SOUTHWESTERN MICHIGAN COLLEGE

advertisement

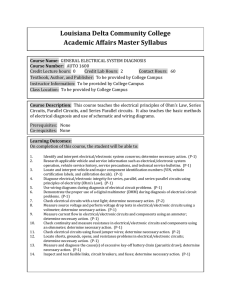

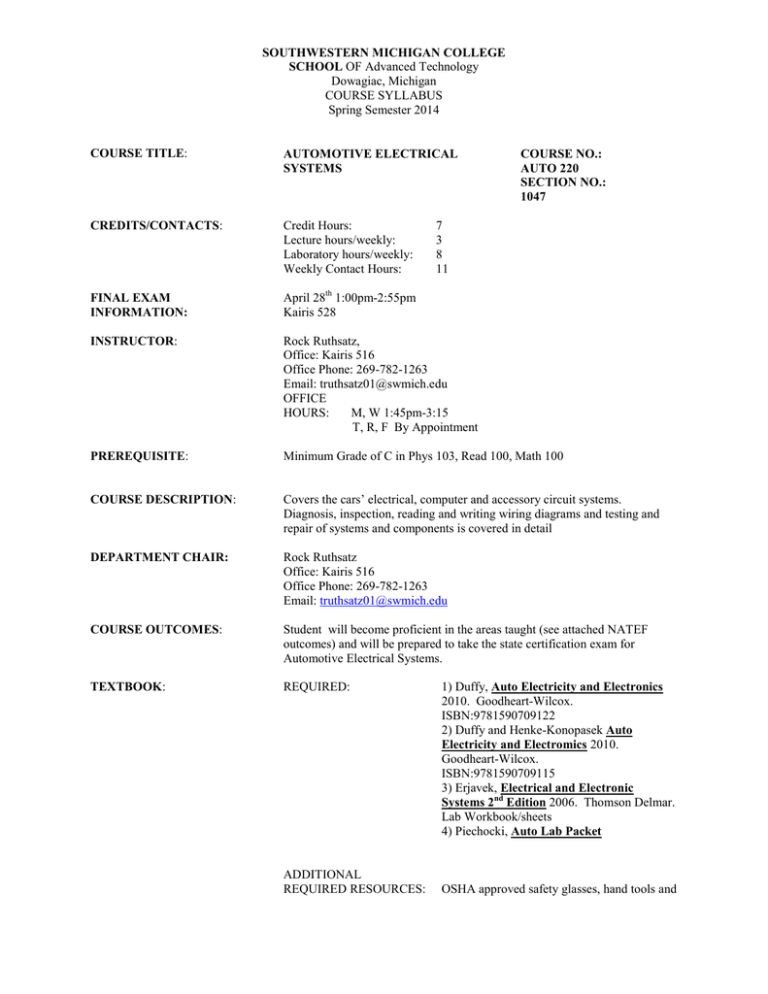

SOUTHWESTERN MICHIGAN COLLEGE SCHOOL OF Advanced Technology Dowagiac, Michigan COURSE SYLLABUS Spring Semester 2014 COURSE TITLE: AUTOMOTIVE ELECTRICAL SYSTEMS CREDITS/CONTACTS: Credit Hours: Lecture hours/weekly: Laboratory hours/weekly: Weekly Contact Hours: FINAL EXAM INFORMATION: April 28th 1:00pm-2:55pm Kairis 528 INSTRUCTOR: Rock Ruthsatz, Office: Kairis 516 Office Phone: 269-782-1263 Email: truthsatz01@swmich.edu OFFICE HOURS: M, W 1:45pm-3:15 T, R, F By Appointment PREREQUISITE: Minimum Grade of C in Phys 103, Read 100, Math 100 COURSE DESCRIPTION: Covers the cars’ electrical, computer and accessory circuit systems. Diagnosis, inspection, reading and writing wiring diagrams and testing and repair of systems and components is covered in detail DEPARTMENT CHAIR: Rock Ruthsatz Office: Kairis 516 Office Phone: 269-782-1263 Email: truthsatz01@swmich.edu COURSE OUTCOMES: Student will become proficient in the areas taught (see attached NATEF outcomes) and will be prepared to take the state certification exam for Automotive Electrical Systems. TEXTBOOK: REQUIRED: ADDITIONAL REQUIRED RESOURCES: COURSE NO.: AUTO 220 SECTION NO.: 1047 7 3 8 11 1) Duffy, Auto Electricity and Electronics 2010. Goodheart-Wilcox. ISBN:9781590709122 2) Duffy and Henke-Konopasek Auto Electricity and Electromics 2010. Goodheart-Wilcox. ISBN:9781590709115 3) Erjavek, Electrical and Electronic Systems 2nd Edition 2006. Thomson Delmar. Lab Workbook/sheets 4) Piechocki, Auto Lab Packet OSHA approved safety glasses, hand tools and Voucher. Voucher is available at SMC bookstore. Michigan Certification Testing: Students are required to take this exam at the end of the semester. METHOD OF INSTRUCTION: Lectures, discussions, Audio/Video materials, textbooks, hands-on learning lab projects, cooperative learning groups and the internet will all be utilized during this class. EVALUATION METHOD: Homework/Handouts/Quizes Tests Lab Exercises Final Exam Total 15% 15% 50% 20% 100% Students are required to complete 100% of lab assignments to receive Lab Exercises credit. The lab credit will be divided into two portions. Half of the lab credit will be issued at Mid-Term upon completion of half of the labs; the remaining half will be issued upon completion of 100% of the total labs assigned. GRADING SCALE: The following grading scale will be in effect for this course: A 93.4-100% C 73.4-76.7% A- 90-93.3% C- 70-73.3% B+ 86.8-89.9% D+ 66.8-69.9% B 83.4-86.7% D 63.4-66.7% B- 80-83.3% D- 60-63.3% C+ 76.8-79.9% F 0-59.9% [IF this class satisfies CORE, add the following: To satisfy Core Curriculum requirements, students must earn a grade of “C” or higher in this class.] ATTENDANCE POLICY: Attendance is critical for success. Below is a table which emphasizes this fact. Tardiness of more than 15 minutes will count as an absence. It is recommended that a student drop the course after 4 absences due to lab constraints, however they are assigned a failing grade after 8. Number of Sessions Absent 1 2 3 4 5 6 7 8 % of Grade Reduced: 2.5% 5% 7.5% 10% 12.5% 15% 17.5% Failing Grade TESTING POLICY: The goal of this class is to develop your skills. In order to evaluate these skills a combination of written and performance evaluations will be given. The schedule of test dates is shown in the attached course outline, but is subject to change. FEEDBACK POLICY: The Instructor