Lithium Sulfur Presentation Energy Futures Lab June 2016 Dr

advertisement

Sulfur - from hell to powering your car

M. Marinescu

EFL Energy Seminar

June 7th , 2016

Motivation

We need better batteries

Emission reduction policies ⇒ Decrease reliance on carbon fuels

• De-carbonise transport ⇒ xEV

• De-carbonise electrical power grids

Better =

• cheap & long-lasting

• energy & power dense

• light, small

• safe

• versatile

Contestabile, Offer, North, Electric vehicles: a synthesis of the

current literature with a focus on economic and environmental

viability, 2012

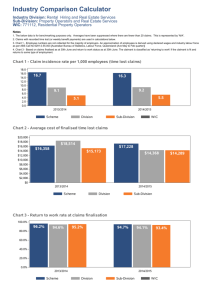

Battery requirements

> 95% Li-ion manufacture for consumer electronics

Standard

EV

Cell capacity (Ah)

4

40

Energy density (Wh/kg)

150

150

Life expect (yrs)

3

15

Cell cost ($/kWh)

<250

400

United States Advanced Battery Consortium energy storage system goals, http://www.uscar.org, 2016

From cell to pack

?

35Wh −→ 30 kWh

• structural support

− mechanical vibrations, crash test

• thermal management

− large cells + tight pack of many

• balanced electrically - many cells

Cost of battery pack = double the cost of cells ($800/kWh,

$21000/30kWh)

Attributes for high energy density

1. Large specific capacity of electrodes

Amount of charge they store

2. High Electropotential

Potential difference between anode and cathode

3. Large stoichiometric coefficient

# e- per mole of reactants

4. Low molar mass of active species

Avenues

• Reversibility!

• Mass and volume of non-active materials!

Oxis Energy Ltd

Avenues

P. Bruce, Nat Mat, 2012

Conversion vs intercalation batteries

Intercalation - limited by:

• active material intercalates reversibly

• Li: 1e- , 4V cell (th): 300mAh/g=1200 Wh/kg

Conversion

• active material changes phase reversibly

• many eType

Example

Vcell

Intercalation (now)

LMO

3.8

Intercalation (th)

Wh/kg (th)

Wh/l (th)

550

Wh/kg (max prac)

110-165

1200

240-300

S

LiS

2.2

2567

2200

300-800

M-air

LiO

3.0

3505

3430

700-1000

Reproduced from Cluzel, Douglas, Cost and performance of EV batteries, Element Energy report for The comittee

on climate change, 2012

Why LiS

• gravimetric energy density 3

• safety (*) 3

• cheap 3

• low temperature performance 3

http://www.shorpy.com/

• power density (discharge rate) 7

• cycle life 7

• volumetric energy density 7

* Hunt, Patel, Szczygielski, Kabacik, Offer, Journal of Energy

Storage 2, 2015

LiS in use

www.airbusgroup.com/int/en/story-overview/

http://www.oxisenergy.com/applications/

• lightweight

• safe

• low operating T

https://protonex.com/blog/what-do-soldiers-carry-and-whats-

LiS operation

Discharge

LiS operation

Charge

LiS operation

Effect of current

LiS operation

Effect of current

LiS challenges

• improve rate capacity

• improve cycle life

- capture poly-S in cathode

- ensure homogeneous Li plating on anode

- design cathode microstructure

• improve SOC estimation

Manthiram et al, Acc Chem Res 46, 2012

Improving performance and use of LiS through modelling

REVB: Revolutionary Electric Vehicle Battery

• Target: 400Wh/kg LiS cells

• Physics-based models & reduced-order models

• Battery pack design, drive-cycle testing

Funded by EPSRC and Innovate UK

0D model formulation

S8 0 + 4 e− ←−→ 2 S4 2−

S4 2− + 4 e− ←−→ 2 S2− ↓ + S2 2−

0D model formulation

I = iH + iL

IL

V = (E + η)cathode −(E + η)anode

−

|

{z

} | {z } κA

Vcathode

Vanode

• species formed/destroyed by e-chemical reactions

• shuttle = S80 → S42− without e-

• precipitation model with nucleation

• Nernst equations: equilibrium potential of reactions

• Butler Volmer approximation: reaction currents

dSn

dt

Species evolution during operation

• Can track charge status of battery

• Qualitative charge/discharge voltage curves retrieved without

need of differing mechanism

Precipitation during discharge

2.4

EL =

EL0

+

RT

4F

ln

S 2−

cL (S 2−4)2 S 2−

2

Potential (V)

2.35

[S 2(g), k

*

2.3

p

(s -1 )] =

no ppt

0.0001, 100

0.0050, 100

0.0001, 500

0.0050, 500

2.25

2.2

2.15

2.1

0

0.5

1

1.5

2

2.5

Discharge capacity (Ah)

Flat voltage plateau during discharge is caused by precipitation.

