Application Brief

Negative Mutual Inductance in 2-D Extractor

Sometimes 2-D Extractor (a capability within ANSYS Q3D Extractor) returns an inductance

(L) matrix with entries that cause concern. Some users are surprised to see a negative

off-diagonal term in the inductance matrix (mutual inductance) because these entries are

often all positive. These results are correct and not a cause for worry.

Explanation

Negative mutual inductance is quite common in field solvers (like the 3-D

inductance solver in Q3D Extractor) that compute partial inductance. To

generate a negative partial mutual inductance, the current/voltage reference is reversed in direction in one of a parallel set of conductors, perhaps

by swapping the source and sink terminals. Negative mutual inductance can

also occur in field solvers like 2-D Extractor that compute loop inductance,

but the reasons for this may be less clear.

Figure 1. Three-conductor coupled microstrip geometry

To better understand how this can happen, consider a common threeconductor coupled microstrip configuration as shown in Figure 1. The thickness of the FR4 epoxy substrate is 50 microns. The copper signal conductors are 15 microns thick, 50 microns wide, and they are spaced 100

microns apart. The copper ground plane below is 15 microns thick

and 1,000 microns wide.

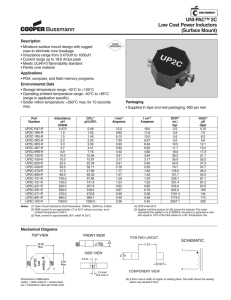

When the loop inductance matrix is computed in 2-D Extractor at 1 GHz, all

of the entries of the inductance matrix are positive (Figure 2).

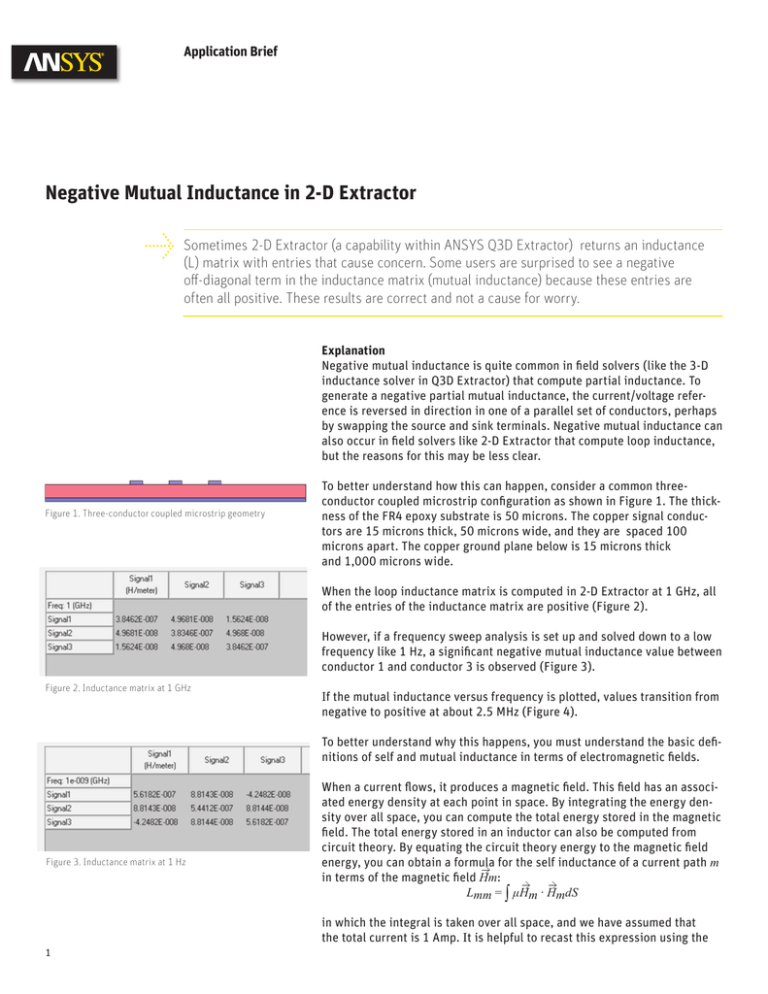

However, if a frequency sweep analysis is set up and solved down to a low

frequency like 1 Hz, a significant negative mutual inductance value between

conductor 1 and conductor 3 is observed (Figure 3).

