1 - Rowan University

advertisement

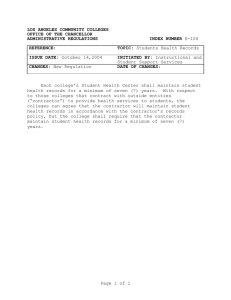

HOLSTEIN WHITE, INC. CONSULTING ENGINEERS 210 E. STREET ROAD TELE # (215)322-7711 SUITE 2D FAX # (215)322-7709 FEASTERVILLE, PA 19053 STUDENT CENTER SITE MAP CS COVER SHEET E1 FIRST FLOOR - POWER AND LIGHITNG PLAN E2 ELECTRICAL DETAILS MP1 FIRST FLOOR - MECHANICAL AND PLUMBING PLAN MP2 MECHANICAL & PLUMBING SCHEDULES AND DETAILS FP1 FIRST FLOOR - FIRE PROTECTION PLAN 201 Mullica Hill Road Glassboro, NJ 08028 DRAWING INDEX ROWAN UNIVERSITY 201 MULLICA HILL ROAD! GLASSBORO, NJ 08028 JEFFREY E. HOLSTEIN, P.E. License No. NJ: 24GE0644300 Authorization No.: 24GA28143700 COVER SHEET ROWAN UNIVERSITY! ELEVATOR UPGRADE Seal Revisions -- -- PROJECT NO: 14-440 DATE: JUNE 16, 2014 DRAWN BY: DS CHECKED: MB SCALE: AS NOTED PLOT DATE: CS -- DRAWING NOTES 1 2 3 4 COORDINATE FINAL LOCATION OF OUTDOOR UNIT WITH THE BUILDING OWNER. CONTRACTOR SHALL PROVIDE A 6" HIGH CONCRETE HOUSEKEEPING PAD. UNIT SHALL BE INSTALLED PER MANUFACTURERS REQUIREMENTS AND ALL SERVICE CLEARANCES SHALL BE MAINTAINED.! ! COORDINATE FINAL LOCATION OF AIR HANDLER UNIT WITH LOCATION OF ELEVATOR EQUIPMENT WITHIN MACHINE ROOM. INSTALL AIR HANDLER UNIT WITH SUPPORT STRUCTURE PER MANUFACTURERS REQUIREMENTS AND ALL SERVICE CLEARANCES SHALL BE MAINTAINED.! ! EXTEND AND CONNECT REFRIGERANT LINES IN CEILING SPACE TO OUTDOOR UNIT PER MANUFACTURERS REQUIREMENTS. REFRIGERANT PIPE SIZING SHALL MEET ALL MANUFACTURERS REQUIREMENTS. CONTRACTOR SHALL BE RESPONSIBLE FOR ALL CORE DRILLING AND PATCHING.! ! PROVIDE CONDENSATE PIPING AND EXTEND FROM AHU TO OUTSIDE. CONDENSATE PIPING SHALL TERMINATE 6" ABOVE GRADE. PROVIDE LITTLE GIANT CONDENSATE PUMP IF REQUIRED. CONTRACTOR SHALL BE RESPONSIBLE FOR ALL CORE DRILLING AND PATCHING. HOLSTEIN WHITE, INC. CONSULTING ENGINEERS 210 E. STREET ROAD TELE # (215)322-7711 SUITE 2D FAX # (215)322-7709 FEASTERVILLE, PA 19053 Seal 1-1/2" DISCHARGE PIPE, TERMINATE A MINIMUM OF 18" ABOVE FINISHED GRADE WITH INSECT SCREEN. DISCHARGE TO CONCRETE SPLASH BLOCK. COORDINATE EXACT LOCATION WITH OWNER. PROVIDE PIPE SLEEVE WITH WEATHERPROOF/FIRE RETARDANT SEALANT! (TYPICAL FOR ALL) STAIRS #5 S5 ELEV EQUIP RM 002A UP MECHANICAL ROOM 004 TELE/COM ROOM ELEV EQUIP 002A1 002 2 3 T 4 AHU 1 ELEVATOR SUMP PUMP ALARM PANEL. COORDINATE FINAL LOCATION WITH OWNER UP ELEVATOR SUMP PUMP SYSTEM WITH OILTECTOR CONTROL, RUN 1-1/2" DISCHARGE PIPE FROM SUMP PUMP TO SPLASH BLOCK ON GRADE. PROVIDE OIL SENSING SWITCH TO SHUT DOWN PUMP AND SEND ALARM TO REMOTE PANEL. CONTRACTOR SHALL PROVIDE CONCRETE SUMP PUMP PIT WITHIN THE ELEVATOR PIT. CONCRETE PIT SHALL NOT AFFECT THE STRUCTURAL INTEGRITY OF THE ELEVATOR SHAFT. COORDINATE THE LOCATION OF THE REMOTE ALARM PANEL WITH OWNER. REFER TO 1/MP2 FOR INSTALLATION DETAILS. SP 1 ELEVATOR #2 ESCF1 201 Mullica Hill Road Glassboro, NJ 08028 HP 1 FIRST FLOOR - MECHANICAL & PLUMBING PLAN 1 ROWAN UNIVERSITY Scott White, P.E. NJ License # 24GE04977900 Authorization No: 24GA28143700 Revisions -- -- DN CORRIDOR H003 1 MECHANICAL & PLUMBING -! FLOOR PLAN SCALE: 1/4" = 1'-0" PROJECT NO: 14-440 DATE: JUNE 16, 2014 DRAWN BY: BA CHECKED: SW SCALE: AS NOTED PLOT DATE: MP1 -- 1.! ! ! 2.! ! ! 3.! ! ! 4.! ! ! 5.! ! ! ! ! 6.! ! ! 7.! ! ! ! ! ! 8.! ! ! 9.! ! ! ! 10. HVAC NOTES:! ! The Contractor shall coordinate with the General Contractor and locate all required cutting and patching and the like required by the installation of the Mechanical work.! ! Provide all specialties, accessories, controls, and the like to provide a complete, quiet, properly operating automatically controlled systems. ! ! The HVAC trade shall provide all safety and operating controls, transformers, motor starters, devices and control wiring required for the systems to operate in a safe and satisfactory manner.! ! Do not operate the air conditioning systems during construction except for testing, and provide new filters for all units and immediately prior to substantial completion. ! ! Ductwork shall be constructed of galvanized sheet metal fabricated and erected in accordance with ASHRAE and SMACNA standards. Provide turning vanes in all elbows, manual volume dampers in all branches, air equalizers, and similar devices as required to properly balance the systems and produce quiet, draftless operation. Ductwork sizes shown on the plans are sheet metal I.D. free area. ! ! Ductwork shall be constructed to the sizes shown and made airtight during erection with caulked, taped or hardcast joints to restrict leakage to 5% or less of circulated air.! ! All ductwork shall be closely coordinated prior to fabrication. The architectural contract drawings and details together with the other contract documents shall be examined for all dimensional information. Full sheet metal shop drawings drawings shall be developed with all spacial requirements worked out and shown on drawings. These drawing must show: locations of openings to be cut through existing construction and any problems. These drawing shall be submitted for review by the architect and engineer prior to fabrication. ! ! Provide UL labeled and inspected fire dampers for all ducts and openings passing through floors, fire rated walls and ceilings, where shown on the drawings, and in locations required by codes.! ! Balance all air quantities to within 5% of the CFM shown on the drawings. Finally balance individual outlets to the occupants’ satisfaction. Install all devices required for balancing in the system during construction. Provide balancing reports for review by the Engineer.! ! Provide written operating and maintenance instructions and warranty certificates, in duplicate, to the Architect. 1.! ! ! ! ! ! ! ! 2.! ! ! ! ! ! ! ! ! ! ! ! 3. IT SHALL BE THE RESPONSIBILITY OF THE MECHANICAL CONTRACTOR TO COORDINATE THE LOCATIONS OF SUPPRESSION SYSTEM PIPING WITH THE ELECTRICAL CONTRACTOR. DUCTWORK SHALL NOT BE INSTALLED WITHIN THE DEDICATED EQUIPMENT SPACE REQUIRED FOR EXISTING OR NEW ELECTRICAL EQUIPMENT. ! ! COORDINATION OF DUCTWORK LOCATIONS SHALL BE SOLEY THE RESPONSIBILITY OF THE MECHANICAL CONTRACTOR. APPROVAL OF SHEET METAL SUBMITTAL DRAWINGS DOES NOT RELEASE THE CONTRACTOR FROM COORDINATION RESPONSIBILITY. FINAL COORDINATION SHALL OCCUR IN FIELD WITH ELECTRICAL CONTRACTOR. FAILURE TO COMPLY WITH THIS REQUIREMENT MAY RESULT IN RELOCATION OF SUPPRESSION SYSTEM PIPING AT CONTRACTOR'S EXPENSE.! ! PER NFPA 70, ARTICLE 110.26(F); DEDICATED EQUIPMENT SPACE SHALL APPLY TO SWITCHBOARDS, DISTRIBUTION PANELS, AND MOTOR CONTROL CENTERS. THE SPACE EQUAL TO THE WIDTH AND DEPTH OF THE EQUIPMENT AND EXTENDING FROM THE FLOOR TO A HEIGHT OF 6' ABOVE THE EQUIPMENT OR TO THE STRUCTURAL CEILING, WHICHEVER IS LOWER, SHALL BE DEDICATED TO THE ELECTRICAL INSTALLATION. NO PIPING, DUCTS, LEAK PROTECTION APPARATUS, OR OTHER EQUIPMENT FOREIGN TO THE ELECTRICAL INSTALLATION SHALL BE LOCATED IN THIS ZONE. Condensate Piping - A/C Refrigerant Piping Piping Subject to Freezing Certainteed Armacell Certainteed Wall! (in.) Vapor! Barrier 1 Alt. insulation 1" Rubatex R-180FS 500° Snap On Yes 1-1/2 Integral Insulate per manufacturer's recommendation Armatuff 500° Snap On 2-1/2 Aluminum EMERGENCY POWER GROUNDED WALL RECEPTACLE ELEVATOR #2 ESCF1 MIN. 4'-0" ABOVE FLOOR GRADE 1-1/2" DISCHARGE PIPE, TERMINATE A MINIMUM OF 18" ABOVE FINISHED GRADE WITH INSECT SCREEN, DISCHARGE TO SPLASH BLOCK, COORDINATE EXACT LOCATION WITH ARCHITECT/OWNER SHUTOFF VALVE CABLE HOOK CHECK VALVE STEEL PULL PUMP CABLE 1-1/2" COPPER PIPE AHU-1 Indoor Air Handler Unit Designation Basis of Design Mitsubishi AHU Model Number PKA-A24KA Orientation Wall AHU CFM Airflows 570 / 635 / 700 AHU Entering Air Temp. (°F db / °F wb) 80 / 67 Drive Type Direct AHU Dimensions (L x W x H) 46 x 12 x 14 AHU Weight (lbs) 46 Service Elev. Equip . Rm. Indoor AHU Electrical 208V / 1Ø / 60 0.36 AHU Fan FLA 1.0 MCA Outdoor