INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR

advertisement

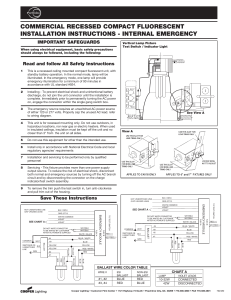

256817B REV. B 797 Printed in U.S.A. INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR MODEL JSL6000 & JSL5400 LIGHT BARS SAFETY MESSAGE TO INSTALLERS OF FEDERAL SIGNAL LIGHT SYSTEMS I. After unpacking the light bar, inspect it for damage that may have occurred in transit. If the unit has been damaged, file a claim immediately with the carrier, stating the extent of damage. Carefully check all envelopes, shipping labels and tags before removing or destroying them. People’s lives depend on your safe installation of our products. It is important to read, understand and follow all instructions shipped with the products. In addition, listed below are some other important safety instructions and precautions you should follow: • To properly install a light assembly: you must have a good understanding of automotive electrical procedures and systems, along with proficiency in the installation and use of safety warning equipment. • When drilling into a vehicle structure, be sure that both sides of the surface are clear of anything that could be damaged. • A light system is a high current device. In order for it to function properly, a separate ground connection must be made. If practical, it should be connected to the negative battery terminal. At a minimum, it may be attached to a solid metal body or chassis part that will provide an effective ground path as long as the light system is to be used. • II. INSTALLATION. The basic light bar is completely wired at the factory and does not require any additional internal wiring. All the conductors necessary for control of any and all basic and optional functions are contained in the cable. Installation of options will require additional wiring in the light bar. The basic light functions of the unit must be controlled by a user supplied control head. Before proceeding, ensure that the light bar has been installed on the vehicle roof in accordance with the instructions packed with the mounting kit. Route the light bar cable as described below. WARNING Light system controls must be located so that VEHICLE and CONTROLS can be operated safely under all driving conditions. A. Route the control cable into the vehicle and under the dash, near the eventual location of the user-supplied control head. Locate light system controls so the VEHICLE and CONTROLS can be operated safely under all driving conditions. • You should frequently inspect the light system to ensure that it is operating properly and that it is securely attached to the vehicle. • File these instructions in a safe place and refer to them when maintaining and/or re-installing the product. UNPACKING. B. For proper light operation, the control cable must be properly terminated inside the user-supplied control head. Table 1 shows the recommended control cable wire colors for various light bar functions. Using figure 1 as a guide, make the applicable electrical connections for the functions installed in your light bar as shown in Table 1. Switch current capacities should be at least 15 amps. Ensure that the lines are adequately fused as shown in figure 1. NOTE Any of the light bar functions can be activated by applying 12VDC to the appropriate control line. The heavy black lead (-) must be connected to vehicle ground, to perform a function check. Failure to follow all safety precautions and instructions may result in property damage, serious injury, or death to you or others. -1- -2- RED RF WHT/GRN RF RED RED TB 1 2 RF RF BLU FLASHER POWER TB TB WORK LIGHT OPTION R RF F F F 5 F WHT/RED F F WHT/RED WHT/RED RF ORN TB WHT/BRN W BLK/WHT TB WHT/RED T.L.C. RF RF RF (TAIL LIGHT) R 290A2453-14 R 290A2453-13B WHT RF RF RF RF RED RF 2 1 J22 WORK (W) STROBE (S) LEFT BRAKE/TURN ORN GRA YEL 15A 15A 8A (+) POWER/IGN. BRN/WHT N.C. (SPARE) FUSE AND SWITCH TO BE ADDED WHEN USED BLK/WHT 15A RF R S RED RF R 290A2453-19 4 6 5 7 6 7 290A2453-21 SUPPLIED WITH LIGHTBAR (-) TO GROUND 290A2453-22B NOTE: JSL5400 HAS 10 SELECTIONS JSL5400 & JSL6000 TM JETSTREAM WITH INDEPENDENT ROTATING LIGHTS EXTERNAL WIRING (SPARE) N.C. INTERNAL WIRING (SHOWN ABOVE) SELECT NEXT OPEN POSITION 3 5 CUSTOMER SUPPLIED 2 4 RED ONE TERMINAL BOARD (7 POS.) SUPPLIED WITH LIGHT BAR R 290A2453-20 TWO STROBES PER J22 POWER SUPPLY WHT/BLK SELECT NEXT OPEN POSITION S R TWO STROBES PER J22 POWER SUPPLY SELECT NEXT OPEN POSITION WHT/BLK RF 290A2453-18 RED TWO STROBES PER J22 POWER SUPPLY WHT/BLK SELECT NEXT OPEN POSITION S RED 3 J22 J22 TRAFFIC CLEARING (T.C.L.) FLASHING (F) RIGHT BRAKE/TURN BLU GRN 8A TAIL LIGHT BRN 8A 15A END ROTATING (R) 15A RED/WHT 1 TB S TB CENTER ROTATING (RF) GROUND RED 15A BLK TB RED/WHT TB GRA BLK RED GRA BLK S GRA S RED BLK RED ACCESSORY CABLE GND. SCREW STANDARD (2 ROTATORS) LIGHT BAR R 360° STROBE OPTION R STROBE OPTION (FRONT) R STROBE OPTION (BACK OR REAR) R Figure 1. Wiring Diagram. 