Effect of Enzymatic Hydrolysis on the Juice Yield from Apple Fruit

advertisement

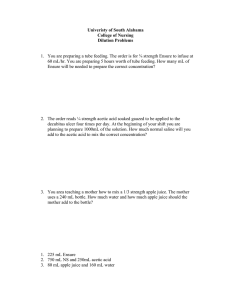

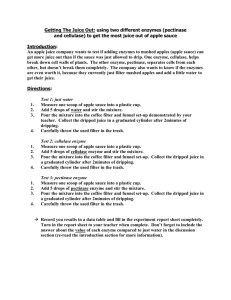

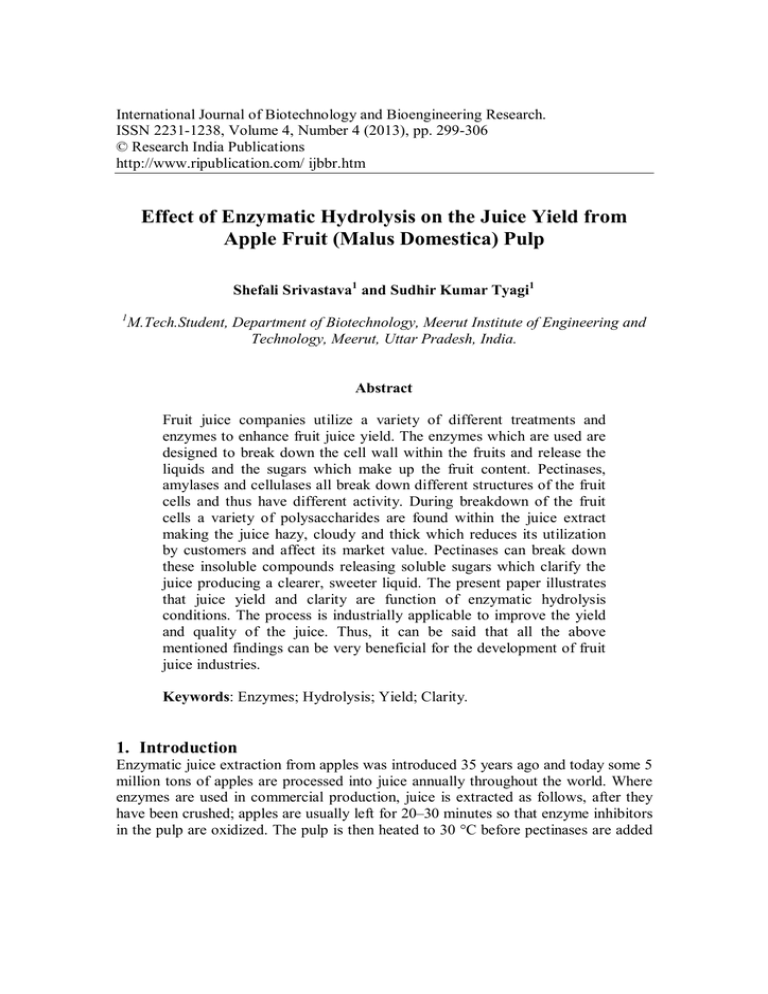

International Journal of Biotechnology and Bioengineering Research. ISSN 2231-1238, Volume 4, Number 4 (2013), pp. 299-306 © Research India Publications http://www.ripublication.com/ ijbbr.htm Effect of Enzymatic Hydrolysis on the Juice Yield from Apple Fruit (Malus Domestica) Pulp Shefali Srivastava1 and Sudhir Kumar Tyagi1 1 M.Tech.Student, Department of Biotechnology, Meerut Institute of Engineering and Technology, Meerut, Uttar Pradesh, India. Abstract Fruit juice companies utilize a variety of different treatments and enzymes to enhance fruit juice yield. The enzymes which are used are designed to break down the cell wall within the fruits and release the liquids and the sugars which make up the fruit content. Pectinases, amylases and cellulases all break down different structures of the fruit cells and thus have different activity. During breakdown of the fruit cells a variety of polysaccharides are found within the juice extract making the juice hazy, cloudy and thick which reduces its utilization by customers and affect its market value. Pectinases can break down these insoluble compounds releasing soluble sugars which clarify the juice producing a clearer, sweeter liquid. The present paper illustrates that juice yield and clarity are function of enzymatic hydrolysis conditions. The process is industrially applicable to improve the yield and quality of the juice. Thus, it can be said that all the above mentioned findings can be very beneficial for the development of fruit juice industries. Keywords: Enzymes; Hydrolysis; Yield; Clarity. 1. Introduction Enzymatic juice extraction from apples was introduced 35 years ago and today some 5 million tons of apples are processed into juice annually throughout the world. Where enzymes are used in commercial production, juice is extracted as follows, after they have been crushed; apples are usually left for 20–30 minutes so that enzyme inhibitors in the pulp are oxidized. The pulp is then heated to 30 °C before pectinases are added 300 Shefali Srivastava & Sudhir Kumar Tyagi (this compares with a temperature of 50–60 °C which is needed if enzymes are not used). Typically, 130 mL of enzyme is added for every ton of apples. Enzyme treatment takes anything from 15 minutes to 2 hours, depending upon the exact nature of the enzyme, the dosage rate, the reaction temperature and the variety of apple used. Some varieties, like Golden Delicious, are very difficult to break down. During incubation, the pectinases degrade soluble pectin in the pulp, making the juice flow more freely. Next, the apples are pressed. Yields of juice may be increased by up to 20% by enzyme treatment, depending upon the age and variety of apple used and whether pre-oxidation is employed. Pectinase treatment is particularly effective with mature apples and those from cold storage. These enzymatic reactions to the pectin molecule not only increase yield, they clarify the juice. The cloud consists of small particles made up of pectin/protein complexes suspended in the juice. These create a haze. Adding enzymes that help break down the pectin changes two things. First, the viscosity of the juice decreases. Second, the enzymes cause ions to form, resulting in electrostatic aggregation which increases the size of the particles. The combination of decreased viscosity and increased particle size causes a floc that settles out, and the clarified juice can be removed. This project investigates some of the factors that affect how fast enzymatic reactions occur. 