Full-Text PDF

advertisement

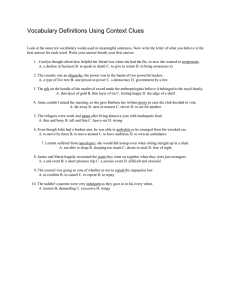

molecules Article SimCP3—An Advanced Homologue of SimCP2 as a Solution-Processed Small Molecular Host Material for Blue Phosphorescence Organic Light-Emitting Diodes Yi-Ting Lee 1 , Yung-Ting Chang 2 , Cheng-Lung Wu 2 , Jan Golder 3 , Chin-Ti Chen 2,3, * and Chao-Tsen Chen 1, * 1 2 3 * Department of Chemistry, National Taiwan University, Taipei 10617, Taiwan; likewithyou@gmail.com Institute of Chemistry, Academia Sinica, Taipei 11529, Taiwan; eveningtin@gmail.com (Y.-T.C.); cdstant@yahoo.com.tw (C.-L.W.) Department of Applied Chemistry, National Chiao Tung University, Hsinchu 30050, Taiwan; jangolder@gmx.net Correspondences: chintchen@gate.sinica.edu.tw (C.-Ti Chen); chenct@ntu.edu.tw (C.-Tsen Chen); Tel.: +886-2-2789-8542 (C.-Ti Chen); +886-2-3366-4200 (C.-Tsen Chen) Academic Editor: Jwo-Huei Jou Received: 5 September 2016; Accepted: 27 September 2016; Published: 30 September 2016 Abstract: We have overcome the synthetic difficulty of 9,90 ,900 ,9000 ,90000 ,900000 -((phenylsilanetriyl) tris(benzene-5,3,1-triyl))hexakis(9H-carbazole) (SimCP3) an advanced homologue of previously known SimCP2 as a solution-processed, high triplet gap energy host material for a blue phosphorescence dopant. A series of organic light-emitting diodes based on blue phosphorescence dopant iridium (III) bis(4,6-difluorophenylpyridinato)picolate, FIrpic, were fabricated and tested to demonstrate the validity of solution-processed SimCP3 in the device fabrication. Keywords: solution process; molecular host material; high triplet gap energy; SimCP2; blue phosphorescence OLED 1. Introduction An increasing number of high-performance blue phosphorescence organic light-emitting diodes (OLEDs) can be found in literature reports. Although remarkable electroluminescence (EL) efficiency as high as ~27%, ~51 lm/W, or ~54 cd/A based on sky-blue phosphorescence dopant iridium (III) bis(4,6-difluorophenylpyridinato)picolate (FIrpic) has been achieved [1–7], vacuum-thermal-evaporation is a common device fabrication process, but it is not favorable for mass production or large panel fabrication. Accordingly, for more desirable production or fabrication process, there have been a number of solution-processable small molecular host materials for blue phosphorescence organic light-emitting diodes in recent years [8–14]. We and others have developed and demonstrated bis(3,5-di(9H-carbazol-9-yl)phenyl)diphenylsilane (SimCP2 in Scheme 1) as one of high-performance solution-processable small molecular host materials for yellow, green, and blue phosphorescence OLEDs [15–22]. More recently, SimCP2 hosted FIrpic OLEDs were reported as having EL efficiency reaching ~11%, ~11 lm/W, or 23 cd/A [23]. Nevertheless, the EL of these FIrpic OLEDs with solution-processed light-emitting layer is far less efficient than those OLEDs fabricated by vacuum-thermal-evaporation. For blue phosphorescence OLEDs, solution-processable small molecular hosts with a high triplet energy gap (ET ) greater than 2.6 eV of the benchmark sky-blue FIrpic are still rare and highly demanded in the field. As our ongoing effort to develop high-performance solution-processable small molecular host materials Molecules 2016, 21, 1315; doi:10.3390/molecules21101315 www.mdpi.com/journal/molecules Molecules 2016, 21, 1315 2 of 11 Molecules 2016, 21, 1315 2 of 11 for blue phosphorescence OLEDs, we have recently overcome synthetic difficulties and successfully 0 00 000 0000 00000 prepared 9,9 ,9 ,9 ,9 ,9 -((phenylsilanetriyl)tris(benzene-5,3,1-triyl))hexakis(9H-carbazole) (benzene-5,3,1-triyl))hexakis(9H-carbazole) (SimCP3) (Scheme 1) as an advanced homologue Molecules 2016, 21, 1315 2 of of 11 (SimCP3) (Scheme 1) as an advanced homologue of SimCP2. Herein, we report the synthesis and SimCP2. Herein, we report the synthesis and characterization of SimCP3 in full detail. A series of characterization of SimCP3 in full detail. A series of SimCP3-hosted OLEDs are fabricated and tested SimCP3-hosted OLEDs are fabricated and tested to demonstrate its as viability as a solution-processed (benzene-5,3,1-triyl))hexakis(9H-carbazole) (SimCP3) (Scheme 1) an advanced homologue of to demonstrate itsfor viability asphosphorescence a the solution-processed host materialoffor sky-blue phosphorescence host material sky-blue OLEDs. SimCP2. Herein, we report synthesis and characterization SimCP3 in full detail. A series OLEDs. of SimCP3-hosted OLEDs are fabricated and tested to demonstrate its viability as a solution-processed host material for sky-blue phosphorescence OLEDs. Scheme 1. Chemical structure of SimCP2 and SimCP3. MM2 energy minimized structures (by Chem 3D) Scheme 1. Chemical structure of SimCP2 and SimCP3. MM2 energy minimized structures (by Chem are shown on the right, respectively. 3D) are shown on the right, respectively. Scheme 1. Chemical structure of SimCP2 and SimCP3. MM2 energy minimized structures (by Chem 3D) 2. Results and on Discussion are shown the right, respectively. 2. Results and Discussion In our earlier reports [16,24,25], both 9,9′-(5-(triphenylsilyl)-1,3-phenylene)bis(9H-carbazole) 2. Results and Discussion 0 -(5-(triphenylsilyl)-1,3-phenylene)bis(9H-carbazole) (SimCP) and SimCP2 were synthesized in a9,9 similar method (Scheme 2). Either chlorotripheylsilane In our earlier reports [16,24,25], both or dichlorodiphenylsilane was reactedin with monolithiated to furnish 1,3In our earlier were reports [16,24,25], both 9,9′-(5-(triphenylsilyl)-1,3-phenylene)bis(9H-carbazole) (SimCP) and SimCP2 synthesized a similar method 1,3,5-tribromobenzene (Scheme 2). Either chlorotripheylsilane dibromophenyl substituted thriphenylsilane and bis-1,3-dibromophenyl substituted diphenylsilane, (SimCP) and SimCP2 were synthesized in a similar method (Scheme 2). Either chlorotripheylsilane or dichlorodiphenylsilane was reacted with monolithiated 1,3,5-tribromobenzene to furnish respectively. The silane compounds werewith then monolithiated brought to a palladium-catalyzed amination reaction or dichlorodiphenylsilane reacted 1,3,5-tribromobenzene to furnish 1,31,3-dibromophenyl substitutedwas thriphenylsilane and bis-1,3-dibromophenyl substituted diphenylsilane, with excess amount of carbazole. Both SimCPand andbis-1,3-dibromophenyl SimCP2 were obtainedsubstituted with a reasonable isolation dibromophenyl substituted thriphenylsilane diphenylsilane, respectively. The silane compounds were then brought to a palladium-catalyzed amination reaction yield of 54% and thethen finalbrought amination It is conceivable that the reaction respectively. The~40%, silanerespectively, compounds in were to reaction. a palladium-catalyzed amination with yields excesswill amount of carbazole. Both SimCP andhigher SimCP2 were obtained with a reasonable isolation lowerof than that of Both SimCP2 if the homologue SimCP3 byisolation a same with excessbe amount carbazole. SimCP and SimCP2 were obtained withisaprepared reasonable yieldreaction of 54% and ~40%, respectively, in the final amination reaction. It is conceivable that the reaction sequence shown in Scheme 2. yield of 54% and ~40%, respectively, in the final amination reaction. It is conceivable that the reaction yieldsyields will will be lower than that ofofSimCP2 homologue SimCP3 is prepared a same be lower than that SimCP2ififthe the higher higher homologue SimCP3 is prepared by aby same reaction sequence shown in Scheme 2. reaction sequence shown in Scheme 2. Scheme 2. Synthetic preparation of SimCP and SimCP2. Due to the much more partial amination products formed SimCP2. in the reaction of synthesizing Scheme Synthetic preparation of SimCP Scheme 2. 