1971-Hall-Heat Transfer near the Critical Point

advertisement

Heat Transfer near the Critical Point

. .

W B HALL

Nuclear Engineering Department. University of Manchester. Manchester. England

I . Introduction

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

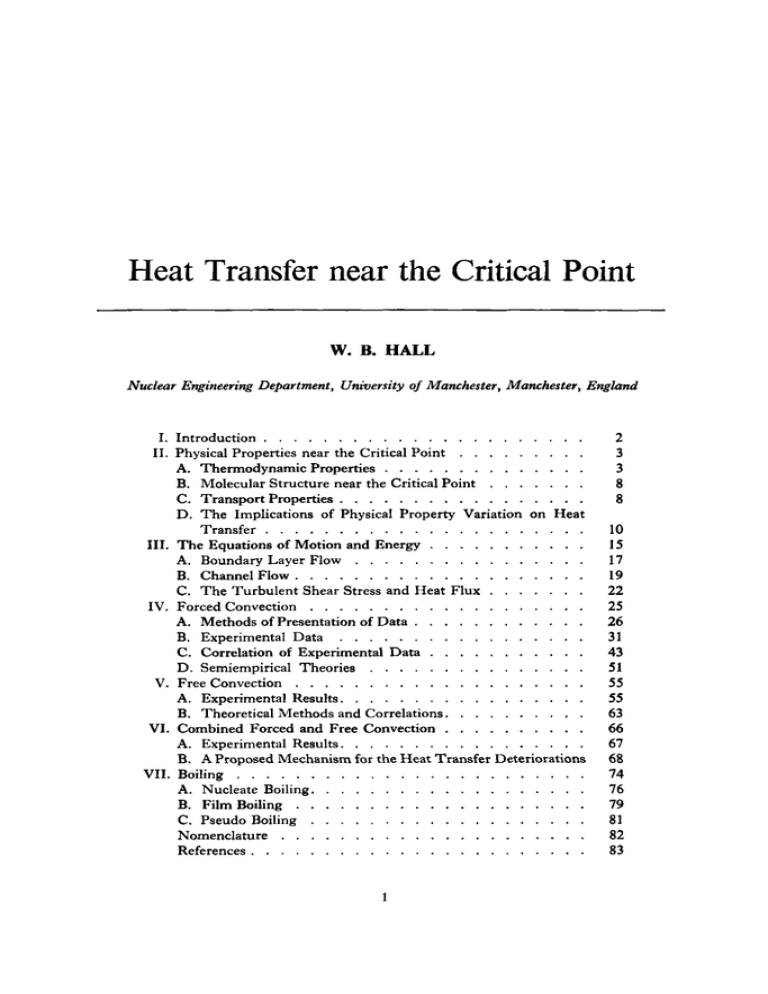

I1. Physical Properties near the Critical Point . .

A. Thermodynamic Properties . . . . . . .

B. Molecular Structure near the CriticalPoint

.......

. . . . . . .

.................

C . Transport Properties

D . The Implications of Physical Property Variation on Heat

Transfer . . . . . . . . . . . . . . . . . . . . . .

I11. The Equations of Motion and Energy . . . . . . . . . . .

A . Boundary Layer Flow . . . . . . . . . . . . . . . .

B. ChannelFlow . . . . . . . . . . . . . . . . . . . .

C . The Turbulent Shear Stress and Heat Flux . . . . . . .

IV. Forced Convection . . . . . . . . . . . . . . . . . . .

A . Methods of Presentation of Data . . . . . . . . . . . .

B. Experimental Data . . . . . . . . . . . . . . . . .

C . Correlation of Experimental Data . . . . . . . . . . .

D . Semiempirical Theories . . . . . . . . . . . . . . .

V . Free Convection . . . . . . . . . . . . . . . . . . . .

A . Experimental Results . . . . . . . . . . . . . . . . .

B . Theoretical Methods and Correlations . . . . . . . . . .

VI. Combined Forced and Free Convection . . . . . . . . . .

A . Experimental Results . . . . . . . . . . . . . . . . .

B. A Proposed Mechanism for the Heat Transfer Deteriorations

VII . Boiling . . . . . . . . . . . . . . . . . . . . . . . .

A . Nucleate Boiling . . . . . . . . . . . . . . . . . . .

B. Film Boiling . . . . . . . . . . . . . . . . . . . .

C. PseudoBoiling . . . . . . . . . . . . . . . . . . .

Nomenclature . . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . .

1

10

15

17

19

22

25

26

31

43

51

55

55

63

66

67

68

74

76

79

81

82

83

2

W. B. HALL

I. Introduction

The rapid growth of research activity in supercritical heat transfer

over the past ten or fifteen years is a consequence of several trends in

engineering. There has been a steady development of steam plant towards

supercritical conditions, and supercritical water has been considered as

a coolant for several types of nuclear reactors. Helium is used at nearcritical conditions as a coolant for the conductors of electrical machines,

and rocket motors are frequently cooled by pumping fuel through

cooling pipes at supercritical pressure.

From a fundamental standpoint, the problem has been regarded as

one in which the variation of physical properties with temperature

becomes extremely important. Effects which, with most fluids, may be

treated as small perturbations of the “constant property” idealization,

sometimes become dominant, rendering existing theoretical models and

empirical correlations useless. In some cases phenomena appear which

have no counterpart with constant property fluids. At the same time

experimental difficulties have hampered the investigation of these effects.

These are not merely the difficulties of operating equipment at high

pressures, but also the problems of compressibility (which becomes very

high near the critical point and makes the density sensitive to relatively

small pressure variations) and of specific heat (which also becomes

large and hinders the accomplishment of thermal equilibrium).

It might be thought that heat transfer experiments of such complexity

would have little to contribute to the understanding of basic mechanisms.

It is true that in constructing models of the process one is forced to

introduce additional assumptions which are difficult to test; nevertheless,

there are some cases where extreme property variations afford a much

more stringent test of some aspects of current theories than could be

obtained in other ways. An example of this is the interaction between

forced and free turbule‘nt convection; with a supercritical fluid the trend

of the results is in the opposite sense to that which one would expect.

This may well lead to a reexamination of the same problem for fluids

with small property variations.

The near-critical region may be thought of as that region in which

boiling and convection merge. When the pressure is sufficiently subcritical or supercritical, the problem tends towards either a boiling

problem or a constant property convection problem; under such conditions existing theoretical and empirical methods are generally adequate.

We shall concentrate on the region rather close to the critical point where

the property variations are severe and where there are very significant

heat transfer effects. Such effects are usually found in a range of pressures

HEATTRANSFER

NEAR

THE

CRITICALPOINT

3

from the critical up to about 1.2 times the critical; they are generally

largest when the temperatures of the hotter surface and the fluid span

the critical temperature.

We begin with a brief description of the behavior of thermodynamic

and transport properties near the critical point. T h e equations of continuity, momentum, and energy are then examined with a view to

revealing the effect of variable properties and deciding whether the same

simplifications can be made as are common with a constant property

fluid. A discussion of the various modes of heat transfer then follows,

particular attention being given to the interaction between forced and

free convection.

11. Physical Properties near the Critical Point

A. THERMODYNAMIC

PROPERTIES

T h e properties of a fluid near its critical point have interested thermodynamicists for the past hundred years. This is hardly surprising in view

of the singular behavior in this region: the classical description indicates]

for example, that the compressibility and the specific heat at constant

pressure both become infinite at the critical point. These factors make

experimentation difficult; it is evident that as (avjap),becomes large,

the hydrostatic pressure variation in the fluid will lead to significant

density variations even for small changes of height and also that the

approach to thermal equilibrium will be slow as cp becomes large.

T h e present state of knowledge of thermodynamic behavior is not

entirely satisfactory, either from a theoretical or from an experimental

standpoint; nevertheless, it is probably true to say that an understanding

of heat transfer in the critical region is limited more by lack of knowledge

of the heat transfer processes (e.g., turbulent diffusion, effect of buoyancy

forces) than by uncertainties in the thermodynamic properties. In these

circumstances, the classical description of the critical point may still

be adequate.

