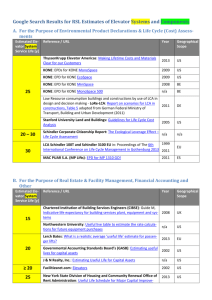

Application References Lifts and Escalators

advertisement

Application References Lifts Lifts and Escalators Site Lifts Material Hoists Escalators product information information produit Austria / Autriche: Freissler-Otis, Wien Kone Elevators, Austria Kone Sowitch, Wien Thyssen, Graz Belgium / Belgique: Ascenseurs Electro-Mécaniques, Jambes Asmolift, Bruxelles Coopman, Kuurne Dumon, Brugge Genorif, Eekloo Kone Belgium S.A., Awans Kone, Bruxelles Kone RCS, Liège Liften Daelemans, Antwerp Otis, Bruxelles Schindler, Bruxelles Thiery Liften, Antwerp Thyssen, Antwerp Thyssen, Bruxelles Brazil / Brésil: Kone, Rio de Janeiro Schindler, Rio de Janeiro Villares, Rio de Janeiro Canada: Ascenseurs Labadie, Montreal Montgomery-Cone, Toronto Denmark / Danemark: Kone, Copenhague Dubai: Otis, Dubai Mitsubishi-Dubai, Dubai France: Camus, Poitiers Kone, Paris Otis, Paris Sacamas, Paris Schindler-RCS, Velizy Soretex/Thyssen, Paris Soulier, Paris Finland / Finlande: Kone Elevators, Finland Kone oy Hissit, Helsinki Germany / Allemagne: Aufzug- und Fördertechnik, Wuppertal Bauer Aufzugsfabrik, Augsburg Beneke Aufzugsbau, Weiden Elektronic-Lift Thoma, Frankfurt Hagman, Köln Haushahn & Co., Stuttgart Kone Aufzug, Berlin Kone Sander Aufzug, Berlin Kone Selzer Aufzüge, Berlin Kone Aufzug, Bremen Kone Aufzug, Dresden Kone Aufzug, Düsseldorf Kone Aufzug, Frankfurt Kone Aufzug, Glatzel & Rieser, Koblenz Kone Aufzug, Hannover FMC715 TIRAK/TIRFOR references elevators, escalators références TIRAK/TIRFOR ascenseurs, escaliers roulants ref.: rev. no.: date: page: M-043 2 04/98 1/2 Kone Aufzug, Leipzig Kone Aufzug, Magdeburg Kone Aufzug, München Kone Aufzug, Stuttgart Kone Aufzug, Velimar Kone Aufzug, Waltersleben Lippert, Gelsenkirchen Otis GmbH, Bad Reichenhall Otis GmbH, Berlin Otis GmbH, Bremen Otis GmbH, Dresden Otis GmbH, Leipzig Otis GmbH, Stadthagen PGH-Aufzugdienst, Reichenbach Schindler, Berlin Schindler, Frankfurt Schindler, Hamburg Thyssen, Hamburg Thyssen, Holzwickede Thyssen, Mannheim Thyssen, Stuttgart-Neuhausen Usto Aufzuge, Enningerloh Hong-Kong: Kone, Marryat & Scott, Hong-Kong Kone Elevator, Thai Lift Building, Bangkok Otis, Hong-Kong Italy / Italie: Kone Ascensori, Pero Stigler-Otis, Milano Schindler, Milano Lebanon / Liban: Otis, Beiruth Luxembourg: General Technic, Luxembourg Malaysia / Malaisie: Hitachi, Kuala Lumpur Poland / Pologne Kone Elevators, Poland Singapour: Hitachi, Singapour Otis, Singapour Schindler, Singapour Spain / Espagne: Eguren Kone, Bilbao Kone Elevadores, Alicante Kone Elevadores, Andora Kone Elevadores, Barcelona Kone Elevadores, Corvado Kone Elevadores, Madrid Kone Elevadores, Rigonza S.A., Mallorca Kone Elevadores, Sabadell Kone Elevadores, Tenerife Kone Elevadores, Valencia Macosa Elevacion, Barcelona Orenstein & Koppel, Madrid Orona, San Sebastian Schindler, Zaragoza Thyssen Boetticher, Madrid Zardoya Otis, Madrid M-242 M-108 M-074 M-073/M-565 M-074 product information information produit Sweden / Suède Kone Hissar AB, Kista Kone Hissar AB, Frölunda The Netherlands / Pays-Bas: Kone Starlift B.V. Otis Liften Nederland, Amsterdam Schindler Nederland, Den Haag V. Swaay & Scheeres, Den Haag Thyssen Nederland, Alkmaar Thyssen Nederland, Amsterdam Turkey / Turquie Kone Asansör, Istanbul U.K. / Grande Bretagne: Express Lifts, Northampton Kone, Hounslow Kone, Lifts Ltd., Middlesex Otis, London Schindler Lifts, Cheltenham USA / Etats Unis: Armour Elevators, Louisville Otis, Chicago Otis, New York FMC715 TIRAK/TIRFOR references elevators, escalators références TIRAK/TIRFOR ascenseurs, escaliers roulants ref.: rev. no.: date: page: M-043 2 04/98 2/2 product information installation of lifts ref.: M-565 rev. no.: date: 08/93 page: 1/2 Application: Installation of lifts. Site: EUROCENTER, Neuss/Germany. Contractors: Bast Bauunternehmen, D-Erkrath Thyssen Aufzüge, D-Stuttgart-Neuhausen Equipment: 3 compact frames with TIRAK T-1000 and wire rope