2. Synthetic preparation of SimCPand and SimCP2. SimCP3, we obtained a series of product mixtures, which were hard to separate by column chromatography. In addition, the purification SimCP3 formed requiredina the tedious process in order to Due to the much more partial aminationofproducts reaction of synthesizing Due to the the much more partial formed thetoreaction of remove amount of carbazole usedmixtures, in products the reaction. Alternatively, we have been able to SimCP3, weexcess obtained a series of amination product which were in hard separate bysynthesizing column synthesize SimCPIn byaddition, mono-lithiated 9,9′-(5-bromo-1,3-phenylene)bis(9H-carbazole) SimCP3, we obtained ausing series of product mixtures, which werea tedious hard toprocess separate by column chromatography. the purification of SimCP3 required in (BrmCP) order to to react with chlorotripheylsilane. However, the same synthetic approach has been problematic in remove the excess amount of carbazole used in the reaction. Alternatively, we have been able to to chromatography. In addition, the purification of SimCP3 required a tedious process in order the preparation of SimCP2 and SimCP3, even though a very recent literature has reported the same synthesize SimCP by using 9,9′-(5-bromo-1,3-phenylene)bis(9H-carbazole) remove the excess amount of mono-lithiated carbazole used in the reaction. Alternatively, we have (BrmCP) been able to synthetic approach in the preparation of SimCP2 and SimCP3 We also approach of 0 -(5-bromo-1,3-phenylene)bis(9H-carbazole) to reactSimCP with chlorotripheylsilane. However, same synthetic[23]. approach hastried beenthe problematic in synthesize by using mono-lithiated 9,9the (BrmCP) Grignard reaction instead n-butyllithium), but it did not work out wellhas either. It seems to us the preparation of (Mg SimCP2 andofSimCP3, even though a very recent literature reported the same to react with chlorotripheylsilane. However, the same synthetic approach has been problematic in that eitherapproach lithiated or BrmCP is relatively thealso reaction In the synthetic in magnesiated the preparation of SimCP2 and unstable SimCP3 under [23]. We tried condition. the approach of the preparation of SimCP2 andthe SimCP3, even though a very recent literature has reported the same case of SimCP2 and SimCP3, chance of either lithiated or magnesiated BrmCP reacting more than Grignard reaction (Mg instead of n-butyllithium), but it did not work out well either. It seems to us synthetic approach in the preparation of SimCP2 and SimCP3 [23]. We also tried the approach of that either lithiated or magnesiated BrmCP is relatively unstable under the reaction condition. In the Grignard reaction instead of but it did not work out wellreacting either. more It seems case of SimCP2(Mg and SimCP3, then-butyllithium), chance of either lithiated or magnesiated BrmCP thanto us Molecules 2016, 21, 1315 3 of 11 that either lithiated or magnesiated BrmCP is relatively unstable under the reaction condition. In the Molecules 2016, 21, 1315 3 of 11 case of SimCP2 and SimCP3, the chance of either lithiated or magnesiated BrmCP reacting more than dichlorophenylsilane or trichlorophenylsilane ratherlow. low.InInaddition, addition,the thereaction reactionisisquite once once with with dichlorophenylsilane or trichlorophenylsilane is is rather quite sensitive to the purity of dichlorophenylsilane or trichlorophenylsilane, which is prone to sensitive to the purity of dichlorophenylsilane or trichlorophenylsilane, which is prone to hydrolysis hydrolysis and generates hydrochloric acid that is detrimental to the reaction. Finally, we were able and generates hydrochloric acid that is detrimental to the reaction. Finally, we were able to synthesize to synthesize and isolate pure SimCP3 in multi-gram scale via reaction with sodium metal, i.e., a and isolate pure SimCP3 Molecules 2016, 21, 1315 in multi-gram scale via reaction with sodium metal, i.e., a Würtz–Fittig-type 3 of 11 Würtz–Fittig-type coupling reaction between chlorosilane and aryl halide (Scheme 3) [26,27]. Instead coupling reaction between chlorosilane and aryl halide (Scheme 3) [26,27]. Instead of a carbon anion of of aonce carbon of BrmCP, a more feasible silyl anion is of rather trichlorophenylsilne involved withanion dichlorophenylsilane or trichlorophenylsilane low. In addition,is the reactioninisthe BrmCP, a more feasible silyl anion of trichlorophenylsilne is involved in the coupling reaction. coupling reaction. quite sensitive to the purity of dichlorophenylsilane or trichlorophenylsilane, which is prone to hydrolysis and generates hydrochloric acid that is detrimental to the reaction. Finally, we were able to synthesize and isolate pure SimCP3 in multi-gram scale via reaction with sodium metal, i.e., a Würtz–Fittig-type coupling reaction between chlorosilane and aryl halide (Scheme 3) [26,27]. Instead of a carbon anion of BrmCP, a more feasible silyl anion of trichlorophenylsilne is involved in the coupling reaction. Scheme 3. SynthesisofofSimCP3 SimCP3 from from BrmCP reaction. Scheme 3. Synthesis BrmCPvia viaWürtz–Fittig Würtz–Fittig reaction. To facilitate the SimCP3 preparation, we improved the synthesis of BrmCP with a significantly Td = 620 oC 60 100 40 Weight (%) Weight (%) 80 20 0 80 Td = 620 oC 60 40 100 200 300 400 500 600 700 800 900 20 0 Temperature (oC) (a) Heat Flow Heat (Endothermic -->) Flow (Endothermic -->) To facilitate theyield SimCP3 preparation, we improved the synthesis of BrmCPreaction, with a SimCP3 significantly better isolation of >90% [12,28]. Regarding the Würtz–Fittig-type coupling betterwas isolation yield of >90% [12,28]. SimCP3 furnished in only modest yieldsRegarding around 30%the dueWürtz–Fittig-type to the competition coupling reaction ofreaction, the potential Scheme 3. Synthesis of SimCP3 from BrmCP via Würtz–Fittig reaction. silicon–silicon bond modest formationyields of oligosilane polysilane However, thereaction desired product was was furnished in only aroundor30% due to[29,30]. the competition of the potential much easier to isolate from the product mixture. In this we also observed silanol side silicon–silicon bond formation ofpreparation, oligosilane polysilane [29,30].of However, desired product To facilitate the SimCP3 weor improved the reaction, synthesis BrmCP withthe a significantly products, although they were readily removed by column chromatography. In addition, there was better isolation yield of from >90% [12,28]. Regarding the Würtz–Fittig-type coupling SimCP3 was much easier to isolate the product mixture. In this reaction, we reaction, also observed silanol no was excess amountinof carbazole involved in the reaction; hence, no extra reaction purification process was furnished modest around 30% due the competition of the potential side products, althoughonly they wereyields readily removed bytocolumn chromatography. In addition, there required for SimCP3. are the main advantages of the[29,30]. Würtz–Fittig reaction over other