2. Materials & Equipments 2.1 Materials Fresh apple fruits (Malus domestica) of kinnaur variety, without any visual defects, were purchased from easy day, govindpuram, ghaziabad (India).The fresh pulp so prepared was used to extract juice. Enzyme source: Pectinase, e.g., Novozymes Pectinex®, 1 ml. Dilute with an equal volume of distilled water immediately before use. OPTIONAL: Cellulase enzyme, e.g., Novozymes Celluclast®, 1 ml. Dilute with an equal volume of distilled water immediately before use. OPTIONAL (if starchcontaining purée is used): Amylase, e.g., Novozymes Termamyl® or Amyloglucosidase, AMG, 1 ml. Dilute with an equal volume of distilled water immediately before use Enzymes. 2.2 Equipment Sharp knife, Balance for weighing out apple pieces, Paper coffee filters, Plastic wrap, Disposable plastic spoons for stirring, Two 1 mL syringes or pipets, Two small funnels, Two 100 mL graduated cylinders, Two 100 mL beaker (or clean glass jars), Water bath (can be as simple as a styrofoam box or insulated chest, big enough to hold the beakers), Distilled water, Timer clock, pH meter, Electronic weighing meter, Calorimeter, Incubator. Effect of Enzymatic Hydrolysis on the Juice Yield from Apple Fruit 301 3. Procedure and Methods 3.1 Procedure 1. Chop the apples into cubes that are roughly 5 mm on a side. (Use care with the knife!) It is important to chop the apple into very small pieces—added surface area helps the enzyme break down the pectin in the plant cell walls, releasing more juice. 2. Use the balance to weigh equal amounts of chopped apple (about 50 g) into each beaker. 3. Prepare the pectinase/amylase/cellulase enzyme. Label the beakers accordingly. 4. Stir the chopped apple pieces in each beaker with a separate plastic spoon. Be sure to wet all of the pieces. Cover the beakers with plastic wrap. 5. Put beakers into water bath at range of temperature for 2 hrs. The water should come up to the level of the chopped apples, the beakers float and tip over. After removing jars from water bath use a wooden spoon to gently stir/squeeze the apple pieces in each. 6. Use the paper coffee filters in funnels to filter the juice from the apple preparations into 100 mL graduated cylinders. Again, label the cylinders so you can keep track of contents. 3.2 Methods The enzyme activity in fruit juice extraction can be understood with the help of these points: 1. 1 Preliminary experiment with different concentration of commercial enzymes 2. At different pH 3. At different temperature 4. Relative activity of enzyme on the basis of percentage transmittance/ juice clarity (table 1) 3.2.1 Preliminary experiment with different concentration of commercial enzymes: Preliminary experiments were performed for the selection of the ranges and levels for the concentration of pectinase, amylase, cellulase. The different concentrations of the pectinase (1-6mg/25g of pulp) were used for the treatment of apple pulp and the juice yield and its quality in the form of viscosity and clarity were observed. (Table1) 3.2.2 Selection of relevant variables and experimental ranges: The initial step was the