HP Electrical 208V / 1Ø / 60 12 Compressor RLA 18 / 30 Outdoor MCA / MOCP Outdoor Heat Pump Unit Designation HP-1 Basis of Design Mitsubishi HP Model Number PUZ-A24NHA Dimensions (L x W x H) 38 x 14 x 38 Nominal Tonnage 2.0 Rated Cooling Capacity (MBH) 24.0 Minimum Cooling Capacity (MBH) --Cooling Total Input (kW) --SEER 17.0 Refrigerant R-410A Refrigerant Lines (Liquid / Vapor) Sized by MFGR Outdoor Unit Weight 165 Accessories & Options Yes Wired Remote Controller Wind Baffle Yes Disconnect Switch Yes Mini Condensate Pump Yes Low Ambient Controls Yes 410A Refrigerant Yes Mounting Bracket Yes NOTE: Warranty-7 yr Compressor/5 yr Parts/1 yr Limited Labor.! Condensing units shall be placed on 6" high housekeeping pad, provided by Mechanical Contractor. UNIT No. LOCATION QTY. FLOW (GPM) SP-1 ELEVATOR 1 20 ELEC. CHAR. HEAD HP (FT) VOLT PH HZ 20 120 1 60 REMARKS 0.5 REFER TO REMARK #1 LISTED BELOW FOR SYSTEM DESCRIPTION AND COMPONENT REQUIREMENTS. REMARKS: HOLSTEIN WHITE, INC. 1. SIMPLEX ELEVATOR SUMP PUMP SYSTEM CONTAINING THE FOLLOWING COMPONENTS: OIL SMART SIMPLEX ELEVATOR SUMP PUMP SYSTEM SHALL BE PROVIDED AND INSTALLED IN ACCORDANCE WITH MANUFACTURERS INSTALLATION INSTRUCTIONS. COMPONENTS SHALL BE SUPPLIED BY THE ALYAN PUMP COMPANY. (1) - EBARA MODEL NO. EPD-5MS1, HIGH QUALITY ALL 304SS SUBMERSIBLE SUMP PUMP, DOUBLE MECHANICAL SEAL CONSTRUCTION WITH INTEGRAL 304SS SUCTION STRAINER, 1½” FNPT DISCHARGE, 1/2 HP, 115V /1Ø, MOTOR, 9.0 FLA, CLASS F INSULATION PREMIUM AIR FILLED MOTOR WITH BUILT IN THERMAL OL PROTECTION - AUTO RESET, MOTOR RATED FOR 20 STARTS PER HOUR, 20 FT. CORD WITH 3 PRONG GROUNDED PLUG. (1) - UL LISTED/CE CERTIFIED MODEL NO. MAPR.75, OIL SMART® CUT-OUT PUMP SENSOR FOR ON/OFF PUMP CONTROL; RATED: 115VAC, 13 AMP SOLID-STATE CONTROL RELAY. INCLUDES INTEGRAL PIGGY BACK THREE PRONG GROUNDED PLUG W/20 FEET CORD LENGTH. (MOUNTED TO PVC DISCHARGE PIPE OR PIT WALL WITH SUPPLIED MOUNTING BRACKET) NOTE: SENSOR MUST NOT BE INSTALLED NEAR FERROUS OR CONDUCTIVE MATERIAL AS THIS CAN INTERFERE WITH SENSOR’S POLARITY. IF SENSOR IS INSTALLED ON DISCHARGE PIPING USE AT LEAST AN 18” RUN OF PVC PIPING THEN TRANSITION TO ALTERNATE PIPING MATERIAL IF REQUIRED BY CODE OR SPECIFICATION OR USE FACTORY SUPPLIED SMART SENSOR MOUNTING BRACKET AND HARDWARE TO MOUNT TO SIDE WALL OF BASIN. (1) - UL/CUL, MODEL NO. OSA-5 OIL SMART® ALARM PANEL. NEMA 4X NON METALLIC ENCLOSURE RATED FOR INDOOR & OUTDOOR USE. PANEL SHALL CONTAIN THE FOLLOWING: HIGH WATER ALARM SYSTEM: AUDIBLE & RED LIGHT BEACON FOR HIGH LIQUID LEVEL, OIL PRESENT INDICATION (AMBER) LIGHT, WATER PRESENT INDICATION (WHITE) LIGHT, 10 FT CORD AND (3) - AUXILIARY CONTACTS FOR REMOTE ALARM SIGNAL FOR ALL CONDITIONS THAT ARE PRESENT (1) - LS-1 SOLID-STATE OPTICAL SENSOR WITH 20 FT POWER CORD. CONSULTING ENGINEERS 210 E. STREET ROAD TELE # (215)322-7711 SUITE 2D FAX # (215)322-7709 FEASTERVILLE, PA 19053 Seal Scott White, P.E. NJ License # 24GE04977900 Authorization No: 24GA28143700 PERFORATED BASIN COVER DRILL 1/8" RELIEF HOLE 5" ABOVE PUMP DISCHARGE TURN ON LEVEL 5" TURN OFF LEVEL ELEVATOR SUMP PIT CONTRACTOR SHALL BE RESPONSBILE FOR CUTTING OF CONCRETE PAD AT THE BASE OF EXISTING ELEVATOR PIT AND THE INSTALLATION OF NEW CONCRETE ELEVATOR SUMP PIT. CONTRACTOR SHALL REMOVE ALL EXCESS MATERIAL FROM SITE. CONTRACTOR SHALL PROVIDE 2-INCHES OF CRUSHED STONE AT THE BOTTOM OF THE NEW CONCRETE SUMP PIT. ! SP-1: ELEVATOR PIT & SUMP PUMP DETAIL 1 NOT TO SCALE SLEEVE ANCHOR AIR ! HANDLER WALL / FLOOR SLEEVE THROUGH! CONCRETE WALL /! FLOOR (2" LARGER! IN DIA. THAN PIPE) INSULATED! SUCTION LINE SUPPORT ! VERTICAL! PIPING CONDENSING UNIT SEALANT AND! BACKER PIPE THROUGH! SLEEVE SEALING BUSHING Revisions CONDENSATE PIPED! TO THE EXTERIOR NOTE: REFRIGERANT PIPING SHALL BE SIZED IN! ACCORDANCE WITH THE MANUFACTURERS REQUIREMENTS. -- 2 NOT TO SCALE -- NON-FLAMMABLE! FILL AROUND! PIPE FILL AREA AROUND! SLEEVE WITH! NON-SHRINKING! GROUT INTERIOR REFRIGERANT PIPING DETAIL WALL / FLOOR PIPE WALL / FLOOR ! PENETRATION DETAIL 3 NOT TO SCALE MECHANICAL SYMBOLS & INDICATIONS Disconnect Switch, Fused Supply Air Duct Flexible Connector, Duct Supply Air Diffuser T Thermostat Return or Exhaust Air Duct S Motion Sensor w/ Timer Return, Exhaust Air Diffuser 2. CONDENSATE SHALL BE COLLECTED AND RUN WITH ADEQUATE PITCH TO THE CLOSEST SAFE-WASTE. PROVIDE CONDENSATE PUMPS IF PITCH CAN NOT BE ACHIEVED. CONDENSATE PIPING SHALL BE SIZED AS FOLLOWS: CONDENSATE PIPE SIZING CHART TONS SIZE 0-10 3/4"! 10-25 1"! 25-40 1-1/4"! 30-50 1-1/2" Type "L" Copper "ACR" Copper ------ Type Remarks 1-1/2" COPPER DISCHARGE PIPE PIPING AND DUCT CRITERIA 1.! ALL DUCTWORK SHALL BE SIZED USING A STANDARD ! DUCTULATOR. THE FOLLOWING CRITERIA SHALL BE ! USED TO CALCULATE DUCT SIZES: ! ! a.! SUPPLY DUCTS SHALL BE NO MORE THAN ! ! 0.10 IN. PER 100 FEET OF PRESSURE DROP.! b.! RETURN AND EXHAUST DUCTS SHALL BE NO ! MORE THAN 0.05 IN. PER 100 FEET OF ! PRESSURE DROP.! c. VENTILATION DUCTS SHALL BE NO MORE THAN 0.075 IN. PER 100 FEET OF PRESSURE DROP. Basis of! Design Basis of Design X X UC 14-440 FD Fire Damper w/ Access Door DATE: JUNE 16, 2014 90° Combustion Air Intake Terminal SD Smoke Damper w/ Access Door DRAWN BY: BA EF Exhaust Fan CHECKED: SW RTU Roof Top Unit SCALE: AS NOTED Volume Damper AD-X! CFM PROJECT NO: Rise or Drop Roof Exhaust Terminal WxH ELECTRICAL COORDINATION Insulation 201 Mullica Hill Road Glassboro, NJ 08028 GENERAL NOTES:! ! Contractor shall provide all labor, materials, tools, apparatus and equipment required to complete his work in accordance with the contract documents, codes, laws and ordinances, and accepted trade procedures.! ! The Contractor shall review all of the contract documents including those of the other trades in order to acquaint himself with the existing and related conditions that may, will or could affect his work. He shall be experienced, skilled and knowledgeable with this type of construction and shall be expert and proficient in the preparation of estimates and the comprehension, implementation, and interpretation of contract documents such as those prepared for this project.! ! The contractor by his acceptance of the contract guarantees that all work installed shall be free from all defects in workmanship and materials and that all apparatus furnished by him shall develop the capacities and characteristics specified. He further guarantees that if, during a period of one (1) year from the date of the certificate of completion and acceptance of the work, any such defects in workmanship, material or performance appear, such defects shall be remedied by him without cost to the owner. If the contractor fails to remedy the defects as outlined within a reasonable length of time, to be specified in a notice from the owner's authorized representative to the contractor, the owner will have such work done, and he will charge the cost to the contractor.! ! Mechanical equipment shall be installed in a neat and workmanlike manner in accordance with the latest and best practices of the trade. Only mechanics skilled in this type of work shall be employed and utilized by the Contractor for this division in the execution of this work.! ! The contract drawings are diagrammatic and indicate the general arrangement of systems. The Contractor shall provide all work required for a complete installation. The contract drawings are not to be scaled. The architectural contract drawings and details together with the other contract documents shall be examined for all dimensional information.! ! The Contractor shall follow the contract drawings in laying out his work, and he shall also check the contract drawings of the other trades to verify spaces in which his work shall be provided. Equipment locations shall be coordinated with the Architect and the General Contractor.! ! The Contractor shall, without