synthetic silicon–silicon bond These formation of oligosilane or polysilane However, the desired product was was no excess amount of carbazole involved in the reaction; hence, no extra purification process methods of preparing Several mixture. spectroscopic and physical much easier to isolate SimCP3. from the product In this reaction, we alsomethods observedwere silanolused side to was required forthe SimCP3. These are main advantages of the Würtz–Fittig reaction over other characterize homogeneity thinthe film and the optoelectronic properties SimCP3 products, although they wereofreadily removed bynecessary column chromatography. In addition,ofthere was as synthetic of preparing SimCP3. Several spectroscopic and physical methods were nomethods excess amount ofhost carbazole involved in the reaction; hence, no extra purification process wasused to a solution-processable material for FIrpic OLEDs. characterize theas homogeneity ofare thin film necessary optoelectronic properties of SimCP3 as a required for SimCP3. mainand advantages of the Würtz–Fittig reaction over other synthetic First, shown in These Figure 1,the SimCP3 is the very thermally stable with a thermal decomposition methods of SimCP3. Several spectroscopic methods were used to solution-processable host material temperature (Td)preparing as high as 620 for °C, FIrpic where OLEDs. 5% weight lossand wasphysical determined by thermogravimetric characterize the homogeneity of thin film and the necessary optoelectronic properties of SimCP3 as analysis (TGA) under a nitrogen atmosphere. Second, SimCP3 exhibits amorphous or semi-amorphous First, as shown in Figure 1, SimCP3 is very thermally stable with a thermal decomposition a solution-processable hostthermograms material for FIrpic OLEDs. scanning calorimetry (DSC). As shown in ◦ characteristic based on the of differential temperature (Td ) as high as 620 C, where 5% weight loss was determined by thermogravimetric First, as shown Figure 1,temperatures SimCP3 is very stable with a thermal decomposition Figure 1, SimCP3 hasinmelting (Tmthermally ),SimCP3 crystallization temperatures (Tcsemi-amorphous ), and glass analysis (TGA) under nitrogen exhibits amorphous or temperature (Td)a as high asatmosphere. 620 °C, whereSecond, 5% weight loss was determined by thermogravimetric transition temperatures (Tg) of 330, 223, and 174 °C, respectively. Two very weak exothermic signals characteristic on the thermograms of differential scanning calorimetry (DSC). As shown in analysisbased (TGA) under a nitrogen atmosphere. Second, SimCP3 exhibits amorphous or semi-amorphous around 290 and 330 °C may be the inhibited crystallization process of thermally annealed SimCP3. based on the thermograms(T ofmdifferential scanning calorimetry (DSC). As shown in Figure 1,characteristic SimCP3 has melting temperatures ), crystallization temperatures (Tc ), and glass transition The Tm and Tc of SimCP3 disappeared, and Tg was observed after the first heating scan, indicative of ◦ Figure 1, SimCP3 has melting temperatures (T m ), crystallization temperatures (T c ), and glass temperatures (Tg ) oftendency 330, 223,ofand 174 C, respectively. Two very weak exothermic signals around 290 the amorphous SimCP3. temperatures (Tg) of 330, 223, and 174 °C, respectively. Two very weak exothermic signals ◦ C may be and 330 transition the inhibited crystallization process of thermally annealed SimCP3. The Tm and Tc around 290 and 330 °C may be the inhibited crystallization process of thermally annealed SimCP3. of SimCP3 disappeared, and Tg was observed after the first heating scan, T 330 C indicative of the amorphous The Tm and T100 c of SimCP3 disappeared, and Tg was observed after the first heating scan, indicative of tendency SimCP3.tendency of SimCP3. theofamorphous Heating 100 200 300 400 500 600 700 800 900 Figure 1. TGA (a) and DSC (b) Temperature (oC) (a) o m st 1 nd 2 rd 3 o Tc 223 C o Tm 330 C st Cooling 1nd 2 rd Heating 1st 3 o Tg 174 Co nd 2 rd 3 Tc 223 C st Cooling 1nd 100 150 200 250 o T 174 C 300 350 o 2 rd 3400 g Temperature ( C) (b) 100 150 200 250 300 o thermograms of SimCP3. Temperature ( C) 350 (b) Figure 1. TGA (a) and DSC (b) thermograms of SimCP3. Figure 1. TGA (a) and DSC (b) thermograms of SimCP3. 400 Molecules 2016, 21, 1315 4 of 11 Molecules 2016, 21, 1315 4 of 11 Similarly, or Similarly, amorphous or semi-amorphous semi-amorphous characteristics characteristics are are evident evident from from the the X-ray X-ray diffraction diffraction Molecules 2016, 21,amorphous 1315 4 of 11 (XRD) spectrum (Figure 2a) of the solution-casting thin film of SimCP3. The XRD spectrum (XRD) spectrum (Figure 2a) of the solution-casting thin film of SimCP3. The XRD spectrum is is basically basically aa featureless halo, indicative of semi-amorphous an nature. Macroscopically, thefrom homogeneity the solution Similarly, amorphous or characteristics are evident thehomogeneity X-rayof diffraction featureless halo, indicative of amorphous an amorphous nature. Macroscopically, the of the (XRD) spectrum (Figure 2a) of the solution-casting thin film of SimCP3. The XRD spectrum is basically spin-coated SimCP3 thin film is evident from the photoluminescence (PL) images of the neat film and solution spin-coated SimCP3 thin film is evident from the photoluminescence (PL) images of the neat a featureless halo, indicative of an amorphous nature. Macroscopically, the homogeneity of the FIrpic-doped SimiCP3 thin films (Figure 2b), which show uniform color and no sign of agglomeration film and FIrpic-doped SimiCP3 thin films (Figure 2b), which show uniform color and no sign of solution spin-coated SimCP3 thin film is evident from the photoluminescence (PL)(AFM) images of the neat or phase separation. Microscopically, atomic force microscopy (AFM) demonstrated thedemonstrated homogenous agglomeration or phase separation. Microscopically, atomic force microscopy film and FIrpic-doped SimiCP3 thin films 2b),orwhich uniform color(Figure and no3).sign of and flat surface morphology of SimCP3 thin(Figure films with without a FIrpic the homogenous and flat surface morphology of SimCP3 thin show films with dopant or without a FIrpicWhereas dopant agglomeration or phase separation. Microscopically, atomic force microscopy (AFM) demonstrated thin film3). ofWhereas poly(3,4-ethylenedioxythiophene) doped with poly(styrenesulfonate) (PEDOT:PSS[CC1]) (Figure thin film of poly(3,4-ethylenedioxythiophene) doped with poly(styrenesulfonate) theahomogenous and flat surface morphology of SimCP3 thin films with or without a (RMS) FIrpic dopant had higher surface roughness of 0.68 nm, a rather small values of root-mean-square roughness (PEDOT:PSS[CC1]) had a higher surface roughness of 0.68 nm, a rather small values of root-mean(Figure 3). Whereas thin film of poly(3,4-ethylenedioxythiophene) doped with poly(styrenesulfonate) of 0.25 and 0.33 nm was observed for the thin film of SimCP3 and SimCP3:FIrpic (10 wt %), respectively. square (RMS) roughness of 0.25 and 0.33 nm was observed for the thin film of SimCP3 and (PEDOT:PSS[CC1]) had a higher surface roughness of 0.68 nm, a rather small values of root-meanRegarding the (10 flatness the thin films, none ofthe theflatness discernable features AFMofsurface images SimCP3:FIrpic wt %),ofrespectively. Regarding of the thin films,innone the discernable square (RMS) roughness of 0.25 and 0.33 nm was observed for the thin film of SimCP3 and had a height over 5.5 nm, 2.1 nm, and 2.7 nm, for PEDOT:PSS, SimCP3, and SimCP3:Firpic thin features in AFM(10 surface images had a height over the 5.5 flatness nm, 2.1 nm, 2.7 nm, none for PEDOT:PSS, SimCP3, SimCP3:FIrpic wt %), respectively. Regarding of theand thin films, of the discernable films, respectively. and SimCP3:Firpic thin images films, respectively. features in AFM surface had a height over 5.5 nm, 2.1 nm, and 2.7 nm, for PEDOT:PSS, SimCP3, and SimCP3:Firpic thin films, respectively. (a) 2000 1500 (a) Intensity Intensity (a.u.)