1 . The van der Waals Model

I n 1873, van der Waals proposed an explanation of thermodynamic

behavior near the critical point. His model, in which an allowance is

made for the attractive and repulsive forces between molecules, leads to

an equation of state of the following form:

W. B. HALL

4

The physical arguments underlying the equation are well known and

need not be repeated here; it is sufficiently to note that the constant b

accounts for the strong, short range repulsive forces (imposing a limit

to the reduction of volume as pressure is increased), and the term a i r 2

represents the long range attractive forces between molecules. Figure 1

illustrates the shape of isotherms on a p , V diagram, according to van der

Waals equation.

Consider a particular isotherm, marked abcdef in Fig. 1. The fluid

I

!?'

3

Lo

a

!?'

Volume, V

-

FIG. 1. The van der Waals isotherms.

can exist in a homogeneous state along the section of the isotherm marked

abc and def; the section cd represents conditions in which the thermodynamic inequality

( W W T

<0

is not satisfied, and the fluid would separate into two distinct phases.

The regions bc and de represent, respectively, superheated liquid and

subcooled vapor; the extent of these metastable regions is indicated by

broken lines in Fig. 1. Equilibrium between the liquid and vapor phases

(with a plane interface between them) is achieved with states marked b

and e. (Note that unstable equilibrium between liquid and vapor can be

achieved with a curved interface along bc and de. In these cases, surface

tension forces at the bubble or droplet surface lead to a difference

between the liquid and vapor pressures.)

The isotherm marked o in Fig. 1 is known as the critical isotherm and

HEATTRANSFER

NEAR

CRITICAL

POINT

THE

5

passes through the critical point. It represents the isotherm for which

the points bcd and e all coincide, thus giving a point of inflection at the

critical point (CP on Fig. I), so that

(ap/aV)c,= 0

(aZpplaP2);

=0

2. The Law of Corresponding States

The behavior of the critical isotherm, as embodied in Eqs. (2) and (3),

can be used to eliminate the constants a and b in the van der Waals

equation as follows: Equation (1) may be written as

p

= R T / ( P - b)

-

alpz

and, using Eqs. (2) and (3),

-RTc

2a

(*);=

0 = (VC b y t($)+

2RTc -- 6a

-

(P)S

(Be

(P)4

1

3

a/b2;

T e = 8a/27bR

- b)3

from which we find that

VC

= 3b;

=

Introducing the “reduced” quantities,

the van der Waals equation becomes

( p * + 3/(V*)’)(3V* - 1)

= 8T*

(4)

An interesting aspect of this equation is the fact that it involves only

p*, V*, and T* and not any quantities that are characteristic of a

particular substance. I n the above form it applies only to substances for

which the van der Waals equation is true; however, the same principle

may be stated in more general terms by asserting that there is a unique

relationship between p*, V*, and T* for all substances. This is known as

the princzple of corresponding states and is frequently stated in the form

2 = Z ( p * , T*)

(5)

6

where

W. B. HALL

z =~ P ~ R T

(For those substances for which van der Waal’s equation is true

Zc = pcpe/RTc = 318,

and

Z

=

$P*V*/T*)

T h e “reduced” isotherms, p* = p*(V*), as determined by the

principle of corresponding states, have the same shape for all substances;

we may therefore conclude that for the same value of T*, all substances

conforming to this principle must have the same reduced saturated

vapor pressures and the same reduced specific volumes of saturated

vapor and liquid. Further, the reduced enthalpy of evaporation,

h,,/RTc must be the same function of T* for all substances.

Thus

h,,/RTC =f(T * )

(6)

(This function tends to a constant value of approximately 10 at temperatures appreciably below the critical temperature.)

T h e importance of the principle of corresponding states in the present

context is that it provides a qualitatively accurate description of thermodynamic behavior near the critical point.

3 . Heat Capacities near the Critical Point

Rowlinson (1) has reviewed the state of knowledge concerning

singularities in the thermodynamic and transport properties near the

critical point. While the specific heat at constant volume is always finite

for a van der Waals gas, it has been shown experimentally that this model

is inadequate at the critical point; it appears that cv does in fact become

infinite but that the infinity is much weaker than that in cp , the specific

heat at constant pressure. In most heat transfer problems we are more

concerned with the value of cp ,and, in this case, the van der Waals model

does predict a value of infinity at the critical point; this may be demonstrated as follows: T h e difference in the specific heats is given by the

thermodynamic identity

c, - c y =

w%J/w

v12/(aP/av)T

and it may be shown (2) that the slope of the critical isochor ( 8 ~ j a T ) , ~

is equal to the slope of the vapor pressure curve at the critical point,

which is finite. On the other hand, (@/8V),c is zero, so that cp - cv

becomes infinite.

T h e question of the precise nature of the singularities at the critical

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

7

point is somewhat academic in most practical situations because of the

extreme difficulty of achieving critical conditions precisely. In many heat

transfer systems the pressure will be maintained somewhat above the

critical value; under these circumstances the singularities will be avoided

although the property variations may still be severe. For example, the

peak in the specific heat is large even at pressures considerably greater

than the critical, as may be seen from the data for CO, shown in Fig. 2.

!I

18

-

16

U

.$.'4

- 12

7

P

-P

U

c

10

u

c

a

v)

6

4

2

20

30

40

50

Temperature ("C,

FIG. 2. Specific heat (at constant pressure) of carbon dioxide near the critical point.

4. Compressibility and the Velocity of Sound

T h e compressibility of the fluid may be defined for an isothermal or

for a reversible adiabatic (isentropic) process as follows:

Isothermal coefficient of bulk compressibility,

K~

=

-(aV/ap),/V

Isentropic coefficient of bulk compressibility,

K~

=

-(aV/ap),/ V

I t will be evident from what has been said in section 11, A, 1 that the

isothermal coefficient, K ~ is, infinite at the critical point. It may be

shown (2) that the two coefficients are related in the following manner:

l/KS

= l/KT

+ Tv(ap/aT);/CV

(7)

W. B. HALL

It may also be shown that the vapor pressure curve is continuous with

the critical isochor beyond the critical point. At the critical point,

therefore, (i?p/i?T),is equal to the limiting value of the slope of the vapor

pressure curve, which is finite. Provided that the value of cy at the critical

point is not zero, the isentropic compressibility will be finite.

T h e velocity of sound, c, is given by

From Eqs. (7) and (8) it will be clear that a maximum in c y will lead

to a maximum in K, and a minimum in c near the critical point. Measurements in carbon dioxide at the critical temperature have indicated a

minimum velocity of sound of 140 mjsec at a pressure about 0.5 atm

higher than the critical pressure; at the critical pressure the measured

value was 172 m/sec, compared with the calculated value of 155 mjsec (3).

B. MOLECULAR

STRUCTURE

NEAR

THE

CRITICALPOINT

T h e transition from a subcritical to a supercritical temperature at a

slightly supercritical pressure does not, of course, involve a change of

phase. While from a macroscopic standpoint the change of density is

continuous, there is conclusive evidence that on a molecular scale the

fluid is far from homogeneous. T h e phenomenon of “critical opalescence’’

indicates the presence of a structure large enough to produce scattering

of light; moreover, X-ray diffraction patterns characteristic of the liquid

have been detected at supercritical temperatures when the macroscopic

density is much less than that of the liquid.

An interesting survey of the information on structure has been made

by Smith (4). It appears that as the temperature is increased (at a slightly

supercritical pressure), the liquid structure gives way to liquidlike

clusters in a matrix of gas; these reduce in size until the situation is

virtually one of a gas with a high degree of association. I n most Auid flow

and heat transfer problems it is probably reasonable to regard the fluid

as a continuum because the dimensions of the system will usually be much

greater than the scale of the molecular structure.

C. TRANSPORT

PROPERTIES

T h e pattern of variation of viscosity and thermal conductivity with

temperature and pressure is illustrated in Figs. 3 and 4, which refer to

carbon dioxide in the near-critical region. T h e theoretical basis for

describing the variation of transport properties is less well-developed

than that for the thermodynamic properties, and the problems of

HEATTRANSFER

NEAR

c

20

THE CRITICAL

POINT

30

40

Tern p e r a t u re ( "C I

9

50

FIG.3. Viscosity of carbon dioxide near the critical point.

I

20

I

I

30

40

Temperature

I

50

('C)

FIG.4. Thermal conductivity of carbon dioxide near the critical point: (a) data of

N. V. Tzederberg and N. A. Morosova, Teplmergetika No. 1, 75 (1960); (b) data of

J. V. Sengers and A. Michels, Progr. Int. Res. Thermodyn. Tramp. Prop., Pap. Symp.

Thermophys. Prop. 2nd 1962 (1963).