additional costs to the Owner, make reasonable modifications in the layout of his work in order to prevent! conflicts with the work of other trades or for the proper execution of his work.! ! The contractor shall provide and maintain in good order a complete set of blueline prints of the contract drawings. As the work progresses, the actual location of all work shall be clearly recorded, including all changes to the contract and equipment size and type. These prints shall be available at the site for inspection at all times. At the conclusion of the work, the contractor shall, at his own expense, obtain a set of reproducibles of the original contract drawings, and utilizing the symbols on the contract drawings, shall incorporate all "as built" data in a clearly legible and reproducible manner. All schedules shall be corrected to indicate "as built" conditions. All revisions shall be incorporated on these reproducibles including all sketches and written directives. All concealed equipment, mainfeeders, pull and junction boxes, etc. shall be dimensionally located from the building structure. As a condition for acceptance of the work, the "as built" reproducibles and one (1) set of prints shall be signed, dated and delivered to the engineer.! ! The contractor shall supply all labor required to perform all work which may be claimed by trade organizations within his jurisdiction. All work shall be performed without any additional cost to the owner irregardless of which section of the contract documents the work is described. The contractor shall be responsible to verify with all local organizations the extent of any collective bargaining agreements and/or any jurisdictional decisions rendered regarding disputes between the respective trades, and provide and install his work in accordance with the accepted trade practice in the area.! ! The entire installation shall conform with all pertinent codes and regulations of the local, municipal, county, state, and federal authorities, The National Board of Fire Underwriters, the State of NJ Building Codes, the codes of the International Codes Council, the National Fire Protective Association and all other regulatory bodies having jurisdiction. All materials and equipment shall bear the stamps or seals of the NFPA, ASME, NEMA, IEEE, UL and other recognized industry regulatory groups.! ! The Contractor shall give all necessary notices, obtain all permits, pay all governmental taxes, fees and other costs in connection with his work. He shall file all necessary plans, and prepare all other documents including additional detailed plans that are required for compliance with all applicable laws, ordinances, rules and regulations.! ! The Contractor shall be responsible for all working conditions and shall maintain a safe working environment at the job site for all employees.! ! All work shall be installed in strict accordance with the equipment manufacturer’s recommendations and requirements.! ! Openings around ductwork and piping passing through the construction shall be sealed with fire barrier caulking to UL Standards.! ! All systems are to be tested, adjusted and balanced to provide performance as indicated on the drawings. Test and adjust all safety controls.! ! Coordinate to assure that all work of all trades will be concealed within the wall and ceiling construction and without the need to reduce ceiling heights. Report exceptions to the Architect prior to construction and erection of the work.! ! All work shall be supported from the building structural system. Work shall not be supported from the ceiling suspension system, from! electrical work, nor from other mechanical work.! ! The HVAC and Plumbing trades shall coordinate with the General Contractor, locate all required cutting and patching of existing work required by the installation of the mechanical work, and arrange for his compensation.! ! All work shall be located to avoid conflicts with other work and provide adequate clearances for architectural design, proper operation,! adjustments, filter replacement, component service, and provide a minimum 2” clearance between all piping ductwork, conduit and other work.! ! The Contractor shall maintain as-built drawings and deliver them to the Owner upon completion of the project.! ! Provide supports, hangers, flexible pipe connections, vibration isolation, supplementary supports, controls and wiring, cleaning, painting, specialties and all other labor, materials, devices and services required for a complete, quality installation. Unless otherwise indicated, run all piping, ductwork, and conduit as high as possible. Provide starters for all motor driven equipment. ! ! The HVAC trades shall coordinate all electrical loads with the Electrical Contractor. Material SUMP PUMP SCHEDULE ROWAN UNIVERSITY ! ! 1.! ! ! 2.! ! ! ! ! 3.! ! ! ! ! ! ! 4.! ! ! 5.! ! ! ! 6.! ! ! ! 7.! ! ! 8.! ! ! ! ! ! ! ! ! 9.! ! ! ! ! ! 10.! ! ! ! ! 11.! ! ! ! 12.! ! ! 13.! ! 14.! ! 15.! ! ! 16.! ! ! 17.! ! ! 18.! ! ! 19.! ! ! ! 20.! ! 21.! ! ! ! 22. DX MINI SPLIT SYSTEM MATERIAL AND INSULATION SCHEDULE MECHANICAL & PLUMBING SCHEDULES & DETAILS MECHANICAL SPECIFICATIONS Concealed Rectangle Sheet Metal Ductwork w/ Duct Wrap Insulation & Wall or Ceiling Mounted Supply Air Device Equipment Designation Tag 2" Door Undercut for Air Transfer AD Air Device SA Supply Air RA Return Air EA Exhaust Air OA Outside Air R Existing Relocated PLOT DATE: MP2 -- DRAWING NOTES MECHANICAL ROOM UP TELE/COM ROOM 004 REMOVE EXISTING FEEDER AND CONDUIT! FROM DISCONNECT TO CONTROLLER. 002 002A1 ELEV EQUIP (EX) MCC D S PIT INDICATOR LIGHT AND ! SWITCH TO BE REMOVED.! EXISTING CIRCUIT ! IN PIT FOR CONNECTION TO! NEW PIT LIGHT. D F PE REMOVE EXISTING FIRE ALARM! DEVICES AND CONTINUE ADDRESSABLE ! CIRCUIT AS NECESSARY. REMOVE EXISTING! RECEPTACLE. EXISTING! CIRCUIT TO REMAIN AND ! TO BE REUSED FOR NEW! RECEPTACLE ELEVATOR ESCF1 DN CORRIDOR H003 1 DENOTES MECHANICAL EQUIPMENT EQUIPMEN TYPE.! SEE MECHANICAL DRAWINGS (TYP.) DEMO ELECTRICAL -! FLOOR PLAN SCALE: 1/4" = 1'-0" CU 1 PROVIDE (3) 3/4" EMT C.: (1) INDOOR POWER, (1) INDOOR CONTROLS WIRING, (1) CU POWER, INTERCONNECT AS DIRECTED BY EQUIPMENT MANUFACTURER. WP WP DEMOLITION NOTES DRILL AND SEAL PENETRATION STAIRS S5 ELEV EQUIP RM 002A TELE/COM ROOM 002 UP AHU 1 MECHANICAL ROOM REUSE EXISTING CONDUIT FOR NEW FEEDER TO ELEVATOR 004 ELEV EQUIP 002A1 LOCKABLE DISCONNECT SWITCH FOR ELEVATOR CAB LIGHTS (120V, 20A CKT.) SHUNT TRIP PROVIDE NEW CIRCUIT BREAKER IN EXISTING SPARE BUCKET, CONDUIT AND CONDUCTORS TO 'T1A' AS INDICATED ON THE SINGLE LINE DIAGRAM, DRAWING E2 C PROVIDE COLUMBIA MODEL #K4-232-EU-CSWG4 WITH WIRE GUARD TO REPLACE EXISTING LIGHTING. REUSE EXISTING CIRCUIT AND EXTEND TO NEW FIXTURES AS NEEDED D D TOP OF SHAFT DASH INDICATES MINIMUM CLEAR WORK SPACE (TYPICAL) INTERCONNECT TO SUMP PUMP IN PIT AS DIRECTED BY PLUMB. CONT. PROV. 3/4" C. C C F C B2 D D FIRE ALARM NOTES EXISTING ADDRESSABLE FIRE ALARM SYSTEM IS MANUFACTURED BY EST.! ! RETAIN BUILDING FIRE ALARM CONTRACTOR, FOR ALL FIRE ALARM WORK. ! ! PROVIDE NEW FIRE ALARM DEVICES AS INDICATED ON PLANS.! ! COORDINATE FINAL RECALL REQUIREMENTS WITH ELEVATOR CONTRACTOR. PROVIDE PROGRAMMING OF FIRE ALARM CONTROL PANEL TO ACCOMPLISH ELEVATOR RECALL AND OPERATION DURING TROUBLE AND ALARM EVENTS.! ! EXISTING FIRE ALARM SYSTEM AFFECTING ELEVATOR OPERATION SHALL BE TESTED AND REPAIRED AS NEEDED. ! ! VERIFY ADDRESSABLE LOOP SPARE CAPACITY BEFORE ADDING NEW POINTS. PROVIDE EQUIPMENT AS NECESSARY IN FIRE ALARM CONTROL PANEL TO SUPPORT NEW DEVICES.! ! PROVIDE TESTING OF SYSTEM TO ASSURE PROPER OPERATION.! ! PROVIDE FIRE ALARM MANUFACTURER TECHNICIAN'S TIME IN BASE PRICE PE TYPE 'B1' SHALL BE FLUORESCENT VAPORTIGHT LIGHT FIXTURE, HUBBEL MODEL #LXEM4-35ML-EU D 1.! ! ! 2.! ! ! 3.! ! ! 4.! ! ! ! ! ! ! 5.! ! ! ! 6.! ! ! ! ! 7.! ! ! 