Power Resistors catalogue

advertisement

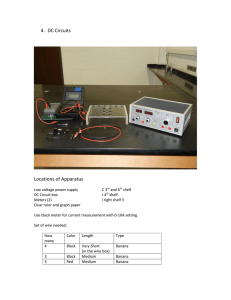

Power resistors LEADING IN SENSORS 2 LEA D I N G I N S E N S O R S TRUST THE X! Reliable Power Resistors – for safe applications! We appreciate your interest in our Metallux power resistors. Every Metallux product stands for high reliability, outstanding quality, extreme accuracy, expertise and innovation. Our company's highly-qualified consultation expertise ensures that our customers receive the best possible added value. As consultants and innovators, we are happy to support our customers. Wire resistors, in the form of classic tube resistors, or in an aluminium profile combine the high load capacity of conventional resistor materials with optimised thermal conduction. An additional performance increase is provided for compact designs with a high degree of protection for assembly on a surface with good thermal conduction properties. The series PWR-S, PWR-R and PWR-O satisfy the requirements of UL508 and are particularly suitable for applications as brake resistor, charging and discharging resistor, or also as heating resistor. Andreas Oberascher Chairman of the board / CEO METALLUX AG – founded in 1986 and for years now a leading manufacturer of sensors, membrane sensors, resistors, pressure sensors and industrial joysticks in thick-film technology. Frank Stuhr CTO Whether a standard resistor or a customised solution: Our power resistors are used in a multitude of areas, e.g. in gate control systems, in wind energy installations, in crane systems, and many more. 3 M E TA LLU X . DE PWR-c Wire power resistor in ceramic casing 4 5-6 7 8 9 10 11 12 13-19 20-21 22-23 PWR-S Wire power resistor in aluminium casing PWR-R Wire power resistor in aluminium casing PWR-O Wire power resistor in aluminium casing PWR-F Wire power resistor in aluminium casing PWR-RFI Wire power resistor in stainless steel casing PWR-GR Resistor assembly with PWR-R PWR-GF Resistor assembly with PWR-F PWR-TR Wire and tube resistors PWR-TR2xx, PWR-TR3xx, PWR-TR4xx and assembly accessories PWR-TR PWR-x Wire and tube resistors in stainless steel casing IP 20 Special designs, Applications, Enquiry form 4 P o w e r r e sis t ors PWR-C Wire power resistors in ceramic casing Wire resistors in ceramic casing are power resistors with high load capacity optimised for use in closed systems. Tried and tested resistor materials guarantee good long-term stability. Easy assembly and variable connection lines are the advantages of this Type series. 9 40 Metallux.de 4312 PWR-C30 40R/K 4.5 Ø HEW cable UL Style 1199 AWG16 60 300 40 14 Type selection and dimensions Type Sample order Without cooling PN at 25°C PWR-C 30 Resistance values PNDC=30% /W/ PNDC=100% /W/ 100 W 30 W 5R – 100R Max. voltage 600 V L1 L2 mm mm 60 40 /g/ 80 PWR-C30 50 R/J 300 mm connection lines Inductance < 0.2 mH at 1 KHz Time constant 4.5 to 5.8 min Degree of protection IP 50 Storage temperature −10°C to +50°C The duty cycle DC in percent is based on a cycle time of 120 sec. Pulse energy Parameter PWR-C 30 J 1000 300 200 100 0 0 5 10 © www.metallux.de 01/2016 15 20 25 Ω Max. surface temperature 250°C Tolerance ±5%, ±10% Temperature coefficient TC ≤ ±150 ppm/K Stability at Pnominal @ 25°C, 1000 h ±5% Max. overload capacity 10 x PNDC=100%, 5 sec Insulation resistance at 500 VDC ≥ 10 GΩ Test voltage 800 V Connection lines UL PTFE wire line AWG16 style 1199, 200°C, 600V 5 M E TA LLU X . DE PWR-S Wire power resistor in aluminium casing 2x Wire resistors in aluminium profile combine the high pulse load capacity of conventional resistor materials with optimised thermal conduction and a high degree of protection. Assembly on a surface with good thermal conduction properties improves the heat dissipation additionally and leads to an increased load capacity. The series PWR-S satisfies the requirements of UL508 and is particularly