A review of performance limits of stainless steelsfor the

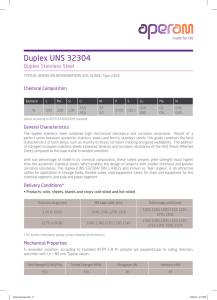

advertisement