Subject to modifications.

Parallel remote control system

IDM 7500

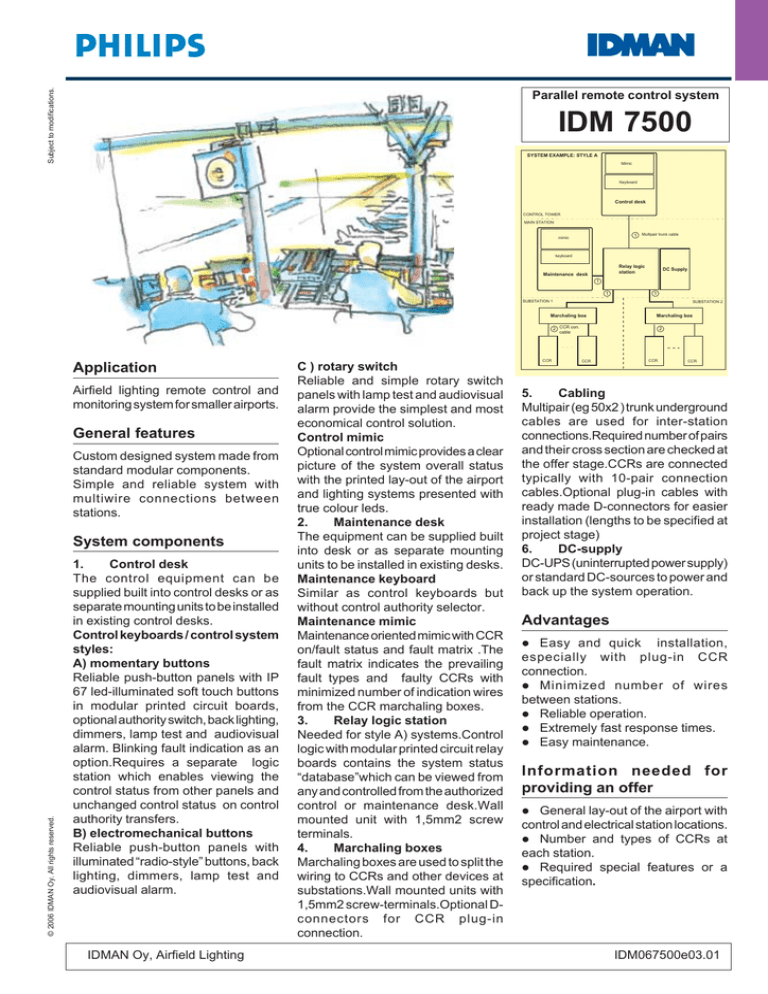

S Y S T E M

E X A M P L E : S T Y L E A

M im ic

K e y b o a rd

C o n tro l d e s k

C O N T R O L T O W E R

M A IN S T A T IO N

1

m im ic

M u ltip a ir tr u n k c a b le

k e y b o a rd

M a in te n a n c e

R e la y lo g ic

s ta tio n

d e s k

D C S u p p ly

1

1

1

S U B S T A T IO N 1

S U B S T A T IO N 2

M a r c h a lin g b o x

2

Application

Airfield lighting remote control and

monitoring system for smaller airports.

General features

Custom designed system made from

standard modular components.

Simple and reliable system with

multiwire connections between

stations.

© 2006 IDMAN Oy. All rights reserved.

System components

1.

Control desk

The control equipment can be

supplied built into control desks or as

separate mounting units to be installed

in existing control desks.

Control keyboards / control system

styles:

A) momentary buttons

Reliable push-button panels with IP

67 led-illuminated soft touch buttons

in modular printed circuit boards,

optional authority switch, back lighting,

dimmers, lamp test and audiovisual

alarm. Blinking fault indication as an

option.Requires a separate logic

station which enables viewing the

control status from other panels and

unchanged control status on control

authority transfers.

B) electromechanical buttons

Reliable push-button panels with

illuminated “radio-style” buttons, back

lighting, dimmers, lamp test and

audiovisual alarm.

IDMAN Oy, Airfield Lighting

C ) rotary switch

Reliable and simple rotary switch

panels with lamp test and audiovisual

alarm provide the simplest and most

economical control solution.

Control mimic

Optional control mimic provides a clear

picture of the system overall status

with the printed lay-out of the airport

and lighting systems presented with

true colour leds.