suitable for applications as brake resistor, charging and discharging resistor, or also as heating resistor. Ø 4.2 - 2.2 METALLUX.DE 0852 PWR-S100 200R/J 22 29,5max 1.5mm2 16 max L2 L1 300min. 2x 30 Ø 4.2 - 2.2 22 29.5max 1.5mm2 METALLUX.DE 0852 PWR-S100A 200R/J 30 16 max L2 L1 300min. Sample order Type selection and dimensions Type 300min. L1 L2 mm mm 300 V (40) 0R9 – 56R 400 V 60 W 1R5 – 110R 90 W 2R2 – 160R Without cooling With cooling Resistance values PNDC=30% /W/ PNDC=100% /W/ PN at 25°C PWR-S 30 20 10 30 W 0R8 – 51R PWR-S 45 30 15 45 W PWR-S 60 40 20 PWR-S 90 60 30 L3 /g/ (30) (5) 25 55 25 15 35 600 V 77 47 15 52 700 V 104 64 20 73 Max. voltage PWR-S30 35 R/J 150 mm connection lines Inductance < 0.2 mH at 1 KHz Time constant 6.6 to 7.1 min. Degree of protection IP 55 (opt. IP 65) Storage temperature 10°C to +50°C The duty cycle DC in percent is based on a cycle time of 120 sec. Pulse energy Parameter PWR-S 30 PWR-S 45 PWR-S 60 PWR-S 90 J 400 300 200 100 0 0 40 © www.metallux.de 01/2016 80 120 160 Ω Max. surface temperature 250°C Tolerance ±5% Temperature coefficient TC ≤ ±150 ppm/K Stability at Pnominal @ 25°C, 1000 h ±5% Max. overload capacity 10 x PNDC=100%, 5 sec Insulation resistance at 500 VDC ≥ 10 GΩ Test voltage 4000 V Connection lines UL SIFGL wire line AWG16 style 3071, 200°C, 600V UL PTFE wire line AWG16 style 1199, 200°, 600V UL FEP wire line AWG16 style 10203, 200°C, 600V 6 P o w e r r e sis t ors PWR-S Wire power resistor in aluminium casing (2) 2x Wire resistors in aluminium profile combine the high pulse load capacity of conventional resistor materials with optimised thermal conduction and a high degree of protection. Assembly on a surface with good thermal conduction properties improves the heat dissipation additionally and leads to an increased load capacity. The series PWR-S satisfies the requirements of UL508 and is particularly suitable for applications as brake resistor, charging and discharging resistor, or also as heating resistor. Ø 4.2 - 2.2 METALLUX.DE 0852 PWR-S100 200R/J 22 29.5max 1.5mm2 16 max L2 L1 300min. 2x 30 Ø 4.2 - 2.2 22 29.5max 1.5mm2 METALLUX.DE 0852 PWR-S100A 200R/J 30 16 max L2 L1 300min. Sample order Type selection and dimensions Type Without cooling With cooling PNDC=30% /W/ PNDC=100% /W/ PN at 25°C 70 30 100 W 2R4 – 180R PWR-S100A 70 30 100 W 2R0 – 130R PWR-S125 85 40 PWR-S125A 85 PWR-S150 PWR-S150A PWR-S100 L1 L2 mm mm 700 V 120 60 86 700 V 120 60 86 125 W 3R9 – 300R 800 V 165 105 115 40 125 W 3R0 – 220R 165 105 115 100 45 150 W 4R3 – 300R 1000 V 180 120 120 100 45 150 W 3R3 – 240R 180 120 120 Resistance values Pulse energy PWR-S100 300min. Max. voltage 800 V 1000 V /g/ PWR-S125 50 R/J 300 mm connection lines Inductance < 0.2 mH at 1 KHz Time constant 6.6 to 7.1 min. Degree of protection IP55 (opt. IP65) Storage temperature −10°C at +50°C The duty cycle DC in percent is based on a cycle time of 120 sec. Parameter PWR-S125 PWR-S150 J 1000 Max. surface temperature 250°C Tolerance ±5% (J); ±10% (K) Temperature coefficient TC ≤ ±150 ppm/K 800 Stability at Pnominal @ 25°C, 1000 h ±5% 600 Max. overload capacity 10 x PNDC=100%, 5 sec 400 Insulation resistance at 500 VDC ≥ 10 GΩ 200 Test voltage 4000 V Connection lines UL SIFGL wire line AWG16 style 3071, 200°C, 600V UL PTFE wire line AWG16 style 1199, 200°, 600V UL FEP wire line AWG16 style 10203, 200°C, 600V 0 0 100 200 300 © www.metallux.de 01/2016 400 500 600 700 Ω 7 M E TA LLU X . DE PWR-R Wire power resistor in aluminium casing Wire resistors in aluminium profile combine the high pulse load capacity of conventional resistor materials with optimised thermal conduction and a high degree of protection. Assembly on a surface with good thermal conduction properties improves the heat dissipation additionally and leads to an increased load capacity. The series PWR-R satisfies the requirements of UL508 and is particularly suitable for applications as brake resistor, charging and discharging resistor, or also as heating resistor. 