BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:35 AM

Page 1

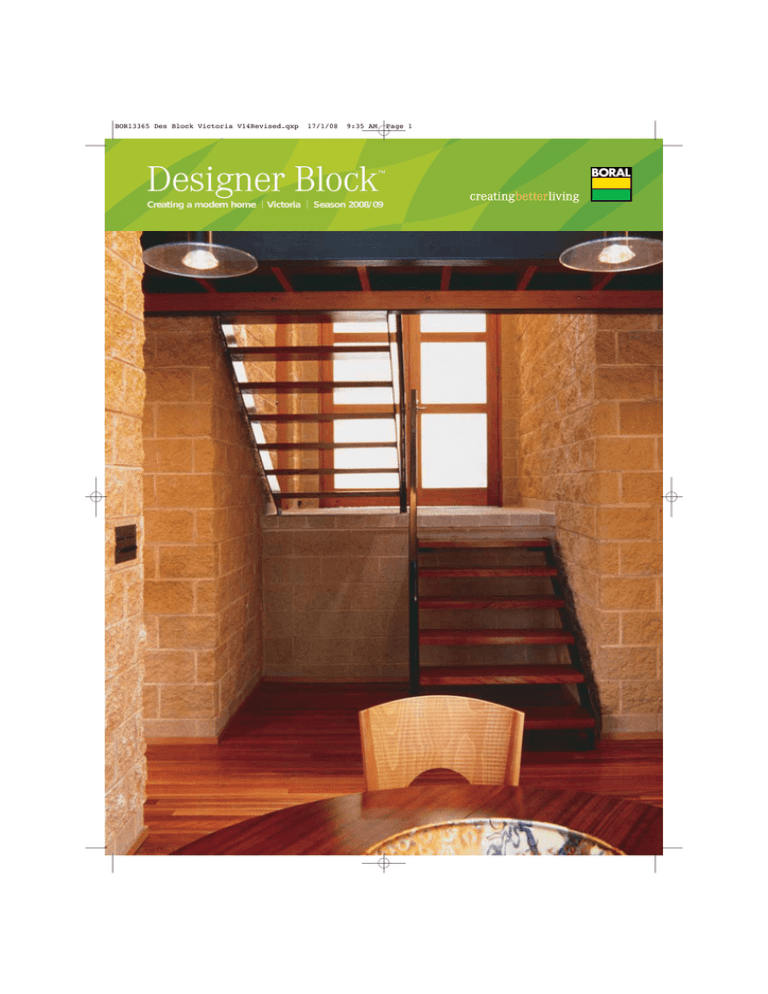

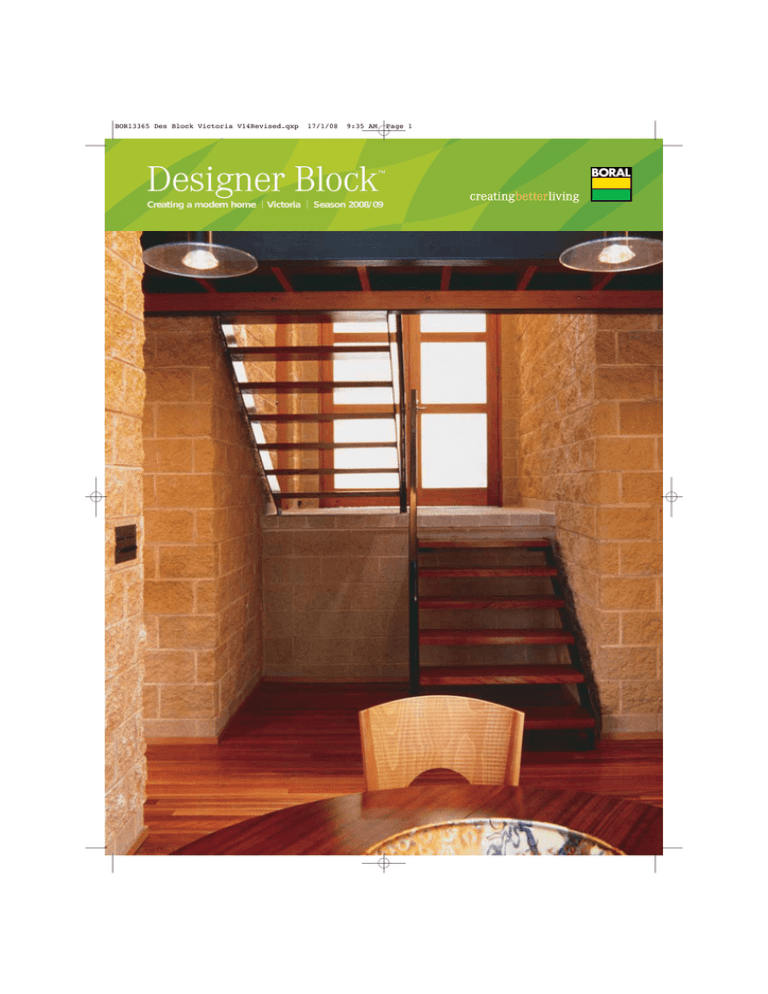

Designer Block

™

Creating a modern home | Victoria | Season 2008/09

BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:35 AM

Page 2

Designer Block Smooth Face

™

With the sophistication of stone.

