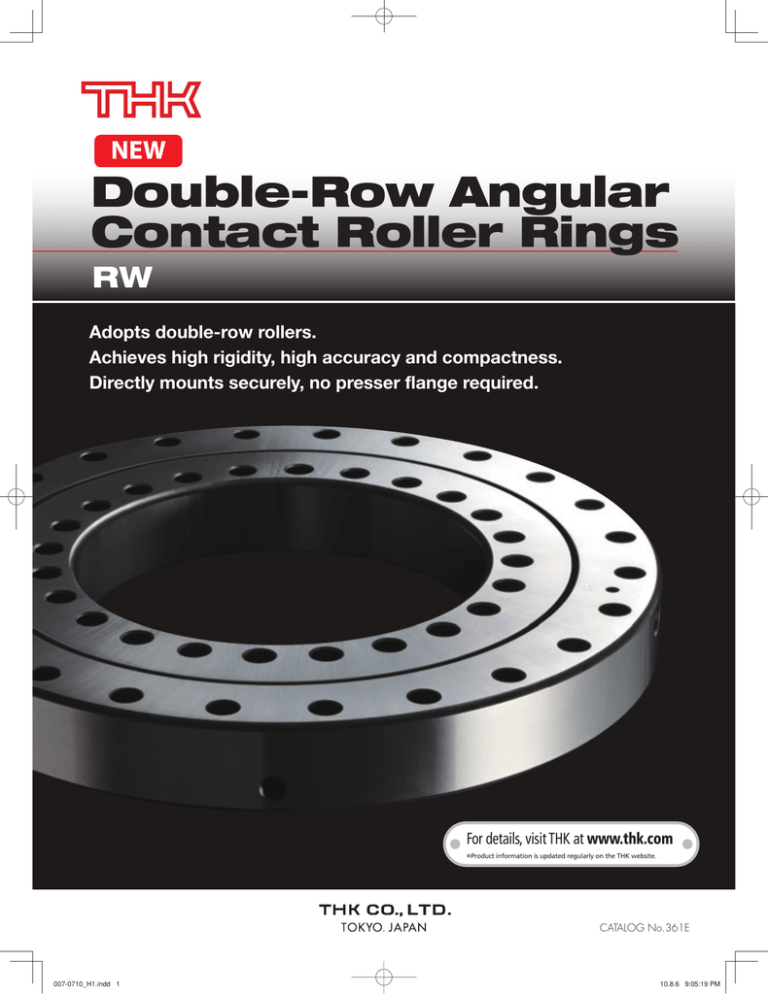

Double-Row Angular

Contact Roller Rings

RW

Adopts double-row rollers.

Achieves high rigidity, high accuracy and compactness.

Directly mounts securely, no presser flange required.

For details, visit THK at www.thk.com

*Product information is updated regularly on the THK website.

CATALOG No.361E

007-0710_H1.indd 1

10.8.6 9:05:19 PM

Double-Row Angular

Contact Roller Rings

Double-row, and simple.

Achieves high rigidity, high accuracy and compactness.

By integrating double-row small-diameter rollers on the raceway, the number of rollers

incorporated in this new model (RW228) is approximately 5 times that of Cross-Roller

Ring model RU*. While maintaining the compactness, it achieves higher rigidity and

accuracy and a lower torque. In addition, the inner and outer rings in integrated

structures have mounting holes, allowing the product to be directly mounted to the

machine.

* Previous Cross-Roller Ring model RU

1

007-0710_P01-P02.indd 1

10.8.18 2:59:32 PM

● Adopts Inner and Outer Rings that has Integrated Structures

High rigidity and high accuracy

● Utilizes Small-diameter Rollers

Lower torque

The inner ring and the outer ring of model RW have integral structures to realize a

Model RW adopts small-diameter rollers to reduce the friction coefficient and realize a

high level of part rigidity. Since the inner ring and the outer ring are machined to

lower torque and low-temperature rise characteristics.

have mounting bolt holes, and the size and number of the mounting bolt holes are

optimally designed, the deformation of the raceway resulting from the mounting can

be minimized and stable rotational performance can be achieved. In addition, the

● Adopts Double-row Unidirectional Rollers

increased machining accuracy results in high rotational accuracy (see Accuracy

Standards on page 5).