2.25 36.5max 1.5mm2 5.4 METALLUX.DE 0852 PWR-R300 94R/J L2 L1 5.5 28max. Sample order Type selection and dimensions Type 300min. Without cooling With cooling Resistance values PNED=30% /W/ PNED=100% /W/ PN at 25°C PWR-R 150 120 45 150 W 1R6 – 180R PWR-R 200 160 60 200 W PWR-R 300 240 70 PWR-R 400 320 PWR-R 500 PWR-R 600 L1 L2 mm mm 1000 V 90 79 180 2R2 – 240R 1000 V 105 94 208 300 W 4R7 – 420R 1500 V 155 144 310 80 400 W 6R8 – 620R 2000 V 200 189 400 400 100 500 W 9R1 – 910R 2300 V 260 249 515 PWR-RTxxx version with integrated temperature switch for all performance classes. 480 120 600 W 12R – 1K2 2800 V 320 309 635 The duty cycle DC in percent is based on a cycle time of 120 sec. Pulse energy Max. voltage /g/ PWR-R300 100 R/J 300 mm connection lines Inductance < 0.2 mH at 1 KHz Time constant 6.6 to 7.1 min. Degree of protection IP55 (opt. IP65) Storage temperature −10°C at +50°C Parameter Max. surface temperature 250°C Tolerance ±5% 4000 Temperature coefficient TC ≤ ±150 ppm/K 3200 Stability at Pnominal @ 25°C, 1000 h ±5% 2400 Max. overload capacity 10 x PNDC=100%, 5 sec 1600 Insulation resistance at 500 VDC ≥ 10 GΩ Test voltage 4000 V Connection lines UL SIFGL wire line AWG16 style 3071, 200°C, 600V UL PTFE wire line AWG16 style 1199, 200°, 600V UL FEP wire line AWG16 style 10203, 200°C, 600V PWR-R: 150 200 300 400 500 600 J 800 0 0 100 200 300 400 © www.metallux.de 01/2016 500 600 700 800 900 Ω 8 P o w e r r e sis t ors PWR-O Wire power resistor in aluminium casing Ø 5.4 8 5.4 4.3 -2 x Wire resistors in aluminium profile combine the high pulse load capacity of conventional resistor materials with optimised thermal conduction and a high degree of protection. Assembly on a surface with good thermal conduction properties improves the heat dissipation additionally and leads to an increased load capacity. The series PWR-O satisfies the requirements of UL508 and is particularly suitable for applications as brake resistor, charging and discharging resistor, or also as heating resistor. METALLUX.DE 0852 PWR-0150 120R/J 45 55.5max 1.5m 30 max L2 L1 L3 Sample order Type selection and dimensions Type 300min. Without cooling With cooling Resistance values PNDC=30% /W/ PNDC=100% /W/ PN at 25°C PWR-0 150 120 45 150 W 1R6 – 180R PWR-0 200 160 60 200 W PWR-0 300 240 70 PWR-0 400 320 L1 L2 L3 /g/ mm mm 1000 V 72 40 16 195 2R2 – 240R 1000 V 87 55 16 235 300 W 4R7 – 430R 1500 V 137 85 26 325 80 400 W 6R8 – 620R 2000 V 182 100 41 415 PWR-0 500 400 100 500 W 9R1 – 910R 2300 V 242 160 41 530 PWR-OTxxx version with integrated temperature switch for all performance classes. PWR-0 600 480 120 600 W 12R – 1K2 2800 V 302 220 41 670 The duty cycle DC in percent is based on a cycle time of 120 sec. Pulse energy Max. voltage PWR-O150 56 R/J 300 mm connection lines Inductance < 0.2 mH at 1 KHz Time constant 6.6 to 7.1 min. Degree of protection IP55 (opt. IP65) Storage temperature −10°C at +50°C Parameter Max. surface temperature 250°C Tolerance ±5% Temperature coefficient TC ≤ ±150 ppm/K 2400 Stability at Pnominal @ 25°C, 1000 h ±5% 2000 Max. overload capacity 10 x PNDC=100%, 5 sec Insulation resistance at 500 VDC ≥ 10 GΩ Test voltage 4000 V Connection lines UL SIFGL wire line AWG16 style 3071, 200°C, 600V UL PTFE wire line AWG16 style 1199, 200°, 600V UL FEP wire line AWG16 style 10203, 200°C, 600V PWR-0: 150 200 300 400 500 600 J 3200 2800 1600 1200 800 400 0 0 100 200 300 © www.metallux.de 01/2016 400 500 600 700 800 900 Ω 9 M E TA LLU X . DE PWR-F Wire power resistor in aluminium casing Ø 4.6 -4 x Wire resistors in aluminium profile combine the high pulse load capacity of conventional resistor materials with optimised thermal conduction and a high degree of protection. Assembly on a surface with good thermal conduction properties improves the heat dissipation additionally and leads to an increased load capacity. The series PWR-F satisfies the requirements of UL508 and is particularly suitable for applications as brake resistor, charging and discharging resistor, or also as heating resistor. 