TriMark

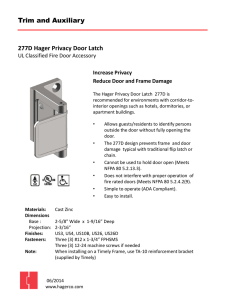

advertisement