870

IEEE TRANSACTIONS ON ELECTRON DEVICES, VOL. 60, NO. 2, FEBRUARY 2013

Printed Half-Wave and Full-Wave Rectifier

Circuits Based on Organic Diodes

Petri S. Heljo, Miao Li, Kaisa E. Lilja, Himadri S. Majumdar, and Donald Lupo

Abstract—Presently, most circuits fabricated using organic materials and printing methods have been adopted directly from

solid-state inorganic electronics. However, the characteristics of

organic electronic devices can differ remarkably from their inorganic equivalents, and therefore, the performance assumptions

made about inorganic devices may not be applicable in organic electronics. In this paper, we report a printed diode-based

half-wave rectifier having high yield, good air stability, and 3.5-V

dc output at 13.56 MHz. Due to the high yield and good performance of the individual diodes, fabrication of more complex

devices is possible. In order to achieve higher output power

and lower ripple voltage, a printed full-wave bridge rectifier is

reported. In addition, the half-wave and the full-wave rectifier

circuits are consistently compared with each other. The output

waveforms, voltages, and power values are presented for both

rectifying circuits. The output measurement results show that

the full-wave rectifier has lower output power and lower output

voltage due to the high voltage drop of the printed diodes. Therefore, the full-wave rectifier would be most useful in low-frequency

applications where low ripple voltage or small capacitor area is

required.

Index Terms—Gravure printing, organic semiconductors, rectifying diode.

I. I NTRODUCTION

O

RGANIC diodes and transistors have been extensively

studied for signal rectification in organic electronics applications. In most reports, the rectification properties have

been studied for organic Radio Frequency IDentification

(RFID) technology at base carrier frequency of 13.56 MHz

[1], [2]. For the profitable production of passive RFID tags, the

price and production rate of the tags are important parameters.

Low-cost manufacturing and high production volumes can be

achieved using conventional reel-to-reel compatible printing

technologies and solution processable materials.

The simple half-wave rectifier, consisting only of one rectifying component and a capacitor, has been extensively studied

Manuscript received July 9, 2012; revised October 5, 2012; accepted

November 27, 2012. Date of publication January 11, 2013; date of current

version January 18, 2013. This work was supported in part by UPM-Kymmene

Corporation and in part by the Academy of Finland. The review of this paper

was arranged by Editor D. J. Gundlach.

P. S. Heljo, M. Li, and D. Lupo are with the Department of Electronics, Tampere University of Technology, 33101 Tampere, Finland (e-mail:

petri.heljo@tut.fi).

K. E. Lilja was with the Department of Electronics, Tampere University of

Technology, 33101 Tampere, Finland. She is now with Biolin Scientific, 02130

Espoo, Finland.

H. S. Majumdar is with the VTT Technical Research Center of Finland,

02044 Espoo, Finland, and also with the Department of Material Sciences, Åbo

Akademi University, 20500 Turku, Finland.

Color versions of one or more of the figures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TED.2012.2233741

in organic electronics. For example, with a pentacene diodebased half-wave rectifier, a dc output voltage of 11 V was

obtained at 14 MHz using an 18-V ac input voltage [3]. With

semicrystalline solution processable polythiophene semiconductors, an output voltage of 4 V was reported at 13.56 MHz

with a 10-V input signal [4]. Due to different input voltages

and different loading of the circuits, comparison between the

rectifying components from different reports is difficult.

In recent years, more sophisticated organic rectifying circuit

designs have been published. The purpose of these circuits

is to deliver more output voltage or power. Most of the circuits are familiar from solid-state silicon-based semiconductor

technology, and the results from different circuit architectures

have been published in detail: a full-wave rectifier [5], [6], a

double half-wave rectifier [7], and a charge pump circuit [8]–

[10]. However, comparison between the different circuit types

is even more complicated due to the reasons explained before.

In addition, the characteristics of the organic components have

an effect on the functionality of most circuits, leading to

unexpected results when compared with conventional siliconbased technology. Therefore, reliable comparison is essential

for further development of the organic electronic rectifying

devices. Deep understanding of the circuit operation will also

give additional insight into device properties and performance.