60 79max. 1.5mm2 METALLUX.DE 0852 PWR-F150 120R/J 18.5max. L2 12 L1 Sample order Type selection and dimensions Type 300min. Without cooling With cooling Resistance values PNDC=30% /W/ PNDC=100% /W/ PN at 25°C PWR-F 150 225 75 150 W 2R2 – 220R PWR-F 200 300 100 200 W PWR-F 300 450 150 PWR-F 400 600 PWR-F 500 PWR-F 600 L1 L2 mm mm 1000 V 80 56 250 3R6 – 390R 1000 V 110 86 350 300 W 5R6 – 560R 1500 V 163 139 500 200 400 W 7R5 – 820R 1500 V 216 192 650 750 250 500 W 10R – 1K 2000 V 270 246 800 PWR-FTxxx version with integrated temperature switch for all performance classes. 900 300 600 W 11R – 1K1 2000 V 300 276 900 The duty cycle DC in percent is based on a cycle time of 120 sec. Pulse energy Max. voltage /g/ PWR-F600 90 R/J 300 mm connection lines Inductance < 0.2 mH at 1 KHz Time constant 6.6 to 7.1 min. Degree of protection IP55 (opt. IP65) Storage temperature −10°C at +50°C PARAMETER Max. surface temperature 250°C Tolerance ±5% Temperature coefficient TC ≤ ±150 ppm/K 2400 Stability at Pnominal @ 25°C, 1000 h ±5% 2000 Max. overload capacity 10 x PNDC=100%, 5 sec Insulation resistance at 500 VDC ≥ 10 GΩ Test voltage 4000 V Connection lines UL SIFGL wire line AWG16 style 3071, 200°C, 600V UL PTFE wire line AWG16 style 1199, 200°, 600V UL FEP wire line AWG16 style 10203, 200°C, 600V PWR-F: 150 200 300 400 500 600 J 3200 2800 1600 1200 800 400 0 0 100 200 300 © www.metallux.de 01/2016 400 500 600 700 800 900 Ω 10 P o w e r r e sis t ors PWR-RFI Wire power resistor in stainless steel casing The extremely flat and, at the same time, sturdy design of the wire power resistors in stainless steel casing make this resistor series interesting for all applications with limited installation space and rough environmental surroundings. 11.8 69 57±0.2 METALLUX 0852 PWR-RFI 12R/K L2 300 min. L1 Type selection and dimensions Type Sample order Without cooling With cooling Resistance values PNDC=100% /W/ PN at 25°C PWR-RFI 600 35 170 W 4R – 150R PWR-RFI 1300 65 320 W 8R – 430R Max. voltage L1 L2 /g/ PWR-RFI600 33 R/J 300 mm connection lines mm mm 1000 V 100 81 200 Inductance < 0.2 mH at 1 KHz 1500 V 202 175 420 Time constant 5.2 to 6.7 min. Degree of protection IP 33 Storage temperature −10°C at +40°C The duty cycle DC in percent is based on a cycle time of 120 sec. Pulse energy Parameter Max. surface temperature 250°C Tolerance ±10% 3000 Temperature coefficient TC ≤ 150 ppm/K 2500 Stability at Pnominal @ 25°C, 1000 h ±10% Max. overload capacity 10 x PNDC 100%, 5s Insulation resistance at 500 VDC ≥ 10 GΩ Test voltage 1500 V Connection lines UL PTFE wire line, style 1199, AWG16, 200°C, 600V PWR-RFI 600 PWR-RFI 1300 J 3500 2000 1500 1000 500 0 0 100 200 300 © www.metallux.de 01/2016 400 500 600 700 800 Ω 11 M E TA LLU X . DE PWR-GR Resistor assembly The type series PWR-GR consists of resistors of the type series PWR-R which are switched variably and connected by means of a terminal box. The basic version is optimised for two or four resistors. Besides that, any combination of resistor values and performances can be adapted. 3 60.5 PWR-2R600 / IP 54 3 69 PWR-4R600 / IP 54 Sample order Type selection and dimensions Type Resistance value Nominal power Max. pulse load Max. voltage L1 L2 /g/ mm mm PWR-2GR 600 4R1...3K0 240 W up to 6 KJ 600 V 460 440 2600 PWR-4GR 600 8R2...1K5 480 W up to 12 kJ 600 V 460 440 3900 PWR-2GR600 100 R/J Degree of protection IP 54 (IP 20) Storage temperature −40°C...