Increased rigidity

Despite having almost the same dimensions as the previous Cross-Roller Ring model

Optimal design of the mounting hole

RU*, model RW has rows of raceways twice that of model RU and has a DB structure to

increase the rigidity.

High rigidity with a integrated outer ring structure

Inner ring (with mounting holes)

High rigidity with a integrated inner ring structure

Double-row unidirectional rollers

Outer ring (with mounting holes)

×10-4

Theoretical Rigidity Comparison between RU228 and RW228

θ [rad]

RU228

RW228

Moment [kN-m]

×10-4

Theoretical Rigidity Comparison between RU297 and RW297

θ [rad]

RU297

RW297 Moment [kN-m]

×10-4

Theoretical Rigidity Comparison between RU445 and RW445

θ [rad]

RU445

RW445

Moment [kN-m]

●RW228

●RW297

●RW445

(outer diameter: 295 mm; inner diameter: 160 mm)

(outer diameter: 380 mm; inner diameter: 210 mm)

(outer diameter: 540 mm; inner diameter: 350 mm)

2

007-0710_P01-P02.indd 2

10.8.18 2:59:35 PM

Product Overview

Double-Row Angular Contact Roller Rings <RW>

Nominal Life

The service life is obtained from the following equation.

fT・C

L=

fw・PC

10

3

( )

106

Temperature factor fT

[Nominal Life]

1.0

0.9

0.8

0.7

0.6

0.5

100

150

200

250

Temperature of the bearing unit (°C)

L :

C

PC

fT

fW

:

:

:

:

Nominal life

(the total number of revolutions that 90% of a group of identical

Double-Row Angular Contact Roller Rings units operating under

the same conditions can achieve without showing flaking from

rolling fatigue)

Basic dynamic load rating* [N]

Dynamic equivalent radial load [N]

Temperature factor (see Fig. 1)

Load factor (see Table 1)

* The basic dynamic load rating (C) of model RW shows the radial load with interlocked

direction and magnitude, under which the nominal life (L) is 1 million revolutions when a

Fig. 1 Temperature factor (fT)

Note) The normal service temperature is 80°C or below. If the product is to be used

at a higher temperature, contact THK.

Table 1 Load Factor (fw)

Service conditions

fw

Smooth motion without impact

1 to 1.2

Normal motion

1.2 to 1.5

group of identical model RW units independently operate under the same conditions. The

basic dynamic load rating (C) is indicated in the specification tables.

Motion with severe impact

[Dynamic Equivalent Radial Load: PC]

1.5 to 3

Moment

(M)

The dynamic equivalent radial load is obtained from the

following equation.

Axial load

(Fa)

(

PC=X・ Fr+

2M

+Y・Fa

dp

)

PC :

Dynamic equivalent radial

load [N]

X :

Fr :

Fa :

M :

Radial load [N]

Axial load [N]

Moment [N-mm]

Y :

dp :

Dynamic radial factor (see

Table 2)

Dynamic axial factor (see

Table 2)

Roller pitch circle diameter [mm]

If Fr = 0 [N] and M = 0 [N-mm], assume that X = 0.67 and Y =

0.67.

For service life calculation with a preload taken into account,

contact THK.

Radial load

(Fr)

Moment

(M)

Table 2 Dynamic Radial Factor and Dynamic Axial Factor

Classification

Fa

Fr+2M/dp

Fa

Fr+2M/dp

X

Y

≦1.5

1

0.45

>1.5

0.67

0.67

[Calculating the Service Life Time]

The service life time of model RW is obtained from the

following equation.

For Rotary Motion

Lh=

Lh :

L

nr 60

Service life time [h]

nr :

Rotation speed per minute

[min-1]

3

007-0710_P03-H4.indd 3

10.8.18 2:44:30 PM

Static Safety Factor

The basic static load rating C0 refers to the static load with constant direction and magnitude, under which the calculated

contact stress in the center of the contact area between the roller and the raceway load is 4,000 [MPa] (if the contact stress

exceeds this value, performance may be affected). This value is indicated as “C 0” in the specification tables. When a load is

statically or dynamically applied, it is necessary to consider the static safety factor as shown below.