8. SUMP PUMP CONTROLLER B1 EXISTING GENERAL ELECTRIC MODEL 7700 LINE CONTROL CENTER FIELD VERIFY LOCATION, PROVIDE UNISTRUT FRAMING AS NEEDED TO SUPPORT EQUIPMENT M PE SUMP PUMP F F S EXTEND EXISTING CIRCUIT TO NEW GFCI RECEPTACLE AND PIT LIGHT SWITCH BOTTOM OF SHAFT DN TRANSFORMER 'T1A' D PANEL 'A1A' D LOCATED ON DOOR SIDE OF PIT LADDER, FIELD VERIFY EXACT LOCATION CORRIDOR H003 ELEVATOR ESCF1 D 1.! ! ! ! ! ! ! 2.! ! ! ! ! ! ! ! 3.! ! ! ! ! ! 4.! ! ! ! ! ! !! 5.! ! ! ! 6.! ! ! ! ! 7.! ! ! ! ! ! 8.! ! ! ! 9.! ! ! ! ! 10.! ! ! ! 11. WHERE EXISTING FACILITIES ARE BEING ALTERED, DISCONNECT AND REMOVE OR RELOCATE ALL EXISTING ELECTRICAL WORK THAT INTERFERES WITH OR IS NECESSARY BECAUSE OF NEW CONSTRUCTION AS SPECIFIES, SHOWN OR REQUIRED.! ! PERFORM ALTERATION AND ADDITIONS TO PRESENT ELECTRICAL SYSTEM WITH A MINIMUM INTERRUPTION IN THE OPERATION OF THESE SYSTEMS. OBTAIN WRITTEN CLEARANCE FROM OWNER FOR SUCH INTERRUPTIONS AND SCHEDULE SAME AT WHATEVER TIME SPECIFIED IN WRITING BY OWNER. ! ! WHERE SPECIFIED OR REQUIRED, EXTEND EXISTING SYSTEMS OR TIE INTO SAME TO PROVIDE A COMPLETE COORDINATED ELECTRICAL SYSTEM TO SATISFACTION OF OWNER AND ARCHITECT. ! ! ALL EXISTING WORK TO REMAIN, BUT DISTURBED AND DISCONNECTED BECAUSE OF ALTERATIONS AND NEW CONSTRICTION SHALL BE REPLACED AND PUT IN OPERATING CONDITION UNLESS INSTRUCTED OTHERWISE IN WRITING BY OWNER OR ARCHITECT. ! ! EXISTING BRANCH CIRCUITS NOT SHOWN SHALL REMAIN INTACT TO EXTENT PRACTICABLE, AND SHALL BE EXTENDED AS REQUIRED. ! ! DISCONNECT AND REMOVE EXISTING WIRING DEVICES, LIGHTING FIXTURES AND ASSOCIATED BRANCH CIRCUIT WIRING NO LONGER REQUIRED BY NEW CONSTRUCTION. ! ! UP ALL WORK NECESSARY TO PERMIT PERFORM OPERATION OF ALL EXISTING SYSTEMS DURING THE CONSTRUCTION PERIOD. PROVIDE AND MAINTAIN APPLICABLE APPROVED TEMPORARY WIRING TO MEET THIS REQUIREMENT.! ! EXISTING BRANCH CIRCUITS NOT SHOWN SHALL REMAIN INTACT TO EXTENT PRACTICABLE, AND SHALL BE EXTENDED AS REQUIRED.! ! DEMOLISH AND REMOVE EXISTING ELECTRICAL EQUIPMENT, FEEDERS AND CONDUIT NO LONGER REQUIRED BY NEW CONSTRUCTION BACK TO ELECTRICAL PANEL. ! ! ALL CIRCUIT BREAKERS NO LONGER REQUIRED BY NEW CONSTRUCTION SHALL BE MADE SPARE AND TURN IN THE OFF POISON. ! ! ELECTRICAL CONTRACTOR SHALL UPDATE ALL PANEL DIRECTORIES AT THE COMPLETION OF WORK. CONSULTING ENGINEERS 210 E. STREET ROAD TELE # (215)322-7711 SUITE 2D FAX # (215)322-7709 FEASTERVILLE, PA 19053 Seal JEFFREY E. HOLSTEIN, P.E. License No. NJ: 24GE0644300 Authorization No.: 24GA28143700 201 Mullica Hill Road Glassboro, NJ 08028 REMOVE EXISTING FEEDER FOR ELEVATOR.! EXISTING CONDUIT TO REMAIN AND TO BE ! USED FOR NEW FEEDER. HOLSTEIN WHITE, INC. ROWAN UNIVERSITY EXISTING ELEVATOR FEED! MAIN DISCONNECT SWITCH TO BE REMOVED THESE NOTES APPLY TO ALL WORK ASSOCIATED WITH THE INSTALLATION AND MODERNIZATION OF EACH OF PASSENGER ELEVATOR .! ! ELEVATOR DISCONNECTS SHALL BE LISTED, AND SHALL CAPABLE OF LOCKING IN THE OPEN POSITION. THE LOCKING PROVISION SHALL REMAIN IN PLACE WITH OR WITHOUT THE LOCK INSTALLED. PORTABLE MEANS FOR ADDING A LOCK SHALL NOT BE PERMITTED.! ! ELECTRICAL CONTRACTOR SHALL ENSURE ALL ELECTRICAL PLANS ARE FURNISHED TO THE ELEVATOR CONTRACTOR FOR INCLUSION WITH SUBMISSION TO ELEVATOR INSPECTOR FOR REVIEW.! ! ELECTRICAL CONTRACTOR SHALL WORK CLOSELY WITH ELEVATOR CONTRACTOR TO ENSURE WORK IN AREAS UNDER ELEVATOR INSPECTOR JURISTICTION ARE APPROVED PRIOR TO INSTALLATION. MAKE MODIFICATIONS AS REQUIRED TO MEET THE REQUIREMENTS OF THE ELEVATOR INSPECTOR.! ! HEAT DETECTORS IN MACHINE ROOMS AND HOISTWAYS SHALL BE LOCATED WITH-IN 2 FEET OF EACH SPRINKLER HEAD, AND SHALL BE RATED TO ALARM AT A LOWER TEMPERATURE THAN THE ADJACENT SPRINKLER HEADS. FIELD VERIFY SPRINKLER HEAD RATING WITH FIRE SUPPRESSION CONTRACTOR PRIOR TO INSTALLATION OF DETECTORS.! ! INTERCONNECT SHUNT TRIP DEVICE FOR ELEVATOR TO THE FIRE ALARM CONTROL PANEL. DEVICE SHALL SHUNT TRIP UPON ACTIVATION OF MACHINEUPROOM OR HOISTWAY HEAT DETECTORS.! ! ELEVATOR LOBBY, HOISTWAY, AND MACHINE ROOM SMOKE DETECTORS SHALL ISOLATED FROM OTHER DETECTORS WITH-IN THE BUILDING TO PROVIDE ELEVATOR RECALL FUNCTIONS AS REQUIRED BY THE PENNSYLVANIA ELEVATOR CODE. ! ! PROVIDE FIRE ALARM MODULES IN ELEVATOR MACHINE ROOM FOR ELEVATOR RECALL, ALTERNATE RECALL, FIRE FIGHTER'S HIGH HAT AND POWER SHUT DOWN.! ! PROVIDE DEDICATED EARTH GROUND TO ELEVATOR MAIN LINE DICONNECT POWER.! ! FLOOR PLANS ARE NOT DIAGRAMMATICALLY ACCURATE. FIELD VERIFY ALL EQUIPMENT LOCATIONS, DIMENSIONS AND EXISTING CONDITIONS AFFECTING THE INSTALLATION OF NEW WORK. ! ! FIELD VERIFY LOCATION OF ALL WIRING DEVICES WITH ARCHITECT PRIOR TO ROUGH-IN.! ! COORDINATE INSTALLATION OF HVAC EQUIPMENT WITH MECHANICAL CONTRACTOR. INSTALL AND WIRE DISCONNECT SWITCHES FURNISHED BY MECHANICAL CONTRACTOR.! ! FIELD VERIFY EXACT LOCATIONS OF ALL LIGHTING FIXTURES WITH ARCHITECT PRIOR TO ROUGH-IN.! ! CONTRACTOR SHALL TAKE CARE NOT TO DAMAGE EXISTING ELEVATOR PHONE LINES. PHONE LINES SHALL BE EXISTING TO REMAIN AND CONTRACTOR IS TO INSTALL IN NEW ELEVATOR CAB. PHONE IS TO BE FULLY FUNCTIONAL AT TIME OF INSPECTION. FIRST FLOOR - POWER AND LIGHTING PLAN STAIRS S5 ELEV EQUIP RM 002A 1.! ! ! ! 2.! ! ! ! ! ! ! 3.! ! ! ! ! ! 4.! ! ! ! ! ! ! ! 5.! ! ! ! ! ! ! ! ! 6.! ! ! ! ! 7.! ! ! ! ! ! ! 8.! ! ! ! ! 9.! ! ! 10.! ! ! ! ! ! 11.! ! ! 12.! ! ! ! ! 13.! ! ! 14. Revisions -- -- PROJECT NO: 14-440 DATE: JUNE 16, 2014 DRAWN BY: DS CHECKED: MB SCALE: AS NOTED (1ST FLOOR LOBBY) F (2ND FLOOR LOBBY) F (3RD FLOOR LOBBY) PE PLOT DATE: 2 ELECTRICAL -! FLOOR PLAN SCALE: 1/4" = 1'-0" E1 -- ELECTRICAL SPECIFICATIONS 1.! ! ! 2.! ! ! ! 3.! ! ! 4.! ! ! 5.! ! 6.! ! ! 7.! ! ! 8.! ! ! ! ! ! ! ! ! ! 9. EXISTING GENERAL ELECTRIC MODEL 7700 LINE CONTROL CENTER 277/480V, 3Ø, 4 WIRE EX REMOVE EXSITING WIRING. EXISTING CONDUIT TO REMAIN (R) 70AT! SHUNT TRIP ELECTRICAL SYMBOLS CONTROL! PANEL HOLSTEIN WHITE, INC. CONSULTING ENGINEERS 210 E. STREET ROAD TELE # (215)322-7711 SUITE 2D FAX # (215)322-7709 FEASTERVILLE, PA 19053 Seal JEFFREY E. HOLSTEIN, P.E. License No. NJ: 24GE0644300 Authorization No.: 24GA28143700 TO SHUNT TRIP 30 Fluorescent Lighting Fixture UNLESS OTHERWISE NOTED, LIGHT LINEWEIGHT INDICATES EXISTING WORK.! ! UNLESS OTHERWISE NOTED, DASHED LINES INDICATE DEMOLITION OF EXISTING EQUIPMENT AND WORK.! ! UNLESS OTHERWISE NOTED, HEAVY LINEWEIGHT INDICATES NEW WORK.! ! UNLESS OTHERWISE NOTED ALL CABLES SHALL BE COPPER, TYPE THHN.! ! EXTERIOR CONDUITS SHALL BE RIGID PVC. ! ! INTERIOR CONDUITS SHALL BE METALLIC TYPE EMT. ! ! ELECTRICAL CONTRACTOR SHALL CONNECT LOAD TO MAINTAIN BALANCE LOAD IN METER CENTER.! ! PROVIDE (1) NORMALLY OPEN AND (1) NORMALLY CLOSED AUXILARY CONTACT FOR EMERGENCY LOWERING PROVISION. CONTACT SHALL MONITOR DEVICE STATUS (I.E. TRIPPED OR OPEN) AND BE INTERCONNECTED TO THE ELEVATOR CONTROLLER. PROVIDE 2#12 IN 3/4"C. BETWEEN CIRCUIT BREAKER AND ELEVATOR CONTROLLERS, COORDINATE TERMINATION LOCATION IN CONTROLLERS WITH ELEVATOR CONTRACTOR. ! ! PROVIDE NEW ELEVATOR CONTROL PANEL WITH INTERGRAL SHUNT TRIP, LOCABLE DISCONNECT SWITCH AND AUXILARY CONTACTOR FOR MONITORING SWITCH POSITION, AS MANUFACTURED BY COPPER BUSMANN, MODEL #! PS1T48R1KGN1BF3. 2#12 + 1 #12 GND Telephone Outlet S Single Pole Switch SM FA Manual Motor Switch EM Emergency Battery Pack Unit L1BD-2-12 D SYSTEM WIRE Low Voltage System Wiring (R) PE D (R) F (R) Electrical Panel Duplex Receptacle - 125V, 2P, 3W D GFI Duplex Receptacle! - 125V, 2P, 3W F 1 Motor Automatic Detector [ Detector Control Function ]! F - Thermal, 135ºF Fixed Temperature! PE - Smoke PhotoElectric Fused Disconnect Switch C Alarm Initiating Contact Branch Circuit Wiring AF Amp Frame AT Amp Trip WP Weatherproof EX Existing to Remain Unfused Disconnect Switch Fused Disconnect Switch EXISTING SINGLE LINE DIAGRAM 1 NOT TO SCALE EXISTING GENERAL ELECTRIC MODEL 7700 LINE CONTROL CENTER Contact Transformer 277/480V, 3Ø, 4 WIRE Single Receptacle - 125V, 2P, 3W 100AF! 45AT EX PROVIDE NEW BUCKET IN EXISTING SPARE COMPARTMENT ELECTRICAL STANDARD MOUNTING HEIGHTS 3#6 +1 #6 GND IN EX. C. 9" Below! Finished Ceiling Wall-Mounted Clocks, Program Bells, Fire Alarm Gongs and Horns 10'-0" Battery Lighting Units and Remote Wall Mounted Lighting Heads (Or 1'-0" Below Finised Ceiling) 8'-6" Pendant Hung Industrial and Strip Lighting Fixtures Center Above! Door or Window! Opening Warning and Signaling Fixtures/Signs 6'-8" or 6" Below Finished Ceiling Fire Alarm Illuminated Flashing Lights (Lowest of the two Heights). Mounting Height to the Bottom of Device. 