+70°C PARAMETER Tolerance 54 6. Weidmüller clamp 800 V / 32 A / 0.5 - 4 mm² (0.5 - 6 mm²) R – resistor, T – temperature switch METALLUX.DE 0852 PWR-R600 70R/J R METALLUX.DE 0852 PWR-R600 70R/J © www.metallux.de 01/2016 METALLUX.DE PWR-4R600 70R/J 480W IP54 0852 440 460 17.5 10 M16 130 165 Ø ± 10% M16 250°C x Max. surface temperature T 12 P o w e r r e sis t ors PWR-GF Resistor assembly 96 The type series PWR-GF consists of resistors of the type series PWR-R which are switched variably and connected by means of a terminal box. The basic version is optimised for two or four resistors. Besides that, any combination of resistor values and performances can be adapted. 96 Metallux.de 0852 PWR-F500 22R/J Metallux.de 0852 PWR-F500 22R/J Sample order Type selection and dimensions Type Resistance value Nominal power Max. pulse load Max. voltage L1 L2 mm mm /g/ PWR-2GF 500 5R0...2K0 500 W up to 8 kJ 600 V 460 440 2900 PWR-2GF 600 5R6...2K2 600 W up to 9 kJ 600 V 490 470 3100 PWR-4GF 500 2R7...3K9 1000 W up to 16 kJ 600 V 460 440 4500 PWR-4GF 600 2R7...4K3 1200 W up to 18 kJ 600 V 490 470 4900 PWR-2GR600 100 R/J Degree of protection IP 54 (IP 20) Storage temperature −40°C...+70°C PARAMETER Tolerance 250°C 130 165 Ø 6. 54x Max. surface temperature 17.5 6. 54 x L2 L1 Metallux.de PWR-4F500 22R/13kJ 1 kW IP54 0852 © www.metallux.de 01/2016 L2 L1 17.5 130 165 Ø 10 Weidmüller terminal 800 V / 32 A / 0.5 - 4 mm² (0.5 - 6 mm²) R – resistor, T – temperature switch R Metallux.de PWR-2F500 11R/6.5kJ 0.5 kW IP54 0752 10 ± 10% T 13 M E TA LLU X . DE PWR-TR 2xx Wire and tube resistor up to 40W Cemented wire tube resistors are thermally optimised resistor designs with a broad spectrum of resistance values and performances. Diverse combination possibilities of the electrical properties, as well as multiple connection and assembly options make these resistors interesting for several applications of automation technology and in mechanical and systems engineering. 6.3x0.8 EN61210 5.5 C 7 D 3.2 Ø 3.2 Ø 2.4 3 W H1 R1.2 L1 2 PWR-TR26x 5R/J 0, 7.2 L2 450 Ø 5. 5± D L3 Type selection and dimensions Type Sample order PN @25°C Resistance value Dmax L1 L2max Weight L3 mm mm mm g mm Connection PWR-TR 260.01 15 W 0R8 – 12K 17 50±0.6 25 30 72±1 C PWR-TR 260 20 W 0R9 – 15K 17 60±0.8 25 36 82±1 B, D PWR-TR 261 30 W 1R5 – 22K 17 80±1.4 25 44 103±1 B, D PWR-TR 262 40 W 1R8 – 27K 17 100±1.8 25 51 123±1 B, D PWR-TR261 5K 5% B H1 Holder H1 (10g) Degree of protection IP 00 Storage temperature −25°C at +40°C PWR-TRR – Adjustable resistors with additional tap clamp Performance-Temperature-Curve Parameter Tolerance ±5% (±10%) Temperature coefficient TC ≤ ± 150 ppm/K 300 Stability at Pnominal @ 25°C, 1000 h ± 5% 250 Max. overload capacity 10 x Pn in 5s 200 Test voltage against holder 1500 V TS - Surface temperature of the resistor, k x PN - proportionate nominal power – PWR-TR 260.01, PWR-TR 260, PWR-TR 261, PWR-TR 262 TS (°C) 350 150 100 50 0 0 0.2 0.4 © www.metallux.de 01/2016 0.6 0.8 1.0 1.2 k x PN 14 P o w e r r e sis t ors PWR-TR 2xx Wire and tube resistor up to 100 W (2) Cemented wire tube resistors are thermally optimised resistor designs with a broad spectrum of resistance values and performances. Diverse combination possibilities of the electrical properties, as well as multiple connection and assembly options make these resistors interesting for several applications of automation technology and in mechanical and systems engineering. 8 Ø 4.1 E H2 4.5 6.3x0.8 EN61210 W L3 PWR-TR26x 2K2/J Ø 10 L2 M5 (H3) H3 L1 D L3 Type selection and dimensions Type Sample order PN @25°C Resistance value Dmax L1 L2max Weight L3 mm mm mm g mm Connection PWR-TR268 5 R 10% E H3 Holder H2 (17g) H3 (34g) Degree of protection IP 00 Storage temperature −25°C at +40°C PWR-TR 265 30 W 1R0 – 16K 24 55 ±0.9 32 45 78±1 C PWR-TR 266 50 W 1R8 – 27K 24 80±1.4 32 60 103±1 B/E PWR-TR 267 75 W 3R0 – 51K 24 120±2.2 32 80 144±1 B/E PWR-TR 268 100 W 4R7 – 68K 24 164±3 32 110 188±1 B/E PWR-TRR – Adjustable resistors with additional tap clamp Parameter Performance-Temperature-Curve TS - Surface temperature