QUESTION BANK UNIT I PART – A (2 MARKS) 1. Differentiate

advertisement

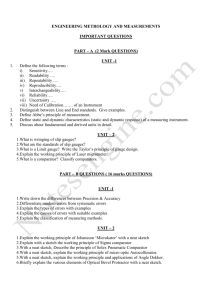

QUESTION BANK UNIT I PART – A (2 MARKS) 1. Differentiate between sensitivity and range with suitable example. 2. Define system error and correction. 3. Define: Measurand. 4. Define: Deterministic Metrology. 5. Define over damped and under damped system. 6. Give any four methods of measurement 7. Give classification of measuring instruments. 8. Define True size 9. Define Actual size 10. What is Hysteresis 11. What is Range of measurement? 13. Define Span 14. What is Resolution? PART – B (16 MARKS) 1. Draw the block diagram of generalized measurement system and explain different stages with examples. 2. Distinguish between Repeatability and reproducibility 3. Distinguish between Systematic and random errors 4. Distinguish between Static and dynamic response. 5. Describe the different types of errors in measurements and the causes. 6. List the various measurement methods and explain 7. Briefly discuss on the applications of measuring instruments 8. Briefly discuss on calibration of temperature measuring devices with suitable examples 9. Explain the various systematic and random errors in measurements? 10. What is the need of calibration? Explain the classification of various measuring methods. http://www.francisxavier.ac.in 11. Describe loading errors and environmental errors. 12. What are elements of a measuring system? How they affect accuracy and precision? How error due to these elements are eliminated UNIT II Part-A (2 Marks) 1. List the various linear measurements? 2. What are the various types of linear measuring instruments? 3. List out any four angular measuring instrument used in metrology 4. What is comparator? 5. Classify the comparator according to the principles used for obtaining magnification. 6. How are all mechanical comparator effected? 7. State the best example of a mechanical comparator. 8. Define least count and mention the least count of a mechanical comparator. 9. How the mechanical comparator is used? State with any one example. 10. State any four advantages of reed type mechanical comparator. Part-B (16 Marks) 1. What is the constructional difference between an autocollimator and an angle dekkor. 2. Explain with the help of neat sketches, the principle and construction of an autocollimator 3. What types of measuring systems are used for linear distance? 4. Explain the working principle of mechanical comparator with a neat sketch. 5. Explain the working principle of Electrical comparator with a neat sketch 6. Explain the working principle of pneumatic comparator with a neat sketch 7. Explain with the help of neat sketches, the principle and construction of an Angle dekkor. 8. Explain the precautionary measures one shall follow at various stages of using slip gauges. Explain the process of ‘Wringing’ in slip gauges. Explain why sine bars are not suitable for measuring angles above 45 degrees. 9. Describe the method of checking the angle of a taper plug gauge using rollers, http://www.francisxavier.ac.in micrometer and slip gauges, 10. State and explain the “Taylor’s principle of gauge design’. http://www.francisxavier.ac.in 11. Explain the working principle of autocollimator and briefly explain its application 12. Describe with the help of a near sketch, a vernier bevel protractor. 13. Shafts of 75± 0.02 mm diameter are to be checked by the help of a Go, Not Go snap gauges. Design the gauge, sketch it and show its Go size and Not Go size dimensions. Assume normal wear allowance and gauge maker’s tolerance. UNIT III Part-A (2 Marks) 1. Name the various methods for measuring effective diameter 2. Name the various methods for measuring pitch diameter. 3. Name the two corrections are to be applied in the measurement of effective diameter. 4. What is best size of wire? 5. Define. Drunken thread 6. What is the effect of flank angle error? 7. What are the applications of toolmaker's microscope? 8. Define: Periodic error. 9. What are the commonly used forms of gear teeth? 10. What are the types of gears? 11. Define: Module 12. Define: Lead angle 13. What are the various methods used for measuring the gear tooth thickness? 14. Name four gear errors. 15. Name the method used for checking the pitch of the gear. Part-B (16 Marks) 1. Explain the construction and working of floating carriage micrometer 2. How are the major and minor diameters of thread measured? 3. Define various terminologies related with screw thread http://www.francisxavier.ac.in 4. Define various terminologies related with screw gears 5. Explain any two taper measurements method. 