(a.u.) 2000 1500 1000 1000 500 500 5 10 15 20 25 30 35 40 45 50 55 60 2 Theta 5 10 15 20 25 30 (degree) 35 40 45 50 55 60 2 Theta (degree) Figure 2. 2. (a) (a) XRD XRD spectra spectra of of the the solution solution drop-casting drop-casting thin SimCP3 on on silicon silicon wafer; wafer; (b) (b) PL PL Figure thin film film of of SimCP3 Figureof 2. solution (a) XRD spin-coated spectra of thethin solution drop-casting thin film ofwt SimCP3 on silicon wafer; (b) PL images films of SimCP3: FIrpic (~10 %) and SimCP3. images of solution spin-coated thin films of SimCP3: FIrpic (~10 wt %) and SimCP3. images of solution spin-coated thin films of SimCP3: FIrpic (~10 wt %) and SimCP3. (a) (a) (b) (b) (c) (c) Figure images of of ITO/PEDOT:PSS ITO/PEDOT:PSS(a); (a);ITO/PEDOT:PSS/SimCP3 ITO/PEDOT:PSS/SimCP3 Figure 3.3. 55 ×× 55 μm μm AFM AFM images (b);(b); andand Figure 3. 5 × 5 µm AFM images of ITO/PEDOT:PSS (a); ITO/PEDOT:PSS/SimCP3 (b); and ITO/PEDOT:PSS/SimCP3:FIrpic (10 wt %) (c). ITO/PEDOT:PSS/SimCP3:FIrpic (10 wt %) (c). ITO/PEDOT:PSS/SimCP3:FIrpic (10 wt %) (c). The of the the host hostmaterial materialfor fora ablue blue phosphorescence dopant such Themost mostimportant important property property of phosphorescence dopant such as as The of the host for awith blue phosphorescence dopant such as FIrpic ET.T.We Weimportant estimated property as neat time-gated acquisition PL PL spectra FIrpic isisEmost estimated the ETT of of SimCP3 SimCP3 asaamaterial neatthin thinfilm film with time-gated acquisition spectra FIrpic istemperatures ET . We estimated the 4a,b). ET of SimCP3 as a neat thin film with time-gated acquisition PL spectra low temperatures (Figure From with either variable delayed time or variable lowlow atatlow (Figure 4a,b). From spectra spectra with either variable delayed time or variable at low temperatures (Figure 4a,b). From spectra with either variable delayed time or variable low max around 400 nm is the delayed temperature, it can be confirmed that the emission band with a λ temperature, it can be confirmed that the emission band with a λmax around 400 nm is the delayed fluorescence and a λ max around 525 nm is the phosphorescence. By taking the onset wavelength of the temperature, it can emission band with By a λmax around 400 nm is the delayed fluorescence and a λbe maxconfirmed around 525that nm the is the phosphorescence. taking the onset wavelength of the high energy edge of phosphorescence bands, we obtain ~461–468 nm (2.69–2.65 eV) as the optical fluorescence and a λ around 525 nm is the phosphorescence. By taking the onset wavelength max high energy edge of phosphorescence bands, we obtain ~461–468 nm (2.69–2.65 eV) as the optical energy gapfor forEETT..From From our measurements, the EET TofofSimCP3 is is sufficiently larger than thatthat ofeV) FIrpic, of the high energy edgeour of phosphorescence we obtain ~461–468 nm (2.69–2.65 as the energy gap measurements, thebands, SimCP3 sufficiently larger than of FIrpic, ensuring triplet state exciton on the phosphorescence dopant rather than its host SimCP3. The UVoptical energy gap for exciton ET . From the dopant ET of SimCP3 sufficiently larger than that of ensuring triplet state onour themeasurements, phosphorescence rather is than its host SimCP3. The UVvisibleensuring absorption and state fluorescence spectra of SimCP3 in solution are rather illustrated initsFigure 4c. FIrpic, triplet exciton on the phosphorescence dopant than host SimCP3. The visible absorption and fluorescence spectra of SimCP3 in solution are illustrated in Figure 4c. UV-visible absorption and fluorescence spectra of SimCP3 in solution are illustrated in Figure 4c. 5 of 11 5 of 11 60000 50000 Neat film @14 K Delayed time 1 ms 7 ms 13 ms 22 ms 28film ms@14 K Neat (a) 40000 Molecules 2016, 21, 1315 60000 20000 Delayed time 1 ms 7 ms 40000 13 ms 0 30000 22 ms 350 400 450 500 550 600 650 700 750 28 ms 50000 (a) 461 nm 10000 200000 180000 160000 140000 120000 100000 80000 200000 60000 180000 40000 160000 140000 20000 1200000 Neat film @ 121 ms delayed time Temperature 250K 200K 150K 100K 50K Neat film @ 121 ms delayed time 14K Temperature (b) 5 of 11 (b) 468 nm 250K 200K 150K 100K 350 50K 400 450 500 550 600 650 700 750 14K Wavelength (nm) 2 120000 40000 100000 ε (M-1cm-1) ε (M-1cm-1) 100000 Wavelength (nm) 80000 140000 (c) 60000 0.8 368 nm 0.80.2 0 60000 20000 1.0 Wavelength (nm) UV-Visible absorption 1.4 0.6 Fluorescence 347 nm 1.2 in CH2Cl2 1.00.4 20000 80000 250 40000 2 300 350 347 nm 400 450 500 Wavelength (nm) 550 Fluorescence Intensity (a.u.) 100000 80000 Wavelength (nm) 60000 468 nm 461 nm 40000 10000 140000 (c) UV-Visible 20000 absorption 1.4 0 Fluorescence 0 120000 1.2 368 nm 350 400 450 500 550 600 650 700 750 350 400Cl450 500 550 600 650 700 750 in CH 20000 Fluorescence Intensity (a.u.) Emission Intensity (Counts) 30000 Emission Intensity (Counts) Emission Intensity (Counts) Emission Intensity (Counts) Molecules 2016, 21, 1315 Molecules 2016, 21, 1315 0.60.0 600 0.4 0.2 0 0.0 (a)Variable spectra of (b) (a) Variabletime-gated time-gatedPL PL spectra ofSimCP3 SimCP3 thin film; (b) Variable Variable temperature, temperature, 121 121 msec msec 250 300 350 400 450 thin 500 film. 550 600 Figure Figure 4. 4. Wavelength (nm)temperature time-delayed (c) Room time-delayed PL PL spectra spectra of of SimCP3 SimCP3 thin thin film. film; (c) Room temperature absorption absorption and and PL PL spectra spectra of of SimCP3 in dichloromethane solution. SimCP3 in dichloromethane solution. Figure 4. (a)Variable time-gated PL spectra of SimCP3 thin film. (b) Variable temperature, 121 msec time-delayed PL spectra of SimCP3 thin film. (c) Room temperature absorption and PL spectra of Knowing an of of 3.573.57 eV (347 nm shown in Figure 4c) and theand HOMO energy SimCP3 inoptical dichloromethane solution. Knowing an opticalenergy energygap gap eV (347 nm shown in Figure 4c) the HOMO level of level 5.95 eV (Figure 5a), which acquired by a low-energy photoelectron spectrometer Rikenenergy of 5.95 eV (Figure 5a),was which was acquired by a low-energy photoelectron spectrometer Knowing an optical energy gap ofSimCP3 3.57 eV (347 nm shown in Figure as 4c)~2.4 and the HOMO energy Keiki AC-2, the LUMO energy level of can thus be calculated eV. Together with the Riken-Keiki AC-2, the LUMO energy level of SimCP3 can thus be calculated as ~2.4 eV. Together level of 5.95 eV (Figure 5a), which was acquired by a low-energy photoelectron spectrometer RikenHOMO LUMO andlevels ET ofand TAPC transporting or electronorblocking with theand HOMO andenergy LUMOlevels energy ET (hole of TAPC (hole transporting electron material) blocking Keiki AC-2,[32], the LUMO energy level of SimCP3 can thus be calculated as ~2.4material) eV. Together the [31,32], FIrpic and TmPyPB (electron transporting or hole blocking [33],with the[33], energy material) [31,32], FIrpic [32], and TmPyPB (electron transporting or hole blocking material) HOMO and LUMO energy levels and ET of TAPC (hole transporting or electron blocking material) the level alignment of materials involved in OLEDs is depicted in Figure 5b. Therefore, TAPC, SimCP3, energy levelFIrpic alignment of materials involved in OLEDsorishole depicted in Figure 5b.