of the resistor, k x PN - proportionate nominal power – PWR-TR 265, PWR-TR 266, PWR-TR 267, PWR-TR 268 Ts (°C) 350 300 250 200 150 100 50 0 0 0.2 0.4 © www.metallux.de 01/2016 0.6 0.8 1.0 1.2 k x PN Tolerance ±5% (±10%) Temperature coefficient TC ≤ ± 150 ppm/K Stability at Pnominal @ 25°C, 1000 h ± 5% Max. overload capacity 10 x PN in 5 sec Test voltage against holder 2000 V 15 M E TA LLU X . DE PWR-TR 3xx Wire and tube resistor up to 200 W 5max. Cemented wire tube resistors are thermally optimised resistor designs with a broad spectrum of resistance values and performances. Diverse combination possibilities of the electrical properties, as well as multiple connection and assembly options make these resistors interesting for several applications of automation technology and in mechanical and systems engineering. 6.3x0.8 EN61210 W E 8 4.5 Ø 4.1 V1 M5 (H4) 20min. PWR-TR30x 2K2/J Ø 16 L2 H4 M50(V1) L1 D L3 Sample order Type selection and dimensions Type PN @25°C Resistance value Operational voltage Dmax L1 L2max Weight L3 mm mm mm g mm Connection PWR-TR 301 75 W 0R4 – 47K 1200 V 35 100±1.8 40 130 124±1 B/E PWR-TR 302 100 W 0R6 – 82K 1500 V 35 135±2.5 40 180 160±1 B/E PWR-TR 303 150 W 0R9 – 110K 2000 V 35 200±3.8 40 270 226±1 B/E PWR-TR 304 200 W 1R2 – 120K 2500 V 35 275±4.6 40 400 302±1 B/E PWR-TR302 28 R 5% E V1 Holder H4 (55g) V1 (29g) Degree of protection IP 00 Storage temperature −25°C at +40°C PWR-TRR – Adjustable resistors with additional tap clamp Parameter Performance-Temperature-Curve TS - Surface temperature of the resistor, k x PN - proportionate nominal power – PWR-TR 301,PWR-TR 302, PWR-TR 303,PWR-TR 304 TS (°C) 450 400 350 300 250 200 150 100 50 0 0 0.2 0.4 © www.metallux.de 01/2016 0.6 0.8 1.0 1.2 k x PN Tolerance ±5% (±10%) Temperature coefficient TC ≤ ±150 ppm/K Stability at Pnominal @ 25°C, 1000 h ± 5% Max. overload capacity 10 x PN in 5 sec Test voltage against holder 3000 V 16 P o w e r r e sis t ors PWR-TR 3xx Wire and tube resistor up to 500 W (2) 5max. Cemented wire tube resistors are thermally optimised resistor designs with a broad spectrum of resistance values and performances. Diverse combination possibilities of the electrical properties, as well as multiple connection and assembly options make these resistors interesting for several applications of automation technology and in mechanical and systems engineering. F Ø 4.2 M6(V2) D L3 Sample order Type selection and dimensions Type PN @25°C Resistance value M6(H5) 20min. PWR-TRR30x 2K2/J Ø 2 8 L2 V2 L1 Operational voltage Dmax L1 L2max Weight L3 mm mm mm g mm Connection PWR-TR 305 200 W 0R7 – 82K 2 000 V≅ 47 130±3 50 300 155±1 F PWR-TR 306 300 W 1R0 – 120K 2 500 V≅ 47 182±3.4 50 400 208±1 F PWR-TR 307 400 W 1R5 – 160K 2 750 V≅ 47 250±4.2 50 550 277±1 F PWR-TR 308 500 W 2R6 – 200K 3 000 V≅ 47 310±5 50 700 337±1 F PWR-TR308 180 K 10% F H5 Holder H5 (91g) V2 (57g) Degree of protection IP 00 Storage temperature −25°C at +40°C PWR-TRR – Adjustable resistors with additional tap clamp Parameter Performance-Temperature-Curve TS - Surface temperature of the resistor, k x PN - proportionate nominal power – PWR-TR 305, PWR-TR 306, PWR-TR 307, PWR-TR 308 Ts (°C) 400 350 300 250 200 150 100 50 0 0 0.2 0.4 © www.metallux.de 01/2016 0.6 5.5 8 0.8 1.0 1.2 k x PN Tolerance ±5% (±10%) Temperature coefficient TC ≤ ±150 ppm/K Stability at Pnominal @ 25°C, 1000 h ± 5% Max. overload capacity 10 x PN in 5 sec Test voltage against holder 4000 V 17 M E TA LLU X . DE PWR-TR 3xx Wire and tube resistor up to 1300 W (3) Cemented wire tube resistors are thermally optimised resistor designs with a broad spectrum of resistance values and performances. Diverse combination possibilities of the electrical properties, as well as multiple connection and assembly options make these resistors interesting for several applications of automation technology and in mechanical and systems