Here, we report a gravure printed rectifying diode with

high yield and good ac performance at 13.56 MHz. Reliable

operation of individual diodes enabled fabrication of printed

full-wave rectifier circuits, consisting of four diodes connected

as a bridge. In addition, a consistent performance comparison is

reported between the half- and full-wave rectifier circuits. The

circuits were measured using a carefully designed measurement

setup. The analysis of the results gives valuable information on

the properties of the printed organic diodes, the performance

of the rectifier circuits, and also on the applicability of printed

diodes to more complex circuits.

II. M ATERIALS AND M ETHODS

The full-wave rectifier circuits were fabricated on a PET

substrate (Melinex ST506, DuPont Teijin Films) with a sheetfed gravure printing press (Labratester Automatic from Norbert

Schläfli Maschinen). A 50-nm layer of copper was evaporated

onto the PET substrate through a shadow mask for the bottom

electrode structures. After evaporation, the substrates were

cleaned by rinsing with deionized water and 2-propanol. The

patterned poly(triarylamine) (PTAA) semiconductor layer was

printed onto the copper electrodes and cured at 115 ◦ C for

5 min. After semiconductor curing, the silver top electrodes

0018-9383/$31.00 © 2013 IEEE

HELJO et al.: HALF- AND FULL-WAVE RECTIFIER CIRCUITS BASED ON ORGANIC DIODES

871

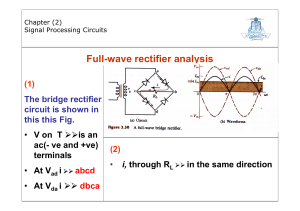

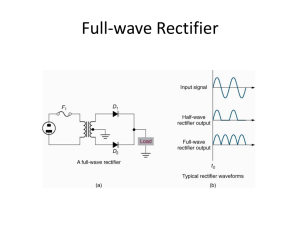

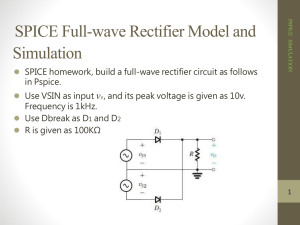

Fig. 2. (a) Half-wave rectifier circuit. (b) Current pathway in a halfwave rectifier during the positive input cycle. (c) Full-wave rectifier circuit.

(d) Current pathway in a full-wave rectifier during the positive input cycle. UD1

and UD2 are voltage drops over the printed diodes, and UR is the voltage drop

over the load resistor.