Table 3 Static Safety Factor (fS)

C0

=fs

P0

fS :

C0 :

P0 :

Load conditions

Lower limit of fS

Normal load

1 to 2

Impact load

2 to 3

Static safety factor (see Table 3)

Basic static load rating [N]

Static equivalent radial load [N]

[Static Equivalent Radial Load: P0]

Moment

(M)

The static equivalent radial load of model RW is obtained

from the following equation.

Axial load

(Fa)

2M

P0=X0・ Fr+

+Y0・Fa

dp

(

P0 :

Fr :

Fa :

M :

)

Static equivalent radial load [N]

Radial load [N]

Axial load [N]

Moment [N-mm]

X0 :

Y0 :

dp :

Radial load

(Fr)

Moment

(M)

Static radial factor (X0 = 1)

Static axial factor (Y0 = 0.44)

Roller pitch circle diameter [mm]

Permissible Load

Table 4 shows the permissible load of model RW.

The permissible load value takes into account the tightening

strength of the mounting bolts. Consider the difference in

the permissible loads between with and without a housing.

If the applied radial load or moment is large, it is

Recommended to insert the product into a housing. (For

housing design, also see sections “Fit” and “Designing

Peripheral Parts” on page 6).

Without housing

With housing

Table 4 Permissible Load of Model RW

Without housing

With housing

Model No.

Radial [kN]

Axial [kN]

Moment [kN-m]

Radial [kN]

Axial [kN]

Moment [kN-m]

RW228

7.5

54.4

2.3

26.6

54.4

3.0

RW297

12.1

97.1

5.0

47.6

97.1

7.1

RW445

16.2

219

9.8

107

219

24

4

007-0710_P03-H4.indd 4

10.8.18 2:44:32 PM

Product Overview

Double-Row Angular Contact Roller Rings <RW>

Accuracy Standards

Model RW is manufactured with the accuracy and the dimensional tolerance in Tables 5 to 8.

[Rotational Accuracy]

Table 5 Rotational Accuracy of the Inner Ring of Model RW

Unit: μm

Radial runout tolerance of the inner ring

Axial runout tolerance of the inner ring

Model No.

Grade P5

Grade P4

Grade P2

Grade USP

Grade TSP

Grade P5

Grade P4

Grade P2

Grade USP

Grade TSP

RW228

8

6

5

2.5

2.5

8

6

5

2.5

2.5

RW297

10

8

5

3

3

10

8

5

3

3

RW445

15

12

7

4

4

15

12

7

4

4

Note) For model RW, grade P5 is the standard rotational accuracy. (Not indicated in model number.)

Table 6 Rotational Accuracy of the Outer Ring of Model RW

Unit: μm

Radial runout tolerance of the outer ring

Axial runout tolerance of the outer ring

Model No.

Grade P5

Grade P4

Grade P2

Grade USP

Grade P5

Grade P4

Grade P2

Grade USP

RW228

18

11

7

4

18

11

7

4

RW297

20

13

8

5

20

13

8

5

RW445

25

16

10

7

25

16

10

7

Note) For model RW, grade P5 is the standard rotational accuracy. (Not indicated in model number.)

[Wobbling Accuracy (Inner Ring of Grade TSP Only)]

Probe

Height measurement

Wobbling Accuracy refers to the pure rotational accuracy

of the bearing calculated by subtracting the profile accuracy

(roundness and flatness) from the rotational accuracy of

the bearing.

Measurement conditions: “height measurement” = “roller pitch circle

diameter”

Table 7 Wobbling Accuracy of Model RW

Unit: μm

Grade TSP

Model No.

Radial direction

Axial direction

RW228

2

2

RW297

2

2

RW445

2

2

Roller pitch circle diameter

Method for wobbling accuracy measurement

[Dimensional Accuracy]

Table 8 Dimensional Tolerance of Bearing Inner Diameter, Outer Diameter and Width of Model RW

Unit: μm

Dimensional tolerance of bearing inner diameter dm Dimensional tolerance of bearing outer diameter Dm

Dimensional tolerance of bearing width B

Model No.