engineering. M6(H6) H6 G Ø 5.3 7 14 L3 PWR-TR3xx 2K2/J L2 41 Ø L1 D Sample order Type selection and dimensions Type PN @25°C Resistance value Operational voltage Dmax L1 L2max Weight L3 mm mm mm g mm Connection PWR-TR 309 750 W 3R6 – 130K 4 000 V≅ 68 390±5.5 68 2 200 430±1 G PWR-TR 310 1000 W 4R7 – 180K 4 500 V≅ 68 515±6.8 68 2 800 555±1 G PWR-TR 320 1300 W 6R2 – 180K 4 500 V≅ 68 660±6.8 68 3 500 700±1 G PWR-TR310 5 R8 5% G H6 Holder H6 (390g) Degree of protection IP 00 Storage temperature −25°C at +40°C PWR-TRR – Adjustable resistors with additional tap clamp Parameter Performance-Temperature-Curve TS - Surface temperature of the resistor, k x PN - proportionate nominal power – PWR-TR 309,PWR-TR 310, PWR-TR 320 TS (°C) 450 400 350 300 250 200 150 100 50 0 0 0.2 0.4 © www.metallux.de 01/2016 0.6 0.8 1.0 1.2 k x PN Tolerance ±5% (±10%) Temperature coefficient TC ≤ ±150 ppm/K Stability at Pnominal @ 25°C, 1000 h ± 5% Max. overload capacity 10 x PN in 5 sec Test voltage against holder 4000 V 18 P o w e r r e sis t ors PWR-TR 4xx Wire and tube resistor Tube resistors wrapped with oxidised resistor wire can utilise the maximum performance of the resistor material. The insulation effect of the oxide sheath allows for continuous wrapping without distance between the windings. This enables higher pulse performances as well as a broad spectrum of resistance values. H6 Ø 5.3 7 14 M6(H5) G L3 PWR-TRR409 193R/K L2 41 Ø D L1 Sample order Type selection and dimensions Type PN @25°C Resistance value Operational voltage Dmax L1 L2max Weight L3 mm mm mm g mm Connection PWR-TR 409 1500 W 4R7 – 1K5 4000 V 68 390±5.5 68 3100 430±1 G PWR-TR 410 2000 W 5R6 – 2K2 4500 V 68 515±7.6 68 3750 555±1 G PWR-TR 420 2600 W 8R2 – 2K7 4500 V 68 660±8.3 68 5600 700±1 G TS - Surface temperature of the resistor, k x PN - proportionate nominal power PWR-TR 409, PWR-TR 410, PWR-TR 420 Ts (°C) 400 350 300 250 200 150 100 50 0 0.2 0.4 © www.metallux.de 01/2016 0.6 Holder H6 (390g) Degree of protection IP 00 Storage temperature −25°C at +40°C Parameter Performance-Temperature-Curve 0 PWR-TR409 40K 5% G H6 0.8 1.0 k x PN Tolerance ±5% Temperature coefficient TC ≤±150 ppm/K Stability at Pnominal @ 25°C, 1000 h ±5% Max. overload capacity 10 x PN, 5 sec Test voltage against holder 4000 V 19 M E TA LLU X . DE 25.5 39 35.5 27.5 Ø 5. 2 Assembly accessories PWR-TR H3 16 5.2 16 5 20 H2 20 5.1 H1 1 19 1.3 1 15.5 8.5 9.4 9 Ø 5. 2 M5 45 63 46.5 35 .2 Ø 6 1.5 20 5.2 1.5 20 H4 9.4 20 H5 M6 20 5.2 M5 1.5 4 9.4 Ø 5.2 6.4 12 Ø 98 23 70 V1 M6 5 1.5 2 M6 40 H6 V2 36 35 35 90 20 14.4 6.4 © www.metallux.de 01/2016 16 Ø 6.2 M6 20 P o w e r r e sis t ors PWR-x Wire and tube resistor in stainless steel casing IP 20 The resistor series PWR-X is a ready-to-install combination of tube resistors. Depending on the casing size and the installed tube resistor, a performance range from 400 W to 6 KW is covered. The type series are characterised by high flexibility and enable various individual solutions. As an option, we offer the matching temperature switch for each performance class. x 50[2"] W Surface A x B x C, D temperature x/y Weight mm mm g -1TR 307S (T) 400 W 5 R...100 R * 8 kJ* max. 80°C 94 x 105 x 275, 375 50/345 1900 -1TR 308S (T) 500 W 5 R...100 R * 10 kJ* max. 80°C 94 x 105 x 335 ,435 50 / 405 2100 -2TR 307S (T) 800 W 5 R...100 R * 16 kJ* max. 80°C 166 x 105 x 275, 375 122/295 2800 -2TR 308S (T) 1000 W 5 R...100 R * 20 kJ* max. 80°C 166 x 105 x 335 ,435 122/355 3100 -4TR 307S (T) 1600 W 5 R...100 R * 32 kJ* max. 80°C 166 x 177 x 275, 375 122/295 4600 -4TR 308S (T) 2000 W 5 R...100 R * 40 kJ* max. 80°C 166 x 177 x 335 ,435 122/355 5200 -6TR 308S (T) 3000 W 5 R...100 R * 60 kJ* max. 80°C 238 x 177 x 335 ,435 194/355 7100 Connection terminal Weidmüller terminal SAK 6 800 V 41 A 0.5 – 6 mm² R – resistor, T – temperature switch T © www.metallux.de 01/2016 METALLUX.DE C Sample order