MALAYSIA

This literature supersedes all previous issues.

GENERAL DESCRIPTION

Clean COLORBOND® ULTRA MATT prepainted steel,

prepainted steel, specifically designed by BlueScope,

combines long term durability and exceptional

corrosion resistance. To determine if warranties apply,

please contact your nearest BlueScope sales office

for advice.

TYPICAL USES

Exterior building profiles in applications requiring low gloss finish and excellent

corrosion resistance. Suitable from moderate to severe marine or industrial environment.

For material selection advice, please contact your nearest BlueScope sales office.

AUSTRALIAN STANDARD

Substrate – AS 1397

Paint Coating – AS/NZS 2728

PREFERRED SUBSTRATES:

ZINCALUME® G550S AZ200 steel (Zinc/Aluminium alloy-coated steel).

ZINCALUME® G300S AZ200 steel (Zinc/Aluminium alloy-coated steel).

PRETREATMENT:

Corrosion resistant proprietary conversion coating.

PRIMER COAT:

Universal corrosion inhibitive primer. Nominal dry film thickness 5µm each side.

FINISH COAT:

Custom formulated polyester paint system with inorganic pigments. Nominal dry film thickness 20µm on the top or weather side.

The finish coat can, if required, be applied to both sides to provide a double-sided product.

BACKING COAT:

Custom formulated Bass Grey. Nominal dry film thickness 10µm.

COLOUR:

A range of standard colours is available. Other specially required colours may be available on request.

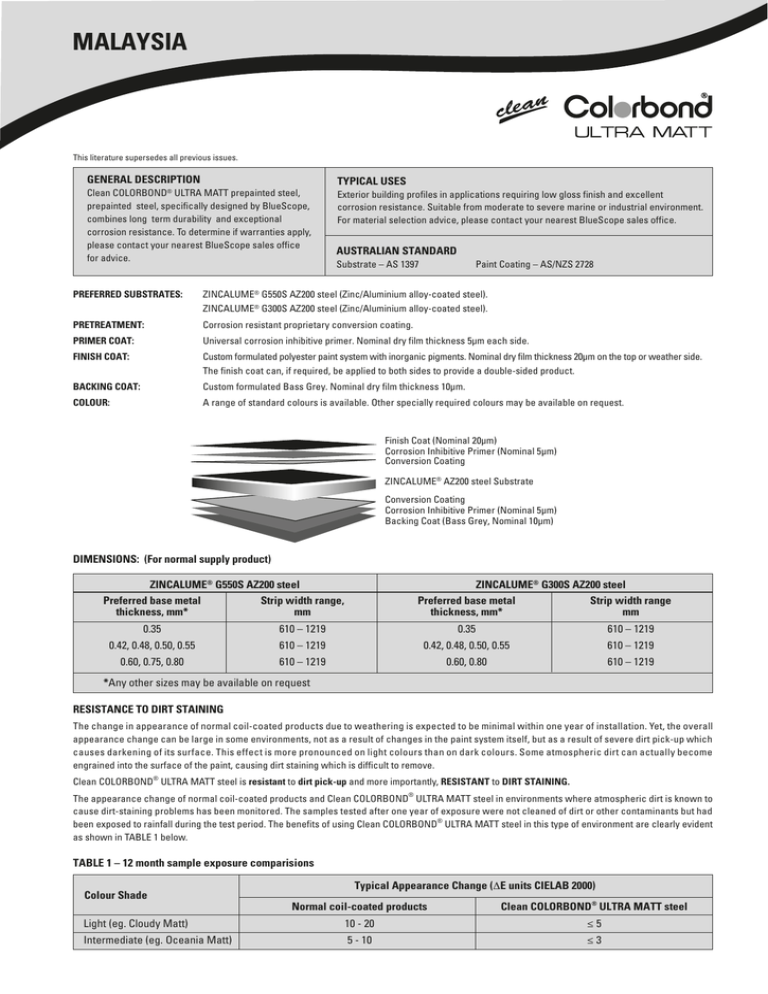

Finish Coat (Nominal 20µm)

Corrosion Inhibitive Primer (Nominal 5µm)

Conversion Coating

ZINCALUME® AZ200 steel Substrate

Conversion Coating

Corrosion Inhibitive Primer (Nominal 5µm)

Backing Coat (Bass Grey, Nominal 10µm)

DIMENSIONS: (For normal supply product)