Upper

Lower

Upper

Lower

Upper

Lower

RW228

0

−25

0

−35

0

−100

RW297

0

−30

0

−40

0

−100

RW445

0

−40

0

−50

0

−150

Note) dm and Dm represent the arithmetic mean values of the maximum diameter and the minimum diameter obtained through two-point measurement of the bearing inner

diameter and the bearing outer diameter.

5

007-0710_P03-H4.indd 5

10.8.18 2:44:32 PM

Radial Clearance

The radial clearance of model RW is adjusted to a negative

value (preloaded) before shipment, which is controlled with

the starting torque of the product.

Table 9 shows the specification values for the starting

torque of model RW.

Table 9 Radial Clearance of Model RW

Starting torque [N-m]

Model No.

Minimum

Maximum

RW228

1

10

RW297

3

20

RW445

10

65

Note) The starting torque does not include seal resistance.

Fit

Although the design of model RW does not require a fitted housing, if positioning accuracy is required or a large load is

applied, it is recommended to insert the product into a housing with a fit tolerance of g6 for the shaft and H7 for the hole (also

see section “Permissible Load” on page 4, and section “Designing Peripheral Parts” below).

If higher rigidity is required, it is recommended to measure the inner and outer diameters of the bearing and to use a slight

interference fit (approximately 0 to 5 μm) that corresponds to the measurements.

* If an interference fit is used, provide tapped hole for ring removal in the bearing/housing.

Designing Peripheral Parts

Table 10 shows the recommended machining accuracy for the peripheral parts (shaft and housing) to which model RW is to be installed.

Table 10 Recommended Machining Accuracy of Model RW s Mating Part

Above

Or less

Roundness

Perpendicularity

Flatness

[μm]

120

180

5

180

250

7

250

315

8

315

400

9

400

500

10

500

630

11

Standard dimension d, D [mm]

Table 10 A

Table 10

φd

A

Table 10

φD

B

Table 10

For the fit depth of the housing, see Table 11 as a guide.

Table 11 Housing Fit Depth for Model RW

Table 10 B

Table 10

Machining accuracy of peripheral part

Fit depth: H

If positioning accuracy is required

0.15 to 0.25×B

If an applied load is large

0.50 to 0.75×B

If high rigidity is required

0.75 to 1.00×B

B

Use of fit

H

H:Fit depth

B:Bearing width

Fit depth of the housing

For the mating bolt holes for securing model RW-X, the values in Table 12 are recommended.

Recommended bolt hole dimensions

Model No.

φd2

Unit: mm

h

Table 12 Recommended Bolt Hole Dimensions of the Mating Part for Model RW-X

Bolt size

d1

d2

h

RW228

M6

7

11

6.5

RW297

M8

9.3

14.5

8.6

RW445

M8

9.3

14.5

8.6

φd1

6

007-0710_P03-H4.indd 6

10.8.18 2:44:32 PM

Product Overview

Double-Row Angular Contact Roller Rings <RW>

Procedure for Assembly

When assembling model RW, follow the steps below.

[Inspect the parts prior to assembly]

Thoroughly clean the housing and other parts to be assembled, and make sure that no burrs or knots are present.

[Install the bearing to the housing or shaft]

The product tends to tilt during installation. To prevent this, gradually drive the product into the housing or onto the shaft by gently tapping it with a

plastic or copper mallet while keeping it perpendicular. Continue to tap until the bearing is properly contacting the reference surface.

Note) When installing the inner ring, only tap the inner ring; when installing the outer ring, only tap the outer ring.

[Tighten the mounting bolts]

(1) Install and align the ring with the required rotational accuracy.

(2) Place model RW onto the housing. Align model RW with the mounting holes.

(3) Insert the securing bolts into the holes. Turn the bolts by hand to make sure they do not show skewing which indicates misalignment of the holes.

(4) Fasten the mounting bolts in three to four steps from loose to fully fastened. Secure the bolts in a diagonal order. (Figure 1)

(5) When tightening the securing bolts, use a torque wrench and evenly tighten the bolts according to the values in Table 13.

17

1

9

24

16

5

25

13

4

22

19

14

7

23

2

10

12

29

Model No.