reelers, 3 MINIFOR powered hoists. The compact frames, mounted at the top of the building in the machine rooms, are used for operating the working platforms suspended inside the lift shafts. RO-114 The first phase of the construction covers the installation of 8 lifts in 2 separate buildings. Height: 46 m, 11 floors. Equipment supplied by GREIFZUG GmbH, D-Bergisch Gladbach. RO-114.2 MC1258 product information installation of lifts ref.: M-565 rev. no.: date: 08/93 page: 2/2 The MINIFOR powered hoists, anchored to the compact frames, are used for lifting and positioning the lift doors. RO-114.7 RO-114.6 MC1258 product information 1 installation of lifts ref.: rev. no.: date: page: M-073 1 10/94 1/1 2 3 TIRAK 4 Application: Installation of lifts Customer: Thyssen-Aufzüge, Stuttgart-Neuhausen/Germany Equipment: TIRAK T-1000 hoist on frame Description of application: In order to carry out installation work inside the lift shaft, the working platform, i.e. the lift cabin, is operated by a TIRAK (2) placed at the top of the shaft. 5 The wire rope is guided by a sheave (1) fixed near the TIRAK with the end anchored at the top. A counterweight is suspended by means of a sheave block (7) to the loopformed. In this case the use of a BLOCSTOP on an additional safety wire rope is not necessary, since there is already the parachute safety device (4) for the elevator. 4 6 7 1 - Slewing guide sheave 5 - Parachute release wire rope 2 - Limit switch 6 - Elevator cabin guide rails 3 - Frame with TIRAK hoist 7 - Reversing sheave 4 - Release mechanism for parachute with counterweight RO/66 FMC690 product information installation of lifts ref.: rev. no.: date: page: M-240 1 10/94 1/1 Application: Installation of lifts Customer: Thinet-Dumez, Jeddah/Saudi-Arabia Equipment: 1 special ALTA platform 2 x 1.70 m, equipped with TIRAK T-1000 and automatic BLOCSTOP BS 15-301 safety device on a separate safety wire rope. guide roller TIRAK T-1000 automatic BLOCSTOP 15.301 safety wire rope suspension wire rope MC389 product information ref.: rev. no.: date: page: installation of lifts suspension wire rope safety wire rope TIRAK automatic BLOCSTOP stirrup Application: Customer: Activity: Equipment: M-108 1 10/94 1/1 Installation of lifts Schindler, Frankfurt/Germany Lift manufacturer Special stirrup with aluminium platforms fitted with TIRAK hoist and automatic BLOCSTOP device. Description of application: Raising of working platform for installation work in lift shaft. The working platform is made of a special 2-meter high stirrup on which are fitted aluminium platforms of 3 different widths (0.8 m, 1.2 m and 1.6 m) depending on the size of the elevator shaft. The platform is equipped with 8 telescopic guide roller assemblies. telescopic guide roller PA/93 FMC779 product information installation of lifts ref.: rev. no.: date: page: M-074 1 10/94 1/1 Application: Installation of lifts Customer: a) Schindler, Hamburg/Germany b) General Technic, Luxembourg Equipement: TIRAK T-1000 with BLOCSTOP safety device, mounted on a special stirrup. Description of application: Raising of a working platform inside an elevator shaft (up to 90 m height) for the installation of slides and landing doors. The platform is equipped with a special stirrup designed for mounting the TIRAK on the main wire rope and a BLOCSTOP on the safety wire rope. The TIRAK is reeved to obtain a capacity of 1 ton for manriding. guides suspension wire rope safety wire rope suspension stirrup RO/65 TIRAK BLOCSTOP level 1 standard cabine frame level 2 PA/66.2 FMC691 product information lifting elevator driving mechanism ref.: rev. no.: date: page: M-241 1 10/94 1/1 Application: Lifting elevator driving mechanism Site: Colonia residential building, Cologne/Germany Equipment: 4 hydraulic TIRFOR TU-16H machines, 2 electric-hydraulic power packs Description of application: Problem: The Colonia Building in Cologne is a 45 storey high residential tower. Four elevator drive mechanisms had to be installed on the 45th floor. These mechanisms weighing 4.2 tons each, were raised by a crane up to the 42nd floor and had to be brought up, from there, to the top floor. 