transformer shall carry a 25-year pro-rated warranty, which shall be standard for the product line. Mirus International Inc. [2012-08-13] 1-888-TO MIRUS www.mirusinternational.com Page 4 of 5 ULL-TS003-A0 MIRUS International Inc. 31 Sun Pac Blvd., Brampton, Ontario, Canada L6S 5P6 III. TYPICAL SPECIFICATION ULLTRA™ & ULLTRA-H1E™ NEMA Premium® Ultra Low Loss TRAnsformer PART 3 EXECUTION 1. INSTALLATION A. The installing contractor shall install the ultra low loss transformer per the manufacturer's recommended installation practices as found in the installation, operation, and maintenance manual and comply with all applicable codes. 2. ACCEPTANCE A. [OPTION] Manufacturer's representative shall visit site, verify installation, and submit to owner a letter stating equipment and installation meets intent of specification and manufacturer's warranties and guarantees are in effect. ********** END OF SECTION ********** Mirus International Inc. [2012-08-13] 1-888-TO MIRUS www.mirusinternational.com Page 5 of 5 ULL-TS003-A0 MIRUS International Inc. 31 Sun Pac Blvd., Brampton, Ontario, Canada L6S 5P6 ULLTRA™ _ TECHNICAL DATA ULTRA LOW LOSS TRANSFORMER (30% LESS LOSSES THAN NEMA TP1) ‘MT1’, ‘MT2’ ENCLOSURE DIM. - inches [mm] GENERAL SPECIFICATIONS: PRIMARY 3-phase, 3-wire, 60Hz SECONDARY 3-phase, 4-wire, 60Hz OPERATING TEMPERATURE RISE 115°C INSULATION CLASS 220°C PRIMARY TAPS 15kVA (and all 208V): ± 1 x 5% 30kVA - 300kVA: + 2 x 2.5%, - 4 x 2.5% 500kVA - 750 kVA: ± 2 x 2.5% K-FACTOR RATING (at 150°C rise) 13 NEUTRAL BUS AMPACITY DIMENSIONS - inches [mm] B C D CASE STYLE A MT1 MT2 29.00 [737] 38.00 [965] 200% of phase current ENERGY EFFICIENCY (see table below) Linear Load: Meets and/or exceeds CSL-3 efficiency requirements by ensuring losses are 30% lower than Nema TP1 Non-Linear Load: Exceeds Nema TP1 requirements 16.75 [425] 21.50 [546] 15.00 [381] 19.50 [495] 19.00 [483] 23.50 [597] E F 13.75 [349] 17.00 [432] 13.00 [330] 17.50 [445] ‘MT3’, ‘MT4’, ‘LT’ ENCLOSURE DIM. - inches [mm] MAGNETISING INRUSH < 10 times FL RMS WINDING MATERIAL Copper INSULATING VARNISH IMPREGNATION Polyester Resin AUDIBLE SOUND LEVEL As per NEMA ST-20 15 - 45kVA: 75 – 150kVA: 225 – 300kVA: 500kVA: 750kVA: ENCLOSURE Type: Paint: Colour: 45dB 50dB 55dB 60dB 64dB CASE STYLE MT3 MT4 LT1 LT2 LT3 NEMA-3R, ventilated Polyester powder coated ANSI 61 Grey ELECTROSTATIC SHIELD Single, [double] A 45.00 [1143] 51.50 [1308] 59.00 [1499] 66.00 [1677] 75.00 [1905] DIMENSIONS - inches [mm] B C D 26.00 [661] 21.00 [534] 25.00 [635] 32.00 [813] 25.50 [648] 29.50 [749] 39.50 [1003] 30.00 [762] 34.00 [864] 44.00 [1118] 34.00 [864] 38.00 [965] 48.50 [1232] 39.00 [991] 43.00 [1092] E F 21.50 [546] 19.00 [483] 23.50 [597] 23.50 [597] 24.00 [610] 32.00 [813] 26.00 [660] 36.00 [915] 27.50 [699] 41.00 [1041] APPLICABLE STANDARDS NEMA ST20, NEMA TP1, NEMA TP2 CSA C9, CAN/CSA-C802.2, DOE CSL-3 OPTIONS: OVER-TEMPERATURE SENSORS [170°C], [200°C] SOLID BOTTOM PLATE (Case ‘MT’ only) [yes], [no] Sizes Linear kVA Case Primary Style 15 30 45 75 112.5 150 225 300 500 750 MT2 MT2 MT3 MT3 MT4 MT4 LT1 LT2 LT3 LT3 Weight lb [kg][1] 250 [115] 375 [170] 500 [227] 850 [386] 1000 [454] 1200 [544] 1800 [820] 2500 [1135] 3175 [1440] 4250 [1928] Efficiency K-13 35% Load[2] 50% Load 97.90% 98.25% 98.39% 98.60% 98.74% 98.81% 98.95% 99.00% 99.09% 99.16% 97.96% 98.35% 98.45% 98.65% 98.82% 98.85% 99.00% 99.07% 99.20% 99.28% Impedance ULLTRA H1E Non-Linear No-Load Zero Sequence @50% Losses Zo Xo Load[3] Watts 97.0% 75 <0.95% <0.3% 97.5% 115 <0.95% <0.3% 97.7% 150 <0.95% <0.3% 98.0% 225 <0.95% <0.3% 98.2% 320 <0.95% <0.3% 98.3% 400 <0.95% <0.3% 98.5% 560 <1.0% <0.5% 98.6% 710 <1.0% <0.5% 98.7% 1100 <1.5% <0.5% 98.8% 1550 <2.0% <1.0% 3-Phase Short Circuit Terminal Sizes Primary 208V 480V Secondary 600V 120/208V 2.0 - 3.5% #2-#14 #6-#14 #6-#14 #6-#14 2.0 - 3.5% 2/0-#6 #2-#14 #2-#14 2/0-#6 2.0 - 3.5% 250MCM-#6 #2-#14 #2-#14 250MCM-#6 2.0 - 3.5% 600MCM-#4 2/0-#6 2/0-#6 600MCM-#4 2.5 – 5.0% 2x350MCM-#6 250MCM-#6 2/0-#6 2x350MCM-#6 2.5 – 5.0% 2x350MCM-#6 350MCM-#6 250MCM-#6 2x350MCM-#6 3.0 – 6.0% Copper Pad Copper Pad Copper Pad Copper Pad 3.0 – 6.0% Copper Pad Copper Pad Copper Pad Copper Pad 4.5 – 7.0% Copper Pad Copper Pad Copper Pad Copper Pad 5.0 – 8.0% Copper Pad Copper Pad Copper Pad Copper Pad Neutral 2x#2-#14 2x2/0-#6 2x250MCM-#6 2x600MCM-#4 4x350MCM-#6 4x350MCM-#6 Copper Pad Copper Pad Copper Pad Copper Pad 1. Approximate values. 2. NEMA Premium & CSL3 specifications. 3. Equivalent to NEMA TP-1. 4. Specifications are subject to change without notice. 5. For additional information refer to: Typical Specifications, Technical Guide, Internal Layout and Connection Diagrams. Mirus International Inc. [2012-08-13] 1-888-TO MIRUS www.mirusinternational.com ULL-S001-A16