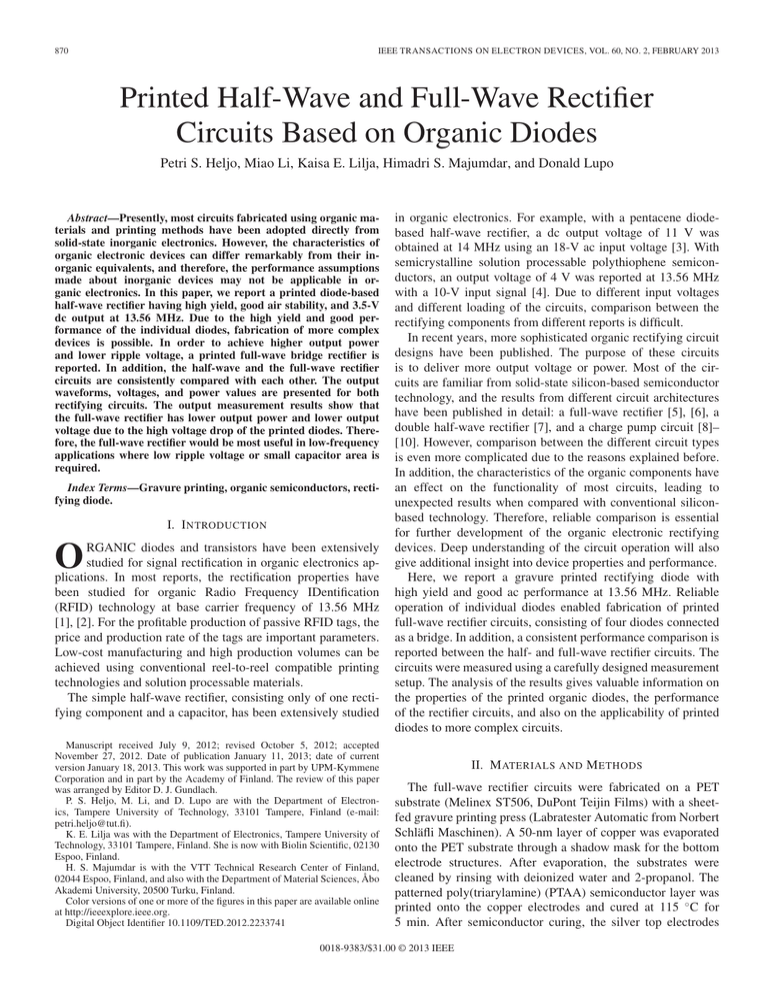

Fig. 1. (a) Photo of the measurement setup used in half-wave rectifier measurements. (b) Photo of the printed full-wave circuit, including four diodes,

where the semiconductor is sandwiched between the Cu and Ag electrodes.

(c) Simplest equivalent circuit for an organic diode with no contact effects,

where R (10 kΩ) describes the bulk resistance of the diode and C (71 pF)

describes the diode geometric capacitance.

were gravure printed using silver flake ink (PM460A from

Acheson Industries Ltd.). The ink was cured at 115 ◦ C for

5 min. All the fabrication steps were performed in a dust-free

environment at room temperature and in ambient air. A photo

of the full-wave circuit is presented in Fig. 1(b). For the halfwave rectifier measurements, individual diodes were separated

from the full-wave circuits, thus ensuring comparable device

operation. Mechanism of operation of the diodes is described

in [11] and [12], including detailed information about the diode

rectification and charge injection properties.

PTAA is known to be a stable semiconductor material in

ambient air [13]. Therefore, all the measurements and characterization were performed in ambient laboratory conditions. In

addition, the samples were stored in ambient air for one month

before the measurements. The results are average values from

three different samples. The thickness of the semiconductor

layer was calculated based on the diode cross-sectional area

(optical microscope Olympus BX51) and measured geometric

capacitance at 13.56 MHz (HP Network analyzer 8752A) using

relative permittivity of 3 for the PTAA. A simple equivalent

circuit with no contact effects was also built for the printed

diodes based on the measured geometric capacitance and effective diode resistance estimated from the output power measurements [see Fig. 1(c)]. A 10-V sinusoidal input (Keithley

3390) and a 4.7-nF discrete load capacitor CL were used in all

rectifier output measurements.

A. Output Voltage

The half- and full-wave measurement circuits are illustrated

in Fig. 2. Measurements were performed using input signal

frequencies between 10 kHz and 40 MHz. The rectified output voltage (RMS) and ripple voltage (peak-to-peak) over the

external 100-kΩ load RL were measured from both circuits

with an oscilloscope (Tektronix DPO4104) using 10× voltage

probes (Tek P6139A from Tektronix). For easier comparison

with earlier reports, the half-wave rectifier output voltage was

also measured in an additional measurement using a 1-MΩ

load. A photo of the measurement setup used in the half-wave

rectifier measurements is presented in Fig. 1(a). For the fullwave rectifier circuit, a different measurement probe was used

due to the different amount of required contact points.

Output voltage waveforms were also measured to ensure

proper function of the circuits. The measurement circuits in

Fig. 2 were used, but the frequency was fixed to 100 Hz to limit

capacitive effects on the resulting waveform.

B. Output Power

Output power as a function of load resistance was measured

for both circuits. Measurements were performed at frequencies

of 10 kHz and 1 MHz using external loads from 1 to 100 kΩ.

Output power was calculated by dividing the square of the

measured RMS output voltage with the output load resistance.

Due to the capacitive nature of the diode, the input impedance

is strongly related to frequency. At frequencies at which the

output ripple voltage is low, the input impedance measurement

would mainly describe the capacitance of the circuit and not

give additional information about the circuit operation.