6. Explain the construction and working of Gear tooth vernier 7. Explain a method used in the measurement of surface finish and flatness 8. How to measure the pitch of the screw thread by using the tool maker’s microscope? Discuss in detail. UNIT IV Part-A (2 Marks) 1. Name the different types of interferometer? 2. Name the common source of light used for interferometer 3. What is crest and trough? 4. What is wavelength? 5. What is meant by alignment test on machine tools? 6. List the various geometrical checks made on machine tools. 7. Distinguish between geometrical test and practical test on a machine tool. 8. What are the main spindle errors? 9. Write the various tests conducted on any machine tools 10. Why the laser is used in alignment testing? 11. Classify the machine tool test. 12. What are the different types of geometrical tests conducted on machine tools? 13. What is CMM? Part – B (16 Marks) 1. With neat sketch explain the various types of CMM based on its construction. Write the advantages of computer aided inspection. 2. Explain the construction and working principle of laser interferometer with neat diagram? Explain the use of laser interferometer in angular measurement. 3. Explain with a neat sketch the working of talysurf instrument for surface finish http://www.francisxavier.ac.in measurement. What is the symbol for fully defining surface roughness and explain each term? 4. Describe in detail the method of checking roundness by using Roundness Measuring Machine. State its advantages. 5. Sketch and describe the optical system of a laser interferometer. http://www.francisxavier.ac.in 6. Define explain the working principle of Tomlinson surface meter with a neat sketch. Define straightness. Describe any one method of measuring straightness of a surface. 7. Explain how the straightness error of a Lathe bed is checked using a Auto-collimator 8. With neat sketches, explain the significance of some important parameters used for measuring surface roughness. Why so many parameters are needed? 9. How surface finish is measured using LASER. How the angle is measured using a laser interferometer? 10. Discuss the steps involved in computing flatness of surface plate. 11. How are CMMs classified with respect to constructional features? Sketch and state their main applications, merits and demerits. 9. Describe the method of inspecting the profile of spur gear by using involute measuring machine. 10. How to check the composite errors of the gear by using Parkinson gear testing machine? Explain it in detail? 11. Briefly describe major, minor and effective diameter of thread? 12. Describe the two wire method of finding the effective diameter of screw threads. 13. Describe the chordal thickness method using gear tooth vernier caliper. 14. Explain one method of assessing the straightness of a straight-edge. 15. Write notes on the types of irregularities of a circular part and mention its causes. 16. What is the ‘best wire size’? Derive an expression for the same in terms of the pitch and angle of the thread, 17. Explain the principle of measuring gear tooth thickness by base tangent method. What is the span length over 5 teeth of gear having 45 teeth module 4mm and pressure angle 20o 18. Derive the formula for measuring the effective diameter of thread by 3-wire method 19. With the aid of sketch describe the principle of operation of a rolling gear testing machine. http://www.francisxavier.ac.in UNIT V Part-A (2 Marks) 1. What are load cells? 2. Give the principle of hot wire anemometer 3. State any four inferential types of flow meters 4. What is thermopile? 5. Mention the principle involved in bimetallic strip. 6. What is thermocouple? 7. What is a Kentometer? 8. What is the principle involved in fluid expansion thermometer? 9. What is the need of inspection? 10. What are the important elements of measurements? 11. What is the basic Principle of measurement? Part – B (16 Marks) 1. Briefly explain various methods of measuring torque 2. Briefly explain various methods of measuring temperature 3. Briefly explain various methods of measuring flow 4. Briefly explain various methods of measuring power 5. Briefly explain various methods of measuring force 6. Explain working of Pressure thermometer and resistance thermometer. 7. Explain the construction and working of Venturimeter and Rotameter 8. Explain the construction and working of Bimetallic strip and Thermocouple http://www.francisxavier.ac.in