Figure 2. Inductance matrix at 1 GHz

If the mutual inductance versus frequency is plotted, values transition from

negative to positive at about 2.5 MHz (Figure 4).

To better understand why this happens, you must understand the basic definitions of self and mutual inductance in terms of electromagnetic fields.

Figure 3. Inductance matrix at 1 Hz

When a current flows, it produces a magnetic field. This field has an associated energy density at each point in space. By integrating the energy density over all space, you can compute the total energy stored in the magnetic

field. The total energy stored in an inductor can also be computed from

circuit theory. By equating the circuit theory energy to the magnetic field

energy, you can obtain a formula for the self inductance of a current path m

in terms of the magnetic field Hm:

Lmm = ∫ μHm ∙ HmdS

in which the integral is taken over all space, and we have assumed that

the total current is 1 Amp. It is helpful to recast this expression using the

1

Negative Mutual Inductance in 2D Extractor

vector potential Am and the current distribution Jm associated with the

magnetic field. It is possible to show that an equivalent formula for self

inductance is

Lmm= ∫ Am · Jm dS

The advantage of this expression is that the integrand is only non-zero in

conducting regions, because the current density Jm goes to zero elsewhere.

In fact, we need to look only at the conductors in the current path m of

interest (signal line and return) to evaluate it. So the integral becomes:

Figure 4. Plot of mutual inductance L13 versus frequency

Lmm = ∫S Am · Jm dS + ∫S Am · JmdS

m

g

Here Sm denotes the cross section of conductor m, and Sg denotes the cross

section of the ground return conductor. Note that the current density Jm

within the signal conductor will be positive, while the current density in

the ground conductor will be negative because it is flowing in the opposite

direction.

The expression for mutual inductance Lmn is similar to the above formula

for self inductance, with one modification:

Lmn =∫S Am · JndS +∫S Am · JndS

n

g

The integrand is now “mixed up” because it uses the vector potential from

current path m multiplied by the current density from path n. The current

density for signal path n is non-zero only over the cross section Sn of signal

conductor n (where it is positive) and the cross section of the ground return

conductor (where it is negative.)

Figure 5. Plot of vector potential at 1 GHz

This formula shows that for a mutual inductance to be positive, the integrand Am · Jn must be positive over most of the cross sectional area of the

signal and return conductors. If the sign of the current and the vector potential differ over a large part of these conducting regions, then the mutual

inductance will be negative.

A plot of the vector potential at 1 GHz is shown in Figure 5.

The field is concentrated in the region surrounding the active line (conductor 1) and drops off rapidly over distance. The physical reason for this is

that the current on the ground plane is bunching up beneath conductor 1 to

minimize the impedance of the loop, which is dominated by the loop’s self

inductance at high frequency.

Figure 6. Plot of vector potential at 1 Hz

The vector potential is positive everywhere and trends toward zero at the

ground plane. Therefore, regardless of the position of the conductors (and

their associated current), the first term in the mutual inductance equation

will be positive and the second term will be zero, resulting in a mutual

inductance that is positive overall.

When plotting the vector potential at 1 Hz, the plot looks quite different

(Figure 6). The magnetic fields now fully penetrate the conductors, and the

2

Negative Mutual Inductance in 2D Extractor

fields are non-zero over a much larger region. This more dispersed magnetic field is due to the ground plane. The ground plane is carrying the return

current for conductor 1. At low frequency, this current is free to spread out

uniformly over the entire ground plane to minimize the self resistance of

the current loop.

Figure 7. Plot of vector potential at 1 Hz using much wider (3,000

um) ground plane

The same plot illustrates that the vector potential becomes negative in

the region around conductor 3. As usual, the current density in the signal

conductor is positive, so this means that the first term of the mutual inductance equation will be negative for conductor 3. This is because the negative vector potential is the ground plane that is carrying a negative current

density and is closer to conductor 3 than is conductor 1, so the ground

plane has a greater influence over conductor 3 than the active signal line.