III. R ESULTS AND D ISCUSSION

Based on the diode geometric capacitance of 71 pF and diode

active area of 0.97 mm2 , the thickness of the printed semiconductor layer was 360 nm. The yield of the individual diodes

was determined by inspecting the output voltage with a 10-V

input at 13.56 MHz. As a result, 31 out of 32 diodes rectified

a constant dc output. Thus, the yield of the individual diodes

was 97%. High yield, good output performance, and reliable

872

IEEE TRANSACTIONS ON ELECTRON DEVICES, VOL. 60, NO. 2, FEBRUARY 2013

Fig. 3. Rectifier output waveforms. The upper and lower figures present the

half- and full-wave rectifier output voltages, respectively. Measurements were

performed at 100 Hz with a 100-kΩ load resistor.

operation of the single diodes at 13.56 MHz enabled the fabrication of more complex devices. Full-wave bridge rectifier

circuits were printed to achieve higher output power and lower

ripple voltage. However, the printed full-wave rectifier performance was strongly affected by the characteristic properties of

the printed diodes. This demonstrates the importance of consistent comparison between the different circuit architectures.

The load capacitor and diode geometric capacitance have an

effect on the output voltage waveform at high frequencies. In

addition, the charge carrier mobility and charge storage phenomenon [14] have a notable effect above 100-kHz frequencies.

However, at low frequencies, the waveforms are easy to identify

and compare. The waveform results at 100 Hz are presented

in Fig. 3. The same input voltage was used for both circuits.

Thus, the differences between half- and full-wave rectification

are easy to observe. The half-wave rectifier output voltage

amplitude was 7.3 V. The voltage drop from the 10-V input is

mainly caused by nonideal metal–semiconductor contacts and

high resistivity of the semiconductor material. The full-wave

rectifier output voltage amplitudes during the positive (4.7-V)

and negative (5.0-V) input cycles have a small difference due to

the small differences between the diode characteristics. These

differences arise mainly from the printing process. The lower

output voltage of the full-wave rectifier can be explained by

the current pathways in Fig. 2. In the full-wave rectifier, the

current has to flow through two diodes and, thus, the voltage

drop caused by the diodes is higher than in the half-wave

rectifier. This explanation corresponds well with solid-state

silicon-based full-wave rectifiers, where in practice the filtered

dc output voltage is the input voltage minus two times the

diode voltage drop. On the other hand, in the half-wave rectifier

circuits, the filtered dc output voltage is in practice the input

voltage minus the voltage drop of a single diode.

The rectified dc output voltages and ripple voltages were

now measured to study the ac rectification differences between

the two filtered circuits (see Fig. 4). The output voltage of the

full-wave rectifier was lower due to the higher voltage drop

over the two diodes, as explained earlier. In addition, the two

diodes in series correspond to a thicker semiconductor layer

Fig. 4. Rectified output and ripple voltages with 10-V ac input. Comparison

between the two circuits was performed using a 100-kΩ load resistor. The halfwave rectifier was measured also with a 1-MΩ load for easier comparison with

previous results.

[see Fig. 2(d)]. This decreases the speed of the device and limits

the output at high frequencies.

In Fig. 4, the advantage of the full-wave rectifier over the

half-wave rectifier can be observed only at low frequencies, at

which the time constant of the load RC circuit and the input

signal period are about the same order of magnitude. For the

half-wave rectifier, the rectified output voltage and the ripple

voltage at 10 kHz were 5.0 V and 1.1 VP −P , respectively,

whereas the output and ripple voltages for the full-wave rectifier

were 3.8 V and 0.44 VP −P , respectively. Therefore, at 10 kHz,

the relative amount of ripple voltage in the full-wave rectifier

output is half of the amount of ripple in the half-wave rectifier

output. At higher frequencies (>100 kHz), the ripple of the

half-wave rectifier circuit decreases to near the same level as

that of the full-wave rectifier. After this point, the full-wave

rectifier is no longer practical due to the slower speed of the

device and lower output voltages.

