PDF file here. - Chicago Powdered Metal Products

advertisement

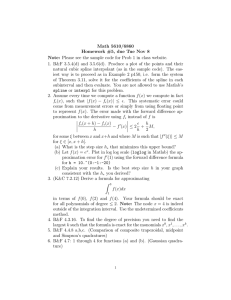

970428 Thomas Miller Chicago Powdered Metal Products Company Francis Hanejko Hoeganaes ABSTRACT Turbine hubs for automatictransmissiontorque convertersare ideal candidatesfor the powder metallurgy(P/M) process. The complex shapeof turbine hubs is costly to producevia conventional forging and machiningoperations. Increasesin engine sizeand torquerequirementsby automotivedesigners requireturbine hubsto possesshigh levelsof mechanicalproperties. High density P/M manufacturingtechniques,in combinationwith high performanceferrousmaterial producescomponents capableof replacinga forged and machinedturbine hub. This paperwill review the conversionof a conventionallyforged and machinedturbine hub usedin a high torque automatictransmissionto a single pressed and single sinteredP/M turbine hub. The material used for the P/M hub was an MPIF FD-O405. Warm compactionprocessingachievedsignificantly increased overall sintereddensitiesin the highly stressedinternal splineregion. Extensivemechanicaland part specific testingwas conductedto verify the suitability of the P/M part. INTRODUCTION The useof PowderMetallurgy (P/M) componentshasgrown at a rate of approximately7% annually since 1990.1During this period, the usageof PIM componentsin the North American auto sector increasedfrom 23 poundsper vehicle to in excessof28 poundsper vehicle.' Notable recentapplications includeconnectingrods powderforged to nearpore-free Corporation density,and P/M main bearingend capsthat are pressed and sinteredto a nominal densityof 6.9 g/cm'2 It was proposedthat the usageof P/M parts per vehicle could reach50 poundsby the year 2000.2 Theseadditional opportunitiesfor P/M can be realized providedthat the P/M processis capableof producinghigher performance componentsat lower cost. Traditional methodsto improve the mechanicalpropertiesof P/M partsinclude restriking, copperinfiltration, or high temperature sinteringto achievethe higher density and the correspondinghigher mechanicalproperties. However, thesemethodsare costly to implementthus slowing the growth ofP/M within the automotivesector. The recentintroduction of the warm compaction technology3enablesP/M part fabricatorsto single press and single sinter multi-level complex P/M partsto densitiesin excessof7.25 g/cm3. Warm compaction processing,althoughapplicableto all ferrousmaterial systems,producesthe greatestbenefits when coupled with high performanceferrousalloy compositions. Achieving densitiesin excessof 7.25 g/cm3using diffusion alloyed materialsand molybdenumprealloyed steelsresult in mechanicalpropertiesthat are comparableto steelforgings and ductile iron castings.4 This paperwill discussthe conversionof a forged steel turbine hub (using AISI 1045steel) to a warm compactedsingle presssingle sinter P/M component. The complex shapeof the componentprecludedthe option of double pressingdouble sintering (DP/DS), and copper infiltration proved unacceptable. WROUGHT TURBINE HUB PROCESSING AND THE WARM COMPACTION PROCESS Turbine hubs in automatictransmissionsare torquecarrying componentsthat haveboth internal and externalsplineswith a provision for riveting. Their function is to transmit torque from the riveted turbine assemblyto the splined transmissioninput shaft.s Powdermetallurgy first was usedin the manufactureof turbine hubs in the early 1960's. The original P/M turbine hubswere compactedto a 6.2 g/cm3density and subsequentlycopper infiltrated for higher strength(Figure 1 is a photographof this early P/M part). As a result of this early pioneeringeffort, nearlyall current automatictransmissionsnow utilize P/M turbine hubs. The most commonly specified material is an MPIF FC-0208,which is a premix of pure iron powderwith approximately2w/o (weight percent) copper,0.8w/o graphite plus lubricant.6 Thesecurrent turbine hubsare processedto a nominal sintereddensity of 6.8 to 7.0 g/cm3with sectionaldensitiesvarying from 6.6 g/cm3to 7.1 g/cm3. resultedin the development of new engines with higher torque for greater towing capabilities. One consequence of this higher engine output was the performance demands exceeded the torque carrying capability of conventionally pressed and sintered turbine hubs. To guarantee system reliability, the transmission designer was forced to switch from conventional P/M to alterl}ative technologies to meet performance demands. Steel forging was one alternative chosen. The complex shape of the turbine hubs processed by the forging and machining process proved to be a costly option. What was needed was a high performance P/M material