[33], Therefore, TAPC, [31,32], [32], and TmPyPB (electron transporting blocking material) the energy and TmPyPB all have HOMO and LUMO energy levels that levels encompass those of FIrpic, and FIrpic SimCP3, TmPyPB all have HOMO LUMO energy thatTherefore, encompass those of FIrpic, level and alignment of materials involved in and OLEDs is depicted in Figure 5b. TAPC, SimCP3, has the smallest E T among all materials involved in the OLED fabrication. This is a good set of materials and TmPyPB all smallest have HOMO and LUMO energy levels that encompass those offabrication. FIrpic, and FIrpic and FIrpic has the ET among all materials involved in the OLED This is a enabling the confinement of triplet exciton on the FIrpic phosphorescence dopant. Accordingly, we has the smallest E T among all materials involved in the OLED fabrication. This is a good set of materials good set of materials enabling the confinement of triplet exciton on the FIrpic phosphorescence fabricated three types of FIrpic OLED having SimCP3 as a solution-processed host material: a singleenabling the confinement of triplet exciton on the FIrpic phosphorescence dopant. Accordingly, we dopant. Accordingly, we fabricated three types of FIrpic OLED having SimCP3 as a solution-processed layer device (SL)—ITO/PEDOT:PSS/SimCP3:FIrpic/CsF/Al—a bilayer device (BL)—ITO/PEDOT:PSS/ three types of FIrpicdevice OLED having SimCP3 as a solution-processed host material: a singlehost fabricated material: a single-layer (SL)—ITO/PEDOT:PSS/SimCP3:FIrpic/CsF/Al—a bilayer layer device (SL)—ITO/PEDOT:PSS/SimCP3:FIrpic/CsF/Al—a bilayer device (BL)—ITO/PEDOT:PSS/ SimCP3:FIrpic/TmPyBP/CsF/Al—and a trilayer device (TL)—ITO/PEDOT:PSS/TAPC/SimCP3:FIrpic/ device (BL)—ITO/PEDOT:PSS/SimCP3:FIrpic/TmPyBP/CsF/Al—and a trilayer device (TL)—ITO/ SimCP3:FIrpic/TmPyBP/CsF/Al—and trilayerconcentration device (TL)—ITO/PEDOT:PSS/TAPC/SimCP3:FIrpic/ TmPyBP/CsF/Al. After optimization, theadopant FIrpic was 4the wt dopant % in all concentration three devices. PEDOT:PSS/TAPC/SimCP3:FIrpic/TmPyBP/CsF/Al. After of optimization, TmPyBP/CsF/Al. AfterCsF/Al optimization, the each dopant concentration of FIrpic was 4 wt % in allwas threefabricated devices. by Except for TmPyBP and cathode, thin film layer of such FIrpic OLEDs of FIrpic was wt % in and all three devices. for film TmPyBP and CsF/Al cathode, each thin film Except for4 TmPyBP CsF/Al cathode,Except each thin layer of such FIrpic OLEDs was fabricated by layer solution process, i.e., the method. of such FIrpic OLEDs wasspin-coating fabricated by solution process, i.e., the spin-coating method. solution process, i.e., the spin-coating method. CPS^0.5 CPS^0.5 12 (a) 11 12 (a) 11 10 10 9 9 8 8 7 7 6 6 5 5 5.955.95 eVeV 4 4 3 3 2 2 1 1 0 0 5.3 5.4 5.5 5.6 5.7 5.8 5.9 6.0 6.1 6.2 6.3 6.4 6.5 5.3 5.4 5.5 5.6 5.7 5.8 5.9 6.0 6.1 6.2 6.3 6.4 6.5 Energy (eV) Energy (eV) Figure 5. (a) Low-energy photoelectron spectra of SimCP3; (b) Energy level alignment of materials Figure 5. 5. (a) (a) Low-energy Low-energy photoelectron photoelectron spectra spectra of of SimCP3; SimCP3; (b) (b) Energy Energy level level alignment of materials materials Figure alignment of involved in OLEDs. involved in in OLEDs. OLEDs. involved Molecules 2016, 21, 1315 6 of 11 EL characteristics of SL, BL, and TL devices are summarized in Figure 6 and Table 1. All three devices exhibit typical sky-blue emissions of FIrpic with a λmax of ~468 nm, although a variation of emission shoulder band around 500 nm (Figure 6a) was observed. Since both BL and TL devices Molecules 2016, 21, 1315 6 of 11 have a similar intensity of the shoulder band and are both more intense than that of the SL device, it can be logically inferredofthat TmPyPB effectively blocks the triplet6 and exciton FIrpic, confining the EL characteristics SL, BL, and TL devices are summarized in Figure Table of 1. All three devices charge exhibit recombination mostly in the of SimCP3:FIrpic light-emitting layer (i.e., farther away from the typical sky-blue emissions FIrpic with a λmax of ~468 nm, although a variation of emission band around 500 nm (Figure 6a) was observed. Since both BLto and TLlow devices a similar cathodeshoulder surface) [19]. Therefore, the same reason can be ascribed the EL have efficiency of the SL intensity of the shoulder band and are both more intense than that of the SL device, it can be logically device (Figure 6b,c), where the triplet exciton of FIrpic generates in an area too close to the cathode inferred that TmPyPB effectively blocks the triplet exciton of FIrpic, confining the charge recombination surface and hence is prone to being quenched. Similarly, the TAPC of the TL device plays a role mostly in the SimCP3:FIrpic light-emitting layer (i.e., farther away from the cathode surface) [19]. of inhibiting triplet exciton from the the device. the EL efficiency Therefore, the same reason can contacting be ascribed to theanode low ELofefficiency of the Therefore, SL device (Figure 6b,c), of the TL device is promoted when compared with the device.surface The maximum where the triplet exciton offurther FIrpic generates in an area too close to BL the cathode and hence isexternal prone to being(EQE), quenched. Similarly, the TAPC of the TL power device plays a role of(PE) inhibiting excitonare ~9%, quantum efficiency current efficiency (CE), and efficiency of thetriplet TL device fromand contacting the anode of the device. Therefore, the device EL efficiency of the TL device is promoted ~20 cd/A, 12 lm/W, respectively. However, the TL has the lowest current density and the when compared with the BL device. 2The maximum external quantum efficiency (EQE), highestfurther turn-on voltage—around 5 V at 1 cd/m (see Figure 6d)—among the three devices. This can current efficiency (CE), and power efficiency (PE) of the TL device are ~9%, ~20 cd/A, and 12 lm/W, be attributed to the two exciton blocking layers in the device, which limits the current density and respectively. However, the TL device has the lowest current density and the highest turn-on elevatesvoltage—around the driving voltage the2 (see device. three devices relatively mild 5 V at 1 of cd/m FigureNevertheless, 6d)—among theall three devices. Thisexhibited can be attributed to 2 (about 38, 30, and 19 mA/cm2 of the SL, efficiency Even at thelayers highinbrightness of 3000 cd/m theroll-off. two exciton blocking the device, which limits the current density and elevates the driving of the device. Nevertheless, three devices exhibited mild Even BL, andvoltage TL devices), an EQE of 3.6%,all4.5%, and 7.4% wererelatively achieved byefficiency the SL,roll-off. BL, and TLatdevices, 2 (about 38, 30, and 19 mA/cm2 of the SL, BL, and TL devices), an EQE of the high brightness of 3000 cd/m which are 95%, 62%, and 81% of the maximum EL efficiency, respectively (Figure 6c). Compared with 3.6%, 4.5%, and 7.4% were achieved by the SL, BL, and TL devices, which are 95%, 62%, and 81% of those of vacuum-thermal-evaporation OLEDs [2,4], the efficiency roll-off observed for the three devices the maximum EL efficiency, respectively (Figure 6c). Compared with those of vacuum-thermalis relatively modest. evaporation OLEDs [2,4], the efficiency roll-off observed for the three devices is relatively modest. 