W. B. HALL

measurement are even more severe. I t appears that the thermal conductivity certainly becomes infinite near the critical point ( I ) , but there

is less certainty about the viscosity.

T h e effect of viscosity variations on fluid flow and heat transfer to

low pressure gases is generally dealt with by using approximate expressions of the form

in which T , is some reference temperature, and ps is the corresponding

viscosity. It is quite clear that this technique will fail completely near

the critical point, and one must seek a more general relationship between

the transport properties and the temperature and pressure. One possible

approach is to attempt to describe the transport in terms of “reduced”

quantities in an analogous manner to the description of thermodynamic

properties by the principle of corresponding states. Such an approach has been proposed by Borishansky et al. (5) and has been

applied by them to the generalization of heat transfer processes at

subcritical pressures. Hirschfelder, Curtiss, and Bird (6) have reviewed

various methods by which the transport properties may be correlated.

T h e most suitable, for our present purpose, relates the viscosity and

thermal conductivity to the reduced temperature and reduced pressure

in the following manner

(Pc )2131 - P*(P*, T*)

P* = P ( R p ) l / 6 / [ ~ 1 / 2

k*

= KM1’2(RTc)1’6/[R(pc)2’9]

= A*@*,

T*)

While the extension of thermodynamic similarity to heat transfer is

certainly interesting, it seems likely that when it is taken together with

the conditions for dynamical similarity, the resulting requirements for

complete similarity will be extremely restrictive in all but the simplest

cases.

T h e matter is considered in more detail in Sections IV, C and V, B,

in which the correlation of experimental data for forced and free convection is considered.

T h e lack of accurate data on transport properties for most fluids near

the critical point makes it essential in reporting experimental work to

quote the raw data so that new theories or proposals for generalization

may be tested against them.

D. THEIMPLICATIONS

OF PHYSICAL

PROPERTY

VARIATION

ON

HEATTRANSFER

T h e problem of physical property variation in an extreme form is a

central feature of all near-critical heat transfer processes. I n many cases

HEATTRANSFER

NEAR

THE

CRITICALPOINT

11

it produces a quantitative difference in behavior, and in some cases a

phenomenon appears which at first sight has no parallel in constantproperty heat transfer. These effects will be considered in detail later;

in this section we consider some of the more general implications of

physical property variation.

1. The Effect of Temperature Diflerence

Heat transfer processes may be divided into two categories depending

upon whether or not physical property variation forms an essential part

of the process. Conduction and forced convection both may take place

in the absence of variation in any property but the heat content of the

substance involved. Boiling and condensation, on the other hand,

involve phase changes with distinct properties for the separate phases;

free convection involves a fluid flow pattern which is a direct result

of density variation caused by heating or cooling.

T h e existence of a meaningful constant property situation is frequently

useful in analyzing forced convection data; the concept of a limiting

value of the heat tranfer coefficient as the temperature difference tends to

zero is often used to separate the effects of property variation from the

inherent heat transfer and fluid flow processes. Provided that they are

relatively small, property variations may be represented by the inclusion

of an empirical function of temperature difference. From a mathematical

standpoint, the constant property situation is important because the fluid

flow and heat transfer problems are separable, and the energy equation is

linear in temperature; complicated boundary conditions may therefore

be built up by the superposition of solutions with simpler boundary

conditions.

In contrast to the case of forced convection, boiling is a process which

necessarily involves variations in physical properties throughout the

fluid. It is true that property variations within the separate liquid and

vapor phases may be small, but the relative proportions in which these

phases are present will, in general, depend upon the rate at which heat is

added to the system, and therefore on the temperature difference between

the fluid and the heating surface. There is, therefore, no meaningful

limit of the heat transfer coefficient for boiling as the temperature

difference tends to zero.

T h e necessity for a simultaneous solution of the equations of motion

and energy renders free convection a more difficult problem, at least

from a mathematical standpoint, than forced convection. T h u s even

when all properties (except density) are constant, superposition is

prohibited by the nonlinearity of the equations; neither does the heat

12

W. B. HALL

transfer coefficient tend to a constant value as the temperature difference

decreases. Nevertheless, it is possible to make a simplification when the

property variations are small. This arises because the term in the

momentum equation that links it (through temperature variation) with

the energy equation involves the difference between the fluid density

and the density that would be obtained if there were no heat transfer;

this term is still important even when changes in density are entirely

negligible in those other terms of the equation where it occurs as a factor.

This simplification, which is implicit in most free convection theory, is

of doubtful validity near the critical point at all but the smallest temperature differences.

2. The Limit as Temperature Di#erence Tends to Zero

While this limit may be of little practical significance, it is often useful,

as mentioned, as a device for separating the effects of property variation

from heat transfer and fluid flow phenomena. It has been suggested in the

preceding section that this limit is relevant only to the cases of conduction, forced convection, and, in a more restricted sense, to free

convection; these cases are considered in more detail in the following.

a. Conduction. Consider the problem of steady conduction through

a slab of fluid at a slightly supercritical pressure, the two surfaces of the

slab having temperatures which span the critical temperature. If the

temperature difference is large, then there will be a thin layer of fluid

in the interior of the slab in which the thermal conductivity exhibits a

peak. If the thickness of the layer is small in relation to the thickness of the

slab, the effect of the peak in conductivity will be negligible. If, however,

the temperature difference is small, the whole of the fluid may have a

conductivity equal to the peak value. Is it then possible that a reduction

in temperature difference could, by increasing the average conductivity

of the fluid, increase the heat flux through the slab ? T h e answer may be

obtained as follows: From the definition of conductivity, k,

=

--~(~)a~/ax

where q is the heat flux through the slab and x is the distance in the

direction of heat flow. Thus

where b is the thickness of the slab, T I is the temperature of the cold

surface, and Tz is the temperature of the hot surface. Equation (10)

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

13

is illustrated in Fig. 5 , which is drawn for a fluid which has an infinite

value of K at the critical temperature, but for which JK(T)dT through

the critical temperature is finite.

'I

'2

Temperature, T

+

FIG.5. Illustration of conduction through a supercritical pressure fluid, Eq. (10).

(Note: if, following Rowlinson (I),we express K( T) near the critical

point of the form

k = C I T - TC (-0.2

then

1K

dT

=

C I T - TC1O.*/0.8

which remains finite as we pass through the critical point.)

Referring to Fig. 5 and Eq. (lo), we see that for a slab of fixed thickness,

the heat flux is proportional J k( T) dT. If TI is held constant, then q can

only decrease as T, is decreased. On the other hand, if the temperature

14

W. B. HALL

difference is maintained at a constant small value, the heat flux will,

of course, change as the temperatures traverse the range. T h e matter

may be summarized by saying that it is not the fact that the conductivity

may become infinite which is important, but that its integral through

the critical temperature remains finite.

Unsteady conduction depends upon the density and specific heat of

the fluid as well as on the thermal conductivity. With constant properties

it is possible to group these three quantities into a single parameter,

klpc,, the thermal diffusivity, which governs the rate of transmission of

temperature changes through the medium. With variable properties the

parameters are k/pc, at some reference condition plus parameters which

express the property variations with temperature. T h e question then

arises as to whether the fact that k/pc, becomes zero at the critical point

(because c, has a stronger infinity than that in k at the critical point)

has any heat transfer significance. T h e matter may be resolved by referring to the unsteady conduction equation which, for a constant pressure

system, may be written in the two identical forms

and

where qz ,qsl ,qz are the heat fluxes in the x-, y-, x-direction.

T h e first equation contains quantities (c, and k) which become infinite

at the critical point. However, it has been shown above that $ k dT

remains finite through the critical temperature; the same is true of J’cP dT.

T h e second equation therefore does not contain any singularities, and the

only heat transfer effect will be that %/at will momentarily become zero

as the temperature of the fluid passes through the critical temperature.

A zero value of the thermal difiusivity does not imply in this case that

the fluid is impervious to heat!

b. Forced Convection. Steady state forced convection is governed by

equations of motion together with an energy equation which is formally

similar to that for unsteady conduction, (see Section 111). As with

conduction, therefore, the singularities in k and cp do not have the implications that might at first be attributed to them; i.e., the zero value of

klpc, does not prevent the diffusion of heat into the flow.