The half-wave rectifier output voltage measurement with a

1-MΩ load resistor can be compared with previously published

results [4], [15]. However, as noted before, the comparison

is not easy due to the different measurement parameters and

measurement conditions. With a 1-MΩ load, the rectified output

voltage of the half-wave rectifier was 3.5 V at 13.56 MHz.

Higher output voltages can be also obtained by printing thinner semiconductor layers. However, the yield of the process

decreases when the semiconductor layer thickness is reduced

below 360 nm. The high yield is of great importance while

designing and manufacturing complex devices in a reel-to-reel

process.

To estimate the device performance in different applications,

the rectified output power was measured as a function of load

resistance (see Fig. 5). For the half-wave rectifier circuit, a

maximum output power value of 0.58 mW was obtained below

10-kΩ loads, and for the full-wave rectifier circuit, a maximum

output power value of 0.17 mW was achieved using a 50-kΩ

load resistor. The effective resistance of the device was estimated to be equal to the load resistance when the output

power is at maximum. For the single diode in the half-wave

rectifier configuration, the effective resistance is in the range of

HELJO et al.: HALF- AND FULL-WAVE RECTIFIER CIRCUITS BASED ON ORGANIC DIODES

873

balance between the charge consumed by the load resistor RL

during one input signal period and charge delivered by the

current flow through the diode during the positive input signal

cycle (2). Leakage current through the diode is assumed to be

insignificant

VDC 2π

=

RL ω

t2

Idiode_forward dt

(2)

t1

where t1 and t2 delimit the forward bias time interval, and

Idiode_forward is described by the space-charge-limited current

assuming perfect injection of charges [17], [18].

Idiode_forward = A

Fig. 5. Rectifier output power at 10-kHz and 1-MHz frequencies. A 10-V ac

input signal and a 4.7-nF load capacitor were used in the measurements.

10 kΩ. For the full-wave bridge, the effective resistance can be

estimated to be about 50 kΩ.

With low output load resistance, the half-wave rectifier seems

to have significantly lower output power at 1 MHz than at

10 kHz (see Fig. 5). The reason for higher power at 10 kHz

is high ripple voltage due to the low RC time constant of the

load circuit, i.e., the capacitor charges to higher voltage and discharges almost completely during the input signal period. Due

to the high peak values of the output voltage, the average value

of the power increases. With high output load resistances, the

lower output power of the high-frequency signals is expected

due to the limited speed of the devices.

The maximum operation frequency of the circuit is mainly

dependent on the diode charge transport characteristics and the

diode geometric capacitance. Limited charge carrier mobility

has an effect on the output at high frequencies. In addition, the

internal diode capacitance will cause capacitive shunting of the

diode that can be seen as decreased input signal amplitude and

will cause drop on the output voltage [16]. In both half- and

full-wave rectifier measurements, capacitive shunting started to

affect at frequencies above 13.56 MHz.

Traditionally, the maximum operation frequency fmax of the

diode can be estimated based on the diode transit time tT

fmax =

1

μ(VIN − VDC )

=

tT

d2

(1)

where μ is the charge mobility, VIN is the input signal amplitude, VDC is the rectified dc voltage, and d is the thickness of

the semiconductor layer. However, in the transit time model,

the maximum operation frequency is assumed to depend only

on the time that is required for the charge carriers to travel from

one electrode to the other. Therefore, the result is a theoretical

maximum frequency taking into account only the charge carrier

mobility.

For the half-wave rectifier circuit, more sophisticated models

have been developed. Because of high input signal amplitude

and dc output voltages of a few volts, the calculations based

on small-signal parameters are not applicable. However, a

model based on large signal analysis was developed in [3].

The maximum operation frequency is calculated based on the

2

9ε0 εr μVdiode

8d3

(3)

where Vdiode = VIN − VDC , i.e., the voltage over the diode.

The dependence of the output voltage on the load resistance

can be observed from (2). If the resistance of the load is

increased, the output dc voltage will increase until a new balance point is achieved. Conversely, with low resistance values,

higher current flows through the load resistor and higher current

is needed through the diode. If the current supplied by the

diode is not adequate, the output voltage will decrease on the

level where the balance is again reached. Correspondingly,

the charge delivered by the current flow through the diode is

frequency dependent due to the limited mobility of the charge

carriers. Therefore, the maximum operation frequency is also

dependent on the load resistance.

