Safe, Low-Cost, High-Energy-Density, Solid-State Li

advertisement

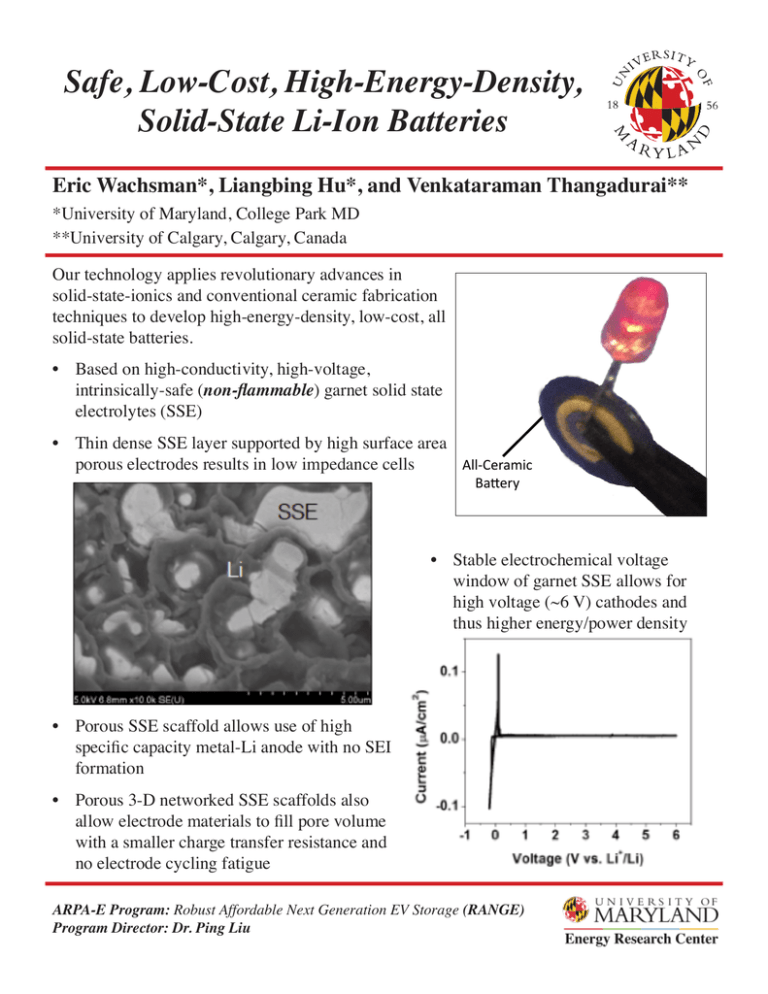

Safe, Low-Cost, High-Energy-Density, Solid-State Li-Ion Batteries Eric Wachsman*, Liangbing Hu*, and Venkataraman Thangadurai** *University of Maryland, College Park MD **University of Calgary, Calgary, Canada Our technology applies revolutionary advances in solid-state-ionics and conventional ceramic fabrication techniques to develop high-energy-density, low-cost, all solid-state batteries. • Based on high-conductivity, high-voltage, intrinsically-safe (non-flammable) garnet solid state electrolytes (SSE) • Thin dense SSE layer supported by high surface area porous electrodes results in low impedance cells All-Ceramic Battery From Dr. Wachsman’s group: the first all • Stable electrochemical voltage window of garnet SSE allows for high voltage (~6 V) cathodes and thus higher energy/power density • Porous SSE scaffold allows use of high specificcapacitymetal-LianodewithnoSEI formation • Porous 3-D networked SSE scaffolds also allowelectrodematerialstofillporevolume with a smaller charge transfer resistance and no electrode cycling fatigue ARPA-E Program: Robust Affordable Next Generation EV Storage (RANGE) Program Director: Dr. Ping Liu Supported by: • Stable Limetal cycling with no dendrite shorting or performance decay 3 mA/cm2 We are developing high-power density, solid-state, lithium-ion batteries that overcome all of the safety, stability, and performance issues of conventional Li-ion batteries. The dense ceramic electrolyte prevents Li-dendrite shorting and overcomes thermal stability issues of currently used organic liquid electrolytes. The all solid-state structure provides revolutionary dimensional tolerance and mechanical strength, decreasing packaging requirements and system weight. Moreover, our technology will also dramatically reduce manufacturing costs using scalable, ceramic fabrication techniques that do not require dry rooms or vacuum equipment. Advantages: Battery Pack * Estimated Performance • “Holy grail” metal anode provides maximum theoretical energy and power density Cell voltage 5V • Dense ceramic SSE prevents dendrite growth Specific capacity 62 Ah/kg Volumetric capacity 230 Ah/L • Li cycles between electrodes by pore filling with no cycle fatigue or dimensional changes Energy density (mass) 340 Wh/kg Energy density (volume) 1,270 Wh/L *Inclusive of packaging • Wide operating temperature range with no thermal runaway concern • Mechanically robust and conformal • Non-flammable and intrinsically safe Research Group webpage www.wachsman.umd.edu Contact information ewach@umd.edu 301-405-8193