As the temperature difference tends to zero, convective heat transfer

HEATTRANSFER

NEAR

THE

CRITICALPOINT

15

tends to a constant property process, and one might expect the usual

correlations to apply, i.e., for a pipe flow

or@

0.023 Reo.8(c,p/k)u.4

which, for a constant mass flow in the pipe gives a proportional to

kO .6,-Cp”. 4,

.4.

In other words, the heat transfer coefficient becomes infinite at the

critical point as the temperature difference tends to zero. This fact has

little practical significance again because the integrals of k and cp with

respect to temperature remain finite through the critical temperature.

Thus the heat flux will remain finite as the temperature difference tends

to zero.

c.

Free Convection. T h e remarks made about the singularities in k and

cp in connection with conduction and forced convection apply equally to

free convection. There is, however, an additional aspect which deserves

mention. I t will be shown in Section I11 that one of the dimensionless

parameters governing free convection, the Grashof Number, arises

naturally from the basic equations in the form

Gr

= gd3 dp/v2p

where d p is a characteristic density difference, usually that between the

fluid at the heated surface and that outside the thermal layer. Because

most normal fluids have a fairly constant expansion coefficient, /3, it is

convenient to write the Grashof Number in the form

Gr

= gd3,6A T / v 2

If this form is used at the critical point, then difficulties will arise

because /3 becomes infinite. Reverting to the original expression for Gr,

however, we see that the true Grashof number remains finite because dp

(corresponding to a given value of A T ) remains finite as the system

temperature traverses the critical temperature.

111. The Equations of Motion and Energy

Well established techniques exist for simplifying the basic equations

when they are to be applied to constant property fluids in particular

circumstances. Thus, for example we frequently use “boundary layer’’

forms of the equations and sometimes neglect the effects of viscous

dissipation, buoyancy forces, and pressure gradients. We now consider

16

W. B. HALL

whether the same techniques may be applied to variable property flows.

We begin with the equation of continuity, momentum, and energy for a

two-dimensional, nonturbulent boundary layer flow (with the x-coordinate in the upward direction)

Continuity:

= u - - - + Tay

ax + per ax

ay

ay

ah

pu -

Energy:

ap

ah

a4

au

(13)

I t is an advantage to use the above form of the shear stress and heat

flux terms when the physical properties p and k vary, as they do, in an

eccentric manner near the critical point. Thus, even though k may

become infinite at the critical point, aT/ay will simultaneously

become zero, the product q = --K 8Tjay remaining finite at some value

between zero and the maximum value q,, at the wall. It is much easier to

make reasonable estimates of q and T than of aT/ay and aujay.

Similar equations may be written down for a turbulent flow. Putting

u =B

u', etc., for the mean and fluctuating components, we find that

the equations become

+

-x

-a@

dp

pu-+pv-=--+--pg

ax

ay

ax

a7

-

ay

where T and q are now given by

Our first concern will be to establish the conditions under which

we may neglect the first and third terms on the right-hand sides of

Eqs. (15) and (16) with respect to the second term in each equation.

I n establishing criteria for neglecting these terms we shall employ

constant property empirical relationships for such quantities as boundary

layer thickness, 6, friction factor,f, and Stanton number, St. T h e criteria

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

17

will therefore be very approximate and will certainly give no indication

of the effect that the terms may have if they are large. We then investigate

the relative importance of the turbulence terms in Eqs. (17) and (18), and

attempt to express them in terms of time mean flow quantities.

We shall consider a boundary layer and a “fully developed” channel

flow. T h e latter type of flow frequently arises with constant property

fluids but is less likely when properties change significantly in the direction of flow; the analysis must therefore be treated with reserve until the

hypothesis can be tested adequately.

A. BOUNDARYLAYERFLOW

T h e turbulent form of the equations will be used, since turbulent

conditions are of the greatest practical interest. If Eq. (15) is applied

to the (nonturbulent) free stream outside the boundary layer, we find

-dWx

= P P , au,lax

+ p,g

(19)

which may be inserted in Eqs. (15 ) and (16), giving

-a@

pu-

ax

+ -ai

pvay

au,

= Ps%%

aT

++ (Ps -P)g

aY

T h e first term on the right-hand side of Eqs. (20) and (21) represents

the effect of the acceleration of the free stream; the last term in Eq. (20)

represents the effect of bouyancy forces; the last term in Eq. (21)

represents the effect of viscous dissipation. We now consider the

magnitudes of these terms in relation to & / ~ J J and aqjay.

1. Buoyancy Eflects

T h e magnitude of 1

I is of the order ~ ~ (where

/ 6 T~ is the wall

shear stress and 6 the boundary layer thickness), and the buoyancy term

therefore may be neglected if

(Ps

-P)gS/70

<1

This will have a maximum value at the wall where

criterion may therefore be written

2 Gr 6

<I

fW,

P

= po

, and the

W. B. HALL

18

where

Gr

Re = u,x/vs ;

= ( p S - p0)gx3/pSv,2;

if

= TO/pSus2

and x is the distance from the start of the boundary layer.

Empirical data for a turbulent boundary layer with a uniform velocity

and Qf = 0.0295 Re-0.2

free stream show that S/x = 0.037

(interpreting 8 as the momentum thickness).

Thus the above criterion becomes, approximately,

Gr/Re2

<< 1

2. Dissipation

T h e dissipation term in Eq. (21) may be neglected if

This will have a maximum value at the wall where

so that the criterion may be written

where

St

= qO/pSuS

Ah;

7

&/ay = r o 2 / p 0 ,

E = u,'/Ah

and Ah is the enthalpy difference from surface to free stream. T h e group

E is the Eckert number, ususally quoted for a constant property situation

(at constant pressure) as u,"/c, d T .

Using again empirical data for a turbulent boundary layer, the

preceding equation becomes, approximately,

E

< 1000

(25)

(The viscosity ratio has been omitted since it will always be between

about 0.5 and 1.0.)

3 . The Effect of Free Stream Acceleration

An acceleration of the free stream produces a pressure gradient which,

acting uniformly on the boundary layer, causes it also to accelerate.

T h e difference, psus &,/ax - P. &/ax, (Eq. (20)), is available for

modifying the shear stress gradient, a ~ / a y and

,

is greatest at the wall

where pU Z j a x = 0. Thus the change in the shear stress gradient at

the wall can be neglected only if psu, au,/ax is much less than ~ ~ / 6 .

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

19

Thus acceleration of the free stream is negligible if

i.e., if

2

s

K-Re-<I

where

f

r

Using empirical data for a turbulent boundary layer, this reduces to

the form

KRe<1

(27)

In a similar manner, the criterion for neglecting the acceleration term

in Eq. (21) is found to be

KKeE<I

(28)

[Note: I n Sections 111, A, 1 , 2, and 3, it has been assumed that the order

' qo:8,

8

respecof magnitude of I &/dy I and I dq dy I is given by ~ ~and

tively. While this is true for the greater part of the thickness of the

boundary layer, it is not true very close to the wall where, for a boundary

layer with a uniform velocity free stream, both &lay and aq,lay become

zero. This means that, for example, viscous dissipation could be significant in a thin layer close to the wall even if the above criterion (Eq. (25))

is satisfied. However, when one reflects that it is the integrated effect

across the boundary layer that matters, the discrepancy is of little

importance. I n view of the fact that the equations are to be integrated,

it would perhaps be better in the first place to compare for exampIe qo

with Ji T a&,laydy.]

T h e virtue of using the shear stress and heat flux in the preceding

equations is seen to be that one can more easily establish criteria for

neglecting certain terms in the eqautions. This is difficult when the

transport properties are introduced, in view of their very drastic variation.

If, however, one wishes to predict the effect of buoyancy forces

(rather than establishing when they may be neglected), then the problem

is much more difficult: the matter is considered in Section VI.

B. CHANNELFLOW

T h e terms containing the pressure gradient can also be eliminated

when Eqs. (15) and (16) are applied to channel flow. Suppose we have a

W. B. HALL

20

channel formed by parallel planes a distance 2b apart, and that fully

developed conditions are established (i.e., p T aii/ax independent of y ) .