selection of experimental ranges for the independent variables. The experimental ranges for the independent variables were selected as temperature in the range of 3555°C for 2 hrs at pH-5 and at pH range (1-8) and temperature fixed at 450C. 3.2.3 Clarity: Juice clarity was measured according to the methods of Krop and Pilnik 1974 and Ough and Crowell 1979. The juice was shaken and 10 ml portion of juice was centrifuged at 3000 rpm for 10 min to remove pulp coarse cloud particles. The clarity of the juice obtained was determined by measuring the transmittance at a 302 Shefali Srivastava & Sudhir Kumar Tyagi wavelength of 450 nm using UV- VIS spectrophotometer. Distilled water was used as a reference. The percent transmittance was considered as a measure of juice clarity. 3.2.4 Viscosity: Clean and dried Ostwald capillary viscometer was used for the measurement of viscosity. Double distilled water was used as a reference. Time required to flow through the capillary section of the Oswald viscometer was noted using a stopwatch for the reference and the sample at 20±2C (Table1) 4. Observations and Results 4.1 Preliminary experiment with different concentration of commercial enzymes: pectinase Table 1 Conc. of Juice viscosity(cps) clarity pectinase(mg/25gpulp) yield% %Transmittance(T) 1 72.3 1.28 20.6 2 74.8 1.20 24.2 3 78.8 1. 13 25.6 4 81.9 1.07 26.8 5 82.5 1.02 27.9 6 83.2 0.8 29.2 7 83.8 0.7 29.8 4.2 Measuring enzyme activity of various enzymes in extraction of Apple juice Variables Types of enzyme and their combinations (table.2) Constant Variety: Kinnaur Apple/50gram; Enzyme: Concentration: 10mg/10ml (D.W.); Incubation Temperature: 40-45 Degree Celsius;Incubation time-2 hrs Effect of Enzymatic Hydrolysis on the Juice Yield from Apple Fruit 303 Table 2 Enzyme pectinase amylase celllulase Amylase + Cellulase Amylase+Pectinase pectinase+ cellulase Volume 22 17.2 19.2 22.5 23.7 22.5 Result Maximum volume obtained by enzyme pectinase and in combination, it is obtained by pectinase + amylase 4.3 Activity of pectinase at different pH used to observe the yield of fruit juice from apples Table 3 Serial No. pH Volume(ml) 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 23.2 24.2 23.5 25.7 27.6 27.4 24 22 Constant Temperature 45 45 45 45 45 45 45 45 Result Maximum activity of pectinase at pH 5.5 enhance the yield of apple juice upto 34ml / 50gm 4.4 Activity of cellulase at different pH used to observe the yield of fruit juice from apples: Table 4 Serial No. 1 2 pH Volume(ml) 1 2 21 22 Constant Temperature0C 45 45 304 Shefali Srivastava & Sudhir Kumar Tyagi 3 4 5 6 7 8 3 4 5 6 7 8 23 26 25 23 20 18 45 45 45 45 45 45 Result Maximum activity of cellulase at pH 4, enhance the yield of apple juice upto 26ml / 50gm 4.5 Activity of amylase at different pH used to observe the yield of fruit juice from apples: Table 5 Serial No. 1 2 3 4 5 6 7 8 pH Volume(ml) 1 2 3 4 5 6 7 8 20.2 21.2 21.8 22.7 24.2 25.8 25.4 24.5 Constant Temperature 45 45 45 45 45 45 45 45 4.6 Activity of pectinase at different temperature used to observe the yield of fruit juice from apple Table 6 Serial No. 1 2 3 4 5 6 Temperature0C Volume(ml) Constant pH 30 19.2 5 35 21.4 5 40 23.5 5 45 25 5 50 24.6 5 55 24.3 5 Effect of Enzymatic Hydrolysis on the Juice Yield from Apple Fruit 305 Result Maximum activity of pectinase at temperature (45-50 0C), enhance the yield of apple juice upto 25ml / 50gm 4.7 Activity of cellulase