Designer Block™ Alabaster is used

in this stunning composite residence.

Architect: Clendonvale Team of Designers

and Builders, Another Henley Company

2

Entrance to residence utilises Designer Block™

Pearl Grey on the retaining wall and Boral

Stylestone pavers.

Architect: Knowlman McDonald McMillan

BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:35 AM

Page 3

Designer Block Honed Face

™

Subtle elegance with a washed, river stone finish.

Designer Block™ in Almond

is used in this formal living area.

Architect: Michael Fountain Architects

Designer Block™ in Charcoal is

featured externally in this residence.

Architect: T.J. Antiohos and Associates

3

BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:35 AM

Page 4

Designer Block Polished Face

™

Contemporary granite design for striking feature walls.

Infuse architectural design into your home

with the unique textures of Designer Block™.

Designer Block™ in Alabaster is an internal

feature of this contemporary residence.

Architect: Mackenzie Pronk Architects

This contemporary home utilises Designer Block™

Alabaster both internally and externally. It creates

a stunning effect by continuing one exterior wall

into the foyer as shown on left.

Architect: Wilson Davis Series

4

BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:35 AM

Page 5

Designer Block Split Face

™

Bring the weathered look of nature indoors.

Designer Block™ in Charcoal creates a timeless

appearance in this modern architectural residence

which is also low-maintenance.

Architect: Suters Architects

Harry Seidler and Associates have used

Almond both internally and externally.

Architect: Harry Seidler and Associates

5

BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:35 AM

Page 6

Designer Block colours and textures

™

Durable and low-maintenance, Designer Block™ is creative and versatile

to meet the individual needs of colour themes, both internally and externally.

Essential Colours

Smooth Face

Split Face

Polished Face

Honed Face

Alabaster

Almond

Charcoal

Accent Colours (minimum quantities or a surcharge may apply*)

Smooth Face

Split Face

Sandune

Sandstone Blend

Four Innovative Textures

Paperbark

Smooth Face A finely textured

finish created through the standard

moulding process.

Honed Face The honing process grinds

2-3mm from the block surface, producing

a matt exposed-aggregate finish.

Pearl Grey

Polished Face This involves producing

a denser block which is honed and then

buffed. Polishing enriches the colour

of the aggregates. The finely finished

polished surface is ideal for feature walls,

trim and banding.

Split Face The splitting process produces

a bold textured, exposed aggregate finish.

6

*See back page for product lead times and additional information. Colours may vary and are indicative only.

BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:36 AM

Page 7

Designer Block component range

™

Ideal for retaining and feature walls or facades, Designer Block™ can add a unique finish to

your home when integrated with other building materials, from timber to metal and glass.

Component Range

Corner Bonding Detail

For the full range contact your Boral Masonry Representative.

Smooth, Honed and Polished Designer Block™

Split Face Designer Block™

10.101

190

10.101

90

390

90

40

390

90

90

10.71 Half Height*

10.01 Full Height*

10.101

10.26

390

10.117 Quarter Height

10.101

10.101

10.101

190

190

10.26

40

390

140

390

190

15.01 Full Height*

50.31 Capping

20.01 Full Height*

90

15

90

* These products are

available in Honed,

or Polished finish.

108

190

100

390

190

50

Series 100 Corner

190

110

10.26 Corner Return

390

190

20.101

10.39 Sill

20.192

Split End 20.101

20.101

Split Face Designer Block™

190

190

20.101

90

20.101

20.101

390

95

95

10.101 Full

390

95

10.101 Full

390

20.192

Split End

10.109 Half Height

Series 200 Corner

190

190

40

390

95

145

10.117 Quarter Height

390

390

195

15.101 Full

20.101 Full

90

15

90

108

190

190

100

195

395

20.192 Split End

190

390

10.26 Corner Return

50

110

190

10.39 Sill

Approximate Material Quantities for 1m3 of Mortar

M3

General

Purpose

M4

Exposure

Grade

Mix in 1: 5 Proportions

Cement

Additive

Sand

16 Bags (20kg each)

8 Litres

1.2m3

Mix in 1:4 Proportions

Cement

Additive

Sand

20 Bags (20kg each)

10 Litres

1.2m3

Notes

• 20 Litres of the Designer Block™ Mortar Additive

will lay approximately 1500-1800 blocks.