will provide prompt and ongoing feedback by returning graded lab assignments within two weeks of submission; all other assignments turned in on time will be returned graded within one week of submission. Current student grades will also be available on student’s Moodle page. NOTICE: Representative student work will be used as a part of SMC’s on-going curriculum assessment program. OTHER COURSE EXPECTATIONS: All shop policies must be followed, using safe work practice rules. These include, but are not limited to: 1. All vehicles, including school owned cars, that enter the shop must have a filled out repair order. 2. Any vehicle that is run in the shop must have an exhaust system in functional condition, and it must be hooked to the shop’s ventilation system. 3. Students will be required to work in the shop with safety glasses and appropriate safety equipment. 4. Steel toed shoes strongly recommended; leather shoes required (no sandals). 5. Students with an Employer Sponsor are encouraged to wear the uniform of their sponsor. 6. Students must wear an instructor-approved uniform type work shirt or lab coat when in the lab. 7. Neat and safe dress and appearance is required at all times. No frayed or torn clothing is permitted. 8. Profanity, ethnic or gender specific comments or jokes have no place in the shop, classroom, or workplace. Lack of respect for other students or personal or school property will be dealt with in an appropriate manner. 1st violation will result in dismissal from the class for the remainder of the day. The student will be marked as absent and will lose attendance credit for that day. 9. All Vehicles will be inspected by the Instructor BEFORE it leaves the shop. 10. Cell Phones are not permitted in the Classroom. Make sure they are set to vibrate. 1st violation will result in dismissal from lecture and loss of 11. 12. 13. 14. CLASSROOM BEHAVIOR: attendance credit for the day. This includes text messaging. A maximum of 5 labs per day may be turned in. 100% of labs must be completed in order to receive Lab Credit NO LATE CLASSWORK will be accepted. NO ONE is allowed in the tool crib except the instructor. 1 st violation will result in dismissal from the lab and loss of attendance credit for the day. Students are expected to assist in maintaining a classroom environment that is conducive to learning. In order to assure that all students have the opportunity to gain from time spent in class; students are prohibited from engaging in any form of distraction. Inappropriate behavior in the classroom shall result, minimally, in a request to leave class. ACCEPTABLE USE OF PERSONAL COMMUNICATION TECHNOLOGY: All phones, iPods, Blackberries, Palm Pilots, pagers, laptops and other technological devices including devices capable of taking photographs must be turned off or placed on vibrate mode and may not be brought out during class. If you are expecting or receiving an urgent call, you are required to leave the classroom before answering. Violation of this policy will result in your removal from the classroom for the class period. Multiple violations of this policy will be referred to the appropriate dean for disciplinary action. Further details or ramifications of violations may be found elsewhere in this syllabus. The instructor has the right to modify this policy to meet the needs of the course. HONESTY POLICY: Cheating or plagiarizing will absolutely not be tolerated at Southwestern Michigan College. Any student found cheating