In the ground plane, the vector potential is generally non-zero and positive

(with a large magnitude) near the signal line and negative (with a small

magnitude) farther away. Because the current density in the ground plane

is uniform and negative, this means that the second integral in the mutual

inductance equation will be negative too, so negative mutual inductance

is observed.

Careful examination of the field lines in Figure 6 reveals that the vector

potential does not trend toward zero as distance from the excited signal

line increases, but it stays negative and actually increases slightly in

magnitude.

Figure 8. Mutual inductance L13 with 3,000 um ground plane

To determine what would happen to the mutual inductance if the ground

plane were larger — sufficient to change the sign of the ground plane integral and make the mutual inductance positive once again — the width of

the ground plane was increased from 1,000 microns to 3,000 microns and

resimulated. The resulting vector potential is plotted in Figure 7.

The region of negative vector potential is pushed much farther out from

the signal lines. The resulting mutual inductance is now positive for all

frequencies, as shown in Figure 8.

Clearly, the low-frequency mutual inductance between the lines is strongly

affected by the size of the ground plane used. To get some idea about how

important this effect is, a parametric sweep of the ground plane width

was performed in 2-D Extractor from widths of 1,000 microns to 3,000

microns in steps of 500 microns. Figure 9 shows the results for the mutual

inductance L13.

Figure 9. Mutual inductance L13 vs. frequency for different ground

plane widths

3

The plot shows that the mutual inductance is positive as long as the ground

plane width is about 1,500 microns or greater. Therefore, it appears from

this example that a reasonable guideline to follow to avoid negative mutual

inductances is to make the ground plane at least five times wider than

the maximum horizontal extent of the signal traces (350 microns in this

example.) You might be tempted to make it huge (perhaps 50 times wider

than the signal line extent), but this would waste computation time. The

low-frequency mutual inductance will always be a strong function of the

Negative Mutual Inductance in 2D Extractor

ground plane size, because the ground plane controls the extent of the

low-frequency current loop.

For frequencies of 10 MHz or higher, the ground plane size has little effect

on the result. This is expected, because at high frequencies the fields

concentrate strongly in the region surrounding the signal line to minimize

the inductive impedance.

Figure 10. Mutual inductance L12 vs. frequency for different

ground plane widths

The low-frequency mutual inductance L12 to the nearest neighbor line is

also affected by the width of the ground plane, as shown in Figure 10. The

variation is less than that for L13 but is still significant. Even the self inductance has a significant dependence on the ground plane width (again only

at low frequency), as shown in Figure 11.

However, an analysis of the fundamental electromagnetic definition for

mutual inductance shows that this is not a bug in the field solver but a

physically reasonable result. Negative mutual inductance is observed

only at low frequencies, and only when a relatively narrow ground return

conductor is present.

Figure 11. Self inductance L11 vs. frequency for different ground

plane widths

ANSYS, Inc.

Southpointe

275 Technology Drive

Canonsburg, PA 15317

U.S.A.

724.746.3304

ansysinfo@ansys.com

© 2013 ANSYS, Inc. All Rights Reserved.

ANSYS, Inc. is one of the world’s leading engineering simulation software providers. Its technology has enabled customers to predict with accuracy that their product designs will thrive in the real world. The company offers a common platform of

fully integrated multiphysics software tools designed to optimize product development processes for a wide range of industries, including aerospace, automotive,

civil engineering, consumer products, chemical process, electronics, environmental, healthcare, marine, power, sports and others. Applied to design concept,

final-stage testing, validation and trouble-shooting existing designs, software from

ANSYS can significantly speed design and development times, reduce costs, and

provide insight and understanding into product and process performance.

Visit www.ansys.com for more information.

Any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in

the United States or other countries. All other brand, product, service and feature

names or trademarks are the property of their respective owners.