0.5 450 500 550 600 650 10 10 1 0 1 10 20 30 40 50 60 70 80 90 100 2 Wavelength (nm) Current Density (mA/cm ) EQE (%) 10 0 10 20 30 40 50 60 70 80 90 100 2 Current Density (mA/cm ) 10000 2 SL BL TL Current Density (mA/cm ) (c) 1 100 1000 100 10000 (d) SL BL TL 2 0.0 400 SL BL TL (b) Brightness (cd/m ) EL Intensity (a.u.) 1.0 Current Efficiency (cd/A) SL BL TL Power Efficiency (lm/w) (a) 1000 10 100 1 10 0.1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Voltage (V) Figure 6. Electroluminescence characteristics of SimCP3-hosted FIrpic OLEDs. (a) EL spectra at ~10 Figure 6. Electroluminescence characteristics of SimCP3-hosted FIrpic OLEDs. (a) EL spectra volt; (b) Current density dependent current efficiency and power efficiency; (c) Current density at ~10 volt; (b) Current density dependent current efficiency and power efficiency; (c) Current density dependent external quantum efficiency; (d) Voltage dependent current density and brightness. dependent external quantum efficiency; (d) Voltage dependent current density and brightness. Table 1. Electroluminescence characteristics of SimCP3-hosted FIrpic OLEDs Table 1. Electroluminescence characteristics of SimCP3-hosted FIrpic 2) e (%) OLEDs. Device λmax (nm) Von a (V) Lmax b (cd/m CE c (cd/A) PE d (lm/W) EQE CIEx,y f Device SL BL TL a SL 472, 492 5.0 8078 7.7, 7.0, 7.7 3.4, 3.4, 3.0 3.8, 3.4, 3.8 0.15, 0.32 c e d BL (nm)476, 500 94402 ) 16.0, 12.7, 10.8 11.1, 7.2, 7.3, 5.8, 4.9 λmax Von a (V)4.5 Lmax b (cd/m CE (cd/A) EQE 0.16, (%)0.34 PE 5.2 (lm/W) CIEx,y f TL 476, 500 5.0 8880 19.6, 18.0, 17.4 12.3, 9.5, 7.3 9.1, 8.4, 8.1 0.16, 0.34 472, 492 5.0 8078 7.7, 7.0, 7.7 3.4, 3.4, 3.0 3.8, 3.4, 3.8 0.15, 0.32 a Turn-on b Maximum luminance. c Current voltage of4.5 10 cd/m2 (Von). efficiency: 476, 500 9440 16.0, 12.7, 10.8 11.1, 7.2, 5.2 maximum, 7.3, 5.8, 4.9at 100,0.16, 0.34 476, 500 5.0 8880 efficiency:19.6, 18.0, 17.4at 100,12.3, 7.3 cd/m 9.1, 8.4, 8.1 0.16, 0.34 d Power 2, respectively. maximum, and9.5, 1000 and 1000 cd/m2, respectively. b Maximum luminance. 2 c Current efficiency: e External Turn-on voltage of 10 efficiency: cd/m2 (Vmaximum, maximum, quantum at 100, and 1000 cd/m , respectively. f Measured at ~10 volt. at 100, on ). 2 d and 1000 cd/m , respectively. Power efficiency: maximum, at 100, and 1000 cd/m2 , respectively. e External quantum efficiency: maximum, at 100, and 1000 cd/m2 , respectively. f Measured at ~10 volt. Molecules 2016, 21, 1315 7 of 11 3. Materials and Methods 3.1. General Instrumentation 1 H- and 13 C-NMR spectra including distortionless enhancement by polarization (DEPT) were measured on a Bruker AV-400 MHz or AV-500 MHz NMR Fourier transform spectrometer (Bruker, Billerica, MA, USA) at room temperature. Elemental analyses (on a FLASHEA 1112 Series, Thermo Electron Corporation, Waltham, MA, USA), matrix-assisted laser desorption/ionization time-of-flight mass spectroscopy (MALDI-TOF MS, The New UltraflextremeTM , Bremen, Germany), and fast atom bombardment (FAB) mass spectroscopy (FAB-MS, JMS-700 double focusing mass spectrometer, JEOL, Tokyo, Japan) were performed by the Elemental Analyses Laboratory and Mass Spectroscopic Laboratory, respectively, in-house service of the Institute of Chemistry, Academic Sinica. Infrared absorption spectra were recorded on a Varian 640-IR FT-IR spectrometer (Palo Alto, CA, USA). The sample of SimCP3 was ground together with KBr powder and compressed into a thin disc. Thermal decomposition temperatures (Td 0 s) of the host materials were measured by thermogravimetric analysis (TGA) using Perkin-Elmer TGA-7 analyzer systems (Waltham, MA, USA). Melting temperatures (Tm 0 s), crystallization temperatures (Tc 0 s), and glass transition temperatures (Tg 0 s) of the host materials were measured by differential scanning calorimetry (DSC) using Perkin-Elmer DSC-6 analyzer systems (Waltham, MA, USA), using a scan rate of 10 ◦ C/min. The X-ray diffraction measurement of the solution-casting thin film was carried out by using a Bruker D8 Advance diffractometer (Billerica, MA, USA) equipped with a Lynxeye detector. The radiation used was a monochromatic Cu Kα bea‘m of wavelength λ = 0.154 nm. AFM measurements were carried out with XE-100 from Park Systems (Suwon, South Korea) using a non-contact mode to obtain topography images of the thin films, which were prepared by a spin-coating chlorobenzene solution of SimCP3 or SimCP3:FIrpic on a PEDOT:PSS-coated ITO-glass substrate. UV-visible absorption spectra were recorded on a Hewlett-Packard 8453 diode array spectrophotometer (Palo Alto, CA, USA). Room temperature fluorescence spectra were recorded on a Hitachi fluorescence spectrophotometer F-4500 (Tokyo, Japan). The ionization potentials (or HOMO energy levels) of SimCP3 were determined with a low energy photo-electron spectrometer (Riken-Keiki AC-2, Riken Keiki Co., Ltd., Tokyo, Japan). LUMO energy levels were estimated by subtracting the optical energy gap (Eg ) from HOMO energy levels. Eg was determined by the on-set absorption energy from the absorption spectra of the materials as thin film. To measure the triplet energy gap (ET ) of a thin film sample, we established a system with a temperature control of Model 350 (LakeShore Company, Westerville, OH, USA) as low as 10 K by Model 22C/350C Cryodyne Refrigerators (Janis Research Company, Woburn, MA, USA) and a tunable laser with excitation wavelengths of 213, 266, 355, 532, and 1064 nm (Brilliant B laser, Quantel Company, Newbury, Berkshire, UK), which was coupled with a time-delay controller of LP920 flash photolysis spectrometer (Edinburgh Instrument, Kirkton Campus, Livingston, England). We also acquired the triplet energy gap of SimCP3 in frozen 2-Me-THF by using Fluorolog III photoluminescence spectrometer (Kirkton Campus, Livingston, UK), which was equipped a xenon lamp as excitation light source. 3.2. Device Fabrication and Performance Measurements The ITO substrate was purchased from Buwon Precision Sciences (Taoyuan, Taiwan with a sheet resistance around 25 Ω/sq and a thickness of 100 nm. The hole transport layer—PEDOT:PSS[CC2] (CH8000)—was purchased from Sigma-Aldrich (St. Louis, MO, USA). The blue phosphorescence dopant FIrpic, the electron transport layer of TmPyPB, and the hole transport layer of TAPC were obtained commercially from Lumtec (Hsinchu, Taiwan). The indium tin oxide (ITO) substrates were pre-coated with the PEDOT:PSS hole transporting layer (HTL) and baked in the air at 150 ◦ C for 10 min. Blends of SimCP3 and FIrpic in chlorobenzene were spin-coated on ITO/PEDOT:PSS. The active layer was then annealed at 90 ◦ C for 30 min. After spin-coating the active single-layer, the TmPyPB (50 nm), an ultrathin CsF (2 nm) interfacial layer, and then an aluminum cathode (100 nm) were Molecules 2016, 21, 1315 8 of 11 vacuum-thermal deposited. In the triple-layer device, a thin layer (~20 nm) of TAPC was spin-coated first on PEDOT:PSS. In this case, TAPC layer was thermally annealed at 90 ◦ C for 10 min before spin-coating SimCP3:FIrpic. A surface profiler (Dektak 150, Veeco Instruments, Plainview, NY, USA) was used for calibrating the thickness of HTL and the active layer. After the deposition of the cathode, the devices were hermetically sealed with glass and UV-cured resins in a glove box (O2 and H2 O concentration below 0.1 ppm). The device’s active area was 0.04 cm2 and was defined by the self-made shadow mask applied in the cathode deposition. Current density and voltage characteristics were measured by a dc current–voltage source meter (Keithley 2400, Tektronix, Beaverton, OR, USA), and the device brightness (or electroluminance, cd/m2 ) and EL spectra were monitored and recorded with a spectrophotometer (PR650; Photo Research, Syracuse, NY, USA). The EQE of OLEDs was calculated from the luminance, current density, and the EL spectra, assuming the EL of the OLED is isotropic, i.e., a Lambertian emission [34]. 