or plagiarizing material in any manner may be assigned a failing semester/session grade in this course. A second such incident while at SMC could result in suspension or expulsion from the institution. A student found in violation of this section of the syllabus will not be allowed to drop this course. Additional detail regarding cheating and/or plagiarism may be found elsewhere in this syllabus. For more detailed information consult the SMC Code of Student Conduct. FIELD TRIP: We will be taking a field trip to the Chicago Auto Show on February 12th. Transportation will be provided and students will be required to attend. There are a limited number of seats and they will be available on a first come first served basis. We will leave at 8:30 that morning and will be returning around 4:30. You will be updated further as more information becomes available. NOTICE: Information in this syllabus was, to the best knowledge of the instructor, considered correct and complete when distributed for use at the beginning of the semester. The instructor, however, reserves the right, acting within the policies and procedures of Southwestern Michigan College, to make changes in course content or instructional techniques. COURSE OUTLINE COURSE OUTLINE AND SCHEDULE Date Subject Text: Read BEFORE class: Be prepared to discuss!!! Assignments DUE Week 1 Jan 13 Week 2 Jan 20 Week 3 Jan 27 Week 4 Feb 3 Week 5 Feb 10 Week 6 Feb 17 Week 7 Feb 24 Week 8 Mar 3 Week 9 Mar 10 Week 10 Mar 17 Week 11 Mar 24 Week 12 Mar 31 Week 13 Apr 7 Week 16 April 16 Introduction; Syllabus review Safety, Electrical and Electronic Systems Chapter 1 Electrical Principles, Electrical Circuits, Ohms Law, Electrical Components Electronic Principles and Components Chapters 2, 3, 4 Safety Test Chapters 5, 6 Reviews Tools, Test Equipment Wiring, Wiring Repairs Chapters 7, 8 Reviews Wiring Diagrams, Manufacturer Service Information Basic Electrical Tests Chapter 9, 10, 11, Reviews Chapters 12, 13, 25 Reviews Chapters 14, 26 Reviews Ignition Systems Chapters 15, 16 Reviews Fuel and Emission Control Systems Wiper and Horn Systems Chapters 18, 19, 30 Reviews Power Accessories, Security Systems, Entertainment Systems and Service Restraint Systems and Service, Chapters 20, 31, 21, 32 Reviews Chassis Systems and Service Hybrid Drive Systems and Service Chapters 22, 33, 23, 24 Reviews On Board Diagnostics, Scan Tools, Sensor, Actuator, Computer Service Ignition System Diagnosis and Repair, Chapters 27, 28 Reviews Chapters 17, 29 Review Automotive Electrical Safety, Computer Operation Batteries and Service Starting Systems and Service Chicago Auto Show Charging Systems and Service Ignition Systems Review for Mid Term Mid Term Exam Spring Break Fuel and Emission Control Systems and Electronics Service Lighting Systems, Instrumentation, Navigation Systems Lighting System Diagnosis and Repair Review for State Exam Week 15 April 21 Week 16 April 28 Field Trip: State Exam State Exam Review for Final Exam FINAL EXAM April 28th 1:00pm-2:55pm Kairis Building Room 528 Review Final Exam Chicago Auto Show All students registered for Wednesday auto classes are required to attend the Auto Show on Feb 12th. Transportation and entrance will be provided. If a student is unable to attend they need to meet with their instructor for approval. An unapproved absence constitutes a grade reduction of 2.5% in accordance with the attendance policy found elsewhere in this syllabus. The following tools are REQUIRED for all students. Basic Tool Set A toolbox capable of holding and organizing the following tools. Lower cabinet (cart) strongly suggested, as carts will be unavailable. 