Integrating Eq. (15) from the wall to the center plane of the channel

gives

or

wheremis the mass flow through the channel per unit width. [Note that the

assumption of uniform aii/ax across the channel is inconsistent with the

acceleration resulting from a pressure gradient which is uniform across

the channel; this would give uniform jiiaiijax. However we shall get

a good estimate of the pressure gradient if we take the gradient of the

mean velocity, diim/dx, in Eq. (29).]

Substituting Eq. (29) into Eqs. (15) and (16) we get, noting that

p. = 0,

As in the case of the boundary layer, we now consider the conditions

under which dissipation, buoyancy forces, and acceleration may be

neglected.

1. Buoyancy Effects

If we consider the case where dii,/dx

=

0 then Eq. (30) reduces to

+ ( a ~ / a+~ G) m -

0 = (~o/b)

And if we use the approximation -&/ay M T ~ / Z J (which is certainly

true if (pm - p ) g is small), then T~ is indeterminate. The point is that

when buoyancy effects are present, they are balanced by the change in

&/ay from its initial value of ~ , / b .Thus, if the buoyancy force assists

the pressure flow near the wall, then I a ~ / a Iy will be greater near the

wall. Buoyancy forces will be significant, therefore, if they are able to

y

the value 7o/b. Thus once

produce a significant change in a ~ / a from

again the criterion becomes

&Pm

-P)g/To

<< 1

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

21

As in the boundary layer case, this may be expressed in terms of the

Grashof and Reynolds numbers

Gr/(Re)l.s

< 0.1

(32)

where in this case

Buoyancy effects are frequently important in forced convection with

supercritical fluids, and have rather large and unexpected results; these

are discussed in Section VI.

2. Dissipation

Following the same argument as that for a boundary layer we find

which, using empirical data for channel flow, becomes

Reo.* E

< 100

where, in this case, Re = u,(4b)/vm and E

(33)

=

urn2/&

3 . Acceleration Efects

Whereas with the boundary layer the acceleration was imposed by

applying a pressure gradient to the free stream, in the case of a channel

of uniform cross section it will occur because of the expansion of the

fluid as it is heated. T h e effect will be greatest at the wall where

P. &/ax = 0 in Eq. (30), and the acceleration term will be negligible

with respect to rO/bif

m

2b dx

b

T~

-

li2 du,

2r0 dx

T h e value of du,/dx may be assessed by calculating the rate of expansion of the fluid as it is heated by the specified heat flux q,, through the

channel walls. As an approximation, this calculation is based on mean

values of the variables taken across the channel (denoted by subscript m).

We find that

dii,,,ldx w e,,$ dhm/dx = 2 q o ~ m ~ m 1 ~ ~ , ,

22

W. B. HALL

T h e criterion then becomes

If we again assume that St m f / 2 this becomes

(Note that for a perfect gas this would become ATIT. T h e group

3/, dh,C,, may in fact have a value of order unity near the critical point,

so that it will not normally be safe to neglect acceleration effects. However, we shall usually find that, unless the pipe diameter is very small,

buoyancy effects are even more important.)

Turning to the energy equation, Eq. (31), we find that the term

k , / b (and the acceleration term (iifi/2b)(diiWJdx),which will usually be

less than U T , / ~ except very close to the critical point where it may be

of the same order) can be neglected if

or

(provided again that St w f / 2 )

C. THETURBULENT

SHEAR

STRESS

AND HEAT FLUX

Equations (17) and (18) define the turbulent shear stress and heat

flux for a variable property fluid. If we are to draw on the large volume of

data on turbulent diffusion in constant property fluids, we must make

( 18) and theircountersome estimate of the differences between (1 7) and

parts for constant property fluids (i.e,, T~ = -pu'v' and q1 = ph'v').

1. The Effect of Variable Properties on T~ and qt

T h e relative magnitude of the terms in Eqs. (17) and (18) may best

be displayed by expressing the equations in dimensionless form. Thus,

we define the dimensionless quantities

HEATTRANSFER

NEAR

CRITICAL

POINT

THE

23

and the subscript s refers to a reference condition, e.g., the free stream.

Equations (17) and (18) then become

7t =

-

-

-@,2 U'V."- pau,U R'U'

qt =

-

Ah H'V'

-

p , ~ , 2R'U'V'

(36)

+ pI Ah 6 R H ' + p p , Ah R H ' V '

__

(37)

T h e fluctuations, R' and H', may be expressed in terms of the dimensionless temperature fluctuations, 8', provided that we may assume that

the turbulent pressure fluctuations are small compared with the mean

pressure.

Thus, if 6' = T'jAT, where AT = To - T , ,

AT

R'=8'-Ps

( aapT )

P

-

-8'f-AT/3,

where

Ps

1

a=-(+

v

av

a2

We now make the assumption that 8' m U', and that the correlations

between 0' and other quantities are the same as between U' and those

quantities. This is the crucial assumption and can be justified only by

appealing to an analogy between the temperature and x-direction velocity

fields. Thus the velocity fluctuations u', normalized by the overall velocity

difference, us are compared with the temperature fluctuations T ' ,

normalized by the overall temperature difference; both are seen as the

result of turbulent transport by the fluctuating velocity 71' in the transverse direction. While this argument is of doubtful validity with extreme

property variations, it probably gives the correct order of magnitude of

the terms.

With these assumption, Eqs. (36) and (37) become

-@82[U'V' - (ti/uS)/3 AT U'U' - /3 AT U'U'V']

___

=~u~c~AT[UV'-(U/U~)B~T

-/3ATU'U'V']

U'U'

~

T~

~

=

~

qt

(38)

(39)

T h e following comments can be made about the quantities in these

equations:

I U'U' I because the correlation between u' and v'

(i) I U'V' I

is usually about 0.4

-

(ii)

u"v'<u

<" because

I U' I

<1

<

us

(iii) for a boundary layer or channel flow 3

(iv) the product /3 AT, which for a perfect gas is ATiT, probably

does not exceed unity except very close to the critical point.

W. B. HALL

24

On this basis, therefore, the last two terms in Eqs. (38) and (39) are

probably negligible, and the expressions revert to the constant property

form. There is one very important point to note, however: while the

expressions for T~ and qt may remain the same, the magnitudes of the

correlations &’ and h’v’, when expressed in terms of the mean flow

quantities, will almost certainly be different. Thus, for example, Hall

el a1 (7) have suggested that the effect of the relatively large expansion

of the fluid undergoing turbulent diffusion may significantly affect the

turbulence level. I t seems likely that such effects will outweigh any errors

resulting from the omission of the lower order terms in Eqs. (38) and (39),

and we therefore proceed using the constant property forms for T~ and q1 .

2.

r t and ql

in Terms of Time Mean Flow Quantities

There is, at present, insufficient data to assess accurately the effect of

T h e approach

variable properties on the correlations UTand

adopted in Sections IV, V, and VI is to use a “mixing length” model

of turbulent diffusion in which

m.

where I is the “mixing length,’) and E is the turbulent diffusixity.

(Townsend (8) has shown that such a model may be derived from the

equation governing the production, dissipation, convection, and diffusion

of the kinetic energy of turbulence, under circumstances when the

production and dissipation are in local equilibrium.)

An assumption concerning the variation of I throughout the flow thus

enables the turbulent shear stress and heat flux to be related to gradients

of the time mean quantities ?i and h. A common assumption is that

I = 0.4y, at any rate in the region close to the wall. From what has been

said, this relationship might well be affected by variable property effects

in supercritical fluids.

An alternative method of specifying the level of turbulent diffusion

is to establish a relationship between the turbulent diffusivity, E , and

position in the flow. This is quite permissible, but one must remember

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

25

that the expressions in common use are based on measurements in

which the shear stress distribution in the flow has its normal constant

property value. From the definition of E we see that it may be expressed

as

and

where d is a characteristic dimension, and s refers to a reference condition

such as the free stream.

Thus, provided that the shear stress distribution, T / T ~is always the

same, that ps/p M 1, and that 1 can be expressed in terms of y, then

E / V , = f (Re, y/d). I n

many supercritical heat transfer problems,

however, buoyancy forces are large enough to change significantly

the shear stress distribution; it is then important to avoid the use of an

expression for E/V, which has in it an implicit assumption concerning

T / T ~

. T h e matter is discussed in more detail in Section VI.

