Provider Guide - Platte River Power Authority

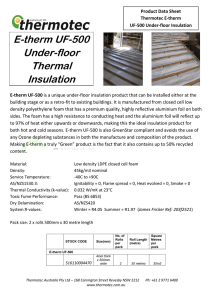

advertisement