supplemental restraint system

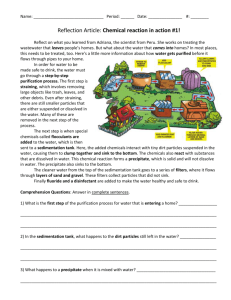

advertisement