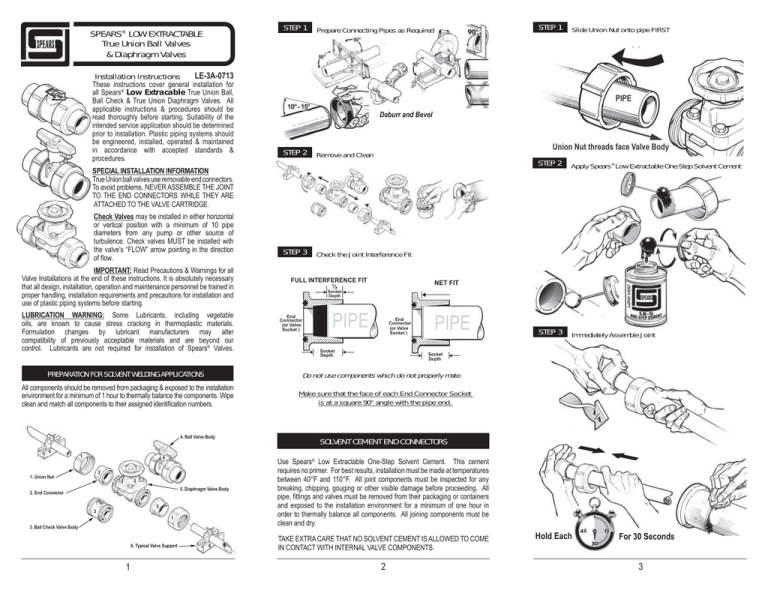

STEP 1

SPEARS® LOW EXTRACTABLE

True Union Ball Valves

& Diaphragm Valves

Installation Instructions

Prepare Connecting Pipes as Required

Check Valves may be installed in either horizontal

or vertical position with a minimum of 10 pipe

diameters from any pump or other source of

turbulence. Check valves MUST be installed with

the valve’s “FLOW” arrow pointing in the direction

of flow.

IMPORTANT: Read Precautions & Warnings for all

Valve Installations at the end of these instructions. It is absolutely necessary

that all design, installation, operation and maintenance personnel be trained in

proper handling, installation requirements and precautions for installation and

use of plastic piping systems before starting.

LUBRICATION WARNING: Some Lubricants, including vegetable

oils, are known to cause stress cracking in thermoplastic materials.

Formulation changes by lubricant manufacturers may alter

compatibility of previously acceptable materials and are beyond our

control. Lubricants are not required for installation of Spears® Valves.

PREPARATION FOR SOLVENT WELDING APPLICATIONS

STEP 2

Remove and Clean

4. Ball Valve Body

4

2

5

5. Diaphragm Valve Body

2. End Connector

2

3

1

3. Ball Check Valve Body

6. Typical Valve Support

1

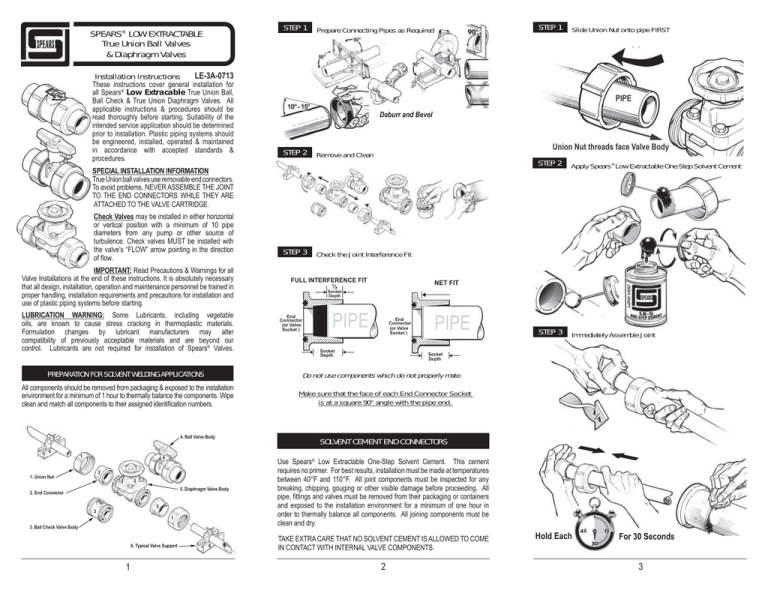

Apply Spears® Low Extractable One-Step Solvent Cement

STEP 3

STEP 3

Immediately Assemble Joint

Check the Joint Interference Fit

FULL INTERFERENCE FIT

NET FIT

½

Socket

Depth

End

Connector

(or Valve

Socket )

PIPE

End

Connector

(or Valve

Socket )

Socket

Depth

Socket

Depth

Do not use components which do not properly mate.

All components should be removed from packaging & exposed to the installation

environment for a minimum of 1 hour to thermally balance the components. Wipe

clean and match all components to their assigned identification numbers.

1. Union Nut

STEP 2

Deburr and Bevel

SPECIAL INSTALLATION INFORMATION

True Union ball valves use removable end connectors.