at different temperature used to observe the yield of fruit juice from apples Table 7 Serial No. Temperature0C Volume(ml) Constant pH 1 30 14.2 5 2 35 17.4 5 3 40 19 5 4 45 21.5 5 5 50 22 5 6 55 21.6 5 Result Maximum activity of cellulase at temperature 50 0C, enhance the yield of apple juice upto 22ml/50gm 4.8 Activity of amylase at different temperature used to observe the yield of fruit juice from apples Table 8 Serial No. 1 2 3 4 5 6 Temperature Volume(ml) Constant pH 30 8.9 5 35 10.2 5 40 13.6 5 45 16.3 5 50 17.7 5 55 17.4 5 Result Maximum activity of cellulose at temperature 50 0C, enhance the yield of apple juice upto 17ml/50gm. 306 Shefali Srivastava & Sudhir Kumar Tyagi 5. Conclusion The present study concluded that juice yield and clarity are function of enzymatic hydrolysis conditions. This study also assesses how process variables of enzymatic treatment of fruit pulp, particularly incubation temperature, incubation time(constant), pH and pectinase/amylase/cellulase concentration affect the % yield and clarity of the juice. The enzymatic hydrolysis of pulp improved the juice yield and quality, in terms of Juice yield, viscosity, clarity (Table1). The process is industrially applicable to improve the yield and quality of the juice. The results indicate that clarity of the juice from untreated pulp to enzymatically treated one is increased. The optimum pectinase concentration obtained was 7mg/25gm pulp. During comparative studies different results were obtained-for cellulose maximum volume obtained at pH-4 and temperature 500C for pectinase maximum volume obtained at pH- 5 and temperature500C, for amylase maximum volume at pH-6 and temperature 500C Reference [1] Baumann, J.W., 1981. Application of Enzymes in Fruit Juice Technology. In: Enzymes and Food Processing, Birch, G.G., N. Blakebrough and K.J. Parker (Eds.). Applied Science Publication, London, pp: 129-147 [2] Demir, N., J. Acar, K. Sario lu and M. Mutlu, 2000. The use of commercial pectinase in fruit juice industry. Part 3: Immobilized pectinase for mash treatment. J. Food Eng., 47: 275-280. [3] Joshi, V.K., S.K. Chahan and B.B. Lal, 1991. Extraction of juice from peaches, plums and apricots by pectinolytic treatment. J. Food Sci. Technol., 28: 65-66. [4] Karangwa, E., H. Khizar, L. Rao, D.S. Nshimiyimana and M.B.K. Foh et al., 2010. Optimization of processing parameters for clarification of blended carrot-orange juice and improvement of its carotene content. Adv. J. Food Sci. Technol., 2: 268-278 [5] Kashyap, D.R., P.K. Vohra, S. Chopra and R. Tewari, 2001. Applications of pectinases in the commercial sector: A review. Bioresour. Technol., 77: 215-227. [6] Sin, H.N., S. Yusof, N.S.A. Hamid and R.A. Rahman, 2006. Optimization of enzymatic clarification of sapodilla juice using response surface methodology. J. Food Eng., 73: 313-319 [7] spring of H.P., M.Sc. Thesis, Dr. Y.S. Parmar University of 2 Joshi VK and Bhutani VP, The influence of enzymatic Horticulture and Forestry, Nauni, Solan (H.P.), 1997. [8] Gautam SK and Chundawat BS, Technology of extraction juice from Sapota by pectinolytic enzyme treatment, Indian Food Pack, 1997, 5, 72-76. [9] McLellen MR, Kime RW and Lind LR, Apple juice 41 clarification with the use of honey and pectinase, J Food Sci, 1985, 50, 206-208. [10] Chang Tung, Siddiq M and Sinha NK, Commercial pectinases and the yield and quality of stanley plum juice Chem, 1992, 40, 784-789.,