process that would survive the higher torque output of the new engines. Figure 2 showsschematicallythe manufacturing sequenceof the wrought turbine hub. AISI 1045bar stock is hot upsetforged to form the flange and top cone. After forging, the blank undergoesapproximately 8 distinct machiningoperationsincluding turning and broachingof the outer (00) and inner diameters(10) and facing of the flange. The final step is induction hardeningof the IO spline for strengthand wear resistance.Figure3 showsthe forged and machined turbine hub. Also shown in Figure2 is the manufacturing sequencefor the warm compactedP/M component. The powderspecifiedwas an MPIF FD-0405. This material is a diffusion alloyed powdercontaining4w/o nickel, 1.5w/ocopperand 0.5w/o molybdenum.6This baseiron was premixedwith graphiteand lubricant; premixing accomplishedby the ANCORDENSETMpremix technology. The press-readypowder and compaction tooling were heatedto the requiredtemperatures utilizing a Cincinnati IncorporatedEI-TempTMmaterial delivery system.7 Temperaturecontrol of the die and heatedpowderwas maintainedwithin +/- 2.5°C of the setpoint. Compactionwasdone in an 825 ton Cincinnati Rigid Reflex press. The turbine hubs weighedapproximately 1100gramseach. Following compaction,sintering wasdone at conventional temperaturesusingan endothermicprotective atmosphere. Figure 1: Early P/M Turbine Hub Consumer demand for higher performance engines in the light truck and van market segments Prior to production part approval, the warm compacted turbine hubs were subjected to extensive mechanical property evaluation. Standard MPIF tensile and fatigue testing was performed. Preproduction hubs were evaluated for internal spline durability and internal spline wear relative to both conventionally compacted PIM hubs and the forged hubs. This investigation was done in an MTS test cell designed specifically for torque testing. The test procedure consisted of fixturing the Warm Compacted P/M I Warm compactpart Wrought Forging I I Hot upsetforge flange andspacer I Bore ID and counter bore spacer I Sinter I I Deburr I I I I Face top of flange and machine spacer MachineaD to stepandundercut I Turn counter bore on ID and burnish Drill rivet holes I Turn aD andundercuton aD I Mill slots on bottom of turbinehub I I I I BroachIDJ I BroachOD I I 1,,11 il=~i =1--b=~=I~--=~*~:-bi:~; ~~~: I.~~~~tl;~He~t T;~~t X~~~;:I-S~'\~c.I I Figure 2: Manufacturing steps of the forged steel turbine hub and the warm compacted turbine hub aD andapplying the designtorqueto the ID spline. For internal spline durability, the torque was dynamically appliedfrom 0 to 890 foot poundsthen back to 0 with a 75% spline engagement.The test was terminatedif the specifiedtorque was not achievedor if the angular rotation of the ID shaft exceededa specified amount. Internal spline wear testing was performed in the same dynamictest cell with test conditions of a constant torqueof 150foot poundswith 90% spline engagement and 4 mm of sliding travel per cycle. The hub was removedat specifiedintervals up to 350,000cyclesfor measurementof the spline wear. RESULTS AND DISCUSSION Figure 3 Forged and Machined Turbine Hub Table 1 summarizesthe tensile properties, hardnessvalues,and rotating bending fatigue characteristicsof both the forged AISI 1045and warm compactedMPIF FD-0405 materials. Data for the forged AISI 1045material is presentedin the annealed and hardenedcondition (the ID is induction hardened). Propertydata for the FD-0405 is presentedin the as-sinteredcondition at a density of 7.25 g/cm3(the overall density of the warm compactedandsintered turbine hub). Data for the P/M material is presentedin the as-sinteredcondition only becauseit wasdetermined that no surfacehardeningof the ID was necessary. Table 2 presentsthe internal spline durability test resultsof conventionallycompactedturbine hubs, forgedturbine hubs,and the warm compactedMPIF FD-0405hubs. Productionpart validation requiredthat 12 hubsbe testedto 1 million cycles with no failures with one additional hub testedto 2 million cycles with no failure. This high torque regime of 0-890-0 foot poundsexceededthe strengthcapability of the standard FC-0208material. Failureswere observedbelow the specifiedminimum value. The forged turbine hub met the test requirementswith no evidenceof failures. Warm compactionof the turbine hubsproducedparts having an overall sintereddensity of 7.25 g/cm3. Despitethe lack of full density,the warm compaction processproducedtorque test resultsthat exceededthe minimum specificationrequirements. That is, twelve hubswere subjectedto 1 million cycles with no failures and I hub was testedto