To avoid problems, NEVER ASSEMBLE THE JOINT

TO THE END CONNECTORS WHILE THEY ARE

ATTACHED TO THE VALVE CARTRIDGE.

1

Slide Union Nut onto pipe FIRST

LE-3A-0713

These instructions cover general installation for

all Spears® Low Extracable True Union Ball,

Ball Check & True Union Diaphragm Valves. All

applicable instructions & procedures should be

read thoroughly before starting. Suitability of the

intended service application should be determined

prior to installation. Plastic piping systems should

be engineered, installed, operated & maintained

in accordance with accepted standards &

procedures.

6

STEP 1

6

Make sure that the face of each End Connector Socket

is at a square 90° angle with the pipe end.

SOLVENT CEMENT END CONNECTORS

Use Spears® Low Extractable One-Step Solvent Cement. This cement

requires no primer. For best results, installation must be made at temperatures

between 40°F and 110°F. All joint components must be inspected for any

breaking, chipping, gouging or other visible damage before proceeding. All

pipe, fittings and valves must be removed from their packaging or containers

and exposed to the installation environment for a minimum of one hour in

order to thermally balance all components. All joining components must be

clean and dry.

TAKE EXTRA CARE THAT NO SOLVENT CEMENT IS ALLOWED TO COME

IN CONTACT WITH INTERNAL VALVE COMPONENTS.

2

Hold Each

For 30 Secondss

3

STEP 4 Repeat STEP 3 to attach opposite end connector to pipe.

Hold joint together for approximately 30 seconds to make sure that the End

Connector Socket does not back off of pipe. Use a cloth to remove any excess

cement from the exterior juncture of the pipe and End Connector.

COMPLETE VALVE ASSEMBLY

STEP 1

STEP 2 Pressure test the system only after all solvent cement

joints have fully cured

Attach Valve Body to End Connector

Allow joint to cure according to

solvent cement instructions.

THREADED END CONNECTORS

Use only quality grade PTFE tape as a thread sealant for Spears® lowextractable applications. Warning: Some pipe joint compounds or PTFE

pastes may contain substances that could cause stress cracking to plastics

and increase the potential for system contamination. 1 to 2 full turns beyond

finger tight is generally all that is required to make a sound plastic threaded

connection. Unnecessary over-tightening will cause damage to both pipe

and fitting.

g

STEP 1

IMPORTANT:

IMPORTANTE:

1/16 Turn

Apply Thread Sealant

to male threads only.

DO NOT OVER TIGHTEN

TIGHTE AS DAMAGE MAY OCCUR

PRECAUTIONS AND WARNINGS

Hand Tighten Only

CAUTION: The system must be designed and installed so as not to

pull the valve in any direction. Pipe must be cut and installed in such

a manner as to avoid all stress loads associated with bending, pulling,

or shifting. Valve must be supported.

If you must

use PTFE Tape

Sealant:

CAUTION: BEFORE THE VALVE IS CYCLED, all dirt, sand, grit

or other material must be flushed from the system. This is to prevent

scarring of internal components; e.g., ball, cup, wedge, seats, etc.

2.5 Mil Thick

Initial wrap must

fully cover the

thread end

STEP 2

WARNING: Systems must not be operated or flushed out at flow

velocities greater than 5 feet per second.

Assemble Joint “FINGER TIGHT”

WARNING: NOT FOR DISTRIBUTION OF COMPRESSED AIR OR GAS

Attach final Union Nut

to Valve Body.

WARNING:

ALL AIR MUST BE BLED FROM THE SYSTEM DURING INITIAL FLUID

FILL. PRESSURE TESTING OF THE SYSTEM MUST NOT BE MADE

UNTIL ALL SOLVENT CEMENT JOINTS HAVE PROPERLY CURED.

INITIAL PRESSURE TESTING MUST BE MADE AT APPROXIMATELY

10% OF THE SYSTEM HYDROSTATIC PRESSURE RATING TO IDENTIFY

POTENTIAL PROBLEMS, PRIOR TO TESTING AT HIGHER PRESSURES.

STEP 3

Wrench Make Up

SPEARS® MANUFACTURING

COMPANY

1-2x

CORPORATE OFFICE

Unnecessary OVERTIGHTENING will cause damage to both pipe and valve.

4

BE SURE T

THAT

HAT

A TTHE

HE FACE OF THE END CONNECTOR SOCKET IS

SQUARELY ALIGNED (FLUSH) WITH THE VALVE BODY AND IS FLUSH

AGAINST THE O-RING. DO NOT USE THE REMAINING UNION NUT TO

DRAW TOGETHER ANY GAPS BETWEEN THE END CONNECTOR AND

THE VALVE BODY.

5

15853 Olden Street, Sylmar, CA

91342

PO Box 9203, Sylmar, CA 91392

(818) 364-1611

www.spearsmfg.com

© Copyright 2015 Spears® Manufacturing Company. All Rights Reserved.

Printed in the United States of America 03/15.

LE-3A-0713