546 Solution: The problem was solved by using 4 TIRFOR TU-16H units of 1600 kg capacity each, motorised by hydraulic rams. These hydraulic TU-16H machines were operated in pair by means of 2 portable electro-hydraulic power packs. The speed of each TU-16H could, at all times, be individually controlled from 0 to 2 meters per minute max. The TIRFOR were fixed to a ceiling beam above the machine shop floor. The wire ropes were dropped down through an aperture, to the 42nd floor where they were attached by means of shackles to the 4 corners of the driving mechanisms. The operator then only had to use the control valves to ensure a precise and gentle lifting of the load. TIRFOR TU-16H electrohydraulic power pack 45nd floor 44nd floor 43nd floor 42nd floor 546 MC710 product information ref.: rev. no.: date: page: site elevators Application: Customer: Activity: Site: Equipment: M-075 1 10/94 1/1 Personnel hoist Focant Marble Yard, Franchimont/Belgium Quarry Rochefontaine quarry – 1ALTA-Mono platform 2 m long – 1 TIRAK T-1000 winch – 1 BLOCSTOP BS 20.321 – 4 wire ropes 45 m long – 1 DELTA III special suspension jib Description of application: PA/69 Special DELTA III suspension access ladder counterweight The suspended platform serves to lower personnel to a work level (depth: 40 meters). Since it travels along a quarry face slightly inclined to the vertical, it is guided sideways by 2 wire ropes. To protect personnel against folling rock, a roof has been fitted on the platform. It is further equipped with a locking device which allows it to be locked in the high position and affords the required stability when the personnel leave the platform. TOP VIEW support roller guide GUIDE WIRE ROPE SUPPORTING BEAM suspension and safety wire rope guide wire rope stretcher counterweight stretcher FMC692 product information emergency rescue ref.: rev. no.: date: page: M-313 1 10/94 1/1 Application: Emergency rescue platform in household waste disposal plant. Site: Household waste disposal plant, Kassel/Germany Customer: Steingass & Sohn, Solingen/Germany Equipment: 1 ALTA mono suspended platform, fitted with TIRAK T-500 hoist, BLOCSTOP safety device, 2 wire rope reelers and a TIRFOR hand operated machine. Description of application: As the unloading ramp for the refuse lorries is not protected by a guard rail, it could hapen that a person or even a vehicle could fall into the dump. To meet any such eventuality, the management have installed an emergency rescue platform, suspended from an overhead monorail system and allowing fast access to the bottom of the dump. A stretcher arrangement is fitted under the floor panel of the cradle to rescue the injured person in case of a serious accident. Even in the event of a power failure, the system can still be operated, using the hand operated TIRFOR suspended cradle equipment, with which the cradle is also fitted. Equipment supplied by GRIFZUG GmbH, Bergisch Gladbach. PA/240 MC833 product information site elevators ref.: rev. no.: date: page: M-229 1 10/94 1/1 Application: Lift for shafts Site: LEP worksite (Electron Positron Accelerator) built by European CERN Organization at the French/Swiss border, near Geneva Customerr: EUROLEP Company Equipment: 8 suspension systems each fitted with: – 1 cradle dim. 2.50 x 1.20 m, capacity 660 kg or 6 people; – 2 TIRAK T-1000 winches, capacity 800 kg, speed 18 m/min; – 2 x 2 BLOCSTOP safety devices. Description of application: The suspension systems and the cradle are used as elevators for the personnel in the different shafts which have a depth of approx. 