3/8 drive deep or shallow six point socket set, US: 3/8, 7/16, 1/2, 9/16, 5/8, 11/16, 3/4, 13/16, 7/8 3/8 drive deep or shallow six point metric socket set: 8, 9, 10, 11, 12, 13, 14, 15, 17, 18, 19 mm 3/8 drive spark plug sockets, 5/8 and 13/16 (best to get the new deep design) 1/4 drive socket set, US: 1/4, 5/16, 3/8, 7/16, 1/2 1/4 drive socket set, metric: 5, 5.5, 6, 7, 8, 9, 10, 11, 12 mm Set of Torx bits: 1/4” Drive T8, T10, T15, T20, T25, and 3/8” drive T25, T27, T30, T40, T45, T50, T55 Impact sockets: 1/2” drive x 3/4” and 13/16” Socket rails to organize above sockets Combination wrench set, US: 1/4 to 7/8 by 1/16 Combination wrench set, metric: 7 to 21 mm Screwdriver set: Standard, Phillips, and PosiDrive Pliers: Slip joint Needle nose (recommend long neck with bent nose) Diagonal cutter 9” channel lock type 6” and/or 10” Locking (vice grip type) Hammers: Ball peen : 8 oz and 20 oz Plastic tip or dead blow Miscellaneous: Pry bar: 16” Brass drift Tire Gauge, 0 - 50 psi HEI Spark Tester Ramp type Spark Plug Gap Gauge Tire Valve Core Remover Tool Ratchet, 3/8” Ratchet, 1/4” Drive adapter, 1/2” female to 3/8” male Drive adapter, 3/8 female to 1/4” male Drive extension sets: 1/4” and 3/8” Brake return spring installer/remover Allen sockets, 3/8” x 3/8” and 8mm x 3/8” Spark plug boot removing pliers Pocket Thermometer (analog or digital) Non-powered test light Tape measure, 25 foot Brake Spring hold down tool Brake adjusting spoon Inspection Mirror Magnetic Pick-up Tool Small flashlight Feeler gauge set Punch and Chisel set External and internal snap ring pliers set Wire stripper / crimper pliers 5/16 insulated battery terminal box ratchet Hook and Pick set The following tools are recommended but optional. You will need these tools to be successful as a technician. Self powered test light Digital Multimeter Torque Wrenches: 10-300 lb./in and 30 - 300 lb./ft Utility knife Drill bit set Oil filter wrenches (3 sizes) Steering wheel puller set Tilt steering pivot pin puller Steering wheel lock plate depressor/remover Flare nut wrench set, US Flare nut wrench set, Metric Gasket scraper Remote starter switch Tubing cutter 36 mm drive axle nut socket Swivel / universal spark plug sockets 3/8 or 1/2 hand impact drive Adjustable wrench set (“crescent” wrench) Bolt extractor set Spark plug wire pliers File set 3/8” air ratchet 1/2” air impact wrench NATEF Program Standards Automobile ELECTRICAL/ELECTRONIC SYSTEMS For every task in Electrical/Electronic Systems, the following safety requirement must be strictly enforced: Comply with personal and environmental safety practices associated with clothing; eye protection; hand tools; power equipment; proper ventilation; and the handling, storage, and disposal of chemicals/materials in accordance with local, state, and federal safety and environmental regulations. VI. A. ELECTRICAL/ELECTRONIC SYSTEMS General Electrical System Diagnosis 1. Identify and interpret electrical/electronic system concern; determine necessary action. P-1 2. Research applicable vehicle and service information, such as electrical/electronic system operation, vehicle service history, service precautions, and technical service bulletins. P-1 3. Locate and interpret vehicle and major component identification numbers (VIN, vehicle certification labels, and calibration decals). P-1 