Bolt size

Tightening torque

[N-m]

RW228

M6

14

RW297

M8

30

RW445

M8

30

20

3

4

19

30

11

14

27

22

7

6

15

28

13

12

3

8

21

20

11

Table 13 Bolt Tightening Torque for Mounting Model RW

24

5

8

21

1 32

9 17

16

6

23

18

In the case of 24 bolts

15 31

10

2 18

26

In the case of 32 bolts

Figure 1: Example of bolt tightening sequence

Permissible Rotation Speed

Table 14 shows the permissible rotation speed of model RW.

Table 14 Permissible Rotation Speed of Model RW

Model No.

Permissible rotation speed

[min-1]

RW228

350

RW297

270

RW445

180

Note 1) The values in Table 14 assume operation under no load.

If a large load is applied or the permissible rotation speed is exceeded,

contact THK.

Note 2) Depending on the lubrication or the load conditions, the product may

generate considerable heat.

[Lubrication Specifications]

For the lubrication specifications of model RW, the lubricants in Table 15 are recommended.

Model RW contains THK AFB-LF Grease as standard.

Table 15 Recommended Lubrication Specifications

Lubrication specifications

Recommended lubricant

Grease lubrication

THK AFB-LF Grease

(standard grease)

Oil lubrication

ISO VG68 Oil

7

007-0710_P03-H4.indd 7

10.8.18 2:44:33 PM

Model Number Coding

RW297 UU CC0 P2 B G X −N

Option symbol

No Symbol : No accessory

-N : Grease nipple attached (A-PT1/8)

Inner Ring Hole symbol

No Symbol : Inner ring counterbore hole

X : Inner ring tapped hole (through hole)

Mounting Hole Orientation symbol【excluding X type】

No Symbol : The counterbore holes of the inner and

outer rings face the same direction

G : The counterbore holes of the inner and

outer rings face opposite direction

Sub-part Accuracy symbol

No Symbol : Rotational Accuracy of the Inner Ring

R : Rotational Accuracy of the Outer Ring

B : Rotational Accuracy of the Inner/Outer Rings

Accuracy symbol

No Symbol : 5-grade rotational accuracy

P4 : 4-grade rotational accuracy

P2 : 2-grade rotational accuracy

USP : USP-grade rotational accuracy

TSP : USP-grade rotational accuracy

+ wobbling accuracy

Radial clearance symbol

CC0 :Minus clearance (preload)

Seal symbol

No Symbol : Without seal

UU : Seal attached on both ends

U : Seal attached on either end

(counterbore side of the outer ring)

UT : Seal attached on either end

(opposite to the counter-bore of the outer ring)

Model No.

8

007-0710_P03-H4.indd 8

10.8.18 2:44:33 PM

Dimensional Table

Double-Row Angular Contact Roller Rings <RW>

2-greasing hole

PCD2

PCD1

L2

L1

2-greasing hole

φd

B

r

r

φD

RW228 to RW445

RW228G to RW445G

RW228X to RW445X

Main dimensions

Model No.

Inner

diameter

Roller

Outer

pitch circle

diameter

diameter

Width

Shoulder height

Greasing hole

Basic load rating

(radial)

C

C0

d

D

dp

B

Hole

diameter

L1

L2

rmin

ds

Dh

[kN]

[kN]

160

295

228.8

35

Rc1/8

10.5

24.5

2

220

240

58.4

158

210

380

299.2

40

Rc1/8

12

28

2.5

285

315

101

287

350

540

445.4

50

Rc1/8

15

35

2.5

425

465

214

647

RW228(G)

RW228X

RW297(G)

RW297X

RW445(G)

RW445X

9

007-0710_P03-H4.indd 9

10.8.18 2:44:33 PM

PCD2

Model RW

φds

Model RW…UU

PCD1

Model RW…U

φDh

Model RW…UT

Option

10

19.5

* Accessories for lubrication (piping joint, grease fitting,

11.5

etc.) other than the standard option may also be

attached.

For inquiry, contact THK (for other accessories for

R1/8

lubrication, see section “Lubrication Accessories” in

11.5

the general catalog).

Grease nipple (type A-PT1/8)

Unit: mm

Mass

Mounting hole dimensions

Inner ring

[kg]

PCD1

12

184

Outer ring

Mounting hole

PCD 2

Model No.