IV. Forced Convection

Almost the whole of the data on forced convection near the critical

point has been obtained using pipes or channels of uniform cross section,

in most cases with a uniform heat flux boundary condition. This apparently simple situation has nevertheless yielded a diversity of experimental

results that is matched only by the range of correlations produced to

describe them! One is faced not only with discrepancies between correlations, but also between sets of data which have been obtained under

apparently similar conditions. This interesting situation cannot be

attributed solely to inadequate experimental techniques, and one must

question whether there are some important factors which were not controlled in the experiments.

We begin by discussing the manner in which forced convection heat

transfer data are commonly presented and the difficulties that arise when

physical property variations are severe. T h e apparent discrepancies

between typical sets of experimental data and the deficiencies of current

methods of correlation are then demonstrated. Finally, the prediction

of heat transfer by numerical solution of the semiempirical equations

of motion and energy is discussed.

26

W. B. HALL

A. METHODS

OF PRESENTATION

OF DATA

Forced convection heat transfer data are frequently presented in a

form in which neither the temperature of the heat transfer surface nor

that of the fluid is given explicitly. T h e implication is that the heat

flux is proportional to the temperature difference between surface and

fluid, and that any effect due to the general level of temperature can be

adequately expressed by evaluating the physical properties of the fluid

at some characteristic temperature, e.g., the bulk mean fluid temperature.

Proportionality of heat flux and temperature difference occurs with

constant property fluids and is a consequence of the facts that the energy

equation is linear in temperature, and the heat transfer process does not

affect the flow process. Presentation of data in this form is inappropriate

for fluids near their critical point, and confusion often results when data

are forced into such a pattern.

T h e matter is best illustrated by presenting the same data in a variety

of forms; this is shown as follows for the case of carbon dioxide at a

pressure of 75.8 bars flowing in a downward direction in a heated

vertical pipe of diameter 1.90 cm (9). (The pressure of 75.8 bars is

somewhat above the critical pressure (73.8 bars). It is usual to relate the

behavior of the fluid to the "transposed critical temperature," Tpc,

the temperature at which the specific heat reaches its maximum value.

At the pressure of 75.8 bars this temperature is 32"CJrather than the

critical temperature of 31.04"C.) Data were obtained for upward flow,

but these gave anomalous results which will be discussed in Section VI.

1. The Experimental Measurements

T h e quantities measured in the experiments were the mass flow of

CO, the fluid inlet temperature, the heat input (which was arranged to

give a very nearly uniform wall heat flux into the fluid), and the temperature of the pipe wall. T h e latter temperature was measured at

intervals of one pipe diameter along the length of the test section. Typical

results are given by the full lines in Fig. 6 , which shows the variation

in wall temperature, T o , along the pipe for three different heat fluxes

but with the same mass flow and inlet fluid temperature. T h e complete

set of results for this mass flow involves three different fluid inlet temperatures each with five different heat flux levels, i.e., fifteen curves in all.

Results in this form embody the whole of the information and should

always be made available in tables if not also in graphs. Subsequent

operations all involve either the input of physical property data (sometimes of doubtful accuracy) or the use of some simplifying hypothesis such

as the elimination of an experimental variable or its combination with

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

27

another. Difficulties are caused not by the well-intentioned attempt to

find simpler means of expressing the results but by the rejection of

information; it may be impossible to recover this from partly processed

results. It is unfortunate that a great deal of the heat transfer data on

supercritical fluids are of considerably less value than they should be

because of such omissions.

;

W a l l temperature

_----_----

-__--,------_--,---__----

Bulk ternperoture

\-/--___----*_ _ - &

*_--

-#

--

&&*-k==

0

20

40

60

a0

100

Distance from start of heatmg (diameters)

120

I

140

FIG. 6. Temperature distribution along a I .9-cm diameter vertical pipe for downward

flow. Carbon dioxide at a pressure of 75.8 bars and a mass flow of I60 gmlsec. (a) wall

heat flux, 3.09 W/cmZ;(b) wall heat flux, 4.05 W/cmz; (c) wall heat flux, 5.19 W/cm2.

2. Description in Terms of Local Conditions Only

One of the most useful concepts in forced convective heat transfer is

that of “fully developed” fluid flow and heat transfer conditions in a

pipe. It is asserted that both the velocity and the temperature distributions across a pipe will become invariant aftes a certain distance from the

pipe inlet. (Note that in the case of temperature it is only the shape of the

distribution that remains unchanged since the bulk temperature must, of

course, increase as heat is added.) There is ample evidence to show that

such conditions are established in about 10 to 20 pipe diameters with a

turbulent constant property fluid and a uniform cross section pipe; and

if we therefore exclude the “entry region,” the heat transfer coefficient

will be independent of position along the pipe. I n the case of a fluid

whose properties change with temperature, and therefore with distance

along the pipe, the hypothesis of a “fully developed” condition is less

plausible and must be tested experimentally.

28

W. B. HALL

Figure 7 shows the results, of which Fig. 6 is a sample, presented in the

form of heat flux against wall temperature, with the bulk fluid temperature

T , as parameter. For this purpose it is necessary to calculate the bulk

fluid temperature along the pipe (shown by dotted lines in Fig. 6);

this may be done by applying a heat balance from the pipe inlet to the

point in question and requires an accurate knowledge of enthalpy as a

function of temperature. The hypothesis is then made that the heat

transfer rate (expressed as heat flux for particular values of wall temperature and bulk temperature) is independent of the point along the

pipe at which these particular conditions occur; the result is Fig. 7.While

w a i l temperature

("c)

FIG. 7. Heat flux versus wall temperature for various bulk fluid temperatures. Same

data as for Fig. 6. Bulk fluid temperature: ( O ) , 19°C; (+), 22°C; (v), 25°C; ( x ) , 28°C;

(O), 31°C.

there is a good deal more scatter of the experimental results than in

the curves of Fig. 6 (in which the experimental points fall within 0.1"C

of the smooth line drawn through them), the result does suggest that

the heat transfer process is very largely governed by local conditions.

The lower parts of the curves are drawn in broken lines because no

results were obtained in this region; it is possible, however, to fix the

point at which they intersect the To axis because at this point q = 0

and To = T , . Incidentally, the slopes of the curves as they cross the To

axis give the limiting value of the heat transfer coefficient as the temperature difference tends to zero.

HEATTRANSFER

NEAR THE CRITICAL

POINT

29

3 . Presentation in Terms of a Heat Transfer Coejicient

This form of presentation is shown in Fig. 8 in which the points are

the same as those of Fig. 7. The heat transfer coefficient is by no means

independent of either the wall temperature or the bulk temperature.

This being so, one must question whether the concept of a heat transfer

coefficient has any useful purpose to serve since the results could equally

well be presented as in Fig. 7. It may perhaps be useful to see whether the

results show a tendency towards a constant heat transfer coefficient in

certain limiting conditions; for example, it appears that this may be so as

the wall temperature increases, the bulk temperature still being below

the transposed critical temperature. However, one might easily be

misled by Fig. 8 into thinking that high heat fluxes could be achieved

with small temperature differences whereas Fig. 7 shows that this is not

the case.

0.5

"

0

N

5

-3\

0.4

C

m

.r

c

"

0)

0

L

2

0

--

03

0

0

0

I

+ A x

0

0.2

I

I

20

I

I

40

Wall

temperature

I

I

60

I

J

80

("c)

FIG. 8. Heat transfer coefficient versus wall temperature for various bulk fluid

temperatures. Same data as for Figs. 6 and 7. Bulk fluid temperature: (a),19°C; (+),22"C;

(A), 25°C; ( x), 28°C; ( o ) ,31°C.

30

W. B. HALL

T h e usefulness of the heat transfer coefficient when applied to supercritical fluids has been questioned by Goldman (10); he has suggested

that rather than expressing heat transfer results as a relationship between

Nusselt number, Reynolds number, and Prandtl number, it is more

appropriate to collect together all the terms in the dimensionless groups

that are temperature dependent. Thus starting from the assumption that

Nu

=c

Ren Prs

(42)

where c, n, and s are constants, he obtains

qod'-"/(P)"

= f(T0 I

Tm)

(43)

This presentation is rather like that of Fig. 7 except that it postulates a

specific form of variation with pipe diameter, d, and mass velocity, pu,

whereas the data of Fig. 7 are for one pipe diameter and one mass velocity

only. Equation (43) is, however, no more valid than Eq. (42) from which

it was derived; there is no a priori reason to suppose that with a supercritical fluid Reynolds number and Prandtl number effects are adequately

represented by an equation of the form of Eq. (43).

