ARTISTAR REMOTE METAL HALIDE (ES16)

advertisement

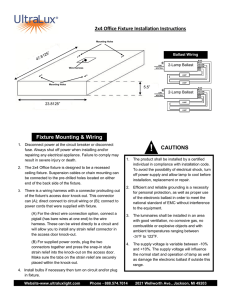

ARTISTAR™ RM ES16 METAL HALIDE Standard Anchor Base Installation 3/16” and 5/64” Allen wrench NEEDED FOR Wire connector INSTALLATION: Warning High Voltage (recommended silicone filled wire connectors) Drill bit and Drill Hot Surface Mounting hardware By Others INSTRUCTIONS PERTAINING TO A RISK OF FIRE, OR INJURY TO PERSONS IMPORTANT SAFETY INSTRUCTIONS Lighted lamp is HOT! WARNING - To reduce the risk of FIRE OR INJURY TO PERSONS: Turn off/unplug and allow to cool before replacing lamp. Lamp gets HOT quickly! Contact only switch/plug when turning on. Do not touch hot lens, guard, or enclosure (see diagram/ picture). Keep lamp away from materials that may burn. Do no touch the lamp at any time. Use a soft cloth. Oil from skin may damage lamp. Do not operate the luminaire fitting with a missing or damaged shield. SAVE THESE INSTRUCTIONS IMPORTANT SAFETY INFORMATION - READ, FOLLOW, AND SAVE ALL SAFETY AND INSTALLATION INSTRUCTIONS • Product must be installed by a qualified person in a manner consistent with its intended use and in compliance with the National Electrical Code, Canadian Electrical Code, and all Local and Provincial Codes. • Follow product label information and instructions. • Qualified Personnel must perform all servicing or relamping of this product. • Before wiring to power supply and during servicing or relamping, turn off power at fuse or circuit breaker before service. • The use of accessory equipment not recommended by the manufacturer or installed contrary to instructions may cause an unsafe condition. The use of damaged components may cause an unsafe condition and void product warranty. • Do not block light emanating from product in whole or part, as this may cause an unsafe condition. • Never operate the fixture with missing or damaged lens. Lens must be cleaned on regular basis. • Entire fixture may become extremely hot. Do not touch hot lens or fixture body. Do not touch the lamp at any time. Use a clean, dry, soft cloth to handle the lamp. Oil from skin may damage the lamp and cause it to rupture. • Replace lamp only with correct wattage and type of lamp marked on fixture label. • All gaskets, o-rings and sealing surfaces must be kept clean during installation and service; failure to do this may cause an unsafe condition and void product warranty. IMPORTANT LISTINGS AND CERTIFICATIONS · Suitable for wet locations · Additionally suitable for mounting within 4 ft. of the ground REMOTE WIRING #8-32 Stainless Steel set screw Remote ballast installations require inter-connected wiring between the lamp and ballast (by others) and have specific wiring requirements between these components. Ballast manufacturers regularly recommend the following wiring details for such installations. Electronic Ballast 1/4”-28 Stainless Steel Black Oxide Socket Head Cap Screw • 1 Foot Minimum and 15 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). • Lamp leads must be run in a separate, dedicated metal conduit. • Lamp leads must be 18 gauge, wire type SF-2 or SFF-2. • Lamp leads must be placed in a minimum 1/2” internal diameter conduit, pipe, or flexible conduit. • The use of metal clad cable assemblies or service power cords (SJ, SO, etc.) is prohibited. Magnetic Ballast • 35 Watt = 15 Foot Minimum and 50 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). • >35 Watt = 1 Foot Minimum and 50 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). Please consult the factory through your local B-K Lighting Sales Representative prior to finalizing any installation detail utilizing