100 to 150 m. Each suspension system consists of 2 suspension lines, with the TIRAK winches and two overspeed BSO-1000 BLOCSTOP, as well as 2 safety lines, with two electromagnetic BLOCSTOP. These are controlled by mercury switches placed on the cradles. All wire ropes are wound onto motorised reelers. PA177.4 PA177 MC700 product information ref.: rev. no.: date: page: materials hoist Application: Site: Customer: Equipment: M-258 1 12/88 1/1 Materials hoists Oran University, Algeria E.R.C.O., Bir El Djir, Oran – 1 materials hoist TIRALIFT 25 M, cap. 1400 kg, lifting height 60 m – 10 materials hoist, as above, but with lifting height 25 m. Description of application: Following an international bid, we secured an important order for the supply of 11 materials hoists to be erected on the ORAN University Site in Algeria. They were used over heights of up to 60 meters for the supply of internal building materials like sanitary, plumbing, electrical and flooring goods. These machines offer an unusual loading surface (6 m x 1.20 m). The platform is lifted by two TIRAK T-1000 M machines placed on ground level and guided by two masts. The controls use micro-processors and have a digital floor-level display. PA/195.2 PA/195 FMC/725 PA/195.3 product information ref.: rev. no.: date: page: materials hoist M-082 1 12/88 1/1 Application: Vertical materials hoist Customer: "Parc de l'Europe", Dommeldange/Luxembourg Site: Residential building "Parc de l'Europe", Dommeldange Equipment: - TIRAK T-820M with wire rope reeler - 1 wire rope 16 m long - 2 control panels, 0 level and -8 - 1 vertical tower with platform and guide pulleys. Description of application: TIRAK, reeved, used as winch for a materials hoist, capacity 500 kg, 8 m height of lift, lifting speed 5 m/min. in a residential building. TIRAK is placed at top level. The free end of the wire rope is wound onto a reeler. control box 3000 2000 RO/53.1 800 GROUND FLOOR TIRAK 8000 Wire rope reeler RO/53 latice-work doors Pit RO/53.2 FMC/699 800 BASEMENT product information escalators Application: Site: Customer: 554 2 TIRFOR TU-16H 4th floor 2 anchorage points ref.: rev. no.: date: page: M-242 1 11/94 1/1 Installation of 7 escalators, weight 9 tons, Department store, Berlin/Germany OTIS GmbH, Berlin The installation of this elevators offered a splendid opportunity for demonstrating the versatility and advantages of the motorised TIRFOR TU-16H. The escalators were delivered by special trucks and unloaded by crane. As each escalator was unloaded, guide wheels were fitted to it for ease of manoeuverability. The escalator was then hung by its motorised end at the top from four pulleys, raised slightly, and tensioned by means of a reeved manually operated TIRFOR attached to its lower end to guard against excess loading. In this way the escalator assembly could be gently moved, in a horizontal position, into the shaft. Once in the shaft, two motorised TU-16H's were attached to set the escalator at the right angle and then hoist the whole structure to a point just higher than its final mountings. It was then possible to position the escalators precisely, without changing the rams. This operation was repeated for each of ascending escalators. To install the 3 descending escalators in the same shaft, but in a vertical plane parallel to the first, all that was required was to move the motorised TU-16H's and snatch blocks to new position. Once the new anchorage points had been established, this second part of the operation was carried ou as quickly and simply as the first. The operation as a whole was a difficult one, involving precise timing and co-ordination between the operators. However, by using motorised TIRFOR TU-16H machines, the total installation time was cut by half, and only two men were required to operate the hoists. Furthermore, as there was no undue fatigue, the work schedule was uninterrupted. Large escalator installers throughout the world use motorised TIRFOR (see reference list M-043). 2 anchorage points 2 TIRFOR TU-16H 3rd floor 2nd floor 1st floor manual TIRFOR ground floor (motor) top end weight: 6 tons MC711 lower end weight: 3 tons