4. Diagnose electrical/electronic integrity for series, parallel and series-parallel circuits using principles of electricity (Ohm’s Law). P-1 5. Use wiring diagrams during diagnosis of electrical circuit problems. P-1 6. Demonstrate the proper use of a digital multimeter (DMM) during diagnosis of electrical circuit problems. P-1 7. Check electrical circuits with a test light; determine necessary action. P-2 8. Measure source voltage and perform voltage drop tests in electrical/electronic circuits using a voltmeter; determine necessary action. P-1 9. Measure current flow in electrical/electronic circuits and components using an ammeter; determine necessary action. P-1 10. Check continuity and measure resistance in electrical/electronic circuits and components using an ohmmeter; determine necessary action. P-1 11. Check electrical circuits using fused jumper wires; determine necessary action. P-2 12. Locate shorts, grounds, opens, and resistance problems in electrical/electronic circuits; determine necessary action. P-1 13. Measure and diagnose the cause(s) of excessive key-off battery drain (parasitic draw); determine necessary action. P-1 14. Inspect and test fusible links, circuit breakers, and fuses; determine necessary action. P-1 15. Inspect and test switches, connectors, relays, solid state devices, and wires of electrical/electronic circuits; perform necessary action. P-1 16. Repair wiring harnesses and connectors. P-1 17. Perform solder repair of electrical wiring. P-1 VI. ELECTRICAL/ELECTRONIC SYSTEMS B. Battery Diagnosis and Service 1. Perform battery state-of-charge test; determine necessary action. P-1 2. Perform battery capacity test; confirm proper battery capacity for vehicle application; determine necessary action. P-1 3. Maintain or restore electronic memory functions. P-1 4. Inspect, clean, fill, and replace battery. P-2 5. Perform slow/fast battery charge. P-2 6. Inspect and clean battery cables, connectors, clamps, and hold-downs; repair or replace as needed. P-1 7. VI. C. Start a vehicle using jumper cables and a battery or auxiliary power supply. P-1 ELECTRICAL/ELECTRONIC SYSTEMS Starting System Diagnosis and Repair 1. Perform starter current draw tests; determine necessary action. P-1 2. Perform starter circuit voltage drop tests; determine necessary action. P-1 3. Inspect and test starter relays and solenoids; determine necessary action. P-2 4. Remove and install starter in a vehicle. P-1 5. Inspect and test switches, connectors, and wires of starter control circuits; perform necessary action. P-2 6. VI. D. Differentiate between electrical and engine mechanical problems that cause a slowcrank or no-crank condition. P-2 ELECTRICAL/ELECTRONIC SYSTEMS Charging System Diagnosis and Repair 1. Perform charging system output test; determine necessary action. P-1 2. Diagnose charging system for the cause of undercharge, no-charge, and overcharge conditions. P-1 3. Inspect, adjust, or replace generator (alternator) drive belts, pulleys, and tensioners; check pulley and belt alignment. P-2 4. Remove, inspect, and install generator (alternator). P-1 5. Perform charging circuit voltage drop tests; determine necessary action. P-1 VI. E. 1. ELECTRICAL/ELECTRONIC SYSTEMS Lighting Systems Diagnosis and Repair Diagnose the cause of brighter than normal, intermittent, dim, or no light operation; determine necessary action. P-1 2. Inspect, replace, and aim headlights and bulbs. P-2 3. Inspect and diagnose incorrect turn signal or