remote ballast wiring. Failure to comply with specific wiring requirements will void product warranty. #8-32 Stainless Steel set screw Anchor Base B-K LIGHTING 40429 Brickyard Drive • Madera, CA 93636 • USA 559.438.5800 • FAX 559.438.5900 www.bklighting.com • info@bklighting.com RELEASED 11-4-13 REFERENCE NUMBER INS132000 THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF B-K LIGHTING, INC. AND ITS RECEIPT OR POSSESSION DOES NOT CONVEY ANY RIGHTS TO REPRODUCE, DISCLOSE ITS CONTENTS, OR TO MANUFACTURE, USE OR SELL ANYTHING IT MAY DESCRIBE. REPRODUCTION, DISCLOSURE OR USE WITHOUT SPECIFIC WRITTEN AUTHORIZATION OF B-K LIGHTING, INC. IS STRICTLY FORBIDDEN. ARTISTAR™ RM ES16 METAL HALIDE Standard Anchor Base Installation Fixture Installation 1. Study anchor base plan. Prepare mounting surface for anchor base. 2. Use 5/64” Allen wrench loosen three (3) #8-32 stainless steel set screws (do not remove set screws from fixture base). Remove anchor base from bottom of fixture. 3. Pull wires from remote ballast housing necessary for installation (By Others). Feed wiring through anchor base. REMOTE POWER SUPPLY LINE COM 7. Use 3/16” Allen wrench to slightly loosen ¼”-28 stainless steel black oxide socket head cap screw at the knuckle for vertical aiming purposes. Rotate fixture at base and aim fixture to desired horizontal location. (+) FIXTURE (-) GROUND 5. Make two connections from remote ballast housing to fixture leads using proper wire connectors (By Others). Connect incoming ground wire to ground wire provided in fixture body. See wiring diagram. 4. Secure anchor base to solid surface (i.e. wood, concrete) using appropriate hardware for specific surface. GROUND WIRING DIAGRAM WIRING DIAGRAM All line voltage connections must be made in compliance with the National Electrical Code. Failure to do so will void warranty. 6. Place fixture onto mounted anchor base and press straight down until the two pieces are flush with each other. 8. Tighten the three (3) #8-32 stainless steel set screws on anchor base and 1/4”-28 stainless steel locking screw at the knuckle to secure all aiming positions. IMPORTANT SAFETY INFORMATION LISTED ON REVERSE READ, FOLLOW, AND SAVE ALL SAFETY AND INSTALLATION INSTRUCTIONS B-K LIGHTING 40429 Brickyard Drive • Madera, CA 93636 • USA 559.438.5800 • FAX 559.438.5900 www.bklighting.com • info@bklighting.com 3167387 ETL LISTED CONFORMS TO ANSI/UL STANDARD 1838, CERTIFIED TO CSA STD C22.2 NO.250.7 CSA STD C22.2 TIL B-58A RELEASED 11-4-13 REFERENCE NUMBER INS132000 THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF B-K LIGHTING, INC. AND ITS RECEIPT OR POSSESSION DOES NOT CONVEY ANY RIGHTS TO REPRODUCE, DISCLOSE ITS CONTENTS, OR TO MANUFACTURE, USE OR SELL ANYTHING IT MAY DESCRIBE. REPRODUCTION, DISCLOSURE OR USE WITHOUT SPECIFIC WRITTEN AUTHORIZATION OF B-K LIGHTING, INC. IS STRICTLY FORBIDDEN. ARTISTAR™ RM ES16 METAL HALIDE Power Pipe™ Installation NEEDED 3/16” and 5/64” Allen wrench FOR INSTALLATION: Wire connector (recommended silicone filled wire connectors) Warning Phillips Screwdriver Hot Surface High Voltage By Others INSTRUCTIONS PERTAINING TO A RISK OF FIRE, OR INJURY TO PERSONS IMPORTANT SAFETY INSTRUCTIONS Lighted lamp is HOT! WARNING - To reduce the risk of FIRE OR INJURY TO PERSONS: Turn off/unplug and allow to cool before replacing lamp. Lamp gets HOT quickly! Contact only switch/plug when turning on. Do not touch hot lens, guard, or enclosure (see diagram/ picture). Keep lamp away from materials that may burn. Do no touch the lamp at any time. Use a soft cloth. Oil from skin may damage lamp. Do not operate the luminaire fitting with a