ZINCALUME® G550S AZ200 steel

Preferred base metal

Strip width range,

thickness, mm*

mm

ZINCALUME® G300S AZ200 steel

Preferred base metal

Strip width range

thickness, mm*

mm

0.35

610 – 1219

0.35

610 – 1219

0.42, 0.48, 0.50, 0.55

610 – 1219

0.42, 0.48, 0.50, 0.55

610 – 1219

0.60, 0.75, 0.80

610 – 1219

0.60, 0.80

610 – 1219

*Any other sizes may be available on request

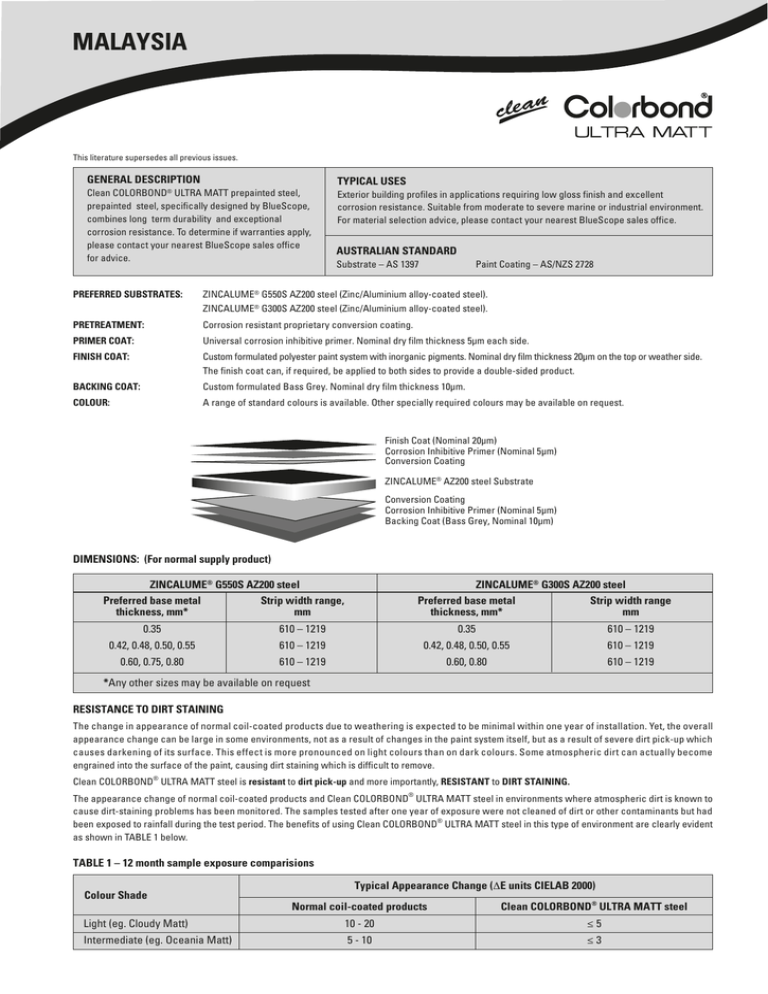

RESISTANCE TO DIRT STAINING

The change in appearance of normal coil-coated products due to weathering is expected to be minimal within one year of installation. Yet, the overall

appearance change can be large in some environments, not as a result of changes in the paint system itself, but as a result of severe dirt pick-up which

causes darkening of its surface. This effect is more pronounced on light colours than on dark colours. Some atmospheric dirt can actually become

engrained into the surface of the paint, causing dirt staining which is difficult to remove.

Clean COLORBOND® ULTRA MATT steel is resistant to dirt pick-up and more importantly, RESISTANT to DIRT STAINING.

The appearance change of normal coil-coated products and Clean COLORBOND® ULTRA MATT steel in environments where atmospheric dirt is known to

cause dirt-staining problems has been monitored. The samples tested after one year of exposure were not cleaned of dirt or other contaminants but had

been exposed to rainfall during the test period. The benefits of using Clean COLORBOND® ULTRA MATT steel in this type of environment are clearly evident

as shown in TABLE 1 below.

TABLE 1 – 12 month sample exposure comparisions

Colour Shade

Typical Appearance Change (ΔE units CIELAB 2000)

Normal coil-coated products

Clean COLORBOND® ULTRA MATT steel

Light (eg. Cloudy Matt)

10 - 20

≤5

Intermediate (eg. Oceania Matt)

5 - 10

≤3

TYPICAL PROPERTIES

Specular Gloss (60˚)

7 ± 3 units (AS/NZS 1580.602.2; ASTM D523)

Scratch Resistance

Good, typically 2000g (AS 2331.4.7)

Reverse Impact

≥10 Joules (AS/NZS 2728 App. E)

Pencil Hardness

HB minimum (AS/NZS 1580.405.1)

T-Bend Adhesion

6T maximum (AS/NZS 2728 App. F)

Heat Resistance

Suitable for continuous service up to 100˚C. Continuous service at higher temperatures may cause some

colour change of the paint film.