3 #6 & 1 #8G., 1" EMT C. TRANSFORMER 'T1A'! 30kVA - 3Ø - 60Hz! 480 - 208/120V BUSSMAN ELEVATOR DISC. 100 AF 6'-8" Top of Back-Mounted Wall Exit Signs (Not Mounted Above Doors) 6'-6" Top of Flush and Surface Mounted Electrical Panelboards and Communication System Cabinets 6'-0" Top of Highest Electrical Safety Disconnect Switches, Magnetic Motor Starters and Contactors 4'-6" Wall Mounted Telephones and Pay Stations (3'-6" at Handicap Locations) 3'-6" Fire Alarm Pull Stations 3'-4" Wall Mounted Electrical Device Lighting Switches 2'-0" Electrical Receptacles in Mechanical Spaces, Electrical and Elevator Rooms 80 AT 4 #2 & 1 #8G., 1-1/2" EMT C. 1'-6" Electrical Receptacles, Television Outlets, Telephone Outlets, and Computer Outlets 0'-0" Finished Floor Revisions 3 #6 & 1 #6 GND, 1" EMT C. 1 DCA Comments 2 #12, 3/4" C. SWITCH POSITION COORD TERM W/ ELEV. VENDOR CONTROL! PANEL Mounting Heights to center of outlets unless otherwise noted. In masonry construction the mounting heights shall be used for! reference to the nearest block or brick coursing. ! The above mounting heights shall be adhered to unless specifically noted or detailed on the Architectural drawings or specifications. 30 MOTOR, CONTROLLER, AND INTERCONNECTIONS BY ELEV. VENDOR NEW ELEVATOR NEW SINGLE LINE DIAGRAM 2 480V A B C TO FIRE ALARM CONTROL! RELAY FOR POWER SHUT ! DOWN! ST 201 Mullica Hill Road Glassboro, NJ 08028 Extend the existing Base Building Fire Alarm System as indicated and required. All existing elevator lobby, shaft, and machine room initiating devices shall be replaced with new devices compatible with the existing building fire alarm system, and shall be rewired to the existing system to provide recall and shunt trip of the elevators. The system shall include, but not limited to: alarm initiating and indicating peripheral devices, conduit, wire and accessories required to furnish a complete operational system. Provide expansion of existing panel as required to accommodate installation of new devices. The equipment and installation shall comply with the current provision of the National Fire Protection Association Standards, 70, 72, and all local codes. All equipment shall be UL listed. New Fire Alarm devices shall be type and style to match base building standards. New Flashing lights shall be ADA approved, candela as required by location. Contractor shall use Building fire alarm vendor / service provider for all system tie-ins, testing and programming. Building Fire Alarm Vendor: Joseph C Petsch of FRANKLIN ALARM COMPANY at 856-728-6424! ! FIRE ALARM SUBMITTAL REQUIREMENTS: In addition, the contractor shall prepare a Fire Alarm system submittal to fulfill the requirements of the New Jersey DCA. Submit (3) sets of Signed and Sealed plans prepared by a certified Fire Protection Engineer for Fire Marshall review. The submittal shall include the following: Scaled plans indicating Fire Alarm work, Project Name and Address, Square footage of affected space, Fire Alarm symbols list, Device matrix showing description and quantity of devices, Equipment Cut sheets, Wiring information including size, type, and all point to point wire runs, Fire Alarm Riser diagram including initiating and annunciating devices, Battery calculations indicating existing batteries are of adequate capacity and/or sizing of new batteries, and voltage drop calculations signed and sealed submittals for submission to DCA. ! ROWAN UNIVERSITY 42.1! ! ! ! ! ! ! ! ! ! 42.2 ELECTRICAL DETAILS Contractor shall provide all labor, materials, tools, apparatus and equipment required to complete his work in accordance with the contract documents, codes, laws and ordinances, and accepted trade procedures.! ! In preparing his estimate, the contractor shall review all of the contract documents including those of the other trades in order to acquaint himself with existing and related conditions that may, will, or could affect his work. He shall be experienced, skilled, and knowledgeable with this type of construction and shall be expert and proficient in the preparation of estimates and the comprehension, implementation, and interpretation of contract documents such as those prepared for this project.! ! The contractor by his acceptance of the contract guarantees that all work installed shall be free from all defects in workmanship and materials and that all apparatus furnished by him shall develop the capacities and characteristics specified. He further guarantees that if, during a period of one (1) year from the date of the certificate of completion and acceptance of the work, any such defects in workmanship, material or performance appear, such defects shall be remedied by him without cost to the owner. If the contractor fails to remedy the defects as outlined within a reasonable length of time, to be specified in a notice from the owner's authorized representative to the contractor, the owner will have such work done, and he will charge the cost to the contractor.! ! Electrical equipment shall be installed in a neat and workmanlike manner in accordance with latest and best practices of the trade. Only mechanics skilled in this type of Work shall be employed and utilized by Contractor for this Division in the execution of this Work.! ! The contract drawings are diagrammatic and indicate the general arrangement of all systems and work included in the contract. The contract drawings are not to be scaled. The architectural contract drawings and details together with the other contract documents shall be examined for all dimensional information.! ! The contractor shall follow the contract drawings in laying out his work, and he shall also check the contract drawings of the other trades to verify spaces in which his work shall be provided.! ! The contractor shall, without additional costs to the owner, make reasonable modifications in the layout of his work in order to prevent conflicts with the work of other trades or for the proper execution of his work.! ! The contractor shall provide and maintain in good order a complete set of blueline prints of the contract drawings. As the work progresses, the actual location of all work shall be clearly recorded, including all changes to the contract and equipment size and type. These prints shall be available at the site for inspection at all times. At the conclusion of the work, the contractor shall, at his own expense, obtain a set of reproducibles of the original contract drawings, and utilizing the symbols on the contract drawings, shall incorporate all "as built" data in a clearly legible and reproducible manner. All schedules shall be corrected to indicate "as built" conditions. All revisions shall be incorporated on these reproducibles including all sketches and written directives. All concealed equipment, mainfeeders, pull and junction boxes, etc. shall be dimensionally located from the building structure. As a condition for acceptance of the work, the "as built" reproducibles and one (1) set of prints shall be signed, dated and delivered to the Owner or Owner's Representative.! ! The contractor shall perform all work in accordance with the prevailing wage rate.! ! The entire installation shall