missing or damaged shield. SAVE THESE INSTRUCTIONS IMPORTANT SAFETY INFORMATION - READ, FOLLOW, AND SAVE ALL SAFETY AND INSTALLATION INSTRUCTIONS • Product must be installed by a qualified person in a manner consistent with its intended use and in compliance with the National Electrical Code, Canadian Electrical Code, and all Local and Provincial Codes. • Follow product label information and instructions. • Qualified Personnel must perform all servicing or relamping of this product. • Before wiring to power supply and during servicing or relamping, turn off power at fuse or circuit breaker before service. • The use of accessory equipment not recommended by the manufacturer or installed contrary to instructions may cause an unsafe condition. The use of damaged components may cause an unsafe condition and void product warranty. • Do not block light emanating from product in whole or part, as this may cause an unsafe condition. • Never operate the fixture with missing or damaged lens. Lens must be cleaned on regular basis. • Entire fixture may become extremely hot. Do not touch hot lens or fixture body. Do not touch the lamp at any time. Use a clean, dry, soft cloth to handle the lamp. Oil from skin may damage the lamp and cause it to rupture. • Replace lamp only with correct wattage and type of lamp marked on fixture label. • All gaskets, o-rings and sealing surfaces must be kept clean during installation and service; failure to do this may cause an unsafe condition and void product warranty. IMPORTANT LISTINGS AND CERTIFICATIONS · Suitable for wet locations · Additionally suitable for mounting within 4 ft. of the ground 1/4”-28 Stainless Steel Black Oxide socket head cap screw REMOTE WIRING #8-32 Stainless Steel set screw Power Pipe Remote ballast installations require inter-connected wiring between the lamp and ballast (by others) and have specific wiring requirements between these components. Ballast manufacturers regularly recommend the following wiring details for such installations. Electronic Ballast • 1 Foot Minimum and 15 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). • Lamp leads must be run in a separate, dedicated metal conduit. • Lamp leads must be 18 gauge, wire type SF-2 or SFF-2. • Lamp leads must be placed in a minimum 1/2” internal diameter conduit, pipe, or flexible conduit. • The use of metal clad cable assemblies or service power cords (SJ, SO, etc.) is prohibited. Magnetic Ballast • 35 Watt = 15 Foot Minimum and 50 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). • >35 Watt = 1 Foot Minimum and 50 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). Optional Stability Flange Please consult the factory through your local B-K Lighting Sales Representative prior to finalizing any installation detail utilizing remote ballast wiring. Failure to comply with specific wiring requirements will void product warranty. #8-32 Stainless Steel round head Phillips screws B-K LIGHTING 40429 Brickyard Drive • Madera, CA 93636 • USA 559.438.5800 • FAX 559.438.5900 www.bklighting.com • info@bklighting.com RELEASED 11-4-13 REFERENCE NUMBER INS132000.1 THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF B-K LIGHTING, INC. AND ITS RECEIPT OR POSSESSION DOES NOT CONVEY ANY RIGHTS TO REPRODUCE, DISCLOSE ITS CONTENTS, OR TO MANUFACTURE, USE OR SELL ANYTHING IT MAY DESCRIBE. REPRODUCTION, DISCLOSURE OR USE WITHOUT SPECIFIC WRITTEN AUTHORIZATION OF B-K LIGHTING, INC. IS STRICTLY FORBIDDEN. INE ARTISTAR™ RM ES16 METAL HALIDE Power Pipe™ Installation OptionalOption Power Pipe Mounting Finished grade Stability Flange Finished grade Finished grade Concrete Optional