Spring 2012 Edition - Bretting Manufacturing

advertisement

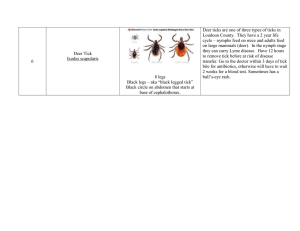

Spring 2012 Page one Vol. 14 No. 1 Page two Improving on History Letter from the CEO David Bretting Page three Page four Mike Willis Duly Noted Andrea Ludtke Always Listening Improving on History Nurses Corner Continued Anne Smith, RN C. G. Bretting Manufacturing Improving on History C. G. Bretting Manufacturing Co., Inc. has tested history and excellence in manufacturing through four generations of management. There are several themes that have been consistent for Bretting – quality people, investment in technology, unparalleled customer service, and products that exceed the expectations of the industry. These are themes that have led to success for more than 120 years. In the early 1960s Tad Bretting reinvented the company to concentrate on the design and manufacture of equipment for use in the tissue paper converting industry. Tad surrounded himself with people who were entrepreneurial in nature, like himself. Throughout his tenure as president, Tad accomplished many things, including receiving the Small Business Person of the Year Award from President Bush in 1989 and being inducted into the Paper Industry International Hall of Fame in 1999. This staff created the basis of high quality engineering and manufacturing for extraordinary expansion for the future. Every new hire over the years from the original 12 employees in the 1960s to about 450 employees today has met the criteria of wanting to achieve excellence – excellence that translates to the highest quality products and customer service available in the industry. It all comes down to one premise – the customer always comes first. During this growing time into the 1970s the Bretting product line expanded and engineering enhanced the equipment to include Bretting’s pioneered automatic count and separation. The next generation of equipment included interfolders for singlefold and multifold hand towels, facial tissue interfolders, and C-fold towel machines. Today the product line also includes rewinders, table cover machines, flexographic printers, and a variety of packaging equipment. Our specialty equipment is utilized in other industries such as aluminum foil, wax paper, plastics, non-wovens, and other disposable products. Equipment ranges from small manual equipment for small converters to large high-production converting lines that help make multi-national operations successful. The sales staff and engineers truly listen to each customer so each machine exactly meets the needs of the customer’s manufacturing operation. Over the years Bretting has made strategic acquisitions in Europe and the United States. In 2011, Bretting acquired certain assets of S&S Specialty Systems, Inc. The company is a leader in the design and manufacture of converting equipment for nonwovens and other specialty substrates. Investing in technology has been another central theme to the success of Bretting Manufacturing. Bretting strives to stay a step ahead, and does so through expansion of machining capabilities in the Machine Shop and providing top level engineering software solutions for the Engineering Department. Some of the Machine Shop investments include fivesided large capacity milling machines (10’X26’X4’), large lathe turning capability (43’X312”), and many other vertical milling and turning machines. In addition to the manufacture of Bretting products, adding this capacity has made the Bretting Contract Manufacturing Services (CMS) Group able to assist manufacturers all over North America with custom parts production. Other support services include water-jet cutting, programming, painting, outside diameter and surface grinding, assembly, and much more. The company currently occupies over 280,000 square feet of office, manufacturing and assembly space. In the Beginning n The C. G. Bretting Manufacturing Co., Inc. is currently managed by the fourth generation of the Bretting family. Current family members include David Bretting, President and Chief Executive Officer, and Paul Bretting, Chief Operating Officer. You can’t truly appreciate the vibrancy and innovative character of Bretting Manufacturing without looking at its history. Christopher George Bretting purchased the Parish Iron Works in 1890. The site of this company on the shore of Lake Superior in Ashland, Wisconsin continues as the site of Bretting Manufacturing today. From 1890 to the 1920s the company manufactured machinery and equipment for the sawmill industry, meeting the needs of the world’s largest concentration of sawmills. continued on page two Page one Greetings from Ashland The history of Bretting Manufacturing is filled with the entrepreneurial spirit, dedication to customers, innovation, and a never-ending quest to be the best. Having a diverse background and changing with the times – from logging to mining to paper – has kept Bretting one of the top employers in the Ashland area. With the past generations of owners being future-minded, we have been able to keep ahead of our competition – no matter the industry. Tad Bretting put us on the track we are on now – constantly creating new, better, and faster equipment for the paper converting industry. He saw a bright future in this industry – ever-changing needs of customers and end-consumers keep us in a continual loop of re-inventing and upgrading machines to produce product faster and with better quality. Tad’s many accomplishments stretched throughout the industry…he was able to take part in the beginning of the paper converting industry expansion; some of the first machines Tad put into production are still being used today. His eye for innovation is still present with the staff we have today – always thinking and testing new ideas will put us, and ultimately our customers, at the forefront of this highly competitive industry. a relatively stress-free environment by