conform with all pertinent codes and regulations of the local, municipal, county, state, and federal authorities, The National Board of Fire Underwriters, the codes of the International Codes Council, the codes of the National Fire Protective Association, The New Jersey Uniform Construction Code, ASME 17.1 (including 2002 Addendum), and all other regulatory bodies having jurisdiction. All materials and equipment shall bear the stamps or seals of the NFPA, ASME, NEMA, IEEE, UL and other recognized industry regulatory groups.! ! The owner shall obtain all permits, pay all governmental taxes, fees and other costs in connection with the work. The owner shall file all necessary plans, and prepare all other documents including additional detailed plans that are required for compliance with all applicable laws, ordinances, rules and regulations.! ! Before starting any work under this Contract, file for inspection with the New Jersey Department Of Community Affairs (DCA) or other Governing Inspection Agency. Upon completion of the work, furnish Electrical Certificates from said Agency for all Electrical equipment and systems installed or furnished and installed as part of the work. Notify the owner before contacting DCA! ! The contractor shall at all times keep the premises free from the accumulation of waste materials or rubbish caused by his employees or work. At the completion of the work, he shall remove all superfluous materials, equipment and debris resulting from the work. The jobesite shall be cleaned at the end of each work day.! ! All branch and feeder wiring shall be soft drawn copper of 98% conductivity, installed in code conforming metallic raceways or cable assemblies. All wiring (except fixture wire) shall be copper, thermoplastic covered insulated Type 75° C. THW or 90° C. Type THHN, 600 volt rating. Wire No. 8 AWG and smaller shall be solid. Wire larger than No. 8 shall be stranded. ! ! Where conductors connect directly to equipment, the insulation temperature rating of the conductor shall meet or exceed the equipment temperature rating.! ! Color code conductors to designate neutral conductor and phases. ! ! 120 Volt Switches shall be quiet toggle type with totally enclosed case, rated 20 ampere, specification grade, white color.! ! Standard duplex receptacles shall be polarized, duplex, parallel blade, U-grounding slot, specification grade, rated 20 amperes, 125 volts, white color.! ! Dry-Type Distribution Transformers shall comply with NEMA ST 20, and list and label as complying with UL 1561.B. Cores: One leg per phase. Enclosure: Ventilated, NEMA 250, Type 2. Core and coil shall be encapsulated within resin compound, sealing out moisture and air. Transformer Enclosure Finish: Comply with NEMA 250, Gray color. Provide two (2) 2.5 percent taps above and four (4) 2.5 percent taps below normal full capacity. Insulation Class: 220 deg C, UL-component-recognized insulation system with a maximum of 150 deg C rise above 40 deg C ambient temperature. Energy efficiency shall comply with NEMA TP 1, Class 1 efficiency levels, tested according to NEMA TP 2. Each winding shall have an independent, single, full-width copper electrostatic shield arranged to minimize interwinding capacitance. Wall brackets, as needed, shall be as recommended by the equipment manufacturer.! ! Panelboards shall be dead front type with plated aluminum bus, bolt-on breakers, fully rated neutral bus and grounding bus block. Cabinet shall be code gauge galvanized steel, NEMA 1, minimum 20” wide, 5-3/4”deep. Cover shall have door and trim and adjustable clamps, gray baked finish, and tumbler type key lock. Directories shall be typed. “Spaces” shall be fully bussed and drilled, ready for breaker installation.! ! Circuit Breakers shall be molded case, bolted, thermal magnetic trip in each pole, enclosure-compensated to carry full rated load at 40°C., trip-free handles shall clearly indicate trip, on and off condition, quick-make and quick-break action. Lugs approved for copper and aluminum conductors and compression type. Ground Fault type breakers shall be provided with thermal and magnetic protection, UL Class A, 5 milliampere ground fault sensitivity, where required. Circuit breakers used as switches in 120 and 277 volt circuits feeding incandescent, fluorescent, and/or HID fixtures shall be approved for such use and marked "SWD", per NEC. Circuit breakers serving Heating and Air Conditioning equipment shall be HACR rated.! ! Grounding shall comply with Article 250 of NEC and to approval of local Underwriters inspection authorities.! ! Provide all interior lighting fixtures complete with sockets, reflectors, diffusers, shades, holders, lamps, energy saving ballasts, protective devices and all other required appurtenances.! ! Test equipment, including panelboard s, enclosed circuit breakers, disconnect switches, and all other equipment and wiring for unintended grounds, short circuits, open circuits, continuity, current leakage, and that equipment will operate as specified. Test feeders for insulation resistance; for load balance of the final installation, and for overall operation of systems. Furnish labor and material required for making such tests and make corrections necessary to balance the load and to obtain proper operation.! ! Provide cutting, patching and refinishing work in accordance with the requirements of the General Contract specifications. Horizontal chases shall not be cut into existing walls or partitions without approval of Architect.! ! Where existing facilities are being altered, disconnect and remove or relocate all existing electrical work that interferes with or is necessary because of new construction as specified, shown or required.! ! Perform alterations and additions to present electrical systems with a minimum interruption in the operation of these systems. Obtain written clearance from Landlord for such interruptions and schedule same at whatever time specified in writing by Landlord.! ! Where specified or required, extend existing systems or tie into same to provide a complete coordinated electrical system to satisfaction of Owner and Engineer.! ! All existing work to remain, but disturbed or disconnected because of alterations and new construction shall be replaced and put in operating condition unless instructed otherwise in writing by Owner or Engineer.! ! Perform all work necessary to permit operation of all existing systems during the construction period. Provide and maintain applicable approved temporary wiring to meet this requirement.! ! Existing branch circuits not shown shall remain intact to extent practicable, and shall be extended as required.! ! Update panel directories to reflect new work. Provide new labels for existing panelboards.! ! Provide circuit breakers, safety switches, power feeders, lighting feeders, control circuits, including connections to controller and elevator machine. Also provide pit lights, switches, receptacles, car light circuit to controller and suitable communications connections to cab.! ! Elevator Contractor will provide Shop Drawings of all equipment to be installed for elevator systems. Investigate and determine exact locations for conduit, switches, etc., before installing same and comply with Elevator Contractor requirements for details of installation and materials to be provided. ! ! Circuit breakers used as elevator disconnects shall be listed, and shall capable of locking the breaker in the open position. The locking provision shall remain in place with or without the lock installed. Portable means for adding a lock shall not be permitted.! ! Electrical contractor shall ensure all electrical plans are furnished to the Elevator Contractor for inclusion with submission to Elevator Inspector for review.! ! Electrical contractor shall work closely with