Pea gravel or sand Stability Flange 1. Excavate trench according to designed lighting plan. Dig hole a minimum of 18” deep and 10” wide to accommodate Power Pipe™ at desired fixture location(s). Finished grade Remote Transformer (by others) Pea gravel or sand Pea gravel or sand 2. Slide optional Stability Flange onto Power Pipe™. Use optional Stability Flange to aid in installation of Power Pipe™. Finished grade 3. Pull wires from remote ballast housing necessary for installation (By Others) through Power Pipe™. Allow for additional cable to make connections to fixture lead and future service. Place Power Pipe™ in hole. Concrete Pea gravel or sand 12V 4. Back fill with peaFIXTURE gravel or sand prior to pour. OM LINE REMOTE Optional POWER StabilitySUPPLY Flange COM GROUND 5. Pour concrete (By Others). Label on Power Pipe™ indicates installation depth with finished grade. COM Finished grade Finished grade (+) Finished grade Above Ground InstallationPea gravel or sand 6. Make two connections from remote ballast housing to fixture leads using proper wire connectors (By Others). Connect incoming ground wire to ground wire provided in fixture body. See wiring diagram. Concrete FIXTURE (-) Pea gravel GROUND Pea gravel or sand or sand WIRING DIAGRAM WIRING All line voltage DIAGRAM connections must be made in compliance with the National Electrical Code. Failure to do so will void warranty. 7. Insert wires and connectors into fixture base and attach to Power Pipe™. To aim fixture, use 3/16” Allen wrench to slightly loosen ¼”-28 stainless steel black oxide socket head screw at the knuckle for vertical aiming purposes. Rotate fixture to aim to desired horizontal location. 8. Tighten three (3) #8-32 stainless steel round head Phillips screws at base and 1/4”-28 stainless steel black oxide socket head screw at the knuckle to secure all aiming positions. IMPORTANT SAFETY INFORMATION LISTED ON REVERSE READ, FOLLOW, AND SAVE ALL SAFETY AND INSTALLATION INSTRUCTIONS Below Ground Above Ground Installation Be Ins Concrete B-K LIGHTING Installation 3167387 ETL LISTED CONFORMS TO ANSI/UL STANDARD 1838, CERTIFIED TO CSA STD C22.2 NO.250.7 CSA STD C22.2 TIL B-58A 40429 Brickyard Drive • Madera, CA 93636 • USA RELEASED Concrete 559.438.5800 • FAX 559.438.5900 11-4-13 www.bklighting.com • info@bklighting.com REFERENCE NUMBER INS132000.1 THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF B-K LIGHTING, INC. AND ITS RECEIPT OR POSSESSION DOES NOT CONVEY ANY RIGHTS TO REPRODUCE, DISCLOSE ITS CONTENTS, OR TO MANUFACTURE, USE OR SELL ANYTHING IT MAY DESCRIBE. REPRODUCTION, DISCLOSURE OR USE WITHOUT SPECIFIC WRITTEN AUTHORIZATION OF B-K LIGHTING, INC. IS STRICTLY FORBIDDEN. Pea gravel or sand Pea gravel ARTISTAR™ RM ES16 METAL HALIDE Wall Mount Installation TOOLS NEEDED: 3/16”, 1/8” and 5/64” Allen wrench Wire connectors (recommended silicone filled wire connectors) Warning High Voltage Hot Surface Mounting Hardware By Others IMPORTANT SAFETY INFORMATION - READ, FOLLOW, AND SAVE ALL SAFETY AND INSTALLATION INSTRUCTIONS INSTRUCTIONS PERTAINING TO A RISK OF FIRE, OR INJURY TO PERSONS IMPORTANT SAFETY INSTRUCTIONS • Lighted lamp is HOT! WARNING - To reduce the risk of FIRE OR INJURY TO PERSONS: Turn off/unplug and allow to cool before replacing lamp. Lamp gets HOT quickly! Contact only switch/plug when turning on. Do not touch hot lens, guard, or enclosure (see diagram/ picture). Keep lamp away from materials that may burn. Do no touch the lamp at any time. Use a soft cloth. Oil from skin may damage lamp. Do not operate the luminaire fitting with a missing or damaged shield. SAVE THESE INSTRUCTIONS Product