managing the nerve center of our facility – and has a highly capable staff to troubleshoot issues and upgrade software and hardware to keep us working effectively. Everyone in the building works with Mike every day, even if they never see him…and that’s the way he likes it. Word of mouth forged our name in the minds of many global companies. Now in our fourth generation of family ownership, Bretting Manufacturing continues to strive for excellence in the world marketplace, by investing in machine tools, equipment, R&D, and people. With summer right around the corner, if you are vacationing in our area or just passing through, give us a call and we’d be happy to meet you and give you a tour of our facility. David Bretting President & CEO Being the IT Manager for any business is no easy task – the computer industry changes daily and computer problems are always popping up. Mike Willis is able to manage changes and problems seamlessly – everpresent in the background of daily activity, but always trying to be invisible to every user. He creates In the Beginning continued from page one n In 1904 Christopher George Bretting passed away, and his widow and oldest son Ralph Bretting continued to operate the company. As the white pine forests of the region were depleted, the sawmill industry decreased also. There was an increase in local mining operations, and Bretting adapted and started catering to the needs of the mining and shipping industries. n By 1929 Christopher Bretting’s youngest son Lyman returned to Ashland with an engineering degree from the Massachusetts Institute of Technology and took over management of the company. He was sole operator of the company until 1958, until his son Tad Bretting went into business with him after receiving a business degree from Notre Dame University. n In 1960 Tad took over sole management of the company and again Bretting Manufacturing changed with the times and adapted operations to meet the needs of the converting industry. In 1997 Tad Bretting retired and turned the company over to the fourth generation. He later passed away in 2003. Under Tad Bretting, and the leadership of David and Paul, Bretting Manufacturing has continued to grow and has expanded to become a truly global operation. Page two Duly Noted by Andrea Ludtke n Babies n Bretting Retirements Rachel and Bill Plizka, a boy Doug and Amber Erickson, a boy Bill and Angela Reardon, a boy Ryan and Angela Lunn, a boy Bill Maki – 38 years of service Tim Amrein – 33 years of service n Men’s Potbelly Basketball League The Bretting Men’s Potbelly League team had a great time getting together to play some basketball over the winter months – a good way to get out of the house and be active during the long, snowy weeks. But with a record of 6–8, I think they need to do some extra laps around the court! Better luck next year! n Christmas Parade Float We took 2nd place in the Ashland city Christmas parade this past year. The float was a depiction of “gifts under the tree”. Our prize money was donated to the Ashland Animal Shelter. Front row: (l to r) Joe Popovich, Jesse Henry, and Luke Korpela. Back row: (l to r) Phil Kruzan, Ben Taddy, Dan Huybrecht, and John Zifko. n Citizen of the Year n Upcoming Trade Shows Joe Olson, Services Team Leader, was named Citizen of the Year in Hurley, WI this past winter for his participation in Iron County snowmobile and recreational organizations. Along with those organizations, he is also a Pence town supervisor, Montreal volunteer firefighter, an ATV and snowmobiling instructor, and a baseball coach. Where do you find the time Joe? Congratulations on this big honor! MIAC 2012 10 – 12 October 2012 Lucca, Italy Stand # 17 Tissue World Asia 2012 (Tech.Vantage stand) 14 – 16 November 2012 Shanghai, China Stand # 1G01 Joe Olson, Citizen of the Year in Hurley, WI. 5 Servings a Day! Our most recent health challenge was to eat a minimum of 5 servings of fruits and vegetables a day – it was a good way to get us in the habit of eating more than we typically do. The challenge finished with 56 employees turning in their weekly serving totals. 23 of those people consistently averaged 5 servings or more a day! Congratulations! The winner of a $200 gift certificate to our local food co-op, with 1,214 servings (almost 650 more than the 2nd place finisher!) over 10 weeks is Dan Beirl. On the left is a photo of a typical lunch for Dan… pretty impressive! Congratulations Dan – keep up the good work! Page three Mike Willis, Always Listening A s Information Technology (IT) Manager at C. G. Bretting Manufacturing, Mike Willis coordinates between the Bretting employees and IT staff and makes sure technology resources are being allocated to best service the company. There is a constant need for information between all departments. “On the manufacturing side, they need information from Engineering – and Engineering, in turn needs feedback from Manufacturing with a lot of the information starting out from the sales staff. The IT staff supports everyone who has a need to share information,” Mike states. One of the more difficult tasks for the IT staff is to translate the user’s needs for information into a programmable action plan. When researching user needs, it is important to be able to make anyone feel comfortable with the process of defining the information needed and not overdo the technical language. He explains, “From the IT manager’s point of view, a good portion of the day is spent planning and listening to issues and concerns and translating them into something that will improve business processes and make the end users’ job easier.” Mike’s staff is made up of three programmers, a system administrator, and a system technical support specialist. They are critical to the company and the process of improving business processes. It is their skills that can make or break an IT manager. “I am extremely fortunate that the three programmers (Chris Gonderzik, Andy Pope, and Jason Johnson); System/Network Administrator (Eric Sundberg), and System Technical Support (Chad Soare) have a clear understanding T Mike Willis of the Bretting mission statement. They clearly understand what it means when we hear ‘Delivering on our promise, earning the right to be the customer’s choice.’” “We touch every facet of the business process. From the Machine Shop, Assembly, Sales, Administration, Engineering, facilities’ management - we support everybody’s IT needs, from behind the scenes.” His philosophy is to be proactive, “We want to challenge; however, we don’t want to step too far out so people become uncomfortable with the technology. It is important to take our lead from employees, supervisors, and managers. They understand the business process better than anyone else. The IT staff will have to ask, ‘How does that fit into the business process and will it take the company to the next level?’” When you look at Mike’s background, you could wonder how he ended up in this position. With a background in computers and management, he has honed his skills for project management. He served his country in the USAF as a B52 pilot for over 20 years. He has worked in international arms control, IT project management and operational management. Before arriving at Bretting, he had earned three master’s degrees, in management, finance and aeronautics. After the USAF, Mike worked at the school districts in Superior, Wisconsin and Duluth, Minnesota in IT. From there he moved to a hospital in Hutchinson, Minnesota and managed the conversion and implementation of a new medical system. “The hospital goal was to convert their old system to an updated health system with 15 core modules. They had planned to do it in 18 months, and we did it in 13,” he explains. With the project completed, Mike was given the opportunity to work for Bretting Manufacturing. “I saw this as a great opportunity to continue working and learning.” It was also an opportunity to see his wife every night and be close to family. Mike and his wife, Chris, live in Solon Springs, Wisconsin and have been married since 1974. Chris is a first-grade teacher in the Solon Springs School District. Since entering the service, he has spent a lot of time away from family. “Although it is a 58.7-mile drive each way, it is a lot closer than I’ve been since 1973.” Nurses Corner he warm weather we have been having is great for us…and for the ticks as well. This season has started much earlier due to the warmer weather and the ticks are out in full force. Tick-borne diseases can be prevented by preventing tick bites. In regions where tick exposure is likely, people should wear long sleeved shirts, long pants cinched at the ankle or tucked into the boots or socks, and closed-toe shoes. Walking on cleared trails, away from brushy vegetation, also decreases the opportunity for tick attachment. Spraying clothes with an insect repellent may provide an additional barrier of protection from ticks. Most repellents contain diethyltoluamide (DEET), which repels but does not kill ticks. Permethrin is the active ingredient found in many aerosol spray tick repellents that are designed for use specifically on clothing. Permethrin kills ticks on contact and has a low toxicity in mammals. Field tests done by the US military have shown tick repellents containing permethrin to be 90-100% effective in preventing tick bites. When traveling in tick-infested areas, inspect all parts of the body closely at least twice daily. Some ticks can be on the body for 1-2 hours before attaching. Even after a tick attaches, disease transmission may be prevented by prompt removal. Laboratory studies of ticks infected with the infectious agent that causes Lyme disease showed that disease was rarely transmitted if the tick was attached for less than 24 hours. Redness, itching, and swelling are commonly seen at the site of a tick bite. The standard method for removing an embedded tick is to use rounded tweezers, grasp the tick as close as possible to the skin surface, and then pull with slow steady pressure in a direction away from the skin. Take care not to crush or squeeze the body of the tick, because fluid forced out of the tick may contain infectious agents. If you don’t remove the tick intact, don’t try to dig it out. Instead, apply a triple antibiotic (such as Neosporin) to the area. After the tick is removed, wash the bite site with soap and water or an antiseptic. The person who removed the tick should wash his or her hands thoroughly. It may be a good idea to save the tick in case later identification may be necessary. Traditional methods of tick removal, such as applying fingernail polish, rubbing alcohol, or a hot match head to the tick, do not affect tick detachment. These methods also may induce the tick to salivate or regurgitate into the wound, thus transmitting more of an infectious agent. Monitor the bite area for about two weeks. Tick bites normally look red and slightly inflamed for up Page four to five days. If redness persists or the red area begins to increase in size, see a physician. Also see a doctor if you experience any disease symptoms (such as fever, headache, muscle or joint pain, or nausea) within a few weeks of the tick bite; if possible, bring the preserved tick with you. However, if the tick is removed and is not attached or swollen (meaning it has not been attached for long), it is unlikely Lyme disease will follow. Don’t forget your four-legged friends, too - make sure you give your pets the proper tick treatments throughout the year! Information in article from: www.emedicinehealth.com and www.intelihealth.com C. G. Bretting Manufacturing Co., Inc. 3401 Lake Park Road • Ashland, Wisconsin 54806 USA Tel: 715.682.5231 • Fax: 715.682.4138 E-mail: cgb@bretting.com • www.bretting.com Copyright C. G. Bretting Manufacturing Co., Inc. May 2012. Printed in USA.