Elevator contractor to ensure work in areas under Elevator Inspector juristiction are approved prior to installation. Make modifications as required to meet the requirements of the Elevator Inspector. ! ! Provide all work and equipment required for automatic shutdown of elevator power in accordance with CABO/ANSI.! ! Fully coordinate all work and system requirements with elevator contractor. Provide fire alarm system interconnection to elevator control panel. Contractor shall interlock elevators with fire alarm system for emergency recall in accordance w/ ANSO, CABO and NFPA.! ! Provide engraved phenolic nameplates on all disconnect switches identifying equipment fed and circuit number or feed origin.! ! Where sleeves containing a single conduit penetrate FIRE RATED walls, floors, partitions or slabs, fill and seal conduit to the sleeve with a 1-part intumescent caulk/putty sealant creating a fire stop equal to or exceeding fire rating of construction material being penetrated. Fire sealant shall prevent spread of flame, smoke, air and water through the sleeve and shall pass 3 hour test per ASTM E814 and UL 1479. Fire sealant shall be installed in accordance with manufacturer's written instructions. Where sleeves containing multiple conduits or multiple cables penetrate FIRE RATED walls, floors, partitions, or slabs, fill and seal spaces between the conduits or cables and the sleeve with 2-part intumescent foam sealant creating a fire stop equal to or exceeding fire rating of construction material being penetrated. Fire sealant shall prevent spread of flame, smoke, air and water through the sleeve and shall pass 3 hour test per ASTMA E814 and UL 1479. Fire sealant shall be installed in accordance with manufacturer's written instructions. Where sleeves penetrate exterior walls, fill and seal ends around conduits and/or cables with duct sealant compound equal to Solorite KN--1146, or Link Seal. Install seals in accordance with the manufacturer's recommendations to provide air tightness above ground and hydrostatic sealing below grade. Caulking or other type mastic is not acceptable. Where wiring devices are placed in fire rated construction, fire rating of installed assembly shall meet or exceed the rating of the construction. ! ! PANEL! 'A1A' 1.! ! ! 2.! ! ! ! ! 3.! ! ! ! ! ! ! 4.! ! ! 5.! ! ! ! 6.! ! ! 7.! ! ! 8.! ! ! ! ! ! ! ! ! ! 9.! ! 10.! ! ! ! ! ! 11.! ! ! ! 12.! ! ! ! 13.! ! ! ! 14.! ! ! ! 15.! ! ! 16.! ! 17.! ! 18.! ! ! 19.! ! ! ! ! ! ! ! 20.! ! ! ! ! 21.! ! ! ! ! ! ! 22.! ! 23.! ! ! 24.! ! ! ! ! 25.! ! ! 26.! ! ! 27.! ! ! 28.! ! ! 29.! ! ! 30.! ! ! 31.! ! 32.! ! 33.! ! ! 34.! ! ! ! 35.! ! ! 36.! ! ! 37.! ! ! 38.! ! 39.! ! ! 40.! ! 41.! ! ! ! ! ! ! ! ! SINGLE LINE DIAGRAM NOTES NOT TO SCALE EQUIPMENT GROUNDING! CONDUCTOR DRY TYPE! TRANSFORMER NEUTRAL EXOTHERMICALLY! WELD GROUNDING! ELECTRODE! CONDUCTOR TO! NEAREST STRUCTURAL! STEEL GROUNDING ELECTRODE! CONDUCTOR N INSULATED NEUTRAL! BUS IN PANEL M 120/208V PANEL! WITH MAIN CIRCUIT! BREAKER 3 MAIN BONDING JUMPER PANEL Cir. No. 1 5 7 9 11 13 15 17 19 21 23 A1A Cir. Bkr. 30/2 20/1 20/1 20/1 Wire Size #10 #12 Description CU-1, AHU-1 Sump Pump Control Panel, SP-1 Spare Spare Space Space Space Space Space Space Space 100 A MCB 10 kAIC Load - KW A B 1.3 1.3 24 POLE C A 208/120V - 3Ø - 4W Load - KW B Description C Wire Size Cir. Bkr. Space Space Space Space Space Space Space Space Space Space Space Space 1.2 Cir. No. 2 4 6 8 10 12 14 16 18 20 22 24 TRANSFORMER GROUNDING DETAIL PROJECT NO: 14-440 DATE: JUNE 16, 2014 DRAWN BY: DS CHECKED: MB SCALE: AS NOTED PLOT DATE: N.T.S. Total Phase (KW) A B C Total 1.3 1.3 1.3 1.2 3.8 1.3 1.2 Load Summary by Type Connected Appliance Connected Lighting Connected Motor Connected Air Conditioning Total 3.8 KW KW KW KW KW KW 0.0 0.0 0.0 Options and Accessories - (X) Indicates Selection Feed Through Lugs Subfeed Main Lugs Split Bus Contactor Controlled Top Bottom Total Recessed x Surface Double Panel x Ground Bus Insulated Ground Bus E2 07-11-14 The contractor shall be responsible for the calculation, design approval, conformance and operation of wet and/or dry fire protection and/or suppression systems. The Contractor shall provide signed and sealed hydraulic calculations and shop drawings. The placement of this information on the drawings is for identification only.! ! The Fire Protection Contractor is to furnish a complete fire protection system as shown on plans and/or as required. He is solely responsible to provide a complete working fire protection system designed and installed in accordance with NFPA 13, State and Local Codes, and the Owner's Insurance Underwriter's requirement.! ! The area within the scope of this project is to be 100% protected by the fire suppression system and should be considered a “Light Hazard” classification.! ! The complete sprinkler installation shall include the following: Connection to the existing fire main as required. All required system drain downs to install new branch piping and sprinkler heads. Contractor shall schediule all drain downs with Owner, prior to commencement of work. Contractor shall provide necessary Fire Watch personell for as long as required. All control valves, check valves, alarm valves and necessary tie-in. All pipe, valves, fittings, and sprinkler heads including spare heads in a cabinet. All inserts, hangers and supports for pipe and equipment. All hangers and inserts shall meet the approval of all authorities having jurisdiction.! ! Rowan University shall pay for permits. The contractor shall pay for inspections, tests and approvals related to the sprinkler system as required by all authorities having jurisdiction. This includes supplying erection drawings to the architect in accordance with the general conditions and the mechanical trade requirements of the project.! ! Sprinkler heads shall be approved type of proper temperature rating for its particular location. Fire department connections shall be chrome plated brass, with connections in accordance with the local fire department regulations. All controls, drains, test valves, and alarm valves shall be provided with identification signs of the standard design adopted by the automatic sprinkler industry. 15550.00 Fire Protection Systems! ! For the convenience of the Design/Build Fire Protection Contractors, a set of Fire protection Specifications have been furnished below to act as a design criteria enabling the Fire Protection Contractors to Bid on a defined scope of work. Major items such as the Fire Line, Zone Valves etc. have been indicated and/or mentioned on our drawings for Building Preliminary Design only. The Fire Protection Contractor shall assume full responsibility for the final design requirements, coordination, and installation of the fire protection systems.! ! The Fire Protection Contractor is to provide the fire protection system as shown on plans and/or as required. He is solely responsible to provide a complete working fire protection system designed and installed in accordance with NFPA 13, State and Local Codes, the Owner's Insurance Underwriter's requirement, and as required by the local Fire Marshall. ! ! 