must be installed by a qualified person in a manner consistent with its intended use and in compliance with the National Electrical Code, Canadian Electrical Code, and all Local and Provincial Codes. • Follow product label information and instructions. • Qualified Personnel must perform all servicing or relamping of this product. • Before wiring to power supply and during servicing or relamping, turn off power at fuse or circuit breaker before service. • The use of accessory equipment not recommended by the manufacturer or installed contrary to instructions may cause an unsafe condition. The use of damaged components may cause an unsafe condition and void product warranty. • Do not block light emanating from product in whole or part, as this may cause an unsafe condition. • Never operate the fixture with missing or damaged lens. Lens must be cleaned on regular basis. • Entire fixture may become extremely hot. Do not touch hot lens or fixture body. Do not touch the lamp at any time. Use a clean, dry, soft cloth to handle the lamp. Oil from skin may damage the lamp and cause it to rupture. • Replace lamp only with correct wattage and type of lamp marked on fixture label. • All gaskets, o-rings and sealing surfaces must be kept clean during installation and service; failure to do this may cause an unsafe condition and void product warranty. IMPORTANT LISTINGS AND CERTIFICATIONS · Suitable for wet locations · Additionally suitable for mounting within 4 ft. of the ground REMOTE WIRING Universal Ring 1/4”-28 Stainless Steel Black Oxide socket head cap screw Remote ballast installations require inter-connected wiring between the lamp and ballast (by others) and have specific wiring requirements between these components. Ballast manufacturers regularly recommend the following wiring details for such installations. Electronic Ballast • 1 Foot Minimum and 15 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). • Lamp leads must be run in a separate, dedicated metal conduit. • Lamp leads must be 18 gauge, wire type SF-2 or SFF-2. • Lamp leads must be placed in a minimum 1/2” internal diameter conduit, pipe, or flexible conduit. • The use of metal clad cable assemblies or service power cords (SJ, SO, etc.) is prohibited. Magnetic Ballast • 35 Watt = 15 Foot Minimum and 50 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). #10-24 Stainless Steel hex screw • >35 Watt = 1 Foot Minimum and 50 Foot Maximum Remote Wire Length (Ballast to Lamp Socket). #8-32 Stainless Steel set screw Please consult the factory through your local B-K Lighting Sales Representative prior to finalizing any installation detail utilizing remote ballast wiring. 18 Gauge Wire Failure to comply with specific wiring requirements will void product warranty. IMPORTANT SAFETY INFORMATION - READ, FOLLOW, AND SAVE THESE INSTALLATION INSTRUCTIONS B-K LIGHTING 40429 Brickyard Drive • Madera, CA 93636 • USA 559.438.5800 • FAX 559.438.5900 www.bklighting.com • info@bklighting.com PRELIMINARY 11-4-13 REFERENCE NUMBER INS132000.2 THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF B-K LIGHTING, INC. AND ITS RECEIPT OR POSSESSION DOES NOT CONVEY ANY RIGHTS TO REPRODUCE, DISCLOSE ITS CONTENTS, OR TO MANUFACTURE, USE OR SELL ANYTHING IT MAY DESCRIBE. REPRODUCTION, DISCLOSURE OR USE WITHOUT SPECIFIC WRITTEN AUTHORIZATION OF B-K LIGHTING, INC. IS STRICTLY FORBIDDEN. ARTISTAR™ RM ES16 METAL HALIDE Wall Mount Installation Phase 1 - Rough In Installation of Back box Additional Info • Please follow National and Local electrical codes for your area. • Suitable for through wire. • Suitable for installation into combustible materials. • Rated for 90° C. 1. Install Conduit (By Others) to be used with this product. 