≤ 20mg paint removal per 100 cycles (AS/NZS 1580.403.2)

Taber Abrasion Resistance

TABLE 2 – Early fire hazard ratings (AS/NZS 1530.3)

INDEX

Ignitability Index

Spread of Flame Index

Heat Evolved Index

Smoke Evolved Index

RATING

0

0

0

0-1

RANGE

0 - 20

0 - 10

0 - 10

0 - 10

EXPECTED PRODUCT SERVICE PERFORMANCE

Film Integrity

Clean COLORBOND® ULTRA MATT steel under normal well-washed exposure conditions should show no cracking (other

than that which may occur during forming), flaking or peeling of the paint for 15 years.

Change in Appearance The appearance of Clean COLORBOND® ULTRA MATT steel and other coil-coated products can change over time on exterior

weathering not only due to pick-up of dirt but also to changes in the paint system itself such as gloss loss, chalking and fading of

pigmentation.

Colour change, which is largely due to the changes in pigmentation will depend on the colour chosen. It is measured using a

spectrophotometer, according to ASTM D-2244 on surfaces thoroughly cleaned of dirt, chalk, oxidised film and foreign

contaminants. The typical appearance change of standard Clean COLORBOND ® ULTRA MATT steel colours in normal

environments after 10 years of service are given in TABLE 3 below.

TABLE 3 - Expected colour change after 10 years in natural well-washed exposure (AS/NZS 1580.457.1 & ASTM D-2244)

Colour Shade

Typical Appearance Change (ΔE units CIELAB 2000)

Intermediate (eg. Oceania Matt)

≤6

Dark (eg. Ruby Matt)

≤ 10

Note: Improper storage or use of non-approved rollforming lubricants may adversely affect colour stability. Wet storage should be avoided, however,

materials which become wet while in bundles should be separated and allowed to dry. (refer AS/NZS 2728 Appendix L)

Colour Change Resistance

(QUV 2000 hours)

ΔE units CIELAB 2000: Intermediate Colour : ≤ 5 unit (ASTM G154 & ASTM D-2244)

Corrosion Resistance

(Salt Spray 1000 hours)

Blister density: ≤ 2; Blister size: ≤S3; Undercut from a score: ≤2mm. No loss of adhesion or corrosion. (AS/NZS 2728 App. I)

Humidity Resistance

(Cleveland 500 hours)

Blister density: ≤ 3; Blister size: ≤ S2; No loss of adhesion or corrosion. (ASTM D4585)

Chalking Resistance

(QUV 2000 hours)

Chalk rating: ≤ 4 (ASTM G154 & AS/NZS 1580.481.1.11 (Method B).

Chemical Resistance

The integrity of the paint film on Clean COLORBOND ® ULTRA MATT steel is expected to be largely unaffected by

accidental spillage of solvents such as methylated spirits, white spirits, mineral turpentine, toluene, trichloroethylene and

dilute acids and alkali as long as these spillage are removed immediately by wiping or washing. However, contact with

certain of these chemicals may reduce the resistance of the product to dirt pick-up.

Use Under

Adverse Conditions

If it is intended to use Clean COLORBOND ® ULTRA MATT steel in an exterior application within 1 km of salt marine

locations, severe industrial or unusually corrosive environment, in areas not washed by rain, or in end uses where it will

be wholly or partly buried in the ground, please contact your BlueScope sales office for specialised advice.

Note: Customers should use product promptly (within 6 months) to avoid the possibility of storage related corrosion.

Please ensure you have the current data sheet for this product.

NS BlueScope Malaysia Sdn. Bhd. (223136-P)

(Formerly known as BlueScope Steel (Malaysia) Sdn. Bhd.)

Lot 1551, Jalan Bukit Kapar, 42200 Kapar, Selangor Darul Ehsan, Malaysia.

Tel: +60 3 3361 6888 Fax: +60 3 3361 6889 Website: www.bluescopesteel.com.my

ZINCALUME® and COLORBOND® are registered trade marks of BlueScope Steel Limited.

BlueScope is a trade mark of BlueScope Steel Limited.

Copyright © 2013 by NS BlueScope Malaysia Sdn. Bhd. All rights reserved.