two million cycles with no failure. To evaluatethe durability of the high performanceP/M hub, one was cycled to failure. Structuralfailure of the hub occurredat approximately The as-sinteredyield and tensile strengthsof the MPIF FD-0405 materialwere equivalentto the forged AISI 1045steel. Ductility of the steel forging was higher than the warm compactedP/M part. The fatigue propertiesdevelopedby rotating bendingfatiguetesting demonstratedthat the steelforging in the as-forged condition had a higher fatigue endurancelimit relative to the as-sinteredwarm compactedP/M part. Specific part testing was necessaryto determineif the difference in rotating bendingfatigue performancewasdetrimental to actual componentperformance. Table 1: Summary of Standard Mechanical Property Test for Forge and P/M Hubs For , ged AISl1045 ". ~m"~cO40:$" ,"""'2"5 """' ~ea~T~t~d SIccl045 ccc ""i!;;\ cc"'~ CcC~C~ccccc Yield Strength,psi TensileStrength,psi Elongation,% HRC/B 97 HRB 130,000 16 43 HRC FatigueLimit, psi 45,000 100,000 62,000 90,000 25 "..t~c",. 96,000 '( / """""""'3C" -,..f!"~""',,,C 62,000 117,000 2.6 17HRC *. 35,000 ApplAve.~t Table 2: ill Spline Durability Test Results ~yces~~~~r~ lt F h C Standard P/M hub 1..mi.1l.ioncy~.~ " at890.ft~lbf. Failuresobserved AISI 1045hub 12 parts, no Failures Warm compact FD-O405 12 parts, no Failures Specification 12parts,no Failure ~~jJ.~ioncycles ~" ""' at890 ,L. 'fi~'lb Ic." Failuresobserved 1 part, no failure 1 part, no failure 1 part, no failure O J ~ cat... 89' 0 .t. lbc~.~cc -9,000,000 9 million cycles, significantly in excessof the specified minimum. Spline durability testing of the high performancePIM turbine hub demonstratedthat this processis capableof replacinga steelforging in this critical high torque application. The secondcritical performancecriterion of the turbine hub was internal spline wear. As described earlier,the analysisof the spline wear was performedin the sametest cell as the spline durability evaluation. Table3 summarizesthe wear test resultspresentedas relative measurements.That is, the maximum wear allowed by the specificationis equatedto 1. Any wear numberlessthan 1 implies the wear was lessthan the specifiedmaximum, thus meetingthe specification. Any numbergreaterthan I implies the wear exceeded the specification,thus not meetingthe specification. Table 3: Summary ofm Spline Wear Tests Conventionallycompactedand sintered FC-O208turbine hubswere evaluated. Thesehubs exhibited excessivewear in this high torque application with a relative wear value of 1.4. Wear measurements of the forged hub showedno wear at the specified number of cycles. However,it is noted that the ID spline of the AISI 1045hub was induction hardenedto a hardnessvalue 40 HRC. Without this hardening operation,the forged steelturbine hubs would not meet the specifiedminimum wear perfonnance. Weartesting of the warm compactedMPIF FD-O405showedno measurablewear at the specifiednumber of test cycles. The absenceof wear in the warm compactedturbine hubs is significant becausethesecomponentswere evaluatedin the as-sinteredcondition. The apparent hardnessof the P/M componentswas approximately 15 HRC. The warm compactionP/M processcoupled with the MPIF FD-0405high perfonnancematerial systemeliminatedthe needfor heattreating of the internal spline thus significantly reducingmanufacturing cost and simplifying the manufacturingflow. Figure 4 is a photomicrographof the as-sintered microstructureof the warm compactedturbine hub. It consistsof lamellar pearlite,bainite, nickel rich martensiteareas,and ferrite. This unique microstructure was responsiblefor the excellentwear performance demonstratedin the as-sinteredcondition. Figure 3: Photograph of the Warm Compacted Tnrhinp Hnh Figure 4: Microstructure of the As-Sintered Turbine Hub 14 13r -~ 12rt 11 r -<>- MeasuredPorosity , ~: ~~~=~I~i~:===~= , ~ j ~-- , '-' c- "j 7.40 -0- CalculatedDensity 10 t ~"r ,oJ" ' """ ~ "- ~ ~~ , 7.30 E ~ '-' 7.20 .~:Go - .in 0 ... 