2.

Maintenance desk

The equipment can be supplied built

into desk or as separate mounting

units to be installed in existing desks.

Maintenance keyboard

Similar as control keyboards but

without control authority selector.

Maintenance mimic

Maintenance oriented mimic with CCR

on/fault status and fault matrix .The

fault matrix indicates the prevailing

fault types and faulty CCRs with

minimized number of indication wires

from the CCR marchaling boxes.

3.

Relay logic station

Needed for style A) systems.Control

logic with modular printed circuit relay

boards contains the system status

“database”which can be viewed from

any and controlled from the authorized

control or maintenance desk.Wall

mounted unit with 1,5mm2 screw

terminals.

4.

Marchaling boxes

Marchaling boxes are used to split the

wiring to CCRs and other devices at

substations.Wall mounted units with

1,5mm2 screw-terminals.Optional Dconnectors for CCR plug-in

connection.

C C R

M a r c h a lin g b o x

C C R c o n .

c a b le

2

C C R

C C R

C C R

5.

Cabling

Multipair (eg 50x2 ) trunk underground

cables are used for inter-station

connections.Required number of pairs

and their cross section are checked at

the offer stage.CCRs are connected

typically with 10-pair connection

cables.Optional plug-in cables with

ready made D-connectors for easier

installation (lengths to be specified at

project stage)

6.

DC-supply

DC-UPS (uninterrupted power supply)

or standard DC-sources to power and

back up the system operation.

Advantages

z Easy and quick

installation,

especially with plug-in CCR

connection.

z Minimized number of wires

between stations.

z Reliable operation.

z Extremely fast response times.

z Easy maintenance.

Information needed for

providing an offer

z General lay-out of the airport with

control and electrical station locations.

z Number and types of CCRs at

each station.

z Required special features or a

specification.

IDM067500e03.01

Subject to modifications.

Lead-on light controller

IDM 7015

KD 500

Primary connector kit

FAA L-823

400

Electrical connection

Tcl load PT

Tcl-circuit

CCR

Tcl

Lead-on

load Pl

A

B b

a

170

A

a

C

c

A

C

c

CCR

SB

B

b

B

Lead-on

circuit

C

SB-circuit

Technical data

ICAO Annex 14 Volume I 4th ed.

July 2004.

z Switching electronics moulded in

epoxy resin with special vacuum

technology.

Primary leds and connectors:

3 sets KD500 / FAA L-823

Power dissipation:

10W

Operating temperature:

-400C - +550C

Taxiway circuit:

A,a 2,8 - 6,6A / 5000V

Lead-on circuit:

B,b Max load 150V or 1kW at 6,6A

Stop bar circuit:

C,c 2,8 - 6,6A / 5000V

Weight:

5,7 kg

z

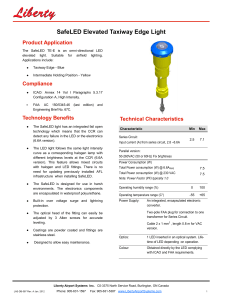

Application

Control of lead-on lights without a

need of any other equipment for

existing and new stop bar / taxiway

centre line installations.

z

Features

No changes to the existing stop

bar / taxiway centre line installation

are needed (CCRs, remote control

etc.). Only a separate loop (min 90m)

has to be arranged for the lead-on

lights which follow the stop bar towards

the runway.

z The unit is to be connected to the

taxiway centre line (A,a), lead-on light

(B,b) and stop bar (C,c) circuits with

standard FAA L-823 connectors and

can be installed into a transformer pit.

z One unit is required for each

interleaved stop bar circuit.

z The unit will automatically switch

off the lead-on lights whenever the

stop bar is illuminated and vice versa.

z Total galvanic isolation between

the stop bar and taxiway centre line

circuits.

z Overvoltage and overload

protections provided.

z Special versions also available

for taxiway guidance systems.

z

IDM067015e03.01

System layout

RUNWAY

A

Taxiway

centerline

lights

Min

90m

Lead-on

lights

B

C

Stop-bar

Taxiway

centerline

lights

A

a

A

C

c

B

b

IDM 7015

Lead-on light

controller

© 2006 IDMAN Oy. All rights reserved.

Specification

IDMAN Oy, Airfield Lighting