3.3. Materials Preparation All chemical and reagents were obtained from commercial suppliers and used without further purification. Solvents were purified according to the standard procedures. Unless specified condition, all reaction were performed under a nitrogen atmosphere using standard Schlenk techniques. Materials involved in OLED fabrication, 4,40 -(cyclohexane-1,1-diyl)bis(N,N-di-p-tolylaniline) (TAPC), and 3,30 -(50 -(3-(pyridin-3-yl)phenyl)-[1,10 :30 ,100 -terphenyl]-3,300 -diyl)dipyridine (TmPyPB) were purchased from Lumtec (Hsinchu, Taiwan) and Ultra Fine Chemical Technology Corp. (Degussa, Dusseldorf, Germany), respectively. They were used as received without further purification. Synthesis and characterization of 9,90 -(5-Bromo-1,3-phenylene)bis(9H-carbazole), BrmCP. The synthesis and isolation of BrmCP are modified from a known procedure of a patent report [28]. To an anhydrous DMF solution (200 mL) containing sodium hydride (60% suspension in oil, 13 g, 0.31 mole), carbazole (52 g, 0.31 mol) was slowly added. The mixture was stirred for 1 h at room temperature. After cooling in an ice bath, 3,5-difluorobromobenzene (12 mL, 0.1 mol) was added dropwise. The solution mixture was then heated at 130 ◦ C for 12 h. After cooling, an excess amount of ethanol–water mixture (10:1) was added and stirred, resulting in white precipitates. The product was isolated by suction filtration, and further purification was achieved by zone-temperature sublimation to afford white solid (44.7 g, 92%). 1 H-NMR (400 MHz, CDCl3 ): δ (ppm) 8.13 (d, 4H, J = 7.6 Hz), 7.85 (s, 2H), 7.78 (s, 1H), 7.53 (d, 4H, J = 7.6 Hz), 7.45 (t, 4H, J = 7.6 Hz), 7.32 (t, 4H, J = 7.6 Hz). 13 C-NMR (100 MHz, CDCl3 ): δ (ppm) 140.72, 140.55, 128.89, 126.58, 124.32, 124.18, 124.04, 120.98, 120.77, 109.81. MALDI-HRMS: calcd MW 486.0726, m/z = 486.0705 (M+ ). Synthesis and characterization of 9,90 ,900 ,9000 ,90000 ,900000 -((phenylsilanetriyl)tris(benzene-5,1,3-triyl)) hexakis(9H-carbazole) (SimCP3). To a refluxing toluene (4 mL), sodium metal (0.2 g, 8.3 mmol) was added. The mixture was stirred for 10 min. Then, BrmCP (2.0 g, 4.0 mmol) and trichloro(phenyl)silane (0.2 mL, 1.3 mmol) dissolved in toluene (4 mL) were added slowly to the refluxing toluene containing sodium metal through an additional funnel. After 3 h of reaction, the reaction solution was cooled to room temperature and an excess amount of methanol was added. The resulting precipitations were isolated by suction filtration and subjected to column chromatography (silica gel, dichloromethane/hexanes: 2/3). A white solid was obtained with a yield of 34% (0.6 g). FT-IR (λ, cm−1 ): 3044 (w), 3013 (w), 1623 (w), 1580 (s), 1490 (m), 1480 (m), 1447(s), 1416 (m), 1374 (m), 1330 (s), 1309 (s), 1227 (s), 1191 (m), 1155 (m), 1120 (m), 1098 (w), 1027 (w), 1002 (w), 959 (w), 923 (w), 904 (w), 882 (w), 840 (w), 798 (w), 778 (w), 746 (s), 706 (s), 722 (s). UV-Vis (CH2 Cl2 ): λmax 293, 311, 325, 339 (3.61 × 104 cm−1 ·M−1 ). 1 H-NMR (400 MHz, CDCl3 ): δ (ppm) 8.07–8.03 (m, 18H), 7.87 (m, 5H), 7.48–7.47 (m, 3H), 7.27 (d, 12H, J = 8.4 Hz), 7.15 (t, 12H, J = 7.6 Hz), 7.00 (t, 12H, J = 7.6 Hz). 13 C- and DEPT NMR (125 MHz, CDCl3 ): δ (ppm) 140.54, 140.04, 137.07, 136.27 (DEPT-90), 133.69, 132.92 (DEPT-90), 131.40 (DEPT-90), 129.19 (DEPT-90), 127.27 (DEPT-90), 126.47 (DEPT-90), 123.89, 120.74 Molecules 2016, 21, 1315 9 of 11 (DEPT-90), 120.62 (DEPT-90), 109.62 (DEPT-90). MALDI-HRMS: calcd MW 1326.4800, m/z = 1326.4757 (M+ ). Anal. Found (calcd) for C96 H62 N6 Si: C 86.66 (86.85), H 4.92 (4.71), N 6.37 (6.33). 4. Conclusions In summary, we have overcome the synthetic difficulty of SimCP3, an advanced homologue of previously known SimCP2. We have examined the amorphous nature and the spectroscopic properties (HOMO and LUMO energy levels as well as the triplet energy gap) of SimCP3. Three sky-blue phosphorescence OLEDs have been fabricated with a SimCP3:FIrpic light-emitting layer, which was spin-coated from solution. A trilayer device exhibits the highest EL efficiency of ~9%, ~20 cd/A, or ~12 lm/W, demonstrating the viability of SimCP3 as a solution-processed host material for sky-blue phosphorescence OLEDs. Acknowledgments: We thank the Ministry of Science and Technology (MOST 103-2113-M-001-021-MY3), Academia Sinica, and National Taiwan University for financial support. We acknowledge Jiun-Haw Lee of National Taiwan University in the calculation of EQE of the OLEDs in this work. Author Contributions: Chin-Ti Chen and Chao-Tsen Chen conceived and designed the experiments; Cheng-Lung Wu, Yung-Ting Chang, Jan Golder, and Yi-Ting Lee performed the experiments; Yung-Ting Chang and Yi-Ting Lee analyzed the data; Chin-Ti Chen and Chao-Tsen Chen wrote the paper. Conflicts of Interest: The authors declare no conflict of interest. References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Romain, M.; Tondelier, D.; Geffroy, B.; Shirinskaya, A.; Jeannin, O.; Rault-Berthelot, J.; Poriel, C. Spiro-configured phenyl acridine thioxanthene dioxide as a host for efficient PhOLEDs. Chem. Commun. 2015, 51, 1313–1315. [CrossRef] [PubMed] Romain, M.; Tondelier, D.; Jeannin, O.; Geffroy, B.; Rault-Berthelot, J.; Poriel, C. Properties modulation of organic semi-conductors based on a donor-spiro-acceptor (D-spiro-A) molecular design: New host materials for efficient sky-blue PhOLEDs. J. Mater. Chem. C 2015, 3, 9701–9714. [CrossRef] Cui, J.-S.; Xie, Y.-M.; Wang, Y.-K.; Zhong, C.; Deng, Y.-L.; Liu, X.-Y.; Jiang, Z.-Q.; Liao, L.-S. Pure Hydrocarbon Hosts for ∼ =100% exciton harvesting in both phosphorescent and fluorescent light-emitting devices. Adv. Mater. 2015, 27, 4213–4217. [CrossRef] [PubMed] Ding, L.; Dong, S.-C.; Jiang, Z.-Q.; Chen, H.; Liao, L.-S. Orthogonal molecular structure for better host material in blue phosphorescence and larger OLED white lighting panel. Adv. Funct. Mater. 2015, 25, 645–650. [CrossRef] Lai, C.-C.; Huang, M.-J.; Cou, H.-H.; Liao, C.-Y.; Rajamalli, P.; Cheng, C.-H. m-Indolocarbazole derivative as a universal host material for RGB and white phosphorescent OLEDs. Adv. Funct. Mater. 2015, 25, 5548–5556. [CrossRef] Huang, J.-J.; Hung, Y.-H.; Ting, P.-L.; Tsai, Y.-N.; Gao, H.-J.; Chiu, T.-L.; Lee, J.-H.; Chen, C.-L.; Chou, P.-T.; Leung, M.