0 ~ "0 Q) ... ~ rI) ~ Q) :2-: 9 c= v 0 7.10 "0 v ~ "3 7.00 C.) ~ U ~ 8 -v- 7 6 5 --J-- 0 5 10 15 20 25 30 Distancealong the ill Spline from the Bottom (mm) Figure5: PorosityDistribution Along the m Spline As mentionedearlier,the overall sintered densityof the turbine hub was 7.25 g/cm3. To achieve this high sintereddensity, the greencompactwas compactedto approximately97% of the pore free densityof the premix. Onebenefit of compactionto this high greendensity is the greateruniformity of density throughoutthe finished part. To documentthis, a productionprocessedhub was sectionedand examined for porosity distribution alongthe length of the spline usingquantitativeimage analysis. Figure 5 is a plot showingthis density profile for a production part. The drop off in density in the small neutral zone is approximately0.15 g/cm3comparedwith the average sectionaldensity of about 7.3 g/cm3. This reduced densitydifferential is a significant improvementrelative to the resultsachievedwith conventionalcompactionin which this density differential can be as great as 0.4 g/cm3. In addition to the mechanicalproperty testing, extensivedimensionaland weight capability studies wereperformedon the process. The resultsindicated that the variationsmeasuredwere consistentwith the v~ri~tinn~nhtainedin conventionalP/M Drocessin2:. SUMMARY Warm compactionof an 1100gram multi-level P/M turbine hub producedan overall as-sintereddensity of approximately7.25 g/cm3. High densitieswere achievedin the critically stressedID regionsof the part. Combiningthe benefitsof the warm compaction technologywith a high performancematerial system, the needfor induction hardeningof the ID splinewas eliminated. This resultedin a simplified manufacturing processand an overall part cost reduction. Extensive preproductiontrials demonstratedthat the warm compactionprocessis a viable manufacturing alternativefor the productionof complex multi-level shapes,in particular automatictransmissionturbine hubsfor high torque engines. This paperdescribedthe conversionof a forged hub to one producedvia this high performanceP/M material processingsystem. Torque testing of preproductionhubs demonstratedequivalent performanceto the wrought componentin termsof both ID spline durability andill spline wear. CONCLUSIONS REFERENCES 1.) Warm compactionprocessingof a complex multi-level turbine hub producedan overall sintered densityof 7.25 g/cm3with high sintereddensities achievedin the criticallD spline region. I.) Capus,JosephM., "Metal Powder,A Global Survey of Production,Application and Markets 1992- 200I", SecondEdition, ElsevierAdvancedTechnology,June 1996. 2.) Warm compactionprocessingof a high torqueautomatictransmissionturbine hub successfully replaceda forged, machined,and heattreatedAISI 1045 steelpart. The P/M processsignificantly reducedthe processingsteps. The reducednumberof processing stepsresultedin overall lower manufacturingcost. 2.) White, Donald G., "Powder Metallurgy in 1995", AdvancedMaterials & Processes,August 1995,pp 49 51. 3.) Rutz, H.G., Hanejko F.G., "High Density Processing of High PerformanceFerrousMaterials", Advancesin Powder Metallurgy and Particulate Materials 3.) Utilizing an MPIF FD-O405material composition,the P/M turbine hub was usedin the as-sinteredcondition eliminating the requirementfor induction hardeningof the 10 spline as requiredin the forged componentit replaced. 4.) Standardtensile and fatigue testing of the P/M material demonstratedthat the P/M componentwas equivalentin yield and tensile propertiesto the wrought steel. The P/M part had a lower rotating bendingfatigue strength. 5.) 10 spline durability and 10 spline wear testing of the warm compacted P/M component met and surpassedthe requirements specified by the end user. 6.) Manufacturingvariability of the warm compactionprocesswas equivalentto the variability of the conventionalcompactionprocesses. ACKNOWLEDGMENTS Vol, 5, Compiled by C. Lall and A.J. Neupaver,pp 117133,Metal PowderIndustriesFederation,Princeton.NJ. 4.) Luk, S.H., Rutz, H.G., Hanejko,F.G., "A New Method For ManufacturingHigh PerformancePowder Metallurgy Components'"Advancesin Powder Metallurgy and Particulate Material-1994, Vol. 5, Compiled by C. Lall and A.J. Neupaver,pp 135-]63, Metal PowderIndustriesFederation,Princeton.NJ 5.) Ford EngineeringSpecification,Part Number ESF4DP-7926-AA,Rev Frame2, May 1989. 6.) "Material Standardsfor PIM Structural Parts- MPIF Standard35", Metal PowdersIndustry, Federation, Princeton,NJ, 1994. 7.) Unkel, R., "Introducing EI- TempTM,A New PIM Part Pressing System", Advances in Powder Metallurgy and Particulate Material-I 994, Vol. 5, Compiled by C. Lall and A.J. Neupaver, pp 135-163, Metal Powder IndustriesFederation,Princeton.NJ The authorswish to thank Mr. Frederick Geromettaand Mr. J. S. Khanujaof the Ford Motor Companyfor their supportof this programand their suggestionsin the preparationof this paper. Additionally, we want to thank the managementof ChicagoPowderedMetal ProductsCompanyand HoeganaesCorporationfor their permissionto publish this paper. In particular,we acknowledgethe assistance of all Chicago PowderedMetals laboratoryand productionpersonneland Jerry Golin, SteveKolwicz and Tom Murphy of the HoeganaesCorporation Metallographic laboratoryfor their assistancein sample preparationand analysis. - 1994,