4. Presentation in Terms of Dimensionless Groups

T h e data of Fig. 8 are shown in dimensionless form in Fig. 9. T h e

form of correlation that has been used is due to Miropolsky and Shitsman

(11) and is of the form

Nu,

= c(Re,)"

(Prmjn)8

(44)

T h e physical properties in the Nusselt number and the Reynolds

number are evaluated at bulk temperature, but the Prandtl number is

the lower of the two values obtained by evaluating properties at the wall

temperature and at the bulk temperature. T h e exponent n has been

chosen as 1.4 to give the best fit to the results, and thus N u , , / ( R ~ , ) ~ . ~

has been plotted against Prmin.

While the correlation appears at first sight to be reasonably good,

it should be noted that in fact the scatter is a good deal more than in the

original data or in the form of presentation shown in Fig. 7. Bearing in

mind the restriction which must be placed on its use in conditions

outside the range of the data on which it is based, the use of such a

correlation is of doubtful value. An even more serious criticism is the

fact that it is impossible to recover the original data from such a presentation of results.

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

31

t

FIG. 9. Correlation of the data shown in Fig. 8. (Physical properties based on bulk

temperature for N u and Re; Prmj,,is the lesser of the values at wall and bulk temperatures.)

B. EXPERIMENTAL

DATA

Existing data for forced convection have been reviewed by Hall,

Jackson, and Watson (12). Most experimenters have used circular cross

section pipes with a uniform heat flux boundary condition. I n spite of the

very considerable amount of data that exists, the situation is still somewhat confused; it is not simply that one is unable to correlate the results

in terms of the usual parameters, but rather that one suspects that there

may be some important parameters that have not been controlled. T h e

situation is made worse by the fact that in some cases experimental

results have been presented in “correlated” form, and the physical

property data used in the correlation has not been quoted. Little purpose

would be served in presenting a detailed review of experimental data

here; it is perhaps more useful to identify the important discrepancies and

to consider what physical factors may have been responsible for them.

Figures 10 and 1 1, which are based on uniform heat flux measurements

in a circular pipe using water (2.3-16), illustrate some of the apparent

discrepancies between experiments. In all cases the measurements

were made in pipes of circular cross section with a uniform wall heat

flux, 4, into the water. Provided that the entry conditions are similar,

one would expect the wall temperature to be a function of the bulk

enthalpy, the mass velocity of the water, the pipe diameter, and the wall

heat flux. T h e latter three parameters are quoted on the figures, and the

W. B. HALL

32

580

560

540

5 20

500

4 80

u 460

.e

P

4 40

420

400

380

360

340

1600

1800

2000

2200

2400

2600

2800

Bulk e n l h o l p y (J/grn)

FIG. 10. Experimental wall temperature distributions as a function of local bulk

enthalpy along a pipe. p* = 1.05 (W. B. Hall, J. D. Jackson, and A. Watson, “Symp,

Heat Transfer and Fluid Dynamics of Near Critical Fluids.” Proc. Znst. Mech. Eng. 182.

Part 31 (1968)). (a) Shitsman (13): q = 34 W/cm*, ni/A = 43 gm/sec cm2, d = 0.8 cm

vertical. (b) Shitsman (13):q = 28.5 W/cm*, m/A = 43 gm/sec cmz, d = 0.8 cm vertical.

(c) Shitsman (13):q = 28.0 W/cm*,& / A = 43 gm/sec cmB,d = 0.8 cm vertical. (d) Domin

(IS):q = 72.5 W/cmz, &/A = 68.6 gm/sec cm*, d = 0.2 cm horizontal. ( e ) Domin (15):

q = 72.5 W/cm2, m/A = 72.4 gm/sec cm2, d = 0.2 cm horizontal.

first is used as abscissa; Fig. 10 is for a pressure closer to the critical than

Fig. 11. While it is not possible to make direct comparisons between the

various experiments, it is difficult to believe that the sharp peaks of wall

temperature in Shitsman’s data, the broader peaks of Domin, of Vikrov

and Lokshin, and of Schmidt, and the sharp depression of wall temperature observed by Domin (Fig. l l ) , all form part of a single consistent

pattern. Nevertheless one can identify certain trends, as follows:

(i) I n all cases where the wall temperature behaves in an anomalous

manner, it does so just before the bulk temperature reaches its critical

value.

(ii) There is a strong heat flux effect evident in all four sets of data;

that is to say, the heat transfer coefficient is strongly dependent on heat

flux. This is strikingly illustrated by Shitsman’s data (curves a, b, and c

on Fig. 10).

(iii) There is evidence both for a local improvement and also for a

local deterioration in heat transfer when the critical temperature lies

between the wall temperature and the bulk fluid temperature.

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

33

Recent data have shown that one of the factors which is important in

forced convection is the orientation of the pipe. Of the above sets of data,

only Shitsman’s was obtained for a vertical pipe, the remainder being

horizontal. This matter will be dealt with in more detail in Section VI.

T h e experimental evidence for local increases and decreases in heat

transfer coefficient are summarized in the following.

“

/

Bulk fluid

temperalure

/

1750

2000

2250

2500

Bulk enthalpy (J/gm)

FIG. 11. Experimental wall temperature distributions as a function of local bulk

enthalpy along a pipe. p * = 1.15 (W. B. Hall, J. D. Jackson, and A. Watson, “Symp.

Heat Transfer and Fluid Dynamics of Near Critical Fluids.” Proc. Inst. Mech. Eng, 182,

Part 3 I (1968)). (a) Vikrev and Lokshin (16): q = 69.9 W/cm2, rit/A = 100 gm/sec cma,

d = 0.8 cm horizontal. (b) Vikrev and Lokshin (16): q = 69.9 W/cm2,1h/A= 40gm/seccm2,

d = 0.8 cm horizontal. (c) Schmidt ( 1 4 ) : q = 58 W/cmz,rit/A = 61 gm/sec cm2,d = 0.5 cm

horizontal.(d) Schmidt (14): q = 82 W/cm2,rit/A = 61 gm/sec cm2,d= 0.5 cm horizontal.

(e)Domin (15):q = 91 W/cma,rh/A = 101 gm/sec cm2,d = 0.2 cm horizontal.(f) Shitsman

(13):q = 39.6 W/cm2, rh/A = 44.9 gm/sec cm2, d = 0.8 cm vertical.

1. Local Increases in Heat Transfer Coefficient

One example of this has already been mentioned (Fig. 11, curve e ) .

A similar effect has also been found in experiments with CO,, three

examples of which follow:

(a) T h e data of Figs. 7 and 8 clearly show an enhancement in the

heat transfer coefficient for conditions in which the heat flux is small and

the critical temperature lies between the wall and bulk fluid temperatures.

W. B. HALL

34

As the heat flux is increased the enhancement becomes less marked.

It is important to note that these data were obtained with a downward

flow in a 1.905-cm diameter vertical tube; results for upward flow can be

quite different, as will be shown later.

2 .o

TPC

0

0

I

O I

0 O1

0

28

30

Bulk

32

34

temperature

36

38

("C)

FIG. 12. Variation of the heat transfer coefficient with bulk temperature for forced

convection in a heated pipe. Data of H. Tanaka, N. Nishiwaki, and M. Hirata, Turbulent

heat transfer to super-critical carbon dioxide. Nippon Kikai Gakkai Rombunshu ( 1 967).

(Carbon dioxide at a pressure of 78.5 bars flowing upwards in a 1.0-cm diameter vertical

pipe.) 0 Theory; ( A ) exp.: G = 140 f 4.4kg/hr, q = 1.44 W/cma. @ theory;

( X ) exp.: G = 140 f 3.1 kg/hr, q = 2.73 W/crne. @ theory; ( 0 )exp.: G = 280 f 5.6

kg/hr, q = 3.32 W/cm2. @ theory; ( 0 ) exp.: G = 280 If 7.8 kg/hr, q = 5.20 W/cm2.