Mounting hole

24-φ7 through φ11 counterbore depth 24.5

RW228(G)

270

24-φ7 through φ11 counterbore depth 24.5

24-M6 depth 18

RW228X

24-φ9.3 through φ14.5 counterbore depth 28

22

240

RW297(G)

350

24-φ9.3 through φ14.5 counterbore depth 28

24-M8 depth 24

RW297X

32-φ9.3 through φ14.5 counterbore depth 35

47

385

RW445(G)

505

32-M8 depth 24

32-φ9.3 through φ14.5 counterbore depth 35

RW445X

10

007-0710_P03-H4.indd 10

10.8.18 2:44:34 PM

Double-Row Angular Contact Roller Rings RW

●Precautions on Handling

Precautions on Use

· Do not disassemble the Double-Row Angular Contact Roller Rings unit.

· Dropping or hitting the Double-Row Angular Contact Roller Rings unit may damage it. Applying an impact force to the product

could cause functional loss even if the product looks intact.

●Lubrication

· Since each Double-Row Angular Contact Roller Rings unit contains high-quality lithium soap group grease No. 2 (THK AFB-LF

Grease), you can start using the product without replenishing grease. However, the product requires regular lubrication since it

has a smaller internal space than ordinary roller bearings and because the rollers need frequent lubrication due to their rolling

contact structure.

To replenish grease, it is necessary to provide a grease path that leads to the oil holes formed on the circumference of the outer

ring. As for the lubrication interval, normally replenish grease of the same type while rotating the ring so that it is distributed

throughout the interior of the bearing at least every six to twelve months even if the product rotates infrequently.

When the bearing is filled up with grease, the initial rotational torque temporarily increases due to the resistance of the grease.

However, surplus grease will run out of the seals and the torque will return to the normal level in a short period.

· Do not mix greases with different physical properties.

· In locations exposed to constant vibrations or in special environments such as clean rooms, vacuum and low/high temperature,

normal lubricants may not be used. Contact THK for details.

· When planning to use a special lubricant, or use the product other than with grease lubrication, contact THK before use.

●Precautions on Use

· Entrance of foreign material may cause functional loss. Prevent foreign material, such as dust or cutting chips, from entering

the product.

· Contact THK if you desire to use the product at a temperature above 80°C.

· Avoid an environment where a coolant may penetrate into the Double-Row Angular Contact Roller Rings unit.

· If foreign material adheres to the product, replenish the lubricant after cleaning the product with clean kerosene.

· When using the product in locations exposed to constant vibrations or in special environments such as clean rooms, vacuum

and low/high temperature, contact THK in advance.

· The seal of the Double-Row Angular Contact Roller Rings unit is a dust seal, and cannot prevent the entrance of fine dust or

liquid foreign material.

● “LM GUIDE,” and “

” are registered trademarks of THK CO., LTD.

● The photo may differ slightly in appearance from the actual product.

● The appearance and specifications of the product are subject to change without notice. Contact THK before placing an order.

● Although great care has been taken in the production of this catalog, THK will not take any responsibility for damage resulting from typographical errors or omissions.

● For the export of our products or technologies and for the sale for exports, THK in principle complies with the foreign exchange law and the Foreign Exchange

and Foreign Trade Control Law as well as other relevant laws.

All rights reserved

For export of THK products as single items, contact THK in advance.

HEAD OFFICE 3-11-6, NISHI-GOTANDA, SHINAGAWA-KU, TOKYO 141-8503 JAPAN

INTERNATIONAL SALES DEPARTMENT PHONE:+81-3-5434-0351 FAX:+81-3-5434-0353

Global site : http://www.thk.com/

NORTH AMERICA

THK America,Inc.