• Use clean, sharp sand and allow 20% for bulking.

Masonry Units

Boral Designer Block™ is manufactured in accordance with the provisions of Australian Standard

AS/NZS4455 : 1997.

Mortar Additive

For the Boral Designer Block™ pre-sealing technology to be effective, the mortar specification

MUST include Boral Designer Block™ Mortar Additive. Use off white cement and appropriate

oxide to match selected block colour.

Block Laying

When core filling Designer Block™ walls, some seepage may occur due to high hydrostatic pressure.

Ensure it is cleaned off before it dries, otherwise staining will occur. It is essential that the block

work is kept clean from mortar smears. This will eliminate the need for aggressive acid based

cleaning solutions which can damage the face or change the colour of the concrete blocks.

7

BOR13365 Des Block Victoria V14Revised.qxp

17/1/08

9:36 AM

Page 8

Designer Block

™

Designer Block™ Additional Information

Block Laying

Masonry walls are to be constructed in accordance with AS3700 : 2001.

Stock Colours and Textures

Lead times apply to all coloured blocks. Accent colours are made

to order. Minimum quantities required or a surcharge may apply.

Ask your representative for details. Boral recommends part size blocks

are cut/bolstered on-site to maintain colour consistency. Blocks can

be cut-to-order.

Textures

Finishes including Honing and Polishing are produced on a ‘made to

order’ basis. Lead times apply as the product must be cured for four

weeks to harden sufficiently before processing.

Contact your nearest Boral Masonry office for approximate lead times

and premiums on special textured finishes. Designer Block™ is available

standard with one face. Additional faces can be ‘made to order’.

Minimum quantities required or a surcharge may apply.

Colour and Texture Variations

The colours shown in this brochure are provided as an indication

of the colours and textures available. Some variations in colour may

occur due to changes in raw materials. In addition variation can occur

between production batches.

Brochure Colours

The printed colours in this brochure are only a guide. Please ask to see

a sample of your chosen colour/texture before specifying or ordering.

Construction and General Cleaning Notes*

1. Blocks must be kept dry on site before use and when laid. Freshly

laid walls must be covered overnight and when rain interrupts

work in order to prevent moisture entering the cores of the blocks.

2. Do not put mortar on the web of the blocks.

3. Ensure that perpends are butted on each side with a void in the

middle. The mortar joints should be well ironed to provide a tight

sealed joint.

4. Ensure mortar smears are removed before mortar sets as acid

cleaning later can discolour the masonry.

5. It is important that retaining walls have good drainage behind the wall.

6. For non-grouted masonry, a horizontal weep hole at the floor joint

of each core should be provided to drain water that may be

trapped inside the blocks. Partially fill the bottom course blocks

with 20mm blue metal or similar drainage material to prevent

mortar droppings from blocking the weep holes.

7. Good Building Practice

Block layers must exercise extra care when laying face concrete

masonry to minimise mortar staining.

Block layers must:

• Keep face blocks as clean as possible while laying and tooling;

• Keep unused pallets of blocks and tops of unfinished walls covered

during rain to prevent water penetration and excessive efflorescence;

• Clean any dags and mortar smears before they set hard.

Remaining stains could be removed following the procedures

set out below.

8. Removal of Mortar Stains with Hand Tools

After using a bucket and brush, remove any remaining mortar

dags and smears by rubbing the surface with a piece of ‘like

coloured’ block or a piece of wood if cleaning polished masonry

(to prevent scratching).

9. Pressure Cleaning

This cleaning method is not a substitute for good building practice

cleaning methods. It should only be used after these procedures

have been carried out if further cleaning is required.

10. Acid Treatments

Only if hand cleaning and pressure washing methods have failed

to fully remove mortar stains, should acid treatments be considered

for cleaning of concrete blockwork.

*Always refer to a cleaning professional.

Please see the Boral Masonry Brick and Block Product Guide for the full range of block sizes available. Boral Masonry reserves the right to change

the details in this publication without notice. For a full set of Terms and Conditions of Sale please contact your nearest Boral Masonry sales office.

Front Cover

The rugged Designer Block Split Face texture is used in the entry of

this home in Almond. Architect: Michael Fountain Architects (MFA).

™ Designer Block

™

is a trademark of Boral Masonry Limited.

© Boral Masonry All Rights Reserved 2007.

Boral Masonry Limited ABN 13 000 223 718

Orders, product samples and sales enquiries

MELBOURNE

17- 47 Turner Street, Port Melbourne VIC 3207

(Plant: Riding Boundary Road, Deer Park. VIC 3023)

Sales

Tel (03) 9363 1944

Fax (03) 9363 6008

www.boral.com.au

Call Specifier Line 1300 360 255

Visit8www.boral.com.au/masonry

01/08