hazard light operation; perform necessary action P-2 VI. F. ELECTRICAL/ELECTRONIC SYSTEMS Gauges, Warning Devices, and Driver Information Systems Diagnosis and Repair 1. Inspect and test gauges and gauge sending units for cause of intermittent, high, low, or no gauge readings; determine necessary action. P-1 2. Inspect and test connectors, wires, and printed circuit boards of gauge circuits; determine necessary action. P-3 3. Diagnose the cause of incorrect operation of warning devices and other driver information systems; determine necessary action. P-1 4. Inspect and test sensors, connectors, and wires of electronic instrument circuits; determine necessary action. P-2 VI. G. ELECTRICAL/ELECTRONIC SYSTEMS Horn and Wiper/Washer Diagnosis and Repair 1. Diagnose incorrect horn operation; perform necessary action. P-2 2. Diagnose incorrect wiper operation; diagnose wiper speed control and park problems; perform necessary action. P-2 3. Diagnose incorrect washer operation; perform necessary action. P-2 VI. H. ELECTRICAL/ELECTRONIC SYSTEMS Accessories Diagnosis and Repair 1. Diagnose incorrect operation of motor-driven accessory circuits; determine necessary action. P-2 2. Diagnose incorrect heated glass operation; determine necessary action. P-3 3. Diagnose incorrect electric lock operation; determine necessary action. P-2 4. Diagnose incorrect operation of cruise control systems; determine necessary action. P-3 5. Diagnose supplemental restraint system (SRS) concerns; determine necessary action. (Note: Follow manufacturer’s safety procedures to prevent accidental deployment.) P-2 6. Disarm and enable the airbag system for vehicle service. P-1 7. Diagnose radio static and weak, intermittent, or no radio reception; determine necessary action. P-3 8. Remove and reinstall door panel. P-1 9. Diagnose body electronic system circuits using a scan tool; determine necessary action. P-2 10. Check for module communication errors using a scan tool. P-3 11. Diagnose the cause of false, intermittent, or no operation of anti-theft system. P-2 Auto 220: Electrical Systems Special Project Name: _____________________________ 200 points Objective: Upon completion of this project, you will have a more complete knowledge of one facet of the electrical/electronic systems available in current vehicles and be able to share that knowledge with others. General Guidelines: You will prepare an instructional video of yourself and your partner performing an Electrical repair on a vehicle. It would be advised that you follow a lab for a guide but you may do any repair you wish; as long as it is Electrical/Electronic related. You may (I recommend) work with a partner. No Groups. You will be responsible for arranging a time to use the camera. The instructor will show you how to set it up but you are responsible for filming/directing. The intent of these videos is to be put on the schools’ youtube.com page. This way when someone searches for a repair on their Electrical system; you will be showing them what to do. Grading criteria: Identify Yourself and Your Class 20pts Proper Inspection/Identification of failed component 20pts Proper Removal/Reinstallation Procedure 50pts Proper Explanation as You are Performing Repairs (terms and grammar) 50pts Properly Verify Repair 10pts Camera Work/Editing 50pts Total 200pts Due Date: All projects must be completed and submitted for approval by April 14 th to allot for proper time to grade. No Exceptions COURSE ASSIGNMENTS BIBLIOGRAPHY