HEADQUARTERS

Phone:+1-847-310-1111

Fax:+1-847-310-1271

CHICAGO OFFICE

Phone:+1-847-310-1111

Fax:+1-847-310-1182

NORTH EAST OFFICE

Phone:+1-845-369-4035

Fax:+1-845-369-4909

ATLANTA OFFICE

Phone:+1-770-840-7990

Fax:+1-770-840-7897

LOS ANGELES OFFICE

Phone:+1-949-955-3145

Fax:+1-949-955-3149

SAN FRANCISCO OFFICE

Phone:+1-925-455-8948

Fax:+1-925-455-8965

DETROIT OFFICE

Phone:+1-248-858-9330

Fax:+1-248-858-9455

TORONTO OFFICE

Phone:+1-905-820-7800

Fax:+1-905-820-7811

SOUTH AMERICA

THK Brasil LTDA

Phone:+55-11-3767-0100 Fax:+55-11-3767-0101

EUROPE

THK GmbH

EUROPEAN HEADQUARTERS

Phone:+49-2102-7425-555 Fax:+49-2102-7425-556

DUSSELDORF OFFICE

Phone:+49-2102-7425-0

Fax:+49-2102-7425-299

FRANKFURT OFFICE

Phone:+49-2102-7425-650 Fax:+49-2102-7425-699

STUTTGART OFFICE

Phone:+49-7150-9199-0

MUNICH OFFICE

Phone:+49-8937-0616-0

U.K. OFFICE

Phone:+44-1908-30-3050

ITALY MILAN OFFICE

Phone:+39-039-284-2079

ITALY BOLOGNA OFFICE

Phone:+39-051-641-2211

SWEDEN OFFICE

Phone:+46-8-445-7630

AUSTRIA OFFICE

Phone:+43-7229-51400

SPAIN OFFICE

Phone:+34-93-652-5740

TURKEY OFFICE

Phone:+90-216-362-4050

PRAGUE OFFICE

Phone:+420-2-41025-100

MOSCOW OFFICE

Phone:+7-495-649-80-47

THK Europe B.V.

EINDHOVEN OFFICE

Phone:+31-040-290-9500

THK France S.A.S.

Phone:+33-4-3749-1400

CHINA

THK (CHINA) CO.,LTD.

HEADQUARTERS

Phone:+86-411-8733-7111

Fax:+49-7150-9199-888

Fax:+49-8937-0616-26

Fax:+44-1908-30-3070

Fax:+39-039-284-2527

Fax:+39-051-641-2230

Fax:+46-8-445-7639

Fax:+43-7229-51400-79

Fax:+34-93-652-5746

Fax:+90-216-569-7150

Fax:+420-2-41025-199

Fax:+7-495-649-80-44

Fax:+31-040-290-9599

Fax:+33-4-3749-1401

Fax:+86-411-8733-7000

SHANGHAI OFFICE

Phone:+86-21-6219-3000 Fax:+86-21-6219-9890

BEIJING OFFICE

Phone:+86-10-8441-7277 Fax:+86-10-6590-3557

CHENGDU OFFICE

Phone:+86-28-8526-8025 Fax:+86-28-8525-6357

GUANGZHOU OFFICE

Phone:+86-20-8523-8418 Fax:+86-20-3801-0456

SHENZHEN OFFICE

Phone:+86-755-2642-9587 Fax:+86-755-2642-9604

THK (SHANGHAI) CO.,LTD.

Phone:+86-21-6275-5280 Fax:+86-21-6219-9890

TAIWAN

THK TAIWAN CO.,LTD.

TAIPEI HEAD OFFICE

Phone:+886-2-2888-3818 Fax:+886-2-2888-3819

TAICHUNG OFFICE

Phone:+886-4-2359-1505 Fax:+886-4-2359-1506

TAINAN OFFICE

Phone:+886-6-289-7668

Fax:+886-6-289-7669

KOREA

SEOUL REPRESENTATIVE OFFICE

Phone:+82-2-3468-4351

Fax:+82-2-3468-4353

SINGAPORE

THK LM SYSTEM Pte. Ltd.

Phone:+65-6884-5500

Fax:+65-6884-5550

THAILAND

THK LM System Pte.Ltd.Representative Office in Thailand

Phone:+660-2751-3001

Fax:+660-2751-3003

INDIA

BANGALORE REPRESENTATIVE OFFICE

Phone:+91-80-2330-1524 Fax:+91-80-2330-1524

©THK CO., LTD.

007-0710_P03-H4.indd 11

201008030 E13 Printed in Japan

10.8.18 2:44:34 PM