(b) T h e data of Tanaka, Nishiwaki, and Hirata (17) are shown in

Fig. 12. Peaks in heat transfer coefficient occur when the bulk temperature is slightly below the transposed critical temperature, the peaks

being more marked when the heat flux is low, i.e., when the wall temperature is also close to (but slightly above) the transposed critical tem-

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

35

Hot wall ternDeroture ("C)

FIG.13. Variation of heat flux through a 1 .O cm high channel (formed by horizontal

planes) with the temperature of the upper (heated) wall. (The lower (cooled) wall temperature is kept constant at 28.25"C.) (Carbon dioxide at a pressure of 75.8 bars; mass

velocity 37 gm/scc cm2). Data ofS. A. Khan, Ph.D. Thesis, University of Manchester, 1965.

perature. These results were obtained in a 1-cm diamater vertical tube

with upward flow.

(c) Hall, Jackson, and Khan (7) measured the overall heat transfer

coefficient for a flat duct 1 x 18 cm in cross section with one of the

longer sides heated and the other cooled. This arrangement produces a

situation which is basically simpler than that in a tube because it is

possible to arrange that the fluid temperature does not change in the

direction of flow. There is thus no convection, and the experiment is a

direct measure of the diffusive power of the turbulent stream. A sample of

the results is shown in Fig. 13 in which the heat flux is plotted against the

temperature of the heated wall, with the temperature of the cooled wall

as parameter. Again, there is a sharp increase in heat flux as the heated

wall passes through the transposed critical temperature (32°C in this

case), and the increase becomes larger as the cooled wall approaches

the transposed critical temperature. T h e flow in these experiments was

horizontal with the upper surface of the duct heated.

2. Local Decreases in Heat Transfer Coeflcient

There appear to be two distinct types of situations in which a local

reduction in the heat transfer coefficient occurs, both of which are

t

p = 2 4 5 bars

p - 2 4 5 bars

515

-

35 25

0

\

*

45-

8b

55-

7b

65 -

6b

75

5b

85 -

95 100

0

I

100

\ \a

200

4 4,h \

\

300

1

400

tw , t b ( O C )

FIG. 14. Wall temperature, t , , and bulk

temperature, te , as a function of distance ( x / d )

along a vertical heated pipe (1.6-cm diameter).

Upward flow of water at a pressure of 245 bars.

Data of M. E. Shitsman, “Symp. Heat Transfer

and Fluid Dynamics of Near Critical Fluids.”

Proc. Inst. Mech. Eng. 182, Part 31 (1968).

(1) m/A = 382 gm/sec cm2, q = 27 W/cm2.

(2) m/A = 382 gm/sec cm2, q = 37 W/cm2.

(3) &/A = 400 gm/sec cmz, q = 45 W/cmP.

(4) m/A = 375 gm/sec cm2, q = 52 W/cm2.

FIG. 15. Wall temperature, t , , and bulk

temperature, t B , as a function of distance ( x / d )

along a vertical heated pipe (1.6-cm diameter).

Downward flow of water at a pressure of 245 bars.

Data of M. E. Shitsman, “Symp. Heat Transfer

and Fluid Dynamics of Near Critical Fluids.”

Proc. Inst. Mech. Eng. 182, Part 31 (1968).

(5) m/A = 400 gm/sec cma, q = 27 W/cmz.

(6) A / A = 400 gm/sec cm2, q = 36 W/cmz.

(7) m/A = 393 gm/sec cm2, q = 43 W/cme.

(8) m/A = 381 gm/sec cm2, q = 50 W/cm2

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

37

illustrated in Figs. 10 and 11. T h e data of Domin, Schmidt, and Vikrov

and Lokshin, all of which are for horizontal pipes, show rather broad

peaks of temperature at higher heat fluxes; similar peaks have been

reported by Griffiths and Shiralkar (18). Shitsman’s data, on the other

hand, show sharp peaks of temperature when the flow is upwards in a

vertical pipe.

(a) Figs. 14 and 15 show some of Shitsman’s data (19) in more detail.

Wall and bulk temperature are plotted against the dimensionless distance

x / d from the pipe inlet, for several (uniform) heat fluxes. Fig. 14 is for

upward flow and Fig. 15 for downward flow. I t is seen that while there

is no anomalous behavior for downward flow, the wall temperature for

upward flow rises to a sharp peak once a particular value of heat flux is

exceeded.

(b) A very similar behavior has been found by the author’s colleagues,

J. D. Jackson and K. Evans-Lutterodt (20) using carbon dioxide

(Fig. 16). These results form part of the same series as those presented

in Fig. 6 but in this case the flow is in the upward direction. T h e pipe,

of diameter 1.905 cm, had some 200 thermocouples distributed along

its length, so that the shape of the temperature peaks could be accurately

100 110

90 -

-

-

nu

80

-

70

-

2

2 60 ?

;

c

3

50

-

40 30

-

20

-

10

‘

I

0

I

20

I

40

Dlstance from

I

60

I

80

I

I00

I

I20

start of heating ( d i a m e t e r s )

FIG. 16. Temperature distribution along a 1.9-cm diameter vertical pipe for upward

flow. Carbon dioxide at a pressure of 75.8 bars and a mass flow of 160gm/sec. Wall heat

flux (a) 3.09 W/cma, (b) 4.05 W/cm2,(c) 5.19 W/cm2,(d) 5.67 W/cm*.

38

W. B. HALL

determined. Again, there is a sharp deterioration in heat transfer once

a particular heat flux is exceeded with the flow in the upward direction.

There is one interesting difference between these results and those of

Shitsman; while it seems that the deteriorations occur in the CO, results

only after the wall temperature has passed through the transposed critical

temperature, they occur in Shitsman’s experiments even when it is

substantially below. They do however also occur in some of Shitsman’s

experiments when the wall temperature has passed the transposed critical

temperature.

(c) T h e data of Tanaka et al. (Fig. 12) was obtained under conditions

rather similar to those described in (b) above, and yet no localized

deteriorations in heat transfer were found. T h e heat flux, mass velocity,

and fluid temperatures are all similar to those used by Jackson and

Evans-Lutterodt, but the tube diameter was 1 cm rather than 1.905 cm;

it will be shown later in Section VI that this difference can account for

the differences in heat transfer behavior.

T h e deteriorations that occur in horizontal tubes are generally less

localized than those in vertical tubes with upflow. Only in a few cases

has the temperature distribution around the tube been measured;

Fig. 17 shows the temperature distribution along the upper and lower

surfaces of a heated horizontal pipe carrying a flow of supercritical

pressure water (21);there is a very considerable difference in temperature,

corresponding to a reduction in the heat transfer coefficient for the upper

surface, when compared with the lower, by a factor of about four.

While such temperature variations may have been suppressed in other

experiments by conduction around the pipe wall, there could then have

been large variations in heat flux around the circumference of the pipe.

I t is probably not worth attempting detailed comparisons between sets

of data for horizontal pipes until the question of circumferential variations

has received much more attention.

3 . Gaps in the Experimental Data

I t has been clear for some time that many of the apparent discrepancies

between different sets of heat transfer data are the result of differences

in the experimental arrangement (sometimes wrongly assumed to be of

no importance and therefore inadequately described). As mentioned,

there is strong evidence to suggest that sharp local reductions in heat

transfer occur with upward flow only and that even then they can be

suppressed by a reduction in heat flux or tube diameter. Also confusion

has been caused by the presentation of results in dimensionless form

without giving the raw measurements or the property data used.

HEATTRANSFER

NEAR

THE

CRITICAL

POINT

39

FIG. 17. Temperature distributions as a function of local bulk enthalpy along heated

vertical and horizontal pipes (1.6-cm diameter). Data of Z. L. Miropolsky, V. J. Picus,

and M. E. Shitsman, Proc. Imt. Heat Tvansj'er Conf., 3rd, Chicago, 1966 Vol. 11, Paper

No. 50 (1967). Water at a pressure of 245 bars, I ~ / =

A 60 gm/sec cm2; q = 52 W/cm'.

(1) Horizontal pipe, upper surface. (2) Horizontal pipe, lower surface. (3) Vertical pipe,

upward flow. (4) Fluid temperature.

In spite of this rather confused situation, the writer believes that the

basic forced convection problem of steady flow in vertical tubes with

uniform heating could be resolved by a relatively small amount of

experimental work. Once it is recognized that buoyancy forces are

responsible for large differences between upward and downward flow

(see Section VI), the data begin to make sense. Because of difficulties

in generalizing physical property data it is still necessary to carry out