To solve the maximum frequency limit, quite rough assumptions have to be made. Some of the assumptions are

not completely applicable for the printed diodes in this paper.

Therefore, the frequency dependence based on the large-signal

analysis is not presented here. The solved equations and assumptions are presented in detail in [3].

IV. C ONCLUSION

Air-stable half- and full-wave rectifier circuits have been

fabricated using solution processable organic materials and

reel-to-reel compatible gravure printing process. The circuit

fabrication method enabled consistent comparison between

the two rectifying circuits. For the half-wave rectifier, high

yield and a 3.5-V dc output at 13.56 MHz were presented.

The output voltage measurement showed that the full-wave

rectifier is useful in low-frequency applications where low

ripple voltage and small capacitor area are required. The output

power measurements further showed the higher output power

of the half-wave rectifier. By increasing the load resistance, the

voltage drop over the diodes could be reduced and higher output

voltages could be obtained. However, this neither increases

the output power nor correlates with many applications. These

results demonstrate important differences between inorganic

and organic device operations. Due to the output characteristics,

the full-wave rectifier is suitable for limited applications only.

However, the full-wave rectifier circuit illustrates the possibility

to manufacture more complex air-stable devices using high

throughput processes.

874

IEEE TRANSACTIONS ON ELECTRON DEVICES, VOL. 60, NO. 2, FEBRUARY 2013

R EFERENCES

[1] M. Jung, J. Kim, J. Noh, N. Lim, C. Lim, G. Lee, J. Kim, H. Kang,

K. Jung, A. D. Leonard, J. M. Tour, and G. Cho, “All-printed and rollto-roll-printable 13.56-MHz-operated 1-bit RF tag on plastic foils,” IEEE

Trans. Electron Devices, vol. 57, no. 3, pp. 571–580, Mar. 2010.

[2] S. Steudel, S. D. Vusser, K. Myny, M. Lenes, J. Genoe, and P. Heremans,

“Comparison of organic diode structures regarding high-frequency rectification behavior in radio-frequency identification tags,” J. Appl. Phys.,

vol. 99, no. 11, pp. 114 519-1–114 519-7, Jun. 2006.

[3] S. Steudel, K. Myny, V. Arkhipov, C. Deibel, S. D. Vusser, J. Genoe, and

P. Heremans, “50 MHz rectifier based on an organic diode,” Nat. Mater.,

vol. 4, no. 8, pp. 597–600, Aug. 2005.

[4] C.-Y. Lin, C.-H. Tsai, H.-T. Lin, L.-C. Chang, Y.-H. Yeh, Z. Pei,

Y.-R. Peng, and C.-C. Wu, “High-frequency polymer diode rectifiers

for flexible wireless power-transmission sheets,” Org. Electron., vol. 12,

no. 11, pp. 1777–1782, Nov. 2011.

[5] R. Rotzoll, S. Mohapatra, V. Olariu, R. Wenz, M. Grigas, and K. Dimmler,

“Radio frequency rectifiers based on organic thin-film transistors,” Appl.

Phys. Lett., vol. 88, no. 12, pp. 123 502-1–123 502-3, Mar. 2006.

[6] D.-H. Lee, J.-M. Kim, J.-W. Lee, and Y.-S. Kim, “Improved organic rectifier using polymethyl-methacrylate-poly 4-vinylphenol double layer,”

Micro Nano Lett., vol. 6, no. 7, pp. 567–570, Jul. 2011.

[7] K. Myny, S. Steudel, P. Vicca, J. Genoe, and P. Heremans, “An integrated

double half-wave organic Schottky diode rectifier on foil operating at

13.56 MHz,” Appl. Phys. Lett., vol. 93, no. 9, pp. 093305-1–093305-3,

Sep. 2008.

[8] E. Cantatore, T. C. T. Geuns, G. H. Gelinck, E. van Veenendaal, A. F. A.

