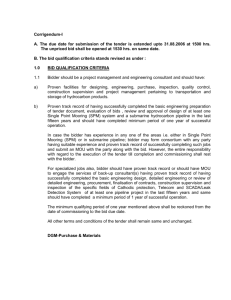

Tender No.SDG4059L15/09 Page 1 of 45 NOTICE Other than the

advertisement