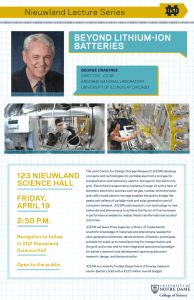

energy storages

advertisement