Gruijthuijsen, L. Schrijnemakers, S. Drews, and D. M. de Leeuw, “A

13.56-MHz RFID system based on organic transponders,” IEEE J. SolidState Circuits, vol. 42, no. 1, pp. 84–92, Jan. 2007.

[9] S. Mutlu, I. Haydaroglu, and A. O. Sevim, “Realization of polymer charge

pump circuits using polymer semiconductors,” Org. Electron., vol. 12,

no. 2, pp. 312–321, Feb. 2011.

[10] P. Heljo, K. E. Lilja, S. Tuukkanen, and D. Lupo, “Charge pump circuit

using printed organic diodes and capacitors,” in Proc. LOPE-C, Frankfurt,

2011, pp. 53–55.

[11] K. E. Lilja, H. S. Majumdar, F. S. Petterson, R. Österbacka, and

T. Joutsenoja, “Enhanced performance of printed organic diodes using a

thin interfacial barrier layer,” ACS Appl. Mater. Interf., vol. 3, pp. 7–10,

Dec. 2010.

[12] K. E. Lilja, H. S. Majumdar, K. Lahtonen, P. Heljo, S. Tuukkanen,

T. Joutsenoja, M. Valden, R. Österbacka, and D. Lupo, “Effect of dielectric barrier on rectification, injection and transport properties of printed

organic diodes,” J. Phys. D, Appl. Phys., vol. 44, no. 29, p. 295 301,

Jul. 2011.

[13] W. Zhang, J. Smith, R. Hamilton, M. Heeney, J. Kirkpatrick, K. Song,

S. E. Watkins, T. Anthopoulos, and I. McCulloch, “Systematic improvement in charge carrier mobility of air stable triarylamine copolymers,”

J. Am. Chem. Soc., vol. 131, no. 31, pp. 10 814–10 815, Jul. 2009.

[14] B. G. Streetman and S. K. Banerjee, Solid State Electronic Devices,

6th ed. Upper Saddle River, NJ: Pearson Prentice Hall, 2005, pp. 208–211.

[15] K. E. Lilja, T. G. Bäcklund, D. Lupo, T. Hassinen, and T. Joutsenoja,

“Gravure printed organic rectifying diodes operating at high frequencies,”

Org. Electron., vol. 10, no. 5, pp. 1011–1014, Aug. 2009.

[16] Y. Ai, S. Gowrisanker, H. Jia, I. Trachtenberg, E. Voge, R. M. Wallace,

B. E. Gnade, R. Barnett, H. Stiegler, and H. Edwards, “14 MHz organic

diodes fabricated using photolithographic processes,” Appl. Phys. Lett.,

vol. 90, no. 26, pp. 262 105-1–262 105-3, Jun. 2007.

[17] A. Rose, “Space-charge-limited currents in solids,” Phys. Rev., vol. 97,

no. 6, pp. 1538–1544, Mar. 1955.

[18] M

.A

. Lampert, “Simplified theory of space-charge-limited currents in an in

sulator with traps,” Phys. Rev., vol. 103, no. 6, pp. 1648–1656, Sep. 1956.

Petri S. Heljo received the M.Sc. degree in biological and chemical measurements from Tampere University of Technology, Tampere, Finland, in 2010.

He is currently with the Department of Electronics, Tampere University of Technology.

Miao Li received the M.Sc. degree in radio frequency electronics from Tampere University of

Technology, Tampere, Finland, in 2010.

Since 2011, she has been a Research Engineer in

the Department of Electronics, Tampere University

of Technology.

Kaisa E. Lilja received the D.Sc. (Tech.) degree

from Tampere University of Technology, Tampere,

Finland, in 2011.

She is currently an Application Specialist at Biolin

Scientific, Espoo, Finland.

Himadri S. Majumdar received the Ph.D. degree in

science from Jadavpur University, Kolkata, India.

He is a Senior Scientist at the VTT Technical

Research Center of Finland, Espoo, Finland, and

an Adjunct Professor at Åbo Akademi University,

Turku, Finland.

Donald Lupo received the Ph.D. degree in physical

chemistry from Indiana University, Bloomington.

He is currently a Professor of electronic materials

in the Department of Electronics, Tampere University of Technology, Tampere, Finland.