Wad PWR- R PWR-2TR308ST 22R/22.5kJ 0.5kW IP 20 0852 PN @25°C Resistance value W A y Type selection and dimensions Type A x 6.5[33/128"] C 50[2"] D METALLUX.DE D PWR-1TR308ST 22R/22.5kJ 0.5kW IP 20 0852 50[2"] 6.5[33/128"] y PWR-1TR308S 50 R 10% Degree of protection IP 20 Storage temperature −40°C to +60°C Parameter Tolerance ±10% Temperature coefficient TC ≤±150 ppm/K Test voltage against holder 1500 V 21 M E TA LLU X . DE PWR-x Wire and tube resistor in stainless steel casing IP 20 (2) 6.5 [33/128"] The resistor series PWR-X is a ready-to-install combination of tube resistors. Depending on the casing size and the installed tube resistor, a performance range from 400 W to 6 KW is covered. The type series are characterised by high flexibility and enable various individual solutions. As an option, we offer the matching temperature switch for each performance class. 155 [6 13/64"] 9 [23/64"] 120 [4 51/64"] 704 Wad Surface tem- A x B x C, D perature PWR- mm x/y Weight mm g -1TR 320S 2000 W 5 R...100 R * 40 kJ* max. 250°C 170 x 120 x 704, 790 155/685 5500 -2TR 320S 5000 W 5 R...100 R * 80 kJ* max. 250°C 185 x 250 x 737, 825 155/712 11000 -3TR 320S 6000 W 5 R...100 R * 120 kJ* max. 250°C 327 x 230 x 737, 847 300/712 13200 R © www.metallux.de 01/2016 PWR-1TR308S 50 R 10% Degree of protection IP 20 Storage temperature −40°C to +60°C Parameter Connection terminal T 185 [7 51/128"] Sample order Resistance value Weidmüller terminal SAK 6 800 V 41 A 0.5 - 6 mm² R – resistor, T – temperature switch METALLUX.DE 250 [10"] 737 Type selection and dimensions PN @25°C PWR-2TR320ST 10R/J 80kJ 5kW IP 20 1217 155 [6 13/64"] 712 825 Type PWR-1TR320ST 50R/35kJ 2kW IP 20 1129 790 METALLUX.DE 170 [6 51/164"] 685 Ceramic terminals T R Tolerance ±10% Temperature coefficient TC ≤ ±150 ppm/K Test voltage against holder 1500 V 22 P o w e r r e sis t ors Special designs/applications Thanks to their simple design, wire resistors are virtually limitless in their variability and, because of this, can be adapted to suit the most applications. On this page, you will find a few examples of this together with typical applications. Starting resistance for compressors and heat pumps The decentralised use of regenerative energy sources has long been a key component of modern building automation. Power resistors equipped with a fuse are essential for limitation of initial current for compressor motors. Precharging resistor To protect the on-board electronics against overvoltage, power resistors are utilised in modern vehicles for a controlled initial start. Brake resistor (lifts) One typical use case of brake resistors is for application in hoisting units. These include particularly lifts for persons and loads. Chopper resistor (chain hoists and cable hoists) Crane, chain, and cable hoists create regenerative energy when lowering loads which must be dissipated in the intermediate circuit. © www.metallux.de 01/2016 23 M E TA LLU X . DE Enquiry form for power resistors 1. 2. Electrical nominal values Resistance type If known Resistance value Ω Tolerance absolute % TCR ppm/K VCR ppm/V Operational conditions Operational voltage V Continuous power rating W Max. performance Pulse form W Charging/Discharging function Rectangle Capacity Triangle 4. Pulse length (sound) sec. Pause time (toff) sec. Cycle DC% Ambient conditions Ambient temperature °C Humidity % r.h. Degree of protection © www.metallux.de 01/2016 5. 6. Mechanical features Length mm Width or diameter mm Connection lines (cable type) If they deviate from standard Length of the connection lines mm Quantity, delivery date Quantity Units Delivery date Calendar week / Year F Other pulse form - please provide a curve © www.metallux.de 01/2016 www.metallux.de Metallux AG Robert-Bosch-Straße 29 71397 Leutenbach-Nellmersbach Germany TEL +49 (0)7195 / 59 80 - 0 FAX +49 (0)7195 / 59 80 - 300 E-mail: info@metallux.de