-K. Orthogonally substituted benzimidazole-carbazole benzene as universal hosts for phosphorescent organic light-emitting diodes. Org. Lett. 2016, 18, 672–675. [CrossRef] [PubMed] Thiery, S.; Tondelier, D.; Geffroy, B.; Jeannin, O.; Rault-Berthelot, J.; Poriel, C. Modulation of the Physicochemical Properties of Donor–Spiro–Acceptor Derivatives through Donor Unit Planarisation: Phenylacridine versus Indoloacridine—New Hosts for Green and Blue Phosphorescent Organic Light-Emitting Diodes (PhOLEDs). Chem. Eur. J. 2016, 22, 10136–10149. [CrossRef] [PubMed] Duan, L.; Hou, L.; Lee, T.-W.; Qiao, J.; Zhang, D.; Dong, G.; Wang, L.; Qiu, Y. Solution processable small molecules for organic light-emitting diodes. J. Mater. Chem. 2010, 20, 6392–6407. [CrossRef] Zhong, C.; Duan, C.; Hung, F.; Wu, H.; Cao, Y. Materials and devices toward fully solution processable organic light-emitting diodes. Chem. Mater. 2011, 23, 326–340. [CrossRef] Xiao, L.; Chen, Z.; Qu, B.; Luo, J.; Kong, S.; Gong, Q.; Kido, J. Recent progresses on materials for Electrophosphorescent organic light-emitting devices. Adv. Mater. 2011, 23, 926–952. [CrossRef] [PubMed] Tao, Y.; Yang, C.; Qin, J. Organic host materials for phosphorescent organic light-emitting diodes. Chem. Soc. Rev. 2011, 40, 2943–2970. [CrossRef] [PubMed] Molecules 2016, 21, 1315 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 10 of 11 Lee, Y.-T.; Chang, Y.-T.; Lee, M.-T.; Chiang, P.-H.; Chen, C.-T.; Chen, C.-T. Solution-processed bipolar small molecular host materials for single-layer blue phosphorescent organic light-emitting diodes. J. Mater. Chem. C 2014, 2, 382–391. [CrossRef] Jiang, W.; Xu, H.; Ban, X.; Yuan, G.; Sun, Y.; Huang, B.; Duan, L.; Qiu, Y. Alcohol-soluble Electron-transport small molecule for fully solution-processed multilayer white Electrophosphorescent devices. Org. Lett. 2014, 16, 1140–1143. [CrossRef] [PubMed] Aizawa, N.; Pu, Y.J.; Watanabe, M.; Chiba, T.; Ideta, K.; Toyota, N.; Igarashi, M.; Suzuri, Y.; Sasabe, H.; Kido, J. Solution-processed multilayer small-molecule light-emitting devices with high-efficiency white-light emission. Nat. Commun. 2014, 5, 5756. [CrossRef] [PubMed] Tsuboi, T.; Liu, S.-W.; Wu, M.-F.; Chen, C.-T. Spectroscopic and electrical characteristics of highly efficient tetraphenylsilane-carbazole organic compound as host material for blue organic light emitting diodes. Org. Electron. 2009, 10, 1372–1377. [CrossRef] Jou, J.-H.; Wang, W.-B.; Chen, S.-Z.; Shyue, J.-J.; Hsu, M.-F.; Lin, C.-W.; Shen, S.-M.; Wang, C.-J.; Liu, C.-P.; Chen, C.-T.; et al. High-efficiency blue organic light-emitting diodes using a 3,5-di(9H-carbazol-9-yl)tetraphenylsilane host via a solution-process. J. Mater. Chem. 2010, 20, 8411–8416. [CrossRef] Liu, S.-W.; Yuan, C.-H.; Yeh, S.-J.; Wu, M.-F.; Chen, C.-T.; Lee, C.-C. Efficiency enhancement of solution-processed single-layer blue-phosphorescence organic light-emitting devices having co-host materials of polymer (PVK) and small-molecule (SimCP2). J. Soc. Inform. Disp. 2011, 19, 346–352. [CrossRef] Liu, S.-W.; Chang, Y.-T.; Lee, C.-C.; Yuan, C.-H.; Liu, L.-A.; Chen, Y.-S.; Lin, C.-F.; Wu, C.-I.; Chen, C.-T. Single-layer blue Electrophosphorescent organic light-emitting diodes based on small-molecule mixed hosts: Comparison between the solution and vacuum fabrication processes. Jpn. J. Appl. Phys. 2013, 52, 012101. [CrossRef] Chang, Y.-T.; Liu, S.-W.; Yuan, C.-H.; Ho, Y.-H.; Chen, K.-Y.; Lee, Y.-T.; Wu, M.-F.; Lee, C.-C.; Wei, P.-K.; Chen, C.-T.; et al. Comparison of light out-coupling enhancements in single-layer blue-phosphorescent organic light emitting diodes using small-molecule or polymer hosts. J. Appl. Phys. 2013, 114, 173106. [CrossRef] Chang, Y.-T.; Chang, J.-K.; Lee, Y.-T.; Wang, P.-S.; Wu, J.-L.; Hsu, C.-C.; Wu, I.-W.; Tseng, W.-H.; Pi, T.-W.; Chen, C.-T.; et al. High-efficiency small-molecule-based organic light emitting devices with solution processes and oxadiazole-based electron transport materials. ACS Appl. Mater. Interfaces 2013, 5, 10614–10622. [CrossRef] [PubMed] Chang, H.-W.; Lee, Y.-T.; Tseng, M.-R.; Jang, M.-H.; Yeh, H.-C.; Luo, F.-T.; Meng, H.-F.; Chen, C.-T.; Chi, Y.; Qiu, Y.; et al. General Application of blade coating to small-molecule hosts for organic light-emitting diode. Synth. Metals 2014, 196, 99–109. [CrossRef] Jou, J.-H.; Chen, S.-Z.; An, C.-C.; Peng, S.-H.; Ting, T.-Y.; Shyue, J.-J.; Chin, C.-L.; Chen, C.-T.; Wang, C.-W. A wet and dry processable phosphorescent green dye based organic light-emitting diodes. Dyes Pigments 2015, 113, 341–350. [CrossRef] Sun, D.; Zhou, X.; Li, H.; Sun, X.; Ren, Z.; Ma, D.; Yan, S. Multi-3,30 -bicarbazole-substituted arylsilane host materials with balanced charge transport for highly efficient solution-processed blue phosphorescent organic light-emitting diodes. ACS Appl. Mater. Interfaces 2015, 7, 17802–17810. [CrossRef] [PubMed] Yeh, S.-J.; Wu, M.-F.; Chen, C.-T.; Song, Y.-H.; Chi, Y.; Ho, M.-H.; Hsu, S.-F.; Chen, C.H. New dopant and host materials for blue-light-emitting phosphorescent organic electroluminescent devices. Adv. Mater. 2005, 17, 285–289. [CrossRef] Wu, M.-F.; Yeh, S.-J.; Chen, C.-T.; Murayama, H.; Tsuboi, T.; Li, W.-S.; Chao, I.; Liu, S.-W.; Wang, J.-K. The quest for high-performance host materials for Electrophosphorescent blue dopants. Adv. Funct. Mater. 2007, 17, 1887–1895. [CrossRef] Bassett, E.A.; Emblem, H.G.; Frankel, M.; Ridge, D. The use of the Würtz–Fittig reaction in the preparation of organo-substituted silanes. J. Soc. Chem. Ind. 1948, 67, 177–179. [CrossRef] Freiser, H.; Eagle, M.V.; Speier, J. Electric moments and structures of organosilicon compounds. II. The aromatic carbon-silicon bond. J. Am. Chem. Soc. 1953, 75, 2821–2824. [CrossRef] Yabe, M.; Shiotani, T.; Sato, H.; Akiyama, S. Tetraaminobiphenyls, Their Charge Transporting or Electroluminescent Materials, and Organic Electroluminescent Devices Using Them. JP 2005047811 A, 24 February 2005. Molecules 2016, 21, 1315 29. 30. 31. 32. 33. 34. 11 of 11 Kipping, F.S.; Sands, J.E. Organic derivatives of silicon. Part XXV. Saturated and unsaturated silicohydrocarbons, Si4 Ph8 . J. Chem. Soc. Trans. 1921, 119, 830–847. [CrossRef] Miller, R.D.; Thompson, D.; Sooriyakumaran, R.; Fickers, G.N. The synthesis of soluble, substituted silane high polymer by Würtz coupling techniques. J. Polym. Sci. Part A Polym. Chem. 1991, 29, 813–824. [CrossRef] Goushi, K.; Kwong, R.; Brown, J.J.; Sasabe, H.; Adachi, C. Triplet exciton confinement and unconfinement by adjacent hole-transport layers. J. Appl. Phys. 2004, 95, 7798–7802. [CrossRef] Lee, J.; Chopra, N.; Eom, S.-H.; Zheng, Y.; Xue, J.; So, F.; Shi, J. Effects of triplet energies and transporting properties of carrier transporting materials on blue phosphorescent organic light emitting devices. Appl. Phys. Lett. 2008, 93, 123306. [CrossRef] Su, S.-J.; Gonmori, E.; Sasabe, H.; Kido, J. Highly efficient organic blue- and white-light-emitting devices having a carrier- and exciton-confining structure for reduced efficiency roll-off. Adv. Mater. 2008, 20, 4189–4194. [CrossRef] Fukagawa, H.; Shimizu, T.; Kawano, H.; Yui, S.; Shinnai, T.; Iwai, A.; Tsuchiya, K.; Yamamoto, T. Novel hole-transporting materials with high triplet energy for highly efficient and stable organic light-emitting diodes. J. Phys. Chem. C 2016, 120, 18748–18755. [CrossRef] Sample Availability: Samples of SimcP3 are available from the authors. © 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).