Zhang, Marinescu, O’Neill, Wild, Offer, Phys. Chem. Chem, Phys. 17, 2015

Marinescu, Zhang, Offer, Phys. Chem. Chem. Phys 18, 2016

3

3.5

Charging rate

Limited by shuttle and precipitation

• fast charge ⇒ ’slow’ dissolution

• slow charge ⇒ shuttle

Limitations of 0D model

No mass transport

⇒ mass transport in 1D model

1D model formulation

• PDE’s species conc

• flux of species mass

• diffusion and

migration

Kumaresan, Mikhaylik, White, J. Electrochem. Soc. 155, 2008

Ghaznavi & Chen, J. Power Sources 257, 2014

1D model predictions

Discharge rate retrieved for slow Li+ diffusion

T. Zhang, M. Marinescu, S. Walus, G. J. Offer, submitted, 2016

1D model predictions

Capacity recovery retrieved for slow Li+ diffusion

T. Zhang, M. Marinescu, S. Walus, G. J. Offer, submitted, 2016

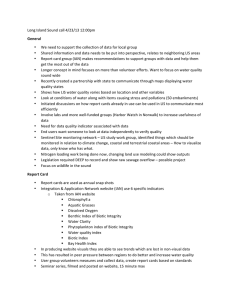

What we learnt from modelling

Models show

• precipitation/dissolution limits charge rate

• transport through separator limits discharge rate

• ’recent history’ effect:

• accumulated precipitate

• concentration gradients in electrolyte

• crucial for SOC estimation

Current work:

• degradation: irreversible vs reversible loss

• thermal coupling

Predictions

Time to market

Chemistry

1st paper/patent

1st commercial cell

1st use series car

LCO

1979

1991

2008 (Tesla)

LMO

1983

1996

2009 (iMieV)

LFP

1994

2006

2007 (MODEC van)

Ni-MH

1967

1990

1997 (Prius)

Reproduced from Cluzel, Douglas, Cost and performance of EV batteries, Element Energy report for The comittee

on climate change, 2012

Conclusions

Chemistry in car in 10 yrs?

• Companies scaling up now

• Only incremental increase

When step change increase?

• Current status = Nature paper

• Step change → 20 yrs

Application targeted chemistry?

• high energy vs high power

• numbers are driven by behaviour

Extra slides

0D model formulation

Species evolution

dS80

dt

= −nS8 aiH − ks S80

dS42−

dt

= nS8 aiH + (1 − fl

dS22−

dt

= nS2 aiL

1

kp Sp S 2− − S∗2−

= 2nS aiL −

vρS

1

=

kp Sp S 2− − S∗2−

vρS

MS8

= ks S80 ,

a=−

ne F

dS 2−

dt

dSp

dt

dSs

dt

Ss

)ks S80 − nS4 aiL

mS

0D model formulation

Reaction equilibrium and kinetics

S8 0 + 4 e− ←−→ 2 S4 2−

S4 2− + 4 e− ←−→ 2 S2− ↓ + S2 2−

Nernst equation for equilibrium potential

!

RT

S80

0

EH = EH

+

ln cH 2−

4F

(S4 )2

!

RT

S42−

0

EL = EL +

ln cL 2− 2 2−

4F

(S ) S2

Butler-Volmer approximation for reaction current

ne F ηH

,

2RT

ne F ηL

iL = 2iL,0 ar sinh

.

2RT

iH = 2iH,0 ar sinh

ηH = V − EH

ηL = V − EL

I = iH + iL

V = (E + η)cathode −(E + η)anode

−

|

{z

} | {z }

Vcathode

Vanode

IL

κA

Definitions from 0D model

n2S4 MS8 v

,

nS8

2 v2

n2 nS2 MS8

cL = S

,

nS4

cH =

(1a)

(1b)