290A2453-17 R 290A2453-16 R 290A2453-15 TWO LIGHTS PER FLASHER FLASHER, SECOND POWER TERMINAL BOARD TB MAY BE REQUIRED. YEL RF SELECT NEXT OPEN POSITION WHT/BRN W R WHT/YEL B/T 290A2453-12 (LEFT BRAKE/TURN) RF SELECT NEXT OPEN POSITION WHT/RED T.L.C. R ONE TERMINAL BOARD (7 POS.) SUPPLIED WITH LIGHT BAR RED TWO LIGHTS PER FLASHER YEL BRN 7 RED RF SELECT NEXT OPEN POSITIONS WHT/RED RF BRN 6 SELECT NEXT OPEN POSITIONS WHT/RED TRAFIC CLEARING LIGHT (T.C.L.) OPTION R BLU RF FLASHING LIGHT OPTION (FRONT & BACK) R RF FLASHER POWER FLASHING LIGHT OPTION (LEFT & RIGHT) R 4 RED/WHT 3 WHT/BLU RF WHT SELECT NEXT OPEN POSITIONS BRAKE/TAIL OPTION & D.O.T. LIGHT TB GRN (RIGHT BRAKE/TURN) R B/T STANDARD (5 ROTATORS) LIGHT BAR R Table 1. Electrical Connections. Control Cable Wire Color RED/WHT BRN/WHT BRN BLU ORN YEL GRN GRY RED BLK BLK/WHT III. BASIC MAINTENANCE. WARNING Functions Center Rotating Lights No Connection Tail Light and D.O.T. Light Flashing Work Left Turn/Brake Right Turn/Brake Strobe Rotating Lights Power (-) Traffic Clearing Light High voltages are present inside the light bar, when the strobe light option is installed. Wait at least ten (10) minutes, after shutting off power, before servicing this unit. Failure to do so may result in property damage, serious injury, or death to you or others. A. Cleaning the Plastic Domes. Ordinary cleaning of the plastic domes can be accomplished by using mild soap and a soft rag. Should fine scratches or a haze appear on the domes, they can ordinarily be removed with a non-abrasive, high quality, automotive paste wax. C. Connect the black lead to chassis ground. D. Connect the light bar's red power lead to a fuse or circuit breaker rated at 50 amperes. Connect the other side of the fuse /circuit breaker to the +12VDC supply. CAUTION The use of other materials such as strong detergents, solvents, petroleum products, etc. can cause crazing (cracking) of the plastic domes. E. The recommended optional function locations are shown in figure 2. Refer to the instructions provided in the option kit for installation details. POSITIONS 1 2 3 4 5 RF 6 7 8 RF 9 10 11 RF R R FRONT POSITIONS STANDARD OPTIONS 1 2 3 4 5 ROTATOR, 90FPM V-MIRROR ROTATOR, 175FPM V-MIRROR V-MIRROR BRAKE/TAIL 6 7 ROTATOR, 175 FPM V-MIRROR 8 9 10 11 V-MIRROR ROTATOR, 175FPM V-MIRROR ROTATOR, 90FPM TCL, WORK, FLASHING, DIRECTIONAL STROBE, OR 360 STROBE TCL, WORK, FLASHING, DIRECTIONAL STROBE, OR 360 STROBE BRAKE/TAIL NOTE: JSL5400 HAS 10 SECTIONS. Figure 2. Recommended Option Locations. -3- 290A2452 B. Lamp Replacement. The strobe light power supply does not contain any user serviceable parts. Should a breakdown in the power supply occur, it should be returned to Federal for repair and replaced. To remove the power supply, proceed as follows: WARNING A serious injury may result if lamp is touched when hot. Always allow lamp to cool before removing. Halogen lamps are pressurized and if broken can result in flying glass. Always wear gloves and eye protection when handling the lamps. 1. Unplug the connector from the power supply. 2. Remove the two #10 screws which secure the power supply. CAUTION Service life of lamp will be shortened if glass portion is touched. If glass has been handled, clean carefully with a grease solvent. 3. Install the new power supply by performing the previous steps in reverse order. See figure 3. To replace the lamp, Twist to unlock and then pull the defective lamp out of the socket. Install a new lamp of the same type in the socket. DO NOT TOUCH THE GLASS PORTION OF LAMP C. Cleaning Reflectors and Mirrors. Use a soft tissue to clean the reflector and mirrors. Avoid heavy pressure and the use of caustic or petroleum base solvents which will scratch or dull the surface. 795 D. Strobe Power Supply Replacement. LAMP SOCKET WARNING High voltages are present inside the light bar, when the strobe light option is installed. Wait at least ten (10) minutes, after shutting off power, before servicing this unit. Failure to do so may result in property damage, serious injury, or death to you or others. 290A2399 Figure 3. Lamp Replacement Diagram. -4-