2. Install junction box so that front face is flush with finished wall or ceiling. 3. Connect box to conduit and pull wires for connections (See Wiring Diagram). Phase 2 - Finish Installation of Fixture. REMOTE POWER SUPPLY LINE COM (+) FIXTURE (-) GROUND GROUND 1. Install universal mounting ring (supplied with fixture) using appropriate mounting hardware (By Others). Align fixture mounting holes to final mounting position. 2. Pull wires from remote ballast housing necessary for installation (By Others). Make two connections from remote ballast housing to fixture leads using proper wire connectors (By Others). Connect incoming ground wire to ground wire provided in fixture body. See wiring diagram. WIRING DIAGRAM 3. Use 1/8” Allen wrench to mount fixture with two (2) #10-24 hex screws to installed back box. Do not over tighten. 4. Use 3/16” Allen wrench to slightly loosen ¼”-28 stainless steel black oxide socket head cap screw at the knuckle for vertical aiming purposes. Use 5/64” Allen wrench to loosen the three (3) #8-32 stainless steel set screws. Rotate to aim fixture to desired horizontal location. 5. Tighten the three (3) #8-32 stainless steel set screws and 1/4”-28 stainless steel black oxide socket head cap screw at the knuckle to secure all aiming positions. WIRING DIAGRAM All line voltage connections must be made in compliance with the National Electrical Code. Failure to do so will void warranty. IMPORTANT SAFETY INFORMATION LISTED ON REVERSE READ, FOLLOW, AND SAVE ALL SAFETY AND INSTALLATION INSTRUCTIONS B-K LIGHTING 40429 Brickyard Drive • Madera, CA 93636 • USA 559.438.5800 • FAX 559.438.5900 www.bklighting.com • info@bklighting.com 3167387 ETL LISTED CONFORMS TO ANSI/UL STANDARD 1838, CERTIFIED TO CSA STD C22.2 NO.250.7 CSA STD C22.2 TIL B-58A PRELIMINARY 11-4-13 REFERENCE NUMBER INS132000.2 THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF B-K LIGHTING, INC. AND ITS RECEIPT OR POSSESSION DOES NOT CONVEY ANY RIGHTS TO REPRODUCE, DISCLOSE ITS CONTENTS, OR TO MANUFACTURE, USE OR SELL ANYTHING IT MAY DESCRIBE. REPRODUCTION, DISCLOSURE OR USE WITHOUT SPECIFIC WRITTEN AUTHORIZATION OF B-K LIGHTING, INC. IS STRICTLY FORBIDDEN. ES16 METAL HALIDE Replacement / Installation Instructions PROJECT: TYPE: LAMP INSTALLATION OR RE-LAMPING IF REQUIRED FOR ES16 METAL HALIDE LAMPS 1. Use 5/64” Allen wrench to loosen #8-32 stainless set screw and remove cap. 2. Firmly insert lamp pins into socket, twist gently until lamp locks into place to make connection. Do not exceed the maximum wattage listed on the fixture label before installing. 3. Place cap on fixture and tighten set screw. Tighten screw to 1/2 inch pounds. Top of screw should sit flush with fixture cap. Warning: Do not over tighten set screw. Doing so will compromise O Ring seal and will void warranty. IMPORTANT SAFETY INFORMATION LISTED ON REVERSE READ, FOLLOW, AND SAVE ALL SAFETY AND INSTALLATION INSTRUCTIONS B-K LIGHTING 40429 Brickyard Drive • Madera, CA 93636 • USA 559.438.5800 • FAX 559.438.5900 www.bklighting.com • info@bklighting.com 3167387 ETL LISTED CONFORMS TO ANSI/UL STANDARD 1838, CERTIFIED TO CSA STD C22.2 NO.250.7 CSA STD C22.2 TIL B-58A RELEASED 11-5-13 REFERENCE NUMBER INS000006 THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF B-K LIGHTING, INC. AND ITS RECEIPT OR POSSESSION DOES NOT CONVEY ANY RIGHTS TO REPRODUCE, DISCLOSE ITS CONTENTS, OR TO MANUFACTURE, USE OR SELL ANYTHING IT MAY DESCRIBE. REPRODUCTION, DISCLOSURE OR USE WITHOUT SPECIFIC WRITTEN AUTHORIZATION OF B-K LIGHTING, INC. IS STRICTLY FORBIDDEN.