15550.01 Sprinkler System and Building Fire Protection Systems! ! Sprinkler systems, shall be provided. All sprinkler work shall be installed in accordance with the requirements of the local rating bureau and the rules and regulations of the local and state codes. The contractor shall be responsible for the calculation, design approval, conformance and operation of wet fire protection suppression systems. The placement of this section of the specification within this division is for identification only. The area within the scope of this project is to be 100% protected by the fire suppression system. The engineer does not assume any responsibility or liability for the design, calculation, approval, review conformance and operation of the items included herewith and/or for the scope and adequacy of these systems.! ! The complete sprinkler installation shall include but not be limited to the following:! ! a. All control valves, check valves, alarm valves and necessary tie-in.! b. All pipe, valves, fittings, and sprinkler heads including (2) spare heads in a cabinet as required.! c. All inserts, hangers and supports for pipe and equipment. All hangers and inserts shall meet the approval of all authorities having jurisdiction.! d. All required system drain downs to install new branch piping and sprinkler heads. Contractor shall schediule all drain downs with Owner, prior to commencement of work. Contractor shall provide necessary Fire Watch personell for as long as required.! ! Rowan University shall pay for permits. The Contractor shall pay for inspections, tests and approvals related to the sprinkler system as required by all authorities having jurisdiction. This includes supplying erection drawings to the architect in accordance with the general conditions and the mechanical trade requirements of the project specifications.! ! All controls, drains, test valves, and alarm valves shall be provided with identification signs of the standard design adopted by the automatic sprinkler industry.! ! Test piping and prove tight for two hours, as required by authorities having jurisdiction in the presence of said authorities, who shall be given ample notice before tests are made. Make preliminary tests and prove satisfactory before requesting witnessing of final test.! ! Make tests in stages if so ordered by the architect to facilitate work by others. Repair defects disclosed by tests, or, if required by the architect replace defective work.! ! Provide all equipment necessary to complete the sprinkler systems including, electrical wiring, and related appurtenances as required.! ! Fire department inlet connections shall be flush mounted, finished as directed by architect and labeled in accordance with local code.! ! 15550.02 Temporary Fire Protection! ! Provide and maintain temporary piping and hose valves as required by local fire department to protect floor areas during construction of building.! ! Refer to local fire department rules for extent of work involved in required temporary fire protection.! ! When directed, remove temporary equipment which is considered unsatisfactory; replace by permanent equipment as specified herein.! ! = New Sidewall Wet Sprinkler Head in Wall 1 = Semi-Recessed Wet Sprinkler Head in Ceiling 15550.03 Piping Installation! ! Hangers and supports shall be provided as required by code. Provide all necessary clamps and rods for properly supporting sprinkler risers and underground piping, all in strict accordance with requirements of N.F.P.A. Pamphlets No. 13 and 24. Sprinkler lines under ducts shall not be supported from duct work but shall be supported from building structure with trapeze hangers where necessary.! ! Inspector's test pipe as required by code for system, extended down to globe valve not more than 6-feet above floor with discharge as shown on the drawings.! ! Test connections as required by code, in riser at point opposite drain connection and equipped with side outlet globe valve. Provide an underwriters' approved gauge, in one outlet, and plug for other outlet.! ! Reductions in pipe sizes shall be made with one piece reducing fittings. Bushing will not be acceptable.! ! Victaulic grooved piping system will be accepted on pipe 1-1/2 inches and larger in lieu of welded flanged or threaded methods. Plain end mechanical push on locking type fittings are accepted on pipe 2-inches and smaller in lieu of threaded method. Couplings and fittings shall be manufactured by Victaulic or an approved equal.! ! All material and products shall be approved for the particular service selected by Underwriter's Laboratories, Inc., Factory Mutual, IBC and local codes where applicable, and installed in accordance with NFPA 13, other applicable chapters and manufacturer's published recommendations.! ! To assure system integrity and performance, all mechanical couplings, fittings, flanges, bolted branch outlets shall be furnished by the same manufacturer.! ! 15550.04 Supports, Hangers, Inserts! ! Support sprinkler piping from building structure by means of hangers, inserts, and other supports as per requirements of N.F.P.A. Pamphlet No. 13.! ! 15550.05 Fire Protection System Seals! ! Provide brass cross-line chain, all brass padlock, 2 keys for each manually operated shutoff valve required to be sealed in open position.! ! 15550.06 Sprinkler Heads! ! Sprinkler heads shall be approved type of proper temperature rating for its particular location.! ! Provide (2) extra heads for each type with wrench and head cabinet.! ! Semi-Recessed chrome pendant type w/chrome escutcheons shall be used in finished areas and where ceilings are suspended.! ! Sprinkler heads shall be installed in a "straight" and organized fashion, however, "Center of Tile" installation is not required.! ! General Notes:! ! 1. All spaces shall be fully protected.! 2. The Fire Protection Contractor shall submit a head layout to the Architect and Owner for review prior to erection of the work.! 3. The Fire Protection Contractor shall submit signed and sealed hydraulic calculations, drawings, and shop drawings for review by the Engineer.! 4. The Contractor shall maintain as-built drawings and deliver them to the Owner upon completion of the project. STAIRS #5 S5 ELEV EQUIP RM 002A UP MECHANICAL ROOM 004 TELE/COM ROOM 002 ELEV EQUIP 002A1 UP SPRINKLER HEAD SHALL HAVE A TEMPERATURE RATING OF 165ºF. 1 CONTRACTOR SHALL PROVIDE (2) SIDEWALL WET SPRINKLER HEADS: (1) LOCATED AT THE TOP OF THE ELEVATOR SHAFT AND (1) LOCATED AT THE BOTTOM OF THE ELEVATOR SHAFT. SPRINKLER HEADS SHALL HAVE A TEMPERATURE RATING OF 165ºF. HOLSTEIN WHITE, INC. CONSULTING ENGINEERS 210 E. STREET ROAD TELE # (215)322-7711 SUITE 2D FAX # (215)322-7709 FEASTERVILLE, PA 19053 Seal Scott White, P.E. NJ License # 24GE04977900 Authorization No: 24GA28143700 201 Mullica Hill Road Glassboro, NJ 08028 1.! ! ! ! ! ! ! 2.! ! ! ! ! ! ! 3.! ! ! ! 4.! ! ! ! ! ! ! ! ! ! ! ! ! ! 5.! ! ! ! ! ! ! 6. IT SHALL BE THE RESPONSIBILITY OF THE FIRE SUPPRESSION CONTRACTOR TO COORDINATE THE LOCATIONS OF SUPPRESSION SYSTEM PIPING WITH THE ELECTRICAL CONTRACTOR. FIRE SUPPRESSION PIPING SHALL NOT BE INSTALLED WITHIN THE DEDICATED EQUIPMENT SPACE REQUIRED FOR EXISTING OR NEW ELECTRICAL EQUIPMENT. ! ! COORDINATION OF PIPING LOCATIONS SHALL BE SOLEY THE RESPONSIBILITY OF THE FIRE SUPPRESSION CONTRACTOR. APPROVAL OF FIRE SUPPRESSION SUBMITTAL DRAWINGS DOES NOT RELEASE THE CONTRACTOR FROM COORDINATION RESPONSIBILITY. FINAL COORDINATION SHALL OCCUR IN FIELD WITH ELECTRICAL CONTRACTOR. FAILURE TO COMPLY WITH THIS REQUIREMENT MAY RESULT IN RELOCATION OF SUPPRESSION SYSTEM PIPING AT CONTRACTOR'S EXPENSE.! ! PER NFPA 70, ARTICLE 110.26(F); DEDICATED EQUIPMENT SPACE SHALL APPLY TO SWITCHBOARDS, DISTRIBUTION PANELS, AND MOTOR CONTROL CENTERS. THE SPACE EQUAL TO THE WIDTH AND DEPTH OF THE EQUIPMENT AND EXTENDING FROM THE FLOOR TO A HEIGHT OF 6' ABOVE THE EQUIPMENT OR TO THE STRUCTURAL CEILING, WHICHEVER IS LOWER, SHALL BE DEDICATED TO THE ELECTRICAL INSTALLATION. NO PIPING, DUCTS, LEAK PROTECTION APPARATUS, OR OTHER EQUIPMENT FOREIGN TO THE ELECTRICAL INSTALLATION SHALL BE LOCATED IN THIS ZONE. ROWAN UNIVERSITY 1.! ! ! ! ! ! ! ! ! 2.! ! ! ! ! ! ! ! ! ! ! ! 3. FIRE PROTECTION SPECIFICATIONS FIRE PROTECTION NOTES FIRST FLOOR - FIRE PROTECTION PLAN ELECTRICAL COORDINATION Revisions ELEVATOR #2 ESCF1 DCA Comments 1 DN CORRIDOR H003 1 FIRE PROTECTION -! FLOOR PLAN SCALE: 1/4" = 1'-0" PROJECT NO: 14-440 DATE: JUNE 